When drilling or cutting 3D printed plastic, you need to realize that this material is not solid the entire way through, so there is a chance that the plastic is going to melt or burn. You need to be careful when drilling or cutting plastic. And, of course, you need to think everything through and make sure you prepared the needed space for cutting.

Drilling and cutting 3D printed plastic is possible; however, there are many aspects you need to take into consideration when doing this. If possible, you need to have a starting point. For that, you can use a smaller hole that you should print beforehand.

The main thing to consider before starting to perform this task is making sure the 3D plastic model is strong enough. It depends on the type of plastic you’re using. If the layer of plastic is thin, then it’s likely to break after you start drilling or cutting.

Can You Drill into 3D Printed Plastic?

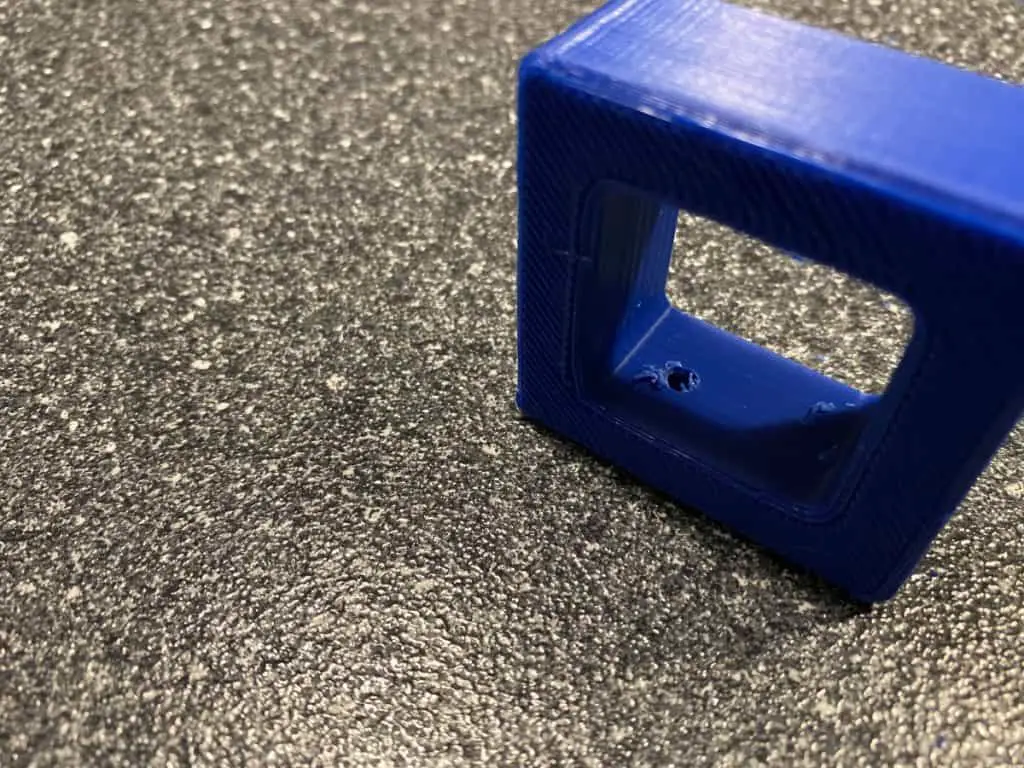

Yes, you can drill into printed plastic. Note that drilling directly into or through an area of the plastic could lead to cracking of the part later, depending on the hole’s functionality. If you print a hole beforehand, it will be significantly stronger than the one you drilled on the completed 3D plastic model.

There is a chance that a drill can cause a split between certain layers of printed plastic. For example, if you are drilling parallel to the layers in your 3D printed part. It is a mistake to do so. That’s why you need to drill perpendicular to the layers of the printed layers.

It’s also good to know that it’s better to drill a warm part rather than room-temperature printed plastic. You can warm a certain part by using a hairdryer. Another thing to consider when drilling 3D printed plastic is that if you’re drilling through supports, it will make your drill wander.

The problem with drilling plastic is that it can melt or burn. If you know that you need to drill the part, then you need to modify the design of the part that you want to drill. While doing that, you need to make sure there will be sufficient internal reinforcement and material in the location of the drill site, so the drill will not destroy the plastic part.

Can You Cut 3D Printed Plastic?

Of course, you can cut 3D printed plastic because it’s thin (if the 3D printed model is simple and without any complicated details) and easy to manipulate. Before cutting 3D printed plastic, take into consideration the type of plastic used for 3D printing. Plastic can be tricky to handle, as it may melt while you’re cutting.

Moreover, if you make an error in cutting, it may lead to irreversible damage to the plastic sheet. That’s why you need to be careful when cutting plastic. There are many different techniques you can use for cutting plastic, and you need to do proper research on that depending on the type of plastic of your printed object.

For 3D printing, ABS plastic is usually used for filament. It’s a kind of thermoplastic polymer with properties that are suitable the most for 3D printing. It’s very affordable compared to other options and suits perfectly for FFF or FDM 3D printers, and this is what makes ABS plastic widely popular.

There are many advantages of using ABS for 3D printing, such as:

- ABS can be easily melted, cooled, reheated again without any signs of degradation, which is a great quality for 3D printing.

- The melting point of ABS is low. Instead of burning when exposed to heat, ABS liquefies.

- ABS is known for its high rigidity and resistance. It has structural strength, which also comes in handy when cutting or drilling it.

- ABS has several applications and is the most used material in objects made by 3D printers.

ABS plastic can be cut by different power tools, but if the piece you’re cutting is thin enough, then you can just use a utility knife. It requires a lot of focus and precision. It may be challenging if you’re cutting out something complex. In those cases, you can just use the power tools to just maneuver the piece while the machine is doing the cutting.

If you want to get a perfect cut, you will need to get some practice before actually doing it on the final object. Mastering cutting techniques requires some time, but it’s definitely worth it, as then you will have less chance to make an error that can damage the plastic.

Also, with acquiring cutting techniques, you will see that cutting large plastic pieces will take less time than it used to at first.

How to Drill into 3D Printed Plastic?

When drilling into 3D printed plastic, you need to check for the points of weaknesses. It’s recommended to plan where you will drill before actually printing an object. Drilling 3D printed plastic requires precise work and calculated actions, as you may ruin the whole part or object if you make an error somewhere.

As mentioned above, you should make a smaller hole in the pace you’re planning to drill into. This will help to avoid unwanted errors, and you will not break the plastic part. Also, if you drill horizontally, this can lead to the separation of layers, so it’s better to drill in the z-direction for better results.

While drilling, make sure you don’t apply too much force so the excess doesn’t get stuck in the drill bit.

How to Cut 3D Printed Plastic?

There are several ways you can cut 3D-printed plastic. At first, it may seem easy to cut plastic, but there is a high chance of damaging the plastic part during the process. That’s why you need to learn certain techniques that will help you to cut plastic perfectly.

There are different tools you can use for cutting the plastic, depending on its thickness. The tools include a plastic cutter that can be used for cutting thin sheets of plastic, a circular saw for cutting more thick sheets.

You can use a jigsaw for more complex and curved cuts on thick plastic. A band saw can be used as well to achieve circular and linear plastic cuts. This is a perfect option for detailed and precise cuts on thick plastic sheets.

Remember to not switch on the saw when it’s in contact with the plastic. This will lead to damages to the plastic parts. That’s why you need to start cutting the plastic part when the saw is already working.

Here are some useful tips for cutting 3D printed plastic perfectly:

- Wear safety gear while cutting plastic: Make sure you protect your eyes while cutting or drilling plastic, as there is a chance of stray plastic pieces may land on you or get in your eyes. It’s also recommended to use protective gloves to prevent cuts that you may have from sharp plastic edges.

- Try using a new blade when cutting if you’re using a saw: An old blade can make the cutting process difficult, damage the plastic and give you a rough cut surface. With a new blade, you will avoid all of these.

- Before cutting or drilling, make a guideline: Masking tape can serve as a great guideline to mark your cut lines. After you’re done cutting, you can peel the tape off.

- Cutting requires some time: The process of cutting creates friction that can cause the material to get warmer, so the plastic starts melting. When cutting or drilling the plastic, take your time. Do not try to finish it as soon as possible. You need to give a material some time to cool off before it starts heating up and melting.

- When cutting, make sure you cut outside from your markup: You need to follow the guideline; however, it’s recommended to just save a little space, so any extra plastic that can stick out can be filed down as you finish cutting.

- Make sure you smooth up the edges of plastic after cutting: After cutting plastic, you will have rough edges left. To smooth those edges, you can use a metal file. This will help to not only smooth up the edges but also get rid of any bumpy or rigid edges. Using long and steady motions will prevent your cut plastic sheet from heating up and melting.

Above, I mentioned that you could use different saws for cutting plastic, but for small details, you can just use a utility knife. However, it would be best if you changed your tools for cutting depending on the plastic’s thickness and what you want to cut out, the complexity of it as well.

Related Articles

- 3D Printing vs. CNC Machining: What’s the Difference?

- How to Print a File from Thingiverse (The Easy Way!)

- What Is 3D Printer Resolution?

- What Computer Do I Need for a 3D Printer?

- Cura Profiles

Recap

Drilling and cutting 3D printed plastic is possible; however, there are many aspects you need to take into consideration when doing this. If possible, you need to have a starting point. For that, you can use a smaller hole that you should print beforehand.

In this article, I gave you explained how you can drill or cut into 3d printed plastics and provided some additional tips along the way. Just make sure you take you time and if possible, practice on a few scrap parts to get used to it.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.