When using PETG filament for 3-dimensional printing, it is essential to consider where to set up and make the project. The right environment is crucial for a successful product and a safe process, primarily if PETG is used as the main filament. Can you print PETG filament indoors, or is it better to utilize it only outside?

You can print PETG filament indoors. The printing process of the PETG filament may cause carbon emissions to occur, but there are no real health risks. The fumes created are non-toxic and safe to be around in an enclosed area.

This article will provide some guidelines on having a successful printing process. It will also troubleshoot some of the problems that may arise while printing PETG filament and recommend how best to solve the issues.

Creating a Successful PETG Print

When printing with PETG filament, three main parts need to be considered: the bed the object is printed on, the extruder that shapes the printed object, and the fan running throughout the whole process.

These three facets can literally make or break a 3D project created with PETG filament.

The Bed

The bed that the project is being built on should always be at a temperature between 167-194 °F (75-90 °C). Keeping the bed at a hot temperature will keep the PETG filament from hardening too quickly.

It will also help prevent moisture in the air from absorbing into the material. This is one benefit of performing the printing process inside an enclosed space—a room indoors will not have the humidity and condensation in the air that the outdoors is subject to.

A printing bed with a glass top is often recommended because you can print directly onto that surface. A bed made out of other materials may need additional layers of tape or glue to have the best outcome.

Additionally, a heated bed is an excellent option for printing PETG. The warmth helps the first layer of filament adhere to the bed easier. It will also come up quicker when finished, making future printing more straightforward.

The Extruder

The extruder needs to be kept at an excruciatingly high temperature to create the best print. Keeping the extruder between 446-482 °F (230-250 °C) is imperative for producing a high-quality project.

Since the extruder needs to be kept at such a high temperature, it is again beneficial to print with PETG indoors. In an outside environment, the heat of the extruder might not be able to reach the scorching height it needs to in order to print correctly.

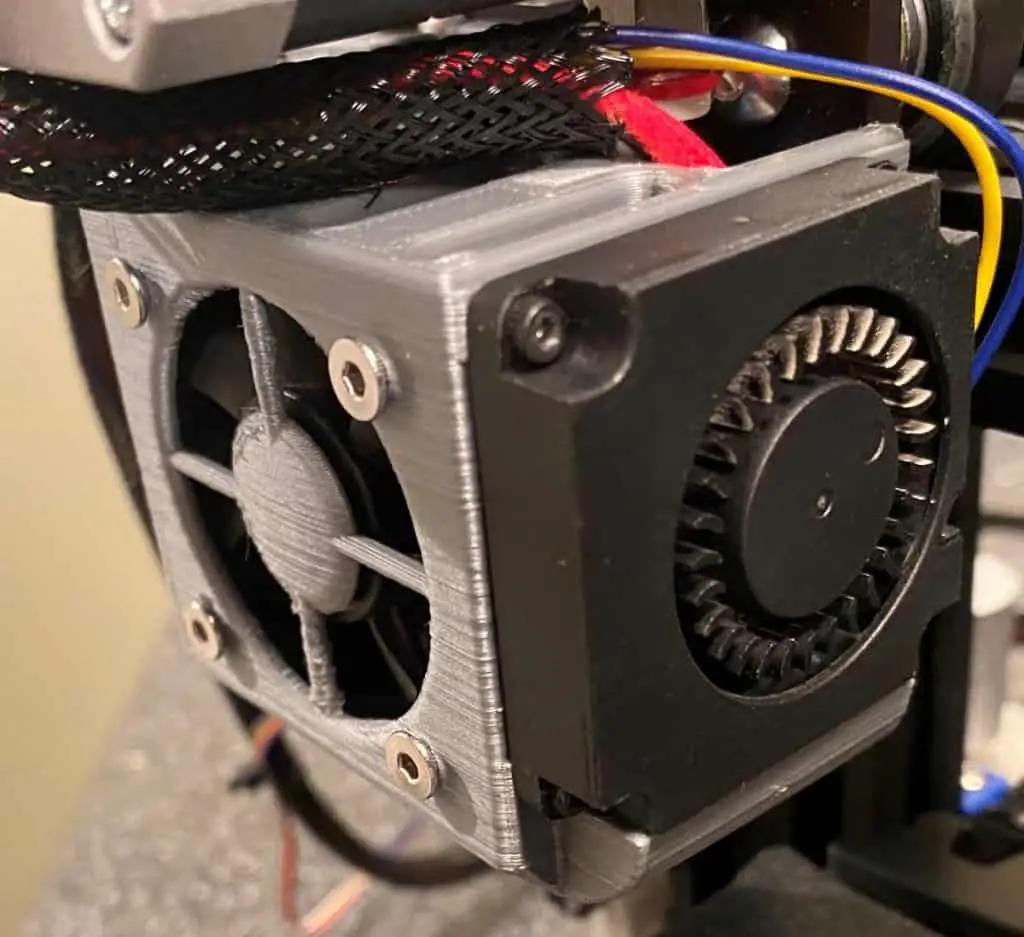

The Cooling Fan

Both the bed and the extruder are kept so hot that a fan is necessary to help keep the project at a regulated temperature. The intensity of the air coming from the fan will depend on what the desired final product should look like.

If the fan is kept at a low speed, it will help the object adhere to itself easier and will increase the durability of the PETG’s final form. If it is kept at a faster speed, the PETG will be able to retain more of the finer details.

In addition to the cooling fan for the project, setting up air purifiers inside the printing room will help keep the space itself ventilated and at a comfortable temperature.

Another benefit of printing PETG filament indoors is that the room can be kept at a specific temperature. Printing outside would mean you’re doing the work in whatever weather occurs that day, and the heat or cold could interfere with the printing process.

Choosing the right bed, extruder, and cooling fan will ensure an excellent final PETG filament print.

Troubleshooting Printing Problems

There are a few issues that occur quite often when printing PETG filament. Due to the nature of the material and the complexity of the projects, problems are bound to arise. Luckily, there are some easy fixes for the most common dilemmas that rear their heads during the printing process.

The PETG Filament Is Stringing

Perhaps the most common problem found when printing PETG filament is when the material separates into strings between the surface layers of the print.

The stringing issue is almost always the result of the retraction on the extruder being calibrated incorrectly. To stop the filament from stringing, simply increase the retraction speed or distance on the extruder. This will help it pull the filament out so that it will not allow it to separate as easily.

The PETG Filament Is Warping or Cracking

Another issue that can arise when printing PETG filament is the material warping into the wrong shape while being printed. The best way to fix this problem is by changing the cooling fan’s speed.

Lowering the fan’s speed will automatically keep the PETG filament at a higher temperature. This will keep the material more pliable and easier to work with, making warping less likely to occur.

Keeping the fan’s speed low or even disabled for the first few layers of the print will also prevent the filament from cracking. If the material stays at a high temperature from the beginning, it will remain malleable and not harden so much that it could break.

The PETG Filament Is Curling or Deforming

If the extruder’s temperature is too high, the PETG filament can go from printing slightly warped to completely losing its shape quite quickly. However, unlike the previous issue, the temperature needs to go in the opposite direction.

Lowering the temperature of the printer itself will keep the filament from getting too hot. If the filament stays at the appropriate temperature, it will retain the desired shape and ultimately prevent the material from curling or losing its form entirely.

Related Articles

- Is PETG Always Stringy? 5 Important Facts

- At What Temperature Does PETG Start to Warp?

- Does PETG 3D Printing Create Toxic Fumes?

- All About 3D Printer Plastic

- Can You Drill Into and Cut 3D Printed Plastic?

Final Thoughts

While PETG filament can be printed indoors, a few steps must not be skipped to avoid any issues arising with the material. Having the right equipment and then ensuring the equipment is calibrated correctly is essential to filament printing well. If these two steps are followed, printing PETG filament indoors will be a breeze.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.