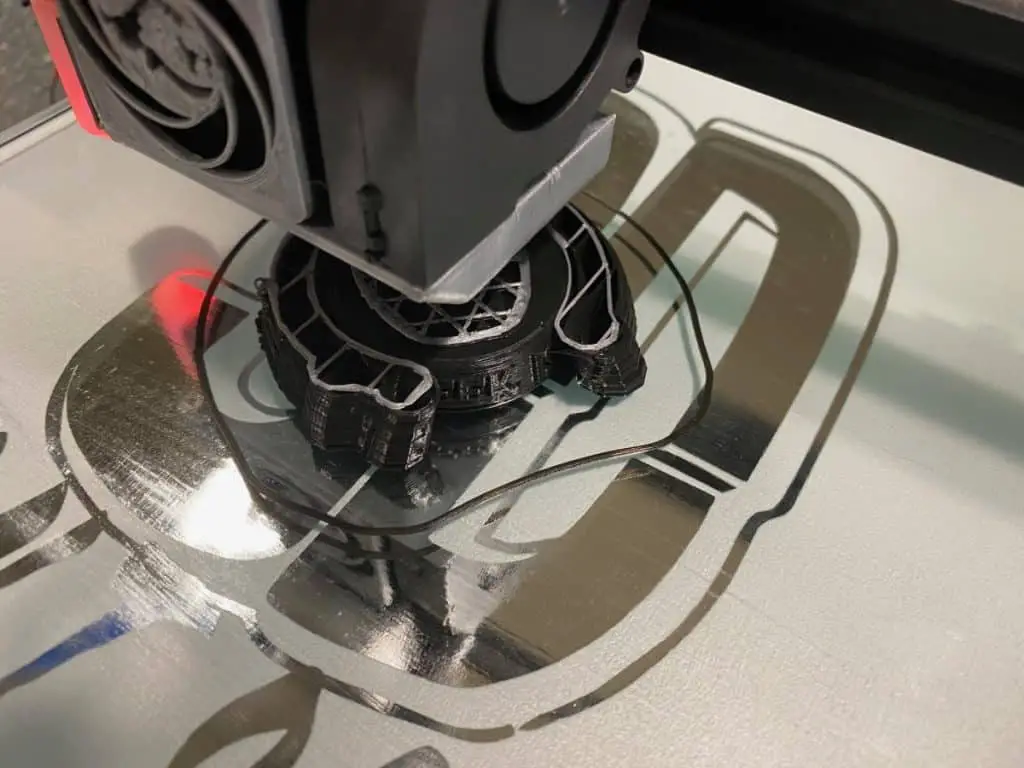

3D printed supports allow you to support your printed models by adding helpful structures to prevent misprints or damage. These supports aren’t part of the printer, so you’ll have to add them in the coding process. Removing them can be a hassle, especially since you don’t want to cause harm to the new print.

To remove 3D printed supports, use a putty knife to chip away at the support. Ensure the knife is as sharp as possible to prevent lumps or jagged cuts, and consider supporting it with a vice. The primary supports include lattice supports (crossed lines) and tree-like supports (intricate structures).

In this article, we’ll break down everything you need to know about 3D printed supports, including how to remove them, various common types, and simple tricks to get the most out of the supports without harming the print. Enjoy!

What Are PLA 3D Printed Supports?

PLA 3D printed supports are unique structures added to hold the weight of a print and stop it from falling over or becoming lumpy and stringy. Polylactic acid (also known as PLA) is a durable 3D printing material, but it requires these supports to stay stable.

You might be wondering when and where you’d ever add these supports. After all, many prints don’t need them. However, they’re crucial to the structural integrity of quite a few prints, most of which we’ve laid out below.

- H-shaped prints need supports in the center. If the H-shaped model has a long midsection, it’ll droop without anything to hold it up. This misshapen appearance can break the print, wasting your PLA and time.

- T-shaped prints should be supported on their outer edges. According to All3DP, failing to support the overhanging ledges on a T-shaped structure (letters, bridges, etc.) will lead to funky lines that ruin the print’s appearance. It can also make them droop, much like the previously mentioned H-shaped prints.

- Y-shaped prints occasionally need supports, depending on how far the overhangs extend. If there’s enough support from an underlying or connected structure, you might not have to use them. However, all free-hanging Y-shaped designs should use a support on either side.

Without further ado, let’s dive into the types of supports you can use for your PLA 3D prints in the following section.

Types of Supports

Choosing the right type of support can prevent your print from looking ugly or getting damaged, but it also affects how easy it is to remove. We’ll cover removal tips in the next subheading, but for now, we’ll focus on why you should decide between tree-shaped and lattice supports for your 3D prints.

Here’s the case for either print support type:

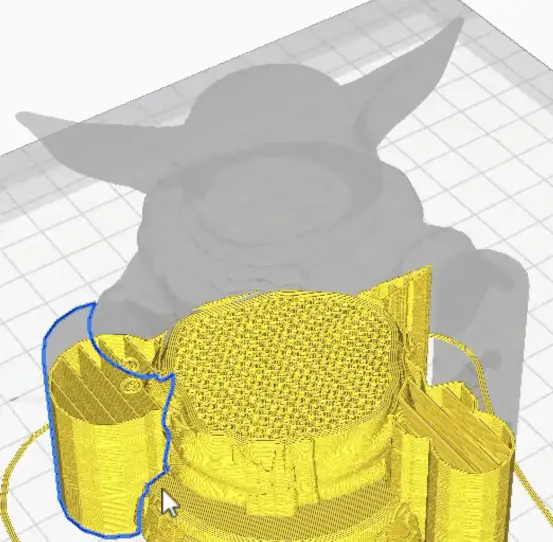

Tree-Shaped Supports

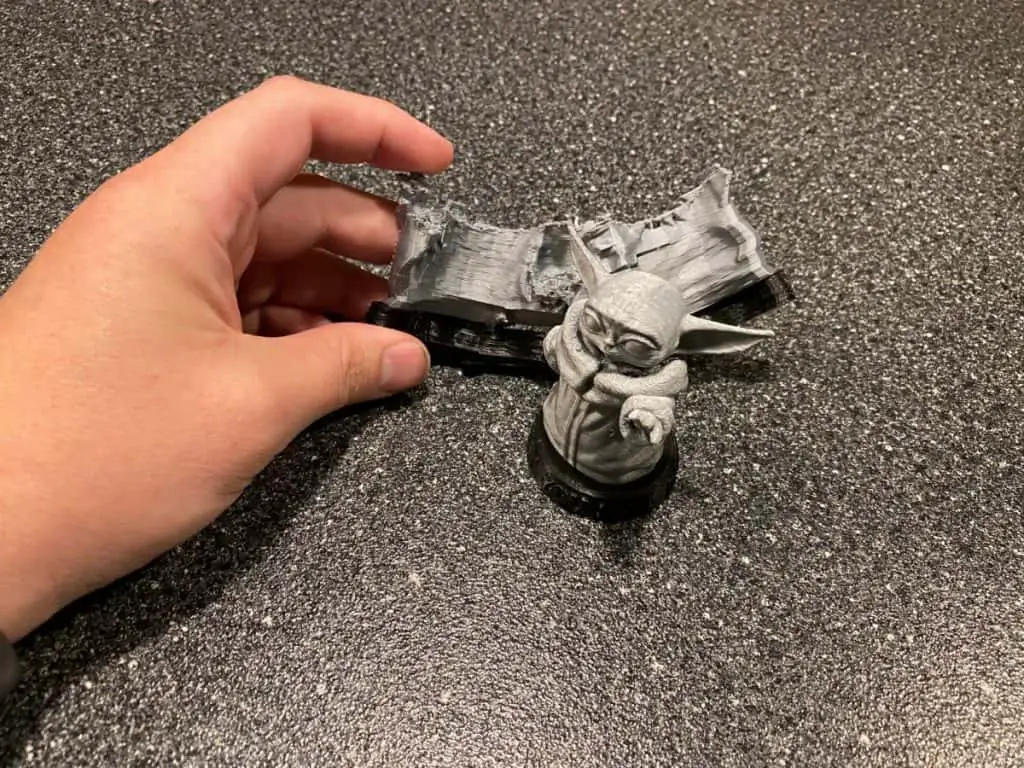

These supports have wide bases and slowly weave to connected trunks as they go up, much like tree branches. Tree-shaped supports are often chosen to save materials, time spent printing, and time spent shaving the support away once it’s done printing.

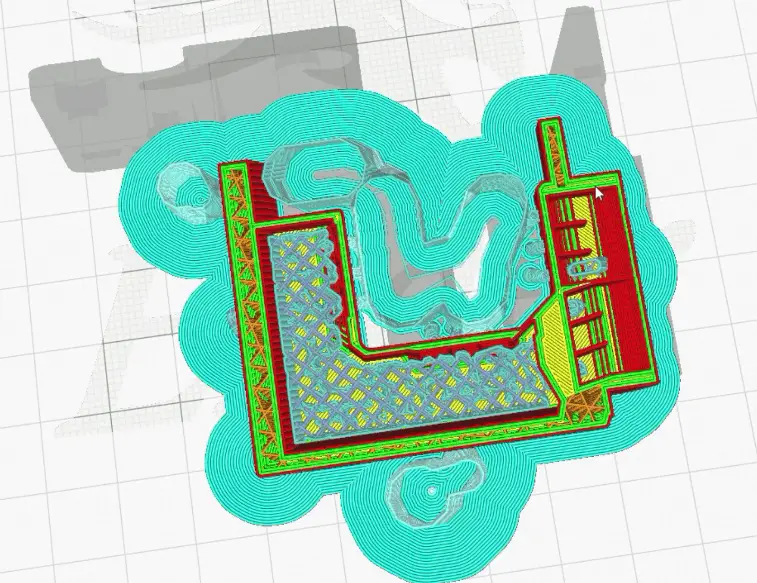

Lattice Supports

Lattice supports structures cross back and forth from top to bottom. They used quite a bit more PLA than tree-shaped supports, but they’re much more stable. If you have a heavy structure, using a lattice support system will yield the best results and protect your print from falling apart.

Lattice is more common than tree-shaped supports because it’s much more reliable. While tree-shaped supports are good for lightweight projects, they don’t have the support offered by lattice structures. That being said, they’re great for tiny prints or organic-looking structures.

How to Remove Supports Without Damaging the Print

To remove supports without damaging the print, follow these step-by-step instructions:

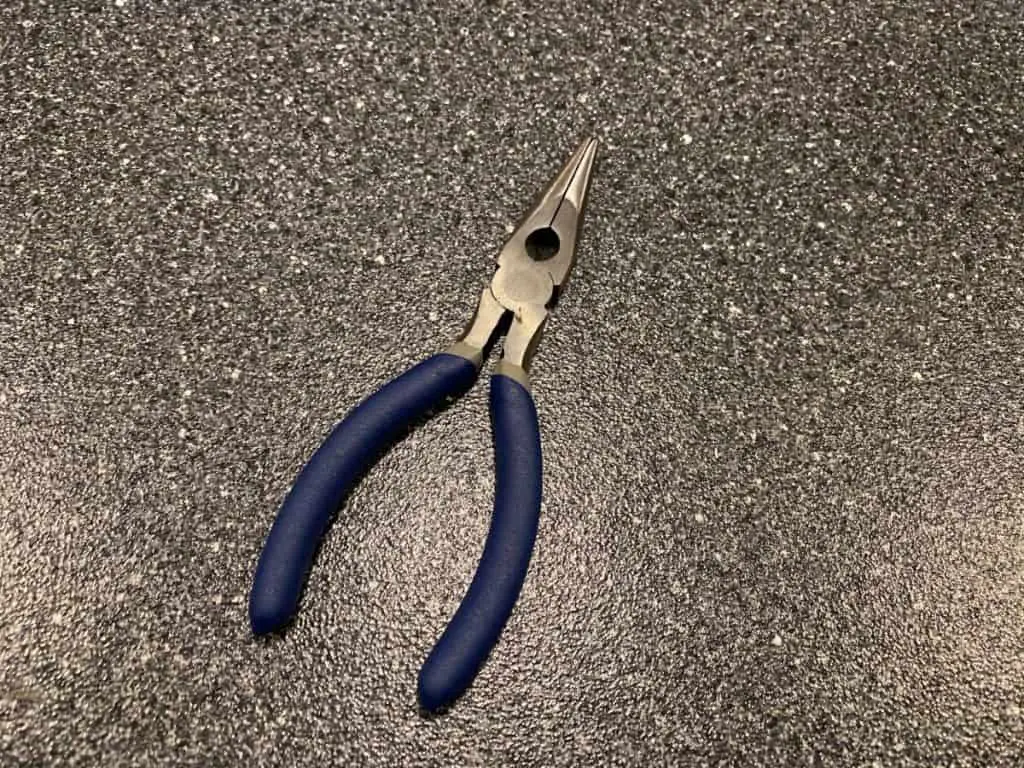

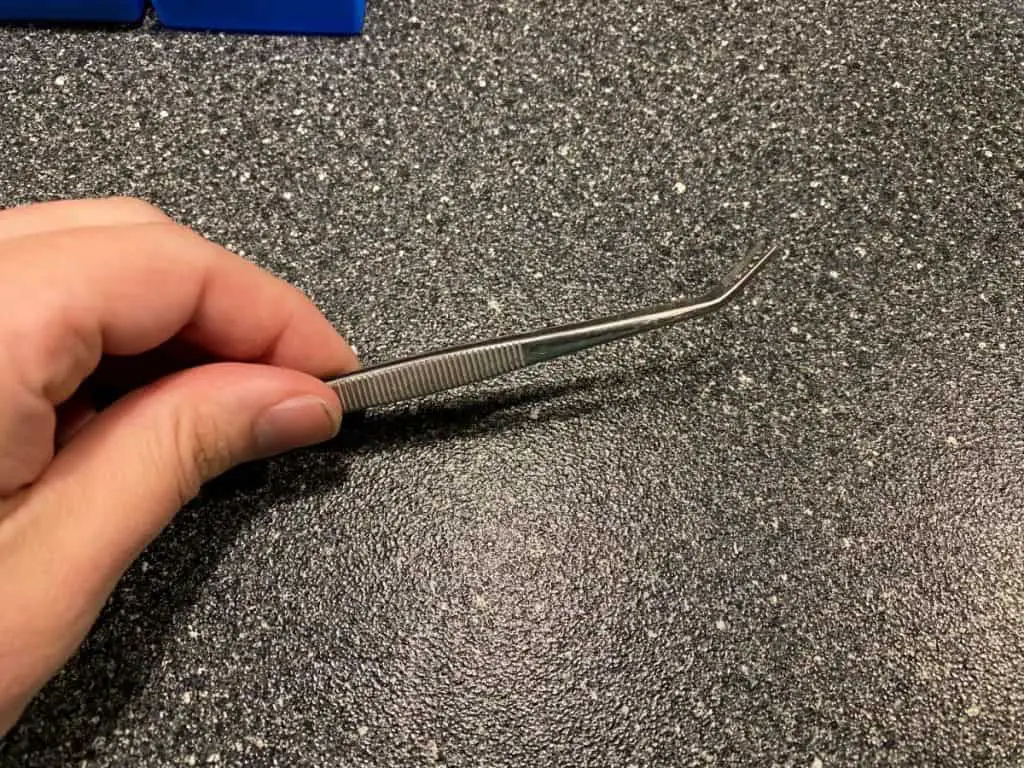

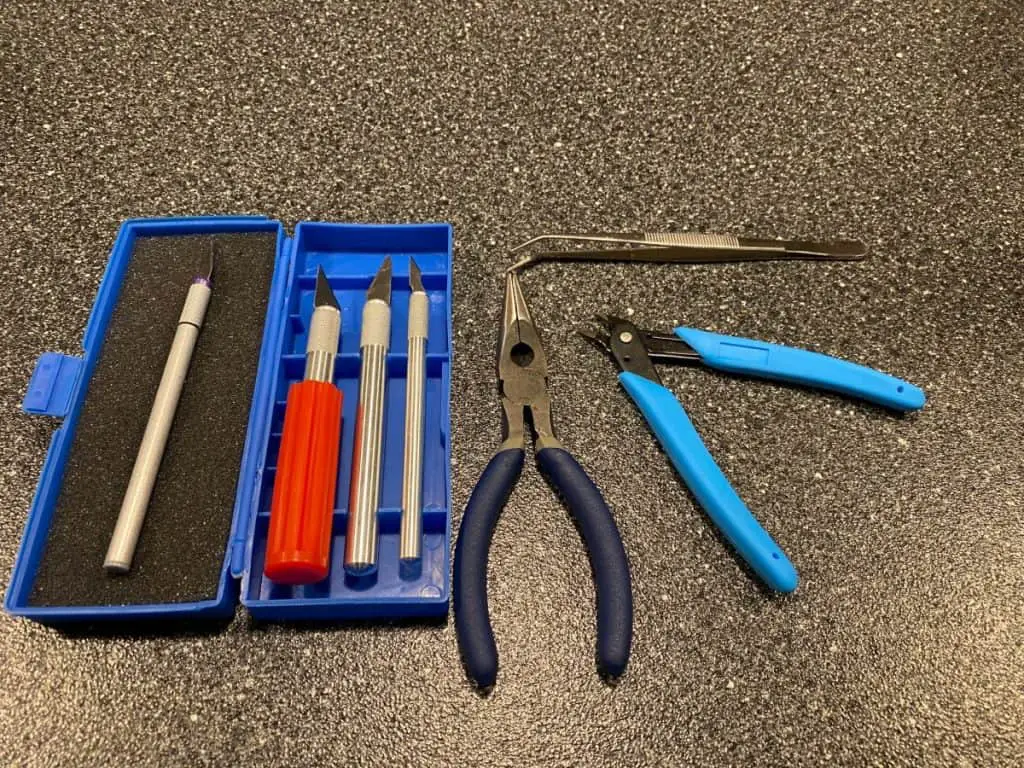

- Break away the extra pieces that aren’t connected to the main structure with pliers. Make sure you don’t use them to pry away thin scraps, or you’ll risk bending the print. The primary purpose of using pliers is to get rid of anything that’s left over from the supports’ printing process.

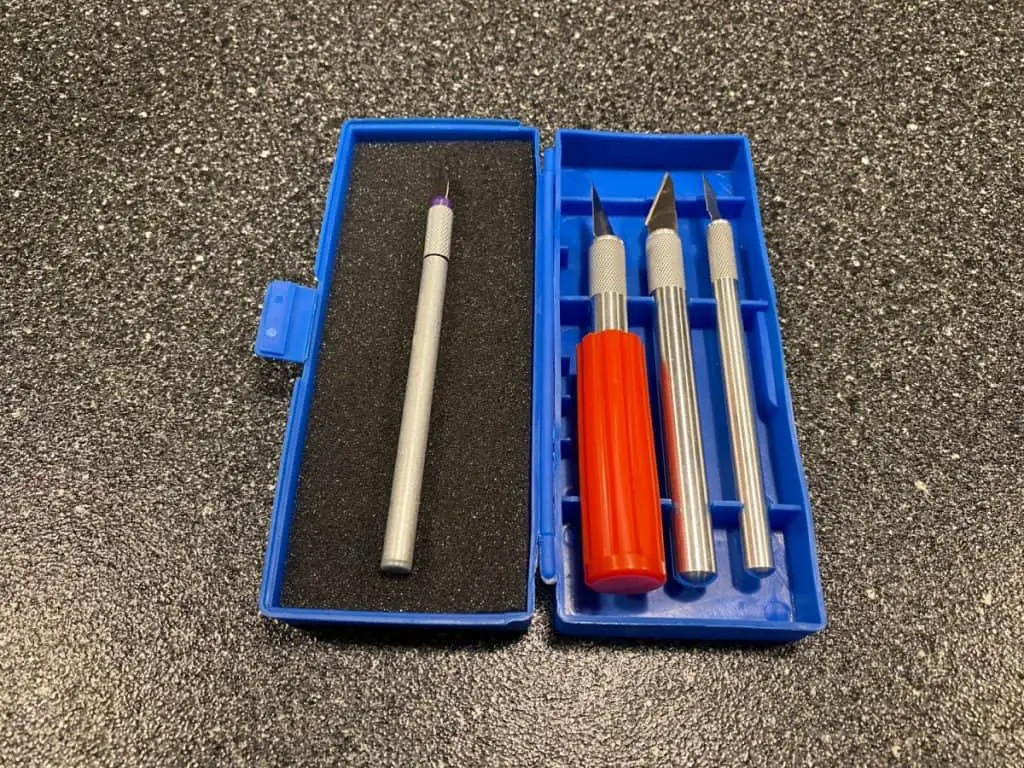

- Chip and cut the rest of the PLA material with an Exacto knife or putty knife. Materialise recommends using a sharpened Exacto knife because it’s about as precise as you can get next to thin, transparent supports. Always work slowly to avoid unwanted damage or deep cuts into the print.

- Use a handheld sanding tool to round the edges with a fine grit. While this step isn’t entirely necessary, it’s perfect for edges that are out of sight or those that are supposed to be smooth and/or spherical. Never use a powered sander, or you’ll shred the print to pieces and risk wasting all of the materials!

Tips and Tricks for Working With Supports

Here’s a handful of suggestions to get the most out of your PLA supports:

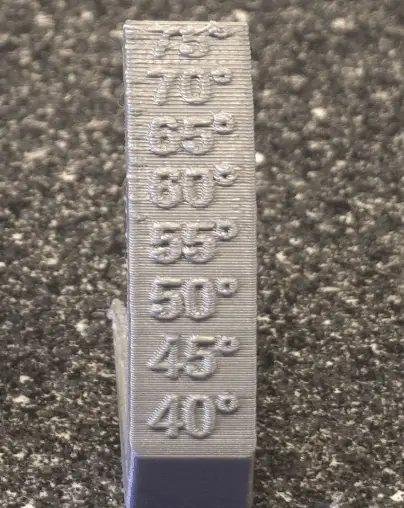

- You only need to add a support if the angle is greater than 45-degrees. While it definitely won’t hurt to support these kinds of structures, you might be wasting precious printing materials and time.

- Thin support systems are often more effective than thick supports. This is because they weave and cross over one another rather than being a straight, vertical beam. This support system is similar to bridges in real life (the Golden Gate Bridge, for example).

- You can use dissolvable supports, but they’re much more expensive than tree-shaped or lattice supports, and they’re not nearly as common. We didn’t list them as a primary type because they’re rare and often require compatible machinery.

- Use tree-shaped supports for lifted animals or faces (flying birds or dragons, for example).

- Separating your print into two separate supporting structures makes it easier to remove the supports when it’s finished printing.

- Some Z-shaped prints need supports, but they’re so few, and far between that it depends on their angles. Many people classify a Z-shaped print as a T-shape since it has horizontal overhangs.

Related Articles

- Choosing the Right Infill Percentage for the Job

- Create a Temperature Tower Using Cura – The Easy Way

- 3D Printing Blobs and Zits: Tips to Avoid Them

- What Shapes Cannot Be 3d Printed? – Details Inside!

- How to Print a File from Thingiverse (The Easy Way!)

Conclusion

Now that you know how to remove a 3D printed support, you don’t have to worry about breaking the print or leaving unsightly lines all over it. A high-quality support can let you create unlimited designs. Remember, it’s always best to create a support and not need it than leave it behind and find out you should’ve added it before you started.

Make sure you check out my YouTube channel, and if you’d like any additional details or have questions, please leave a comment below. For more 3D printing articles click here.