Most people have probably heard of 3D printing. It’s not surprising: the 3D-printing industry is worth $7.3 billion as of 2018. That’s something that you cannot say about CNC machines. In fact, if you’re not a manufacturer or parts maker, you probably won’t even know what a CNC machine is.

But, what’s the difference between 3D printing and CNC machining? The key difference is that 3D printing is an additive manufacturing process, while CNC machining is subtractive.

But what does that even mean? Read on to know what these two processes are, as well as their differences.

3D Printing vs. CNC Machining: Which One Is Better?

When you do 3D printing, you are effectively starting from nothing and then building up the material layer by layer until you get the desired product or design you want. As such, it is considered to be an additive manufacturing process.

With CNC machines, it is the opposite. These machines use several tools to remove parts of the material you are working with until you get your desired form. As such, it is considered to be a subtractive way of making things.

Other than the different methods used by each, what other differences are there?

Accuracy and Precision

CNC machines are designed to be accurate and are made to cut with precision. This does not mean that 3D printers are not precise, though. Compared to CNC machines, 3D printers are just not up to par when it comes to precision. However, you can tweak 3D printers to be very accurate.

Speed

CNC machines can produce pieces and parts in an hour or less. If you work with a 3D printer, the same piece or part will take several hours to finish. It should be noted that these machines work with different materials and come up with different products, so a direct comparison will not be easy to come by.

Materials Used

CNC machines can use different materials to do their work. Most times, it works with metals such as aluminum, brass, copper, and steel. It can also work with thermoplastics, foam, acrylic, hardwood, and other materials.

On the other hand, 3D printers are rather limited when it comes to the materials they can work with. These materials include thermal plastics and resins.

By-Products and Waste

One of the benefits of using 3D printers is that you are not wasting a lot of the material. This is because 3D printers use the exact amount of the material that it needs to create the product.

Because they use a subtractive process, CNC machining is quite wasteful. It can result in a lot of shards, clippings, and cuttings. When working with metal, that includes sharp metal pieces that spurt away from the machine.

Cost

Generally, 3D printers are more affordable than CNC machines. The average 3d printer cost around $700 while CNC machines can easily cost thousands of dollars and offer only the most basic features and capabilities.

According to 3dinsider.com, the average consumer 3D printer sells for around $700. But you can have a cheaper one at prices starting at $200. Most high-end products can set you back thousands of dollars.

CNC printers, on the other hand, are sold at prices from $2,000 for hobbyist equipment or $6,000 upwards for commercial units. In fact, according to Manufacturing Tomorrow, a CNC machine can cost as much as $166,000. Another option is to use a service like cncfirst that provides affordable machining services out of China.

G-Code

CNC machines and 3D printers are controlled using G-code, which is a series of commands that tell them what to do. The G-code will instruct the machine where to go and what to do, and it can even adjust its settings. The G-code will control the cutting speed of a CNC machine, as well as control the nozzle temperature of a 3D printer.

However, there are some differences in the G-code used in 3D printers and the G-code used in CNC machines. What are these?

For one, CNC machines generally have more axes than 3D printers. As such, 3D printers do not get to use the entire code library as CNC machines do.

You do not have to use tool speed commands with a 3D printer. That is because 3D printing does not involve any materials that need to be spun.

Other commands that you do not use with a 3D printer include:

- Commands that control the tool head: 3D printers mostly have fixed tool head(s), which means the commands that swap out bits for better cuts are only for CNC machines.

- 3D printers use mostly M and G commands. G-code uses commands that start in a variety of letters. 3D printers operate in a rather simple manner and, for the most part, it uses only two types of commands: M or G commands.

In other words, if you have problems learning code and keeping track of different commands, then you will like the simplicity of 3D printers because it uses fewer commands than a CNC machine. However, the more G-codes you need to use, the more it proves that CNC machines are much more flexible and accurate than a 3D printer.

3D Printing vs. CNC Machining: Which One Is the Better Choice?

Which one between the 3D printer and CNC machine is the better choice? The answer to this is that you can go either way. Each one has its own pros and cons that make it better than the other. It is all a matter of what you need to make or create.

For instance, if you are a hobbyist or a beginner in the world of manufacturing, then you are more likely to benefit from buying a 3D printer because of its low price point.

On the other hand, if you need to be very precise with the product or the part that you are manufacturing, you should choose a CNC machine. What’s more, you need to know what kind of material you are most likely to be working with. There is only a limited set of materials that can work with 3D printers.

Then you also have to consider the complexity of the piece that you are making. If you use CNC machines for really complex designs, you will find that it may be severely limited by the axes of rotation and the movement that the machine can make.

You can avoid this with 3D printing. Because this process is additive, it builds your part or product from the ground up. As such, it is easier to make complex shapes on a 3D printer than on a CNC machine.

Other Interesting Differences Between 3D Printers and CNC Machines

According to this article, there are other differences that can help you decide between getting a 3D printer or a CNC machine. Here are the questions to ask:

1. Is the strength of the final product important?

The thing is that 3D printers often make weaker products than CNC machines do. A CNC mill, for instance, cuts out a product from a large block of metal. The raw material it uses is already very strong, and the CNC machine is only fashioning something more useful from it.

On the other hand, a 3D printer creates a product layer by layer, which means that there is a chance that the molecular bonds might not be as strong as they should be.

2. Are you working with metal?

While most 3D printers work with resin or plastic filaments, there are now 3D printers available that can handle metal. However, there are certain issues with these metal 3D printers, such as porosity. According to this article, porosity can make metals become brittle and make it prone to cracking and breaking. This leads to the final product being fundamentally weak.

3. How large is the product you want to make?

If you are going to create a large product, it might be better to work with a CNC machine. While a 3D printer is capable of creating bigger products, this can take an inordinately long time to finish.

4. Should you use CNC machines or 3D printers for prototyping?

Prototyping and proof of concept are what most businesses think about when they consider buying a 3D printer. Around 48 percent of manufacturers are also using their 3D printers for production, according to this study.

A much higher percentage, however, is using 3D printing to make prototypes of their new products. Meanwhile, nearly two-thirds say they use it for creating proof of concept.

Prototyping is when you create a full-scale model of your products. You can use 3D printers to turn your ideas into something that you can hold and use. You’re not really in production just yet. Maybe you have a great idea for a device and a great product ready for production, but you still do not have investors. Rather than depend on drawings, you can use a prototype to get investors more excited about your product.

It is interesting to note that Kickstarter, a website where creators can find funding for their projects, is making it mandatory for project starters to have a prototype of their product. It used to be that you can ask for funding using only photorealistic images.

And while 3D printing certainly has a place when it comes to creating prototypes, is it really the best option? Should engineers, inventors, and businesses look at CNC machines?

If you are looking at it cost-wise, then the answer is no. CNC machines make more sense when you are already in production. But if you’re creating just a small batch of your product, 3D printing is perfect due to its lower cost.

Plus, you should consider that ABS and other materials used for 3D printing is probably much cheaper than the metals used for CNC machining. And then you also need to factor in the cost of changing and repairing parts such as CNC heads.

A Deeper Look at CNC Machines

CNC machining starts you off with a block of material that the machine cuts and shapes into the desired product or part. It is pretty much similar to having a block of wood and then chiseling and chipping away at it until it becomes something more useful, such as those wooden cutout letters you see at wedding receptions or a nice figurine.

CNC machining knows which parts to remove because everything is guided by a computer program. The machine itself has an assortment of tools such as grinders, mills, routers, cutters, and lathes, among others.

Three-dimensional parts and products are easily done on a CNC machine. Everything is done by using the programming language G-code.

G-code controls all the features in a CNC machine, such as the feed rate, speeds, locations, and coordination. As such, the machine will know just where to position the block, what tools to use, how much to cut away, and how fast and deep it should be going.

Most Commonly-Used CNC Machines

To better understand how a CNC machine works and what products can it create, it would help if you know what types of CNC machines are most commonly used today.

CNC Lathes

CNC lathe machines are given precise and detailed instructions to create the parts you need. The block of material rotates on the main spindle and the cutting tools are mounted on different axes so that they can each move freely to chip away parts of the material.

CNC lathe machines are often used to produce machine parts that are symmetrical around an axis. You can watch an oddly satisfying video of a CNC lathe machine in action on YouTube.

Plasma Cutters

According to CNC.com, a plasma cutter works on metals such as steel, aluminum, copper, or brass. It can cut through these materials using hot plasma jets.

Like all CNC machines, you work with a computer to cut out specific parts of a material. It uses extreme heat to make the desired cut-outs on a piece of metal.

These cutters are found in welding shops, auto restoration and repair, construction sites, and even in hobbyist workshops. There are low-priced plasma cutting machines available that hobbyists would find affordable.

Water Jet Cutters

A CNC water jet cutter is very much like a plasma cutter, but it uses a jet of water and extreme pressure to cut rubber, wood, and other softer materials. If you are cutting through harder materials, you can add an abrasive substance to the water to make the job quicker and faster. Watch CNC water jet cutters in action here.

CNC Mills

CNC milling can be described as high-speed drilling or cutting. CNC milling uses a cylindrical tool that rotates in different directions. When it makes contact with the metal, the CNC mill will rotate to drill a hole or to cut away certain portions of the material. As such, CNC mills are not only good for drilling, but they are also good at creating different shapes.

A drilling machine has only one axis as it only needs to be able to make a hole in the material. Most CNC mills have three to five axes, making them more flexible than a simple drilling machine. A CNC mill in action is somewhat mesmerizing, as you can see in this video.

CNC Router

Another type of CNC machine is the CNC router. This type works very much like a CNC mill. A CNC router, however, is best used for softer materials such as wood and plastic. A CNC mill handles the tougher materials like a thick slab of metal. CNC routers also work fast.

One great thing about the CNC router is that it can be used as an engraver, as this video shows.

How Does a CNC Machine Work?

According to the McNeel Wiki, a CNC machine uses a computer or digitized data that is fed into a program that will move, automate, and track how the machine moves. Industrial type CNC machines have the computer onboard, but hobbyists can use their desktop or laptop computers.

The controller works with various motors, and it controls the axes and moves the tools. It also executes the programmed movements of the machine.

If you have a CNC machine that is made to cut shapes out of a certain material, it will move in a linear manner using two axes, X and Y. But milling machines and similar types of CNC machines will have more than two, allowing them to move in either a linear or rotary matter.

Everything You Need to Know About 3D Printing

The process of 3D printing involves turning plastic filaments or resin into physical objects. You design on a computer, and it will bring your product to life. Its relatively lower cost makes it ideal for students, hobbyists, and even entrepreneurs and businesses, according to this article from ZDNet.

This additive process builds up layers of plastic to create the product that you have in mind. If you have problems envisioning a 3D printer at work, you can think about it in terms of the ordinary printer, but instead of ink, it uses plastic.

What’s more, traditional printers work on a flat piece of paper. 3D printers, on the other hand, work like plotters that move the print head along two axes: X and Y. These 3D printers work by rows, so after creating one row, it moves up to do another.

The 2 Most Common 3D Printers and How They Work

While there are a lot of types of 3D printers available, two of the most common are fused-deposition modeling and stereolithography. These two work rather differently from each other.

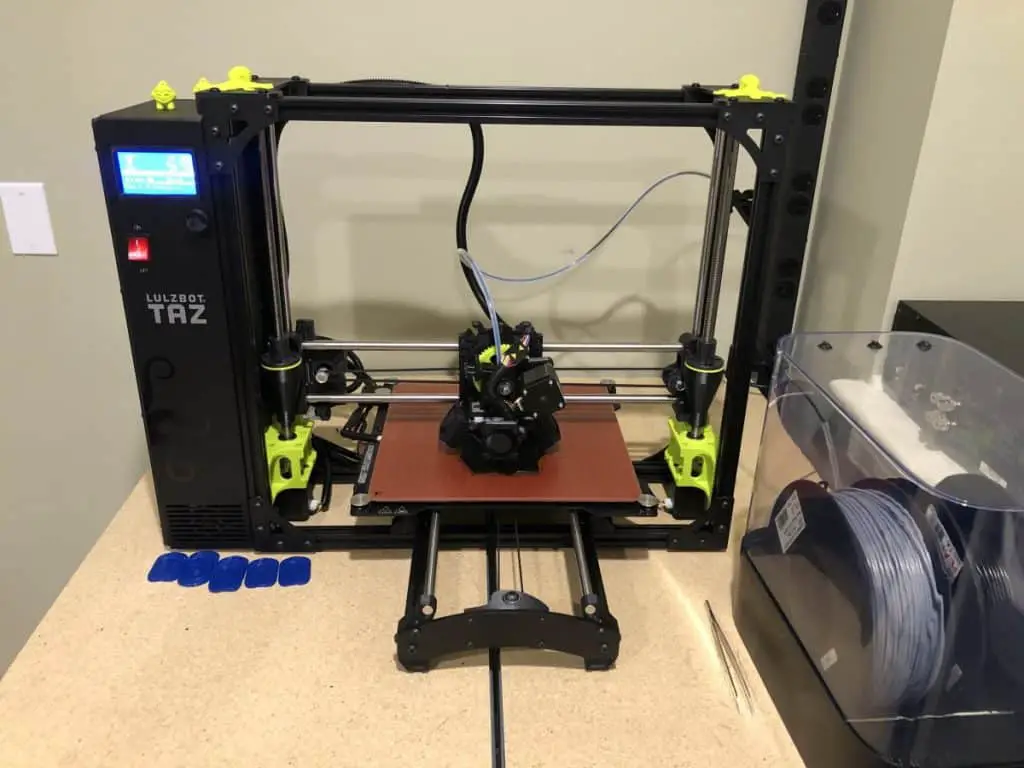

Fused-Deposition Modeling (FDM)

Fused-deposition modeling uses rolls of filament to do its job. The plastic filament is heated by the printer and then pushes it out the extruder nozzle, building your product layer by layer.

Each row is very thin, and a new layer is put on top of the previous layer. These two layers fuse as the earlier one cools down. Here’s a video showing how an FDM 3D printer works.

FDM printers are the first products available to hobbyists. They have more product offerings in the market and have more units sold than any other type of 3D printers.

An FDM printer works with different plastics, but you should know that each type of material has its own set of characteristics. For instance:

- Polylactic Acid (PLA): is the most common filament used in FDM printers because it is very easy to print with it. However, it can deform when placed under sunlight and it can be very brittle.

- Nylon: is flexible and strong. But you should know what settings to use in order for it to work.

- ABS Plastics: This is the material used in LEGO blocks, is very strong. But using this plastic often results in failure and deformation of the print. Its fumes can be toxic, and the odor is not pleasant. You should only use ABS filament if your 3d printer is well ventilated.

Why FDM Prints Fail

A significant number of prints fail due to a variety of reasons. One is the layers not bonding properly. This can be because the plastic cools too quickly, or heats too easily. It could also be because the print becomes detached from the build plate surface.

Sometimes, prints fail because the filament will jam inside the extruder.

Stereolithography (SLA)

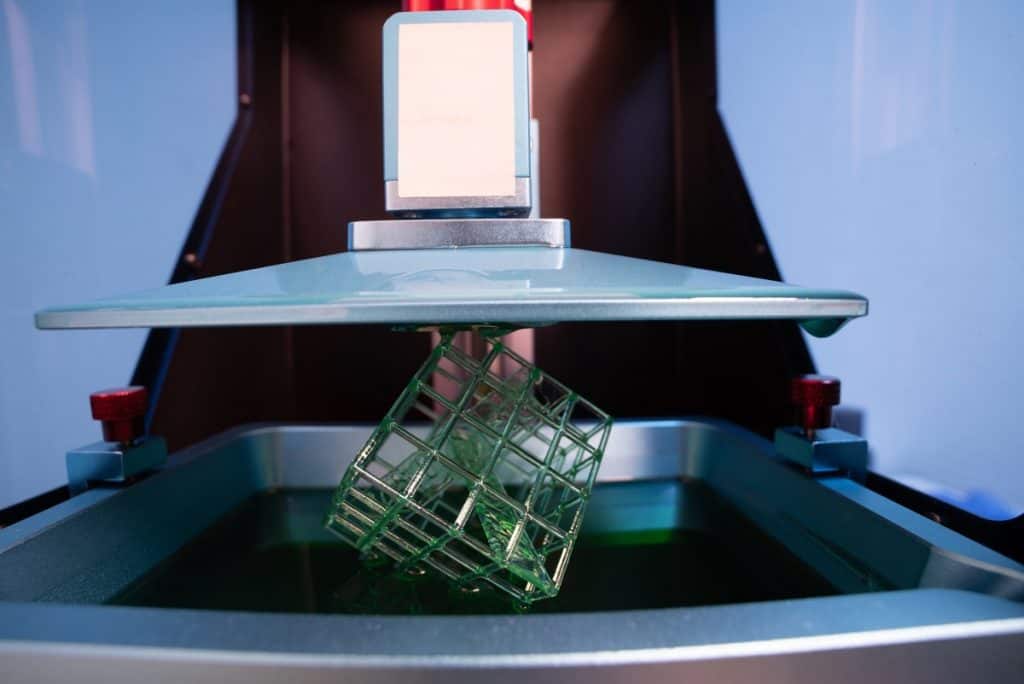

Unlike FDM, which uses material extrusion, stereolithography uses light polymerization.

Stereolithography uses liquid resin for its material. This 3D printer uses a build tray that is lowered into the resin, and when it does, light is shone to it to create a chemical reaction that causes the resin to harden. And yes, it does look cool, as you can see in this video.

There are other types of 3D printers available out there, but they may be too expensive for most people to buy. There’s the powder bed 3D printer, which uses powder, and there’s the laminated object manufacturing, which uses different sheets of material and then cuts them to form your designed shape.

Why You Don’t See a Lot of SLA 3D Printers Around

While hobbyists use FDM printers a lot, SLA printers are not that common. Here’s why:

- The liquid resin it uses is toxic and can cause rashes and burns.

- The prints need to be processed and cured, which can take time.

- When processing, the print can easily be deformed, and these products remain toxic during this time.

- SLA printing is a lot messier than FDM printing.

- SLA printers have smaller build areas, and you can use it only for smaller prints. You can read the article I wrote on SLA print volume here.

- Vendor lock-in is a problem with SLA printers because resins are sometimes specially formulated for a particular printer model.

However, there are still people who use SLA printers because of the finely detailed prints that they can produce. What’s more, prints made with SLA printers are often very smooth with few-layer lines or none. In fact, those who are interested in 3D printing molds, jewelry, dental and medical products, model trains, and miniatures are going to love SLA printers.

Designing and Preparing Your 3D Prints

A lot of people see a 3D printer, and they instantly think of things that they would like to print right then and there. What they fail to realize is that before you can print a bust model of John Lennon, you will need to design and prepare it first.

You will need to do some 3D modeling first using computer-aided design software. CAD is the software for 3D modeling, very much like using Word to write a document, or Photoshop to manipulate an image.

Some CAD software you can use are:

- TinkerCAD

- Fusion360

- ZBrush

- Meshmixer

Another software you need to know is a slicer. This program will produce the G-code needed for your 3D prints.

Will 3D Printing Replace Traditional Manufacturing Methods?

It’s easy to get excited about 3D printing. But the 3D printers you have now will never replace the machines found in a traditional factory.

3D Printing Takes a Long Time to Finish

Here’s the thing, it can take anywhere from hours to days to finish a single 3D print. You can probably finish a low-resolution print in hours, but detailed products can take a few days to complete. Just think about this: LEGO produces around 36,000 blocks per minute. A ZDNet writer tried to make a similar LEGO block with a 3D printer, and it took him 29 minutes to make one brick.

However, this doesn’t mean that you should not use 3D printers. If you have an idea and you want to see how it pans out in real life, you can easily get a 3D printer to create a prototype for you.

The cost of using 3D printing is a small fraction of the cost of having a traditional manufacturer do it for you. You would need to work with the manufacturer and get custom machining, which is already costly processes themselves.

What’s more, it will take days or weeks before you can get your prototype. With 3D printing, you will spend a few hundred or thousands of dollars and do the designing yourself. It doesn’t cost as much, and you can get the prototype more quickly.

Because of the low barriers in both time and cost, you are able to innovate a lot faster.

3D Printing vs. CNC Machining: The Last Word

The thing with 3D printers and CNC machines is that people somehow put them together and try to see which one is better.

Of the two, 3D printers are much more mainstream. And people have initially thought that it will replace the traditional manufacturing machines, including injection molders and CNC machines.

That hasn’t happened yet, because even when it’s awe-inspiring to see your design come to life and become tangible, 3D printing does have its limitations in the same way that CNC machining has its own set of weaknesses, too.

You might want to start thinking of 3D printers and CNC machines not as competing technologies but as complementary ones. You can create parts and products with finer details and more complex and intricate designs with a 3D printer. Meanwhile, you can use a CNC machine to make larger components and to refine and clean up the final product.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.