Polyethylene terephthalate glycol (PETG)is a plastic material popularly used in the 3D printing of things like toys, food containers, and robotic parts. PETG is now preferable to ABS and PLA because it is strong, durable, odorless, and easily colored. But for all its pros, PETG has one downside: stringing.

PETG is not always stringy, but because of incorrect printing settings and/or usage of damp filament, you are more likely to experience stringing with PETG than other materials. Poor configurations and fluid plastic can force the nozzle to leak and, in the process, cause stringing.

This article will teach you the essential facts about using PETG correctly to ensure that it doesn’t string. I will explain how you should regulate the print speed, retraction, extrusion temperature, fan speed, and keep your filament cool.

5 Important Facts To Know for Using PETG Without Stringing

Because most 3D printers lack sensors to alert you when things are not operating smoothly, you have to keep tweaking your settings to ensure proper functionality. If not closely monitored, your print job could end up stringy or blobby.

It is important to learn how to correctly operate your 3D printer before you start making your first design. This will ensure that you know where to go to fix problems that may arise as you work.

Read on for some helpful facts to prevent stringing and optimize printing function.

1. Enable Retraction and Set It To Run Fast

Retraction can ensure that the extruder can pull back the filament from the nozzle when you pause printing in between moves. The faster the extruder does that, the lower the chances of it oozing out and making your product stringy.

Do avoid over-retracting as it can clog the printer and slow it down. Instead, activate combing to print only in areas that need infilling because stringing in those parts can be invisible in the finished product as it’s hidden within.

Also, keep in mind that finding the right retraction speed is based on trial and error. As you work, increase your set pace by 5-mm/s only until you land at the proper speed.

If you want to learn more about retraction, here is a informative video from Vision Miner explaining how to set retraction and why it is vital in 3D printing:

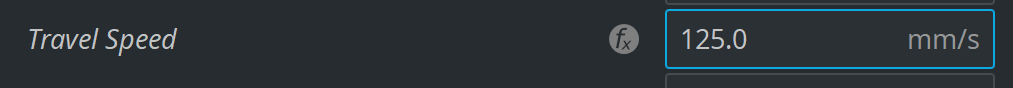

2. Increase Travel Speed

The distance the print head has to travel in between points can determine whether your print gets stringy or not. The shorter the distance, the lower the chance that plastic will drip into the wrong areas.

Tune your print to move as fast as possible to avoid this mess, being careful not to let it be so quick that it causes the plastic to build up in the nozzle and cause oozing.

3. Lower the Extrusion Temperature and the Speed

When the temperature is very high, the plastic in the extrusion will stop being sticky and will start dripping through the nozzle. Oozed plastic can damage the end product of your print.

PETG filaments come with specified temperature configurations that you should use to avoid overheating the plastic. Usually, the best extrusion temperature is around 230-260°C. (446 – 500°F).

If the printer is discharging more filament than needed and causing excessive stringing, you need to lower its speed so that it excludes normally. Fast printing can also stop the plastic from sticking to the platform as it needs time to adhere before another layer is stuck to it. So when you lay the next layer, it will spread in different areas, causing stringing.

4. Run the Print Fan at a Moderate Speed

PETG Filament needs to stay cool to create a clean print. For that to happen, you should run the fan at around 10-30% speed to prevent the plastic from overheating and increasing flow at the nozzle, which can cause the filament to gush through the nozzle and create threads along its surface and edges.

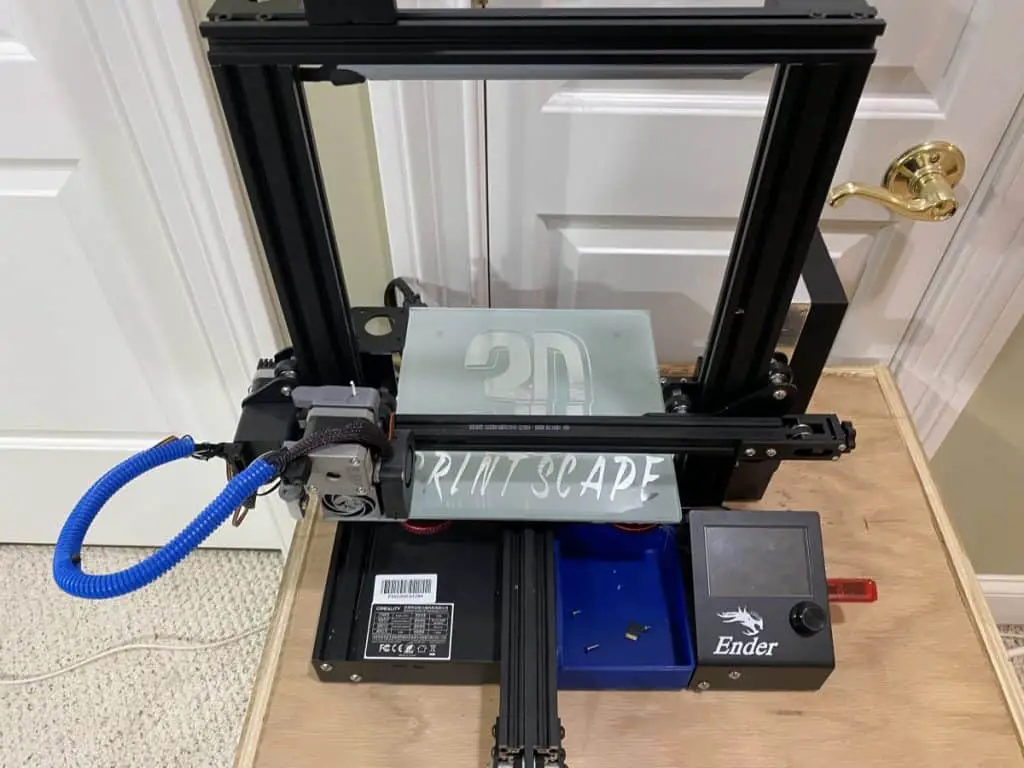

However, there are printers like the Ender 3 Pro that run properly without a cooling fan since it has a heat sink fan that can blow air inside the print head.

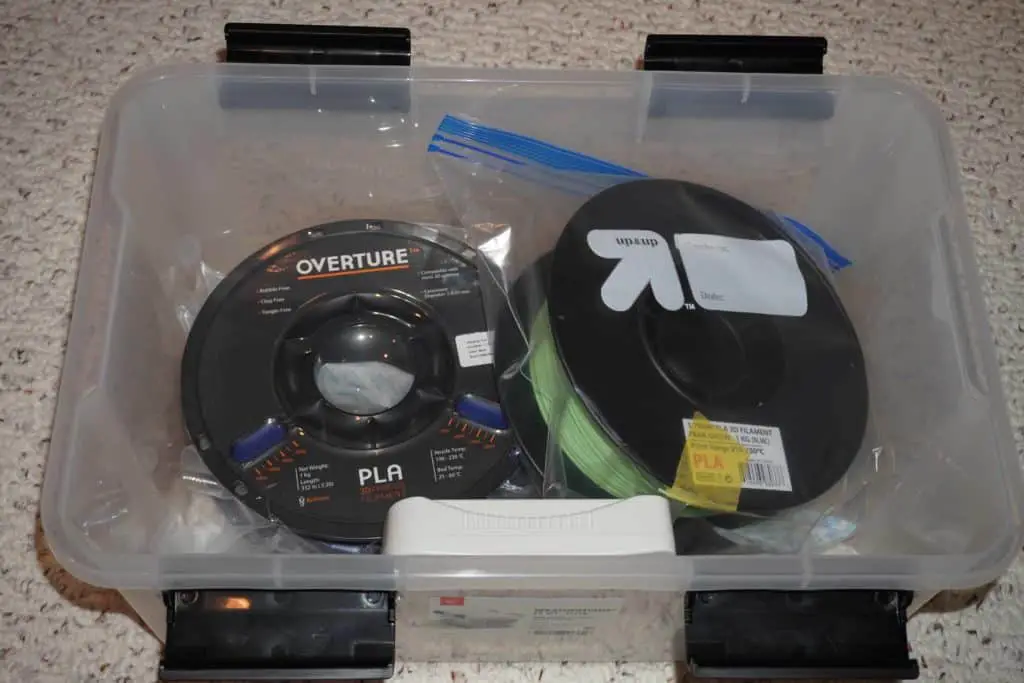

5. Ensure There’s No Moisture in the Filament

Always keep your filament in a cool and dry place and only open the pack when you’re ready to use it. PETG tends to absorb moisture readily, and when it’s damp, it can cause stringing on the edges of the print and weaken the plastic.

If you open a bag of filament and end up not using all of it, seal it in a tight container to keep it protected.

You might want to err on the side of caution and always dry your filament before using it, especially if you live in a humid place or have kept the roll for a long time. You can dry it at 65°C (149°F) in your home oven or use a filament dryer for about 4-6 hours.

Choosing the Best PETG Filament

Before you go ahead and buy the PETG filament, first buy a 3D printer designed to run that plastic so that you don’t waste your fine filament on a gadget that can’t print it correctly.

It should also be capable of creating all the objects you have in mind. I recommend the earlier mentioned Ender 3 Pro from Amazon because it has a tight extruder that makes it easy to print malleable materials like PETG, and it also provides a high-quality print.

Some of the best PETG filaments on the market are available on Amazon.com. My top recommendations are:

- HATCHBOX PETG 3D Printer Filament, which is less clogging.

- Paramount 3D PETG Filament, which is highly compatible with a variety of printers.

- Amazon Basics PETG 3D Printer Filament, which is more affordable and also highly compatible with various printers.

Related Articles

- At What Temperature Does PETG Start to Warp?

- Does PETG 3D Printing Create Toxic Fumes?

- All About 3D Printer Plastic

- Can You Drill Into and Cut 3D Printed Plastic?

- Can I Dry Filament in Microwave? (Details Inside)

Final Thoughts

PETG filament is relatively easy to use to create a variety of products. To prevent stringing, all you have to do is get the printing settings right.

Always keep checking on the printer as you work to confirm that it’s performing as required and when it’s not, tweak the configurations as I suggested above to fine-tune it.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.