Since 3D printing was invented, its use and popularity have skyrocketed to develop an ever-increasingly popular market, especially in the last decade. One thing that many people are concerned about is the potential fumes and smells that are said to be given off by 3D printing.

Does 3D Printing smell? There can be a noticeable smell to 3D printing because the technology used in 3D printers uses heat to mold its “ink,” which is actually filament that can be made from different materials that, when heated up, give off a variety of strong scents.

One thing to know about the smell given off by 3D printing is that it can be very harmful to inhale, especially in large amounts. If you’re interested in learning more about how 3D printing works and how you could possibly use 3D printing yourself, keep reading to learn more.

What Causes 3D Printing to Smell?

Before we discuss exactly how 3D printing works and why it has become so popular in recent years, I think it’s important to reiterate and explain why using 3D printing improperly is something you should avoid.

Although I’m going to explain more about how 3D printing works and what smells can come from 3D printing, basically, the “ink” used to develop the structure produced is actually a moldable filament that can be made from different materials.

The most popular choices for materials in 3D printing inks are usually different types of plastic. The scent of burning plastic can be dangerous to your health, so make sure that if you’re around 3D printing or doing it yourself, that you’re always in a well-ventilated area and taking other appropriate precautions. I’ll get into more detail about how you can do that later.

This process has been shown to make two byproducts from plastic-based ink that you should be concerned about: ultrafine particles (UFPs) as well as volatile organic compounds (VOCs).

There have been investigations into how both of these byproducts can be taken into the body and potentially lead to cancer. However, more research still needs to be done in this area.

How Does 3D Printing Work?

3D printing also has other names, including desktop fabrication, additive manufacturing or rapid prototyping. Before 3D printing can occur, a designer creates a digital 3D plan in which the printer can shape the model.

The 3D design’s file is used to develop a 3D object layer by layer as if it had been sliced into many thin, horizontal pieces that were stacked and then glued together to make the final product. If you think about how a bunch of blocks could be stacked to make a tower, you can get the idea of what’s happening within a 3D printer.

The process is just happening on a much finer scale with significantly more complex end results.

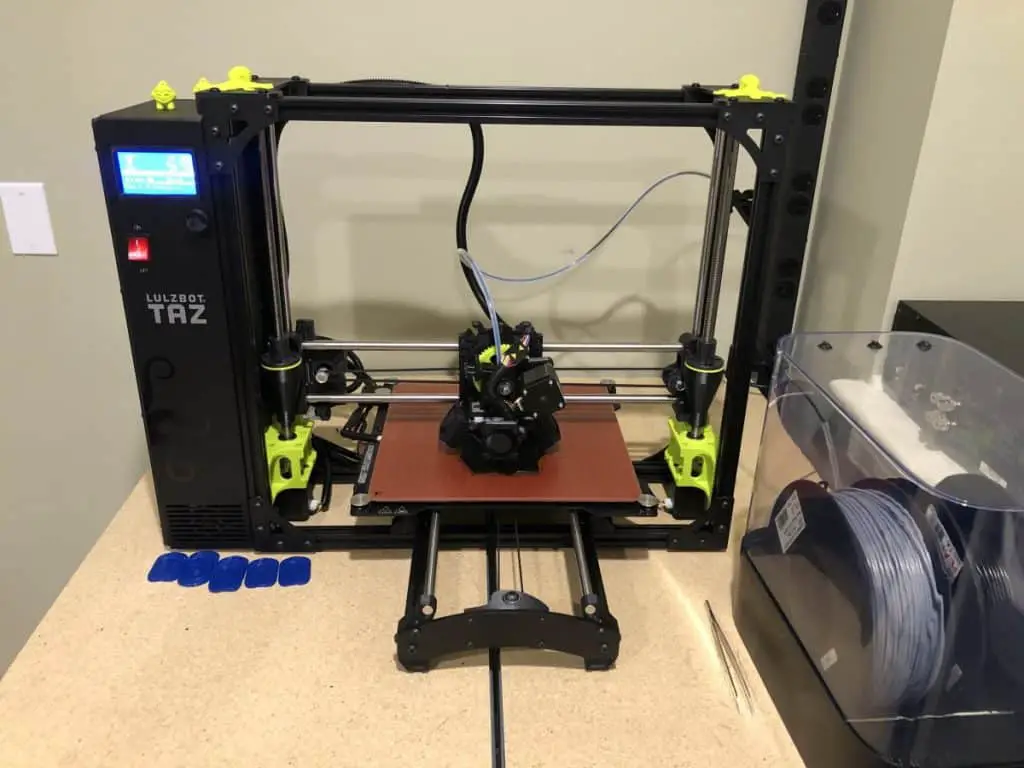

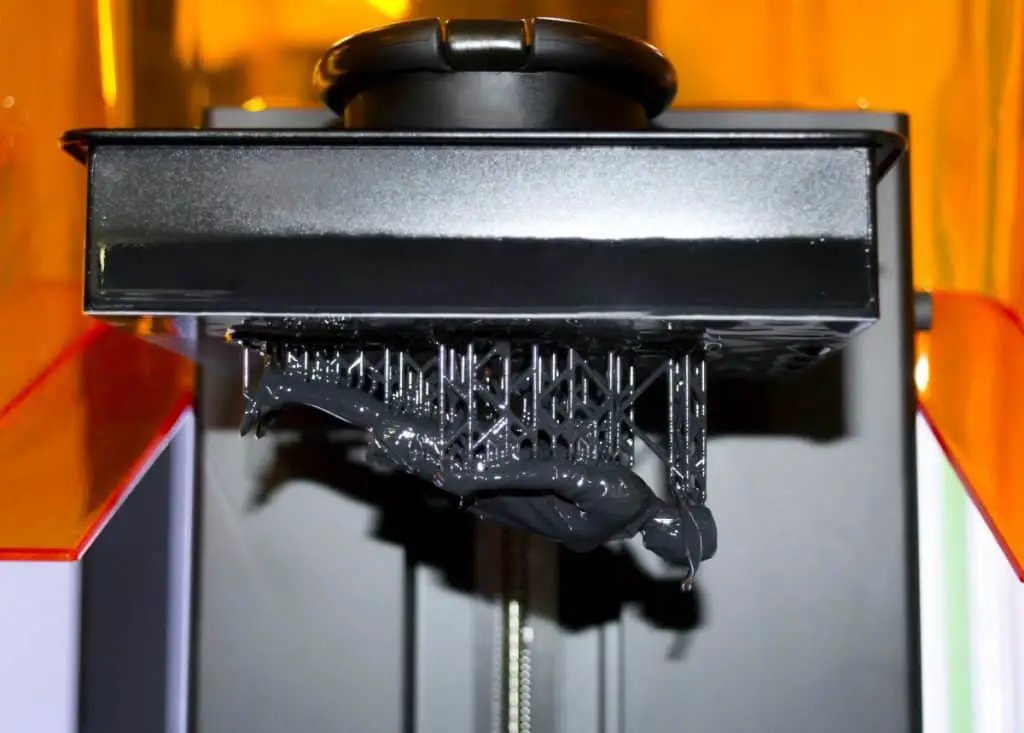

The three most widely used 3D printing technologies are fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). The first method works by liquifying a filament that is pushed through the hot end of the printer. The last two are methods use a liquid resin and light to build the object.

What Materials Do 3D Printers Use?

3D printers can use different materials like:

- plastics (ABS plastic, PLA, polyamide nylon)

- glass-filled polyamide

- epoxy resins (thermoset plastics)

- metals (silver, titanium, steel)

- wax

- photopolymers

- polycarbonate

It’s because so many new materials have been able to be used in 3D printers that the industry has grown so much in recent years.

What Can Be 3D Printed?

Right now, anything that can be made out of the materials that have been determined to be suitable for 3D printing can be manufactured by one of these machines. Many companies have already used 3D printers to build prototypes of a range of things you might find surprising.

That list includes prototypes of:

- Specialty running cleats

- Jet engines

- Bridges

- Jewelry

- Construction equipment

Almost anything you can imagine has the potential to be 3D printed someday, and new advancements are being made in this field all the time. There have even been prosthetic body parts that have been 3D printed, such as prosthetic ears, spinal implants, jaws implants, teeth, and prosthetic limbs.

What Types of 3D Printing Materials Often Produce Smells?

As I explained previously, 3D printers’ mechanism of “printing” relies on heat to soften filaments that become the ink that forms each horizontal layer of the printed object. That process can result in a variety of noticeable smells that the different types of material used in 3D printers can produce.

Below, I’m going to show you which common 3D printing materials produce smells and fumes that have the potential to pose a risk to your health.

| Filament Material: | What Is It Made Of? | What Smell Does It Produce When 3D Printed? | Are The Fumes or Smells Harmful? |

|---|---|---|---|

| PLA | PLA is made from natural materials like maize and sugarcane | Because it is made up of carbohydrates, PLA produces a pleasant, sweet scent when heated and 3D printed. | Non–Toxic: The chemical in fumes from PLA is lactide, a natural and non-toxic compound. |

| ABS | ABS is made from an oil-based plastic material | Many people describe the smell of 3D printing with ABS as emitting an unpleasant burnt-plastic scent. | Toxic: ABS fumes produce styrene, a known carcinogen. |

| PETG | PETG is a plastic resin known as a thermoplastic | PETG is not known for giving off a smell when used in 3D printers. | PETG produces a relatively small amount of fumes, especially in comparison to other plastics. |

| Nylon | Nylon is another thermoplastic, made up of synthetic polymers (long chains of plastic molecules) | Nylon is another 3D printing filament material that produces no odor when used. | Toxic: Nylon has been shown to produce caprolactam particles, which have associated health risks |

| Resin | There are two types of resins commonly used in 3D printing, SLA and DLP, which are vicious, pourable polymers that can be made into solid materials | Different types of resin can produce very strong to more subtle smells. | Toxic: Resins are a material that is already known to be unsafe for skin contact, so it’s unsurprising their fumes are toxic, too |

What Precautions Should Be Taken When 3D Printing?

Although the smells produced from 3D printing can be the most obvious signal that fumes are being produced, a strong smell doesn’t always mean a greater health risk. As you can see from the above table, although PLA filament gives off a noticeable scent when printing, its fumes are largely considered non-toxic.

On the other hand, nylon filaments, which are plastic, produce no smell but its fumes can give off gaseous compounds that are highly dangerous to your health. No matter what filaments you’re using, if you’re 3D printing, it’s important that you implement consistent safety precautions to protect your health.

Beyond making safer choices with which filament materials you choose to use, another precaution you can take is using a 3D printer with certain safety features. If you have access to an enclosed 3D printer that limits the number of particles released into the air. Additionally, 3D printers can have air filters built into them that further reduce your exposure to toxic fumes.

In addition to making sure the machine you’re using can provide a safer printing experience, you can also take steps to prepare the area where you use your printer. Make sure to have access to proper ventilation, such as windows, additional air filtration units, and/or an air quality monitor.

The Risks of Long-Term Exposure

Although the issues of inhaling filament fumes might seem minor, if you have prolonged exposure through your work or because you use a 3D printer in your home, the effect of inhaling toxic fumes will add up over time.

The concern of long-term exposure means that even if you use “safe” filaments like PLA or filaments like PETG that produce little fumes you are still potentially risking your health. After all, as 3D printing has only rapidly grown in popularity recently, the long-term effects of inhaling its fumes cannot yet be fully investigated or understood.

The longer you plan on 3D printing, the more critical it is that you implement and practice sound 3D printing precautions as soon as possible.

The Future of 3D Printing

3D printing is expected to continue to grow as an industry as more materials are able to be adapted for use in these innovative printers. There are already a variety of industries that use 3D printers to develop intricate and consistent products that people need.

Especially since 3D printing is so useful for creating prototypes, it’s easy to imagine that an increasing number of businesses and individuals will find a use for these machines.

Right now, the quality and cost of home-use 3D printers might stop them from keeping pace with the adoption of commercial 3D printing. As 3D printing technology improves, that might change as well.

As 3D printing becomes more widespread, it’s important that the industry and academics keep looking into the potential health impacts of the fumes that are produced by its processes.

Since many people are exploring the limits of 3D printing, both from their professional experience and personal interests, the industry will likely continue to have a rapid rate of growth for many years to come, so the understanding of how people can safely 3D print needs to expand as well.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.