The capabilities of printing have grown substantially over the past few years, and now 3D printing is available to even the average consumer. If you invest in a 3D printer, you’ll have more than one printing technology to choose from. One of the leading methods is stereolithography or SLA printing, which uses a resin to create polymers that make up the body of a three dimensional solid.

How do you choose SLA printer resin? There are several quality resins available. When choosing one, you should take the following factors into consideration:

- Quality of Finish

- Durability

- Flexibility

- Transparency

- Biocompatibility

- Cost

Whatever SLA printer resin you choose, it should cater to what you are printing. The first step to finding the right resin is ensuring that the options you are considering work with your printer and that you know your printer’s specifications. Let’s discuss the best resins on the market today and what they work well for.

SLA Printing Basics

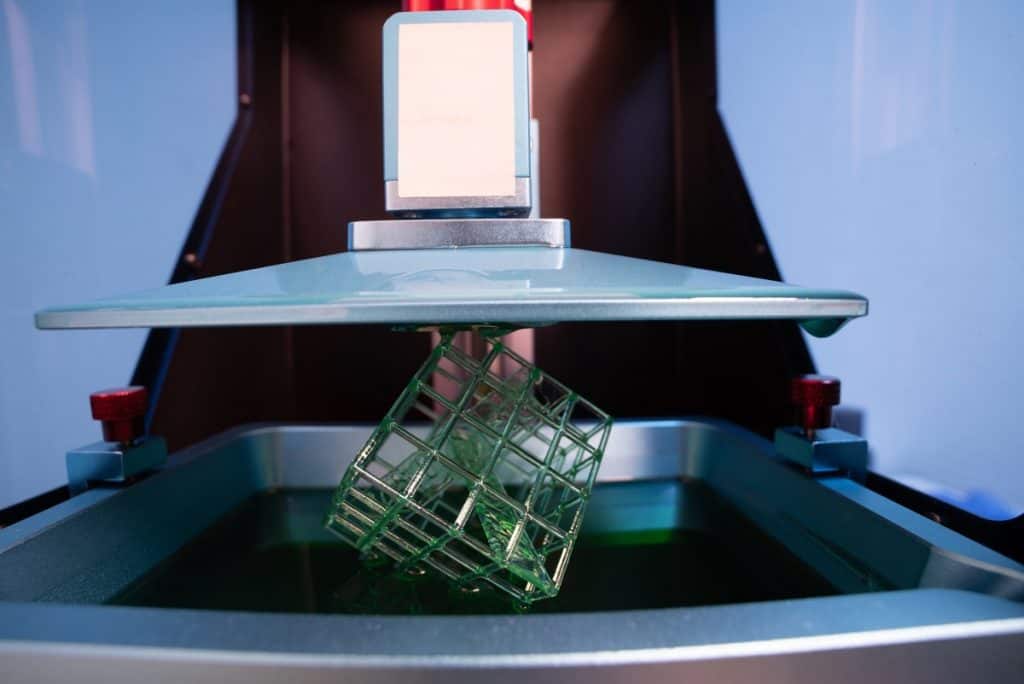

Before we jump into the actual resins used during SLA printing or stereolithography, we will quickly cover the process. Through SLA printing, an object will be created by selectively curing a polymer resin layer by layer, using an ultraviolet (UV) laser beam. The materials that are used in SLA are photosensitive thermoset polymers, which come in a liquid form called resins.

Though there are several other forms of 3D printing now available, SLA has become well known as the first 3D printing technology brought to the market. The technology for this style of 3D printing was introduced in 1986 and has remained one of the most accurate and smoothest printing techniques even today.

For a thorough breakdown of the process, check out this article and the embedded video about how to master the art of this process. Now, onto how to choose a resin and then our picks for some of the best resins on the market.

How to Choose the Right SLA Printer Resin

If you are familiar with FDM printing, you may know that the filaments can be interchanged, but this is not the case with SLA printing. The resins used for SLA printing are designed to fit specific jobs, and you will want to find a resin that fits your specialized product needs. When you research these resins, you will find that many of them excel in a specific area and should be used for a certain type of printing.

When you are narrowing down your search for printer resin that works for you, there are a few key qualities you should consider. While we have already discussed some great brands, some other things to consider are:

- Quality of Finish – Certain specialty resins will create smoother prints than even other 3D printer resins on the market today. You will want to read any information available about the resins and look for those that say they are made for printing with high accuracy and lowered shrinkage. When you want a higher quality print, you need to ensure the resin you choose offers this.

- Durability – SLA prints are not as durable as other options out there, and these resins are known to be more brittle and prone to cracking or breaking. If you need a tougher print, there are resins that have been engineered to stimulate the toughness of molded plastics. You can find resins that have high tensile strength and elasticity that are great for creating functional joints. You can also find resins that specialize in offering flexibility that helps avoid breakage and work great for clamps.

- Flexibility – Adding onto this idea of flexibility, some reasons will even add a rubber-like element to enhance their final flexibility further. They have very low tensile modulus, high impact resistance, high elongation, and work amazingly for prints that need to be bent or compressed. The only issue with this added flexibility is that they can need extensive support to avoid failing while printing. Also, the added rubber does not make them as strong as traditional rubber products, and the resin can break down over time.

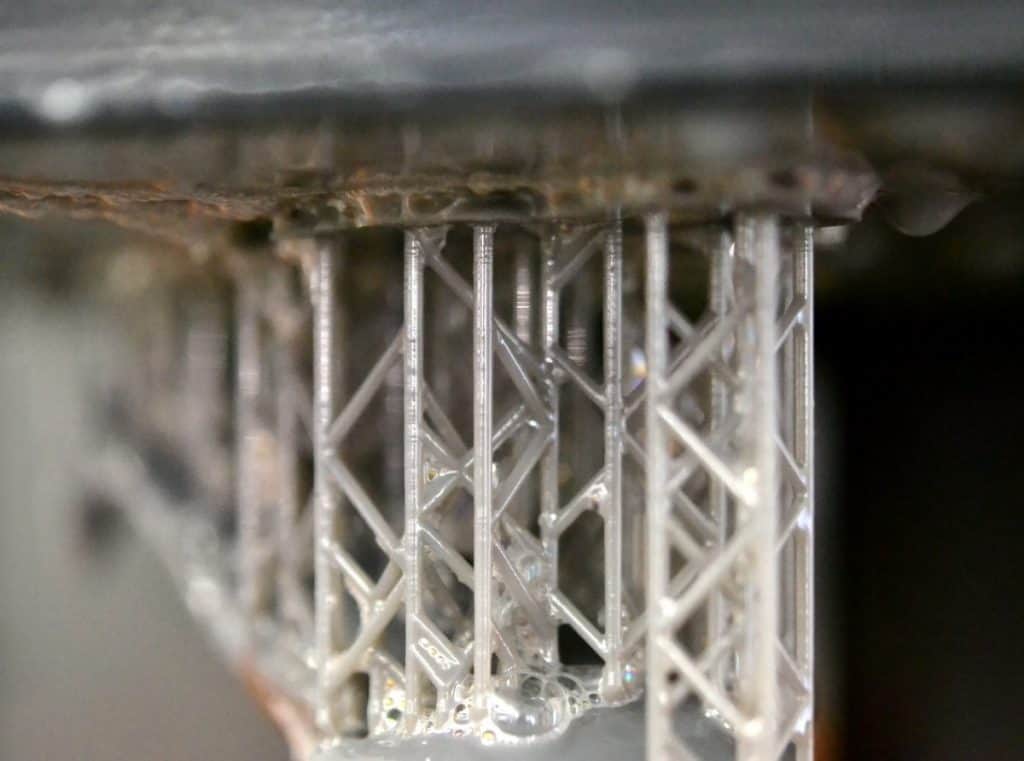

- Transparency – If you need the final printed product to be transparent, you will have to purchase special resins that are made to create transparent objects. There is not a huge difference between standard resins and those that create transparent prints, but they can get clear enough to look like glass if finished correctly. It can take some time to finish these resins correctly, especially if you want a very clear look, but it is possible with some practice.

- Biocompatibility – A big reason that many use SLA printing is for medical equipment and prosthetic devices. These methods have been used to create orthopedic implants, splints, dental retainers, and much more. If you are using these resins for similar purposes, you must use specialty resins that can maintain chemical and structural stability. These pieces must stand up to contact with skin, be fracture-resistant and wear-resistant, be able to undergo high temperatures, and much more.

- Costs – Of course, the cost of your SLA printer resins is extremely important to ensure that the resins you need to fit your budget, and some of these specialty resins are very expensive. For most SLA printers, you will need enough resin to fill the whole vat so that the build platform is completely submerged. Quality resins will cost you at least $50, but some specialty options can cost in the hundreds.

Pros and Cons of SLA Printer Resin

While we have touched on some of the reasons as to why SLA printing is ideal, there are some negatives as well. Comparing the pros and cons of SLA printing and using these resins is important before you take the jump into buying these capabilities.

The Pros of 3D Printing Using Resins

- Faster Printing Possible: When you print with resin, the process is much quicker than other methods that have to extrude filament. When printing with an SLA printer, a single rapidly reorients to point he laser to the liquid resin along with the pre-defined pattern you are using. Most faster-paced industries use resin printers compared to other methods that are much slower.

- Better Resolution: Comparative to using filaments, the resolution produced by using SLA resins is far higher, and these prints often look much better. Resin printing can produce fine details in models and offers a smoother finish with far less post-processing like other methods. In recent years, there have been advancements in other forms of printing that have helped bridge this gap slightly, but SLA resins are the best way to get quality results.

- The Finished Products are Strong: While all 3D prints have a level of weakness and those created with resin can break down over time, they tend to be much stronger than the filament options out there. When you use resins, the curing process can allow for stronger layer-to-layer adhesion, and the finished product is much more uniform across all axes. For many, using resins for printing can create more functional parts and components.

The Cons of Resin Printing

1 – The Higher Costs: As mentioned, SLA resins can be extremely expensive, and these costs can add up quickly when you have to print several items in a relatively quick amount of time. The printers themselves are expensive with the cheapest ones out there costing around $1,000 and most higher-quality options up to $3,000 or more. Some printers will then need several liters of liquid resin to fill up the resin vat, which can add substantially to these costs.

These costs magnify because most of the SLA printers require you to fill up the vat with resin each time you start a project. The problem with this is that you can lose a lot of this excess resin because the unused portions can undergo a process of premature curing. Though you may be able to recycle some of this unused resin, you will often have to throw some out, which is a waste of money.

2 – The Process Can Get Messy: We touched on this previously, but the problem that many have with SLA printing is that these resins can become very messy. Once the piece is printed, the post-processing of a resin print is very messy, and you will have to remove support structures before the post-curing step.

When you remove these soft supports, you also must remove any excess resin that is on the surface of the print with alcohol. As mentioned, you will need to use some form of gloves when doing this, and most also lay out some type of plastic sheet to protect their workspace. Overall, it can get pretty messy.

3 – It can be Difficult to Find Supplies: When 3D printing was first developed, resin printing was the method that was most often used, but this has been replaced by FDM printing due to its lower costs, which also makes FDM materials more abundant compared to resins.

It may be challenging to find the resins that you need, and you will often have to special order them to fit your needs, which can even further add to these higher costs. It can actually be difficult to find resins that fit your needs entirely, and this supply of available resins will probably continue to lower over time.

The Verdict

Overall, if you are interested in creating high quality, high-resolution prints, using an SLA printer is the best choice for you. While these resins can be more expensive than other filament style printing options, the quality you receive is often well worth the price. If you are interested in 3D printing more for hobby and do not need the prints to be the best quality, you may want to opt for a lesser expensive option.

10 Best SLA Printer Resins

There are several quality printer resins on the market today that you can choose from. However, these resins will range in price and printing ability depending on what you are looking for. Some top-rated SLA resins that you can purchase today are:

- Siraya Tech Fast

- AnyCubic 3D Printer Resin

- eSun bio Resin

- Monoprice Rapid UV Printer Resin

- NOVA3D 3D Printer Resin

- ELEGOO 3D Rapid Resin

- Siraya Tech Tenacious

- Sparkmarker 3D Printer SLA Resin

- Monocure 3D Rapid Resin

- SainSmart Rapid UV

- Blu – Siraya’s Strong and Precise High-Res Resin

For many, you will need to buy specialty resins that fit your exact printing needs, which we will talk about more. However, this makes it important to read the resins in detail to ensure they fit your exact needs.

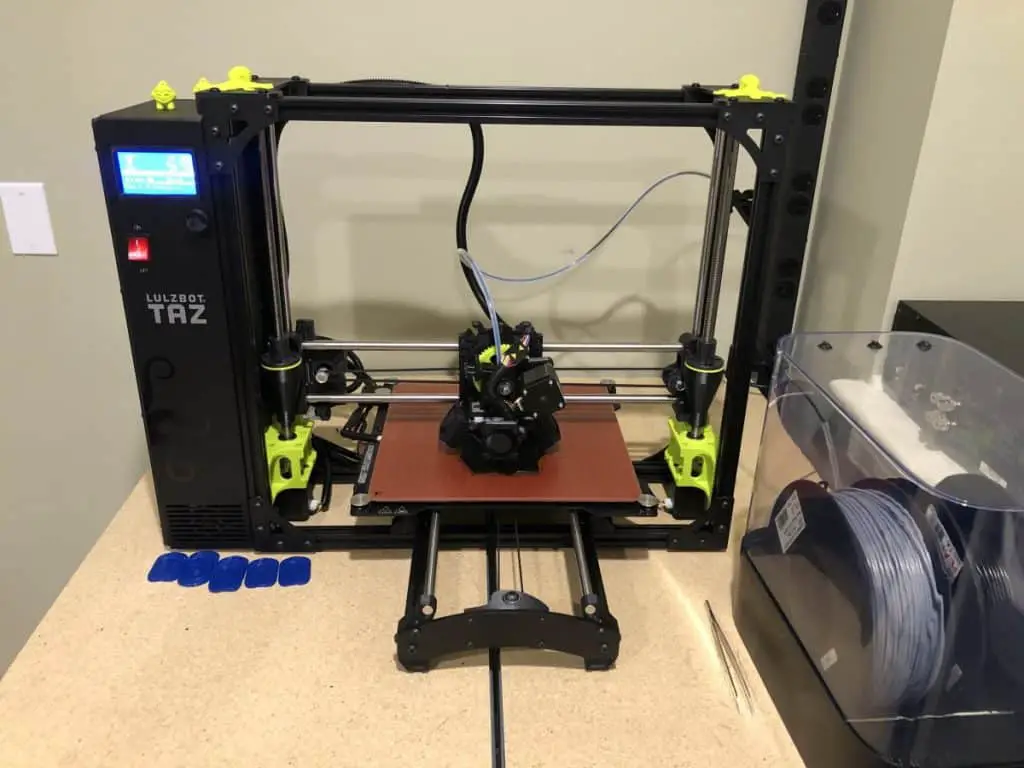

When to Use SLA Printer Resin

For most who are printing items, you have two main choices FDM and SLA. These two methods have benefits and disadvantages that you will want to consider before deciding which will work best for your needs. If you want a higher precision and smooth finish but are not worried about the costs, SLA is a great choice, but FDM is a good, lower-cost choice.

FDM Printing

- Great for building lower-cost models

- Ideal for hobbyists

- Not as precise and surface finish is not as smooth

- Rapid prototyping possible

SLA Printing

- Best for intricate details and smooth surface finishes

- Good for those who want to mass produce products using molds for casting

- May not be as strong or durable as other models. Resin can be affected by the heat.

Now that you have your SLA printer resin and when it is the best choice, let’s talk about how to get optimal results.

How to Achieve Quality Printing Results

You want to do the prep work necessary to guarantee that your SLA prints are top-notch and that your resins are working properly.

- Start by leveling your build plate. You want to ensure that this is done accurately because even small discrepancies can cause the print to separate from the built plate.

- Make sure that your resin tank and resin are clean.

- Make sure that any resins you are using are not expired.

You will want to slice your model in two ways, avoiding 100% infill in order to save you on materials and overall time. You want to avoid weakening the print by allowing the excess resin to become trapped in hollow areas, which means they may need to be drained after printing.

Slicing Your Model for SLA Printing

Slicing your model for resin 3D printing is different from slicing for FDM. The two are similar in that you generally want to avoid 100% infill in order to save material and time. However, the honeycomb infill typically used for FDM is not appropriate for resin 3D printing. If you are not very familiar with the slicing process, you may need to learn more about this by doing further research. Here’s a video to help familiarize you with how it works.

Removing Your Model From the Printer and Curing It

Once you have printed your model, you want to remove and clean it. Use nitrile gloves as an added layer of protection for your skin when working with the resin. You want to remove the print from the build platform slowly and easily to avoid chipping the model. You can allow any extra resin to run back into the resin tank and scoop any excess off of the build platform as well.

You will then rinse the model in isopropyl alcohol, allowing the alcohol to partially fill the model if there are hollow spots. You will want to shake the model slightly to rinse the inside but keep the rinse duration brief, or it will become duller. You can always use a toothbrush to clean off any excess resin should you need to. Remove any supports after rinsing the model using cutting pliers.

To finish the print, you should cure it after drying using a 405-nm UV light. There are curing options out there that you can purchase, or many have made their own cure boxes.

Here are a few curing options that have high ratings:

- FUNGDO UV Resin Curing Light for SLA 3D Printer

- UV Resin Curing Light 405nm for SLA/DLP 3D Printer

- 6W Fast Drying UV Resin Curing Flood Light for SLA/DLP/3D Printed Matter

Safety When Using SLA Resin

When using any type of 3D printer, practicing personal protection and safety is key. Hot materials and even fumes are part of the process. Here is what to have on-hand and what practices to follow to ensure you are covered:

- Chemical-resistant gloves (nitrile or neoprene) – DO NOT use latex gloves.

- Safety glasses/goggles with UV protection

- A dust mask when sanding finished projects

- Cover your clothing or wear clothing you don’t mind throwing away

- Do not eat or drink while using SLA resin

- Avoid skin contact with SLA resin

- If the resin gets on your skin, wash immediately with mild soap

- If resin gets into your eyes, flush immediately and seek medical attention

It is highly recommended to have your SLA printer in a well-ventilated area. An SLA printer should not set up in your bedroom or living space, as many projects take quite a long time to layer. Limiting exposure to SLA fumes is a good idea.

If you’re looking to learn more about SLA printer safety, check out the article I wrote on it here.

Helpful Links

Here are several videos that you can watch to learn more about SLA printing and how you can get the best prints using these resins. These videos can further breakdown the process and what you can expect from SLA printing to guarantee you are getting the best from your resins.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.