From healthcare to construction, 3D printers are making their way into mainstream industries and even everyday homes. You can buy them in different sizes and the applications are virtually endless. Newer models are becoming less and less expensive. To properly operate a printer, you need a number of tools one of which is the build plate which is most often made of glass. So, what is a 3D Printer Glass Bed?

The 3D printer glass bed is a build plate or platform on which you get your 3D printed product, design, or construction. It is an integral part of the printer and a solid bed choice.

Read below to find out more about 3D printer glass beds as well as how to install them and tips on choosing the best fit for you.

What Are 3D Printer Glass Beds?

In order to print 3D objects, you need a plate, base, or bed on which to do so. There are various materials and products but glass beds seem to outperform them all. A 3D printer glass bed is a universal print surface that will accept pretty much any printing filament.

Glass beds are extremely easy to:

- Install

- Clean

- Use

Why Choose a 3D Printer Glass Bed?

The performance of the material of which a build plate is made largely depends on what you intend to print on your 3D printer. With this said, however, a glass bed is perhaps the most popular choice made by people since it’s practical and easy to find.

There are a number of benefits that a glass bed build plate can give you.

Smooth surface

Your printing build plate needs to be as smooth and flat as possible so you can avoid:

- Printing errors

- Bubbles

- Scores

- Other issues

A well-made glass bed can easily fulfill the task and equal the performance of its more expensive counterparts. The Anycubic ultrabase ranks at the top.

Cost

Compared to build plates that are made of other materials, glass beds are much cheaper. More importantly, you get much more out of what you pay. You can use glass beds for a long period of time without the need to replace it. You can find cost-efficient glass beds for as low as $12 to $30 on Amazon.

Easy to Clean

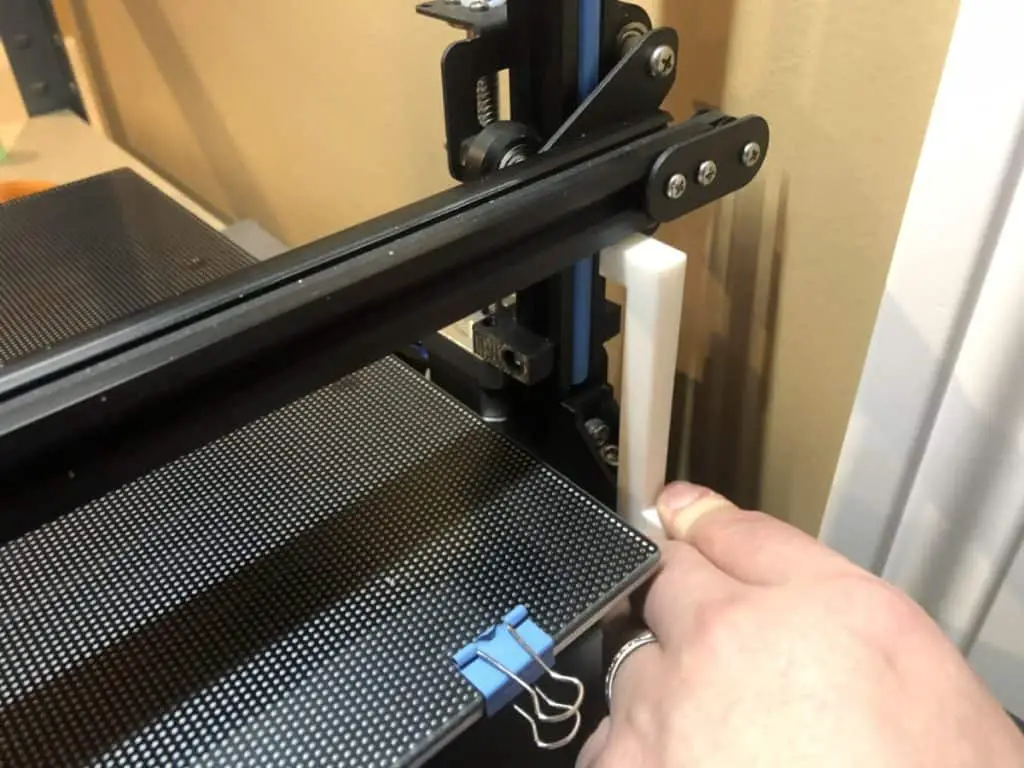

The printing process sooner or later will require you to clean your build plate. Ideally, you shouldn’t have to remove your build plate every time you need to wipe it down or clean it. This requires some time and effort. Glass beds are great because they are super easy to clean. Even if you need to remove the bed, you simply clip off the sides. which brings us to the next reason.

Easy to Install and Remove

A glass bed is both easy to install and remove, you can simply clip it on or use attachment pads. We will go over this point more in the “How to Install a Glass Bed” section.

Thermal Conductivity

To prevent possible buckles or twists during the printing process, sometimes you will have to heat the build plate. Warping or twists happen when the plastic cools down unevenly, and you might end up with inconsistencies in different parts of the printed product. For your build plate to stop this process from taking place, you will need to find one which is thermally stable making glass an ideal choice as it doesn’t succumb easily to high temperatures.

Resistance to Damage

If you print a lot, it is hard to avoid:

- Minor damages

- Scuffs

- Scratches

These can occur on the surface of your build plate. You may be thinking “isn’t glass super vulnerable and the worst choice for damages?” Not really. Glass is durable when compared to plastic or acrylic. Still, you should take precautions to make sure you don’t damage your glass bed.

Easy Print Removal

Once your print and glass bed is cooled, you can easily remove your print without the use of any tools. Removing printed products from plastic build plates can be an extremely arduous task but because glass is smooth and almost slippery by nature, the printed objects can be easily “peeled” off.

These are the most important qualities that you need to look for in a build plate and a glass bed really shines through on all fronts. So, when considering to buy a build plate for your 3D printer, go with glass!

What Type of Glass Bed Should You Choose?

It is one thing to choose a glass bed for your 3D printer, but something entirely different when it comes to selecting the type of glass that you will be attaching to the base of your printer.

While making this choice, you need to understand that quality is all that matters. So, if you can pay an extra $10 for an exponentially better glass bed then go for it, now is not the time to look for cheaper alternatives.

Unfortunately, this means that your uncles plan to swing by Home Depot and have them cut you a piece of ordinary glass is just not going to cut it. With that said, some people have found success with home-mirrors from IKEA but again, it’s not worth the risk, you will end up paying double after a short period of time.

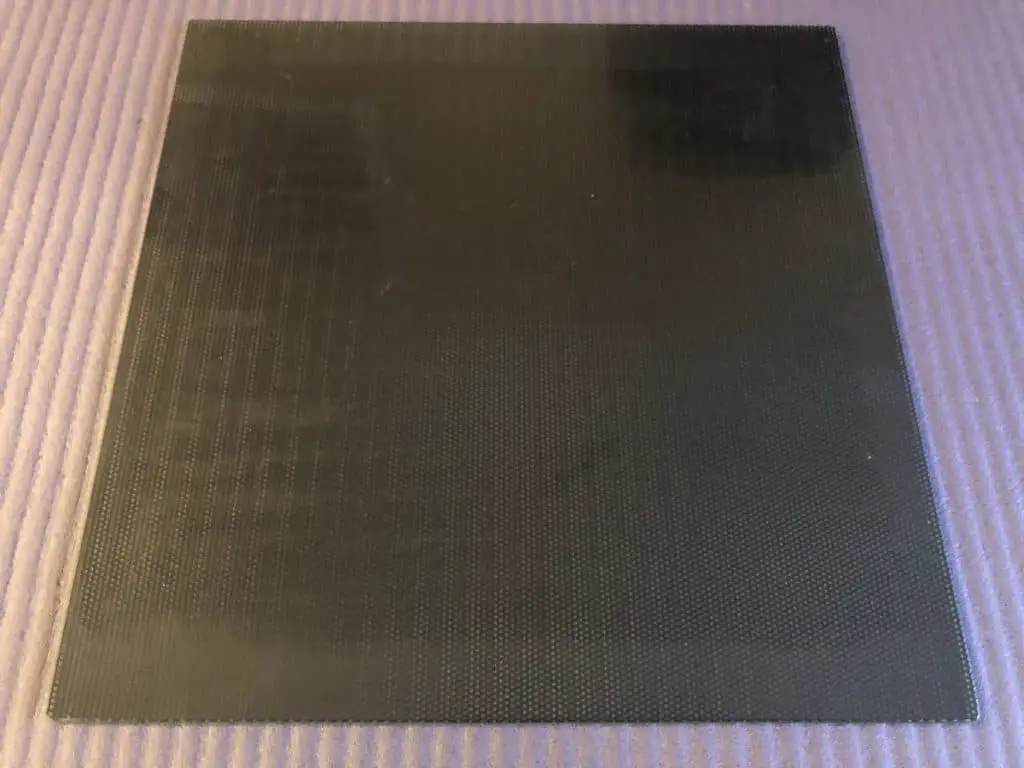

When it comes down to it, your best bet is borosilicate glass. This is the type of glass used in laboratories for beakers or other lab-ware. Borosilicate is a quality glass with a number of beneficial attributes including its damage restart nature and the fact that it is extremely immune to fluctuations in temperature. This means your base won’t warp or melt.

Borosilicate has a very smooth surface and is flat enough to withstand fracture or sudden explosion. You can find borosilicate glass for as cheap as $8 to $30.

Once you have purchased your glass bed you will need to install it. Read below to find out how you can do so.

How to Install a Glass Bed on a 3D Printer?

Installing any given build plate on a 3D printer takes effort and time. You should keep this in mind while undertaking this task. The good news is that glass beds are comparatively more comfortable and easier to install than its counterparts.

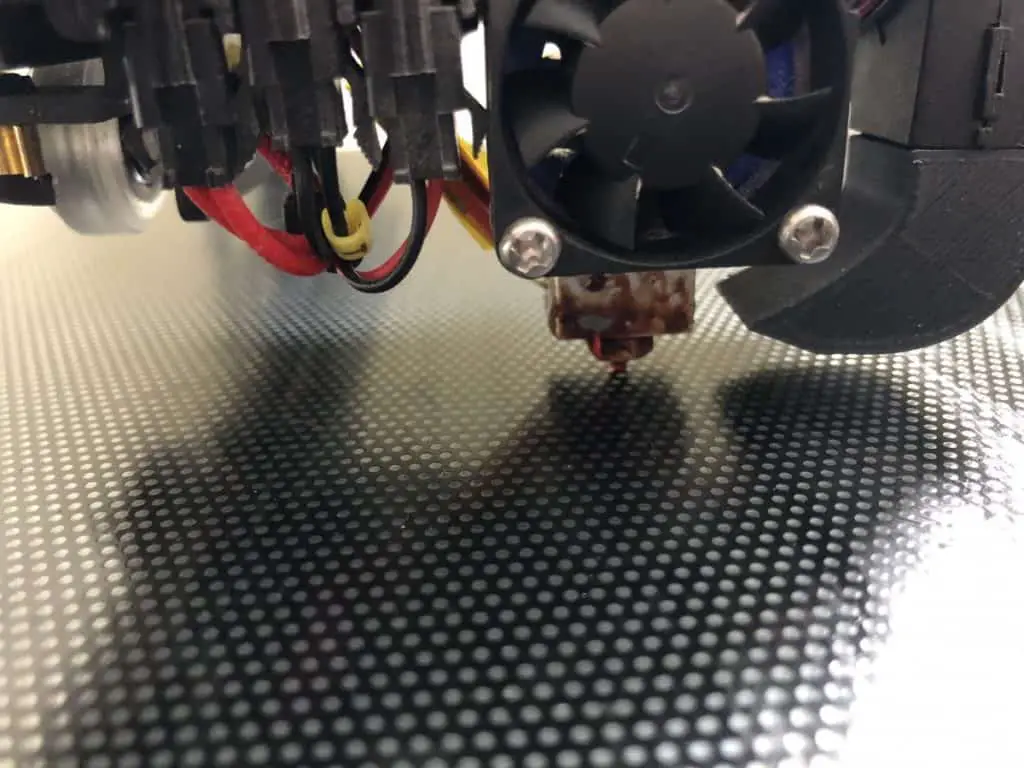

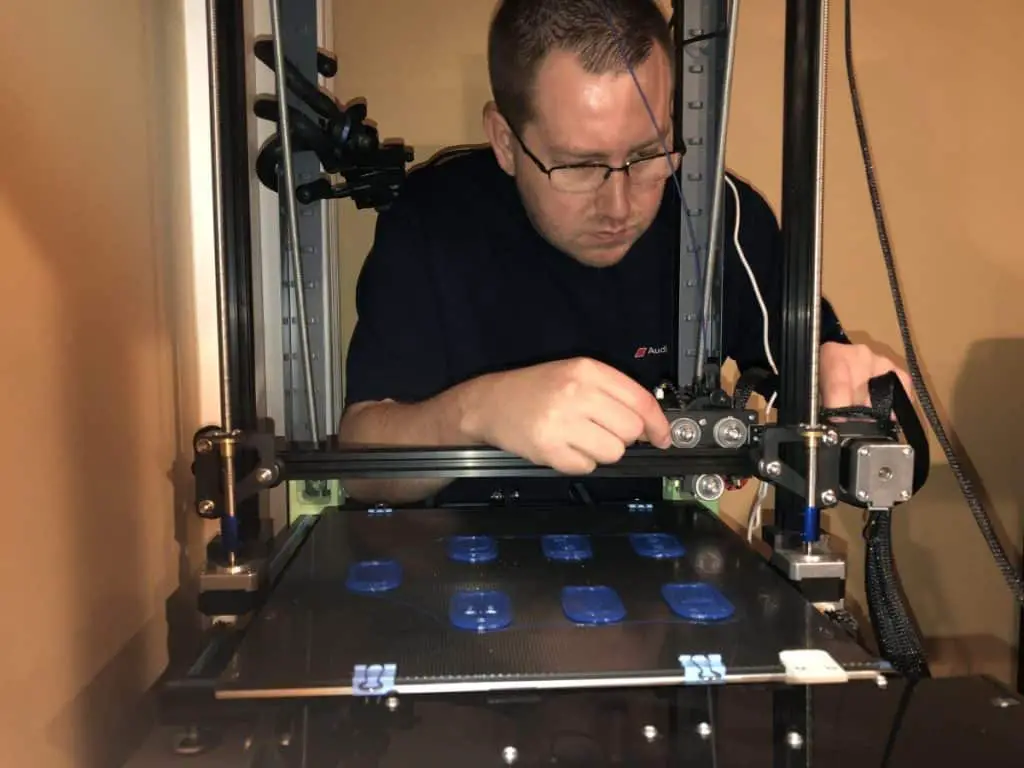

After you have picked out your specific glass bed that you will be installing, you have to consider the types of adhesives you will use. To begin with, you will need to cover the glass with PEI sheets, glue sticks, or specialty adhesives, these are common adhesives you can use. I personally use Layerneer’s Bed Weld (shown below). It’s not that expensive and it does a great job.

Notes on installing PEI sheets

- You have to minimize bubbles on the surface of the glass, so it’s a good idea to put something heavy on the glass to keep it under constant pressure.

- After a minute or two of pressing, you can remove the sheets. This is done to further polish the surface on which you will be printing.

- afterward, you can simply attach the glass bed to the base of your 3D printer by following one of these methods.

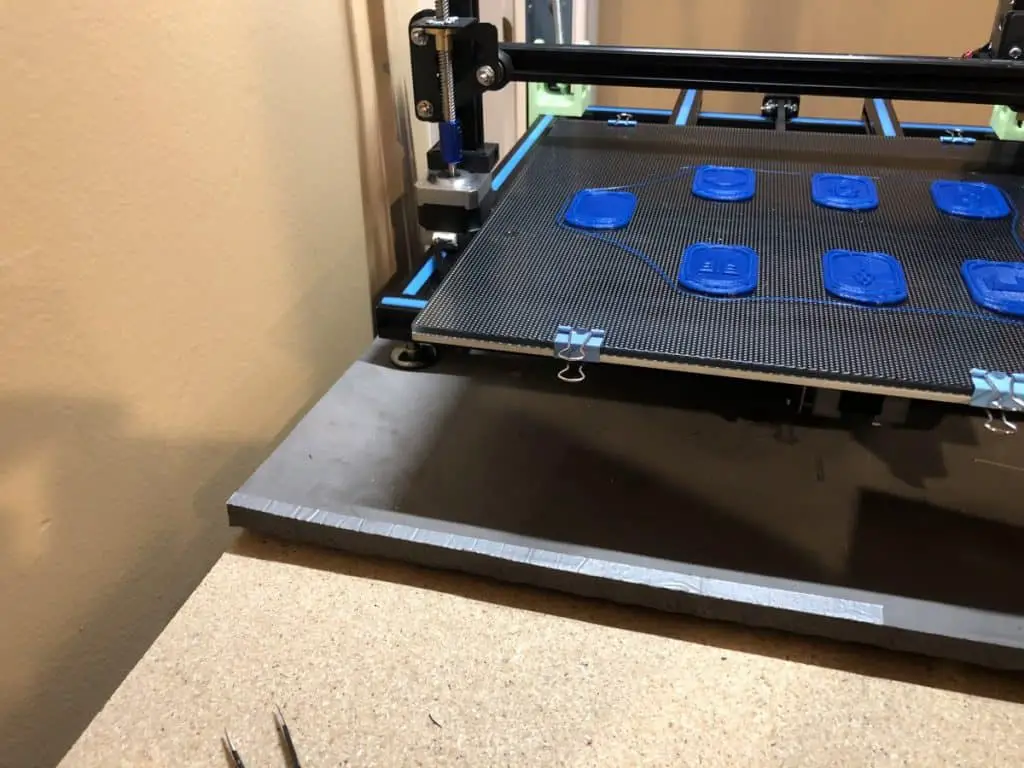

Securing the Glass Bed

You have two real options for securing the glass build bed to the base of the printer.

- Use thermal adhesive pads, cut in squares and place them on the corners of the glass, and attach them to the base of the printer. This might be a little hard to do, but it is a secure way of attaching the glass bed.

- You can just use simple binder clips that are strong enough to keep the glass bed attached to the base of your 3D printer. Usually, two on each side of the glass bed should get the job done. You just need to make sure they have a grip tight enough for the glass bed not to move during the printing process. This is the option I tend to use the most because its easy and it works.

A glass bed is one of the many build plates that you can get for your 3D printer, one that can perform the task with the least amount of setback. So, if you have a 3D printer and are looking to buy a build plate for it or just replace the old one, always go for the glass bed, by far the most reliable and high-quality plate you can buy at a modest price.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.