With affordable 3D printers only being available for the last one or two decades, there are many questions newcomers have about 3D printing plastic. We’ve found the most popular questions and answered them here.

What Is 3D Printer Plastic Made Of?

It’s made of different polymers to create a plastic with targeted properties. For example, ABS is a popular printing plastic made of three components, Acrylonitrile, Butadiene, and Styrene. ABS fumes are toxic, which is why PLA is a better option.

PLA is made from resources such as sugarcane and corn starch. It’s one of the least toxic 3D printing materials. Both are thermoplastics, meaning you can reheat them into a liquid to create more filament.

There are hundreds of different 3D filament plastics with specific properties, like ASA (Acrylic-styrene-acrylonitrile) that UV ray resistant, or PET (Polyethylene terephthalate) that’s rigid, chemical resistive, and safe to use with foods.

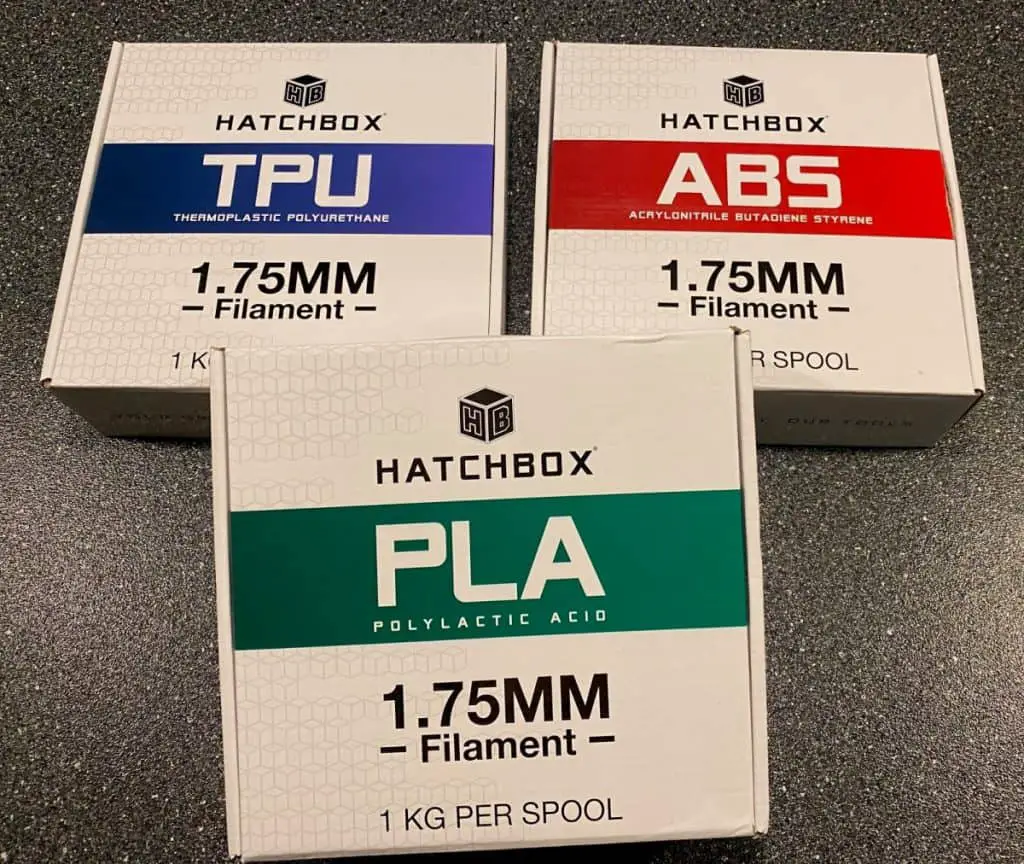

What Types Of Plastic Can 3D Printers Print?

ABS – Affordable, impact-resistant, heat tolerant. The melting point is 392°F (200°C)

PLA – PLA is made to a high standard, it’s more reliable than ABS with precise and consistent diameter throughout the filament.

TPE / TPU – A very flexible plastic ideal for parts like RC tires and other flexible parts.

PET / PETG – This is one of the food-safe 3D printer plastics which is resistant to water and other chemicals. Ideal for making water bottles or lunch containers.

Nylon – A very tough type of plastic, it’s flexible and strong enough to make cable ties with.

PC – Polycarbonate is extremely tough with high heat and impact resistance.

There are hundreds of different plastics available, but these are some of the most popular. When selecting your filament, make sure that your printer is compatible.

What Does 3D Printer Plastic Cost?

Low range ABS filament costs around $20 per kg (2,2lb). High-quality PLA costs around $150 for 500g (1,1lb). With so many options available, you’re likely to find hundreds of different deals if you shop around. These prices are based on two best sellers on Amazon, for the latest deals, click here.

What’s The Best Plastic For 3D Printing?

As a beginner, the best type of plastic to use for 3D printing is PLA because it’s affordable, durable, and easy to work with. It’s a reliable plastic that produces high-quality results. PLA is suitable for many projects like cell phone covers, car parts, ornaments, etc.

Once you know more about the 3D printing process, you can move on to some higher-quality materials if your project requires it.

Other plastics are better for certain prints, but in general, PLA is the best choice for most home 3D printer enthusiasts.

How Hard/Strong Is 3D Printed Plastic?

PLA has a tensile strength of 36 – 55. Plastic is known for its durability and flexibility and usually won’t break easily. ABS plastic has a tensile strength of 25 – 50 MPa (3626 – 7252psi) which is quite strong, especially when the part has thick walls.

Why Is 3D Printing Filament So Expensive?

3D Printing filament is expensive because of the extensive process required to produce the filament. The material cost is only one minor factor in the total cost. The machinery required to shred and melt plastic is expensive because of the level of precision required to transform plastic chips into perfectly wound filament.

It takes a lot of time and oversight to produce high-quality filament, so many workers have to be paid. Simply put, 3D printing filament is so expensive because the running costs of a filament producer are high, not because of the material costs.

Can You Recycle Plastic Bottles For 3D Printing?

Yes you can. Most plastic bottles in the U.S are made of PET plastic. PET is a thermoplastic that can be melted and reused. You just need the right machinery and go through the sorting, cleaning, shredding and melting process in the next section to do it.

Can I Use Recycled Plastic In A 3D Printer?

Yes, you can reuse thermoplastic if you melt it and create a new filament. Here’s how it’s done.

- Collect the plastic.

- Remove any plastic that is dirty and cannot be cleaned.

- Carefully check any labeling to identify the polymer type. This is normally displayed in a triangle with a number inside.

- Sort the plastics according to their own kind. You may need to do some of your own research to identify any that don’t have a label.

- Remove any stickers\glue and dirt from the remaining plastic.

- You can only recycle one type of plastic at a time. If you have three different plastics, you must work them through these steps separately.

- Now you need to break up the plastic into pieces small enough to fit into your plastic shredder.

- Feed the shredded plastic through your extruder, the machine that melts the shredded plastic and pushes it through a small round opening to create a filament of plastic.

NB: As thermoplastics are remelted over and over again, the material degrades and can’t be recycled forever.

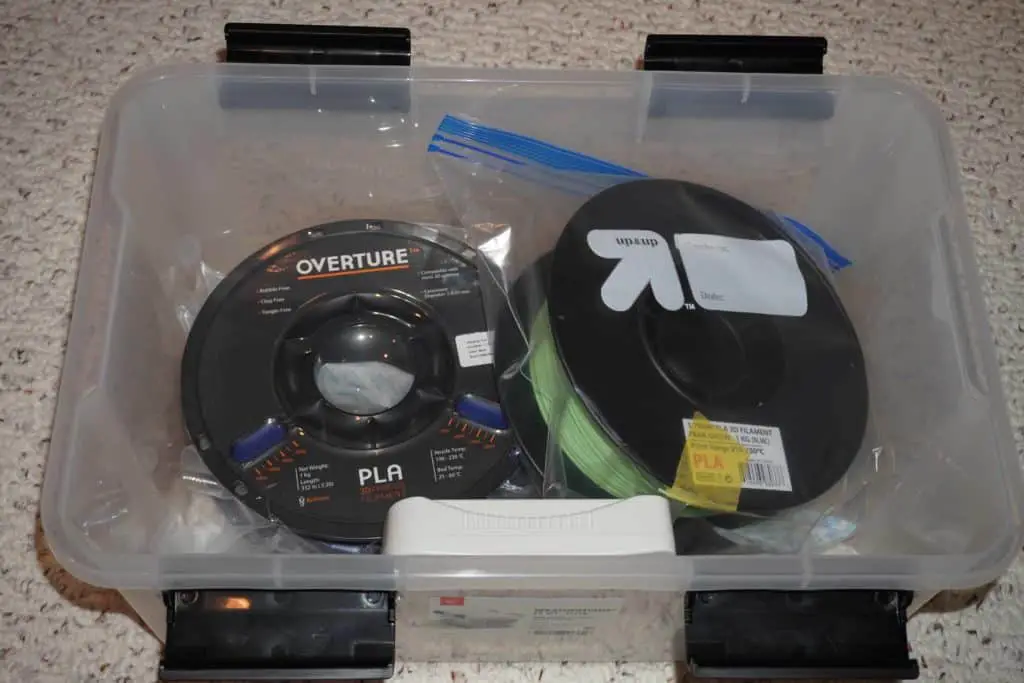

How Long Does 3D Filament Last?

A standard 1kg roll of filament can last anywhere from 50 to 200 hours of print time, depending on what you print. Big prints with little detail will consume your materials faster than small prints with high detail. This is because the flow rate is much slower when printing small details.

To understand it easier, if you print something that weighs 40 grams, that’s 4% of your filament. Print 25 of those and your 1kg roll is done.

Also, most filaments tend to absorb moisture, which can ruin the spool, so it’s important to properly store the filament when it’s not in use. I wrote an article that covers this in more detail that you can see here “3D Printer Filament Storage Options“.

Where Do I Buy 3D Filament?

You can buy 3D filament online or at any 3D printing shop. There are Walmarts that sell it too, 3D filament is available almost everywhere. If you Google “Where do I buy 3D filament” you will get results based on where you’re Googling from.

Is 3D Filament Food Safe?

PET and PLA are two of the most common food-safe plastics. Most plastic bottles are made of PET (PolyEthylene Terephthalate) These plastics don’t fare well with temperature fluctuations after they’ve set, so if you’re planning on making soup bowls or coffee cups, you’d have to use PETG, which withstands higher temperatures.

Ceramic would be your best option for food-safe 3D printing, but this article is more about the plastics.

Is 3D Filament Recyclable?

Yes it is, all thermoplastic filaments are recyclable. You can shred your failed prints and feed them through an extruder to make more filament. Keep in mind that the more you recycle it, the more the material degrades and becomes difficult to work with.

Is 3D Filament Toxic?

Yes, even PLA can be toxic at high-temperatures. They release toxic fumes called Volatile Organic Carbon. ABS releases more toxic fumes than PLA, and ceramics have some of the worst toxicity levels. Even if you’re working with PLA, it’s best to use an enclosure on your machine and make sure you have an extractor fan or air conditioner that can replace all the air in the room with fresh air within 15 minutes.

Can 3D Printers Print Clear Plastic?

3D printers can print clear plastic, but it’s not as easy as buying transparent material and hitting the print button. To achieve clear transparency through the part, the settings of the print need to be fine-tuned. Sometimes, clear plastic prints are achieved by increasing the flow rate, using high nozzle temperatures, increasing build plate temps, disabling fan/print cooling and many other finely tuned settings. (In addition to using the right material)

Can 3D Printers Only Print Plastic?

3D printers can print a multitude of different materials, from ceramic to metal. Plastic is just the most popular printing material because of its low price and the fact that it’s so easy to manipulate, it doesn’t require the most advanced machinery to melt and print.

Can 3D Printers Print Soft Plastic?

Yes, TPU/TPE is known for its elastic properties. It’s made with a mixture of Thermoplastic Elastomers to give it rubber-type properties.

Can You 3D Print Plastic Car Parts?

You can print car parts with a 3D printer. If you’re printing car parts at home ABS and PLA, it’s best to avoid printing anything that’s going to take any load, heat, pressure, friction, etc.

With some time and effort, you could print body parts for your car, but most people don’t bother because of the size of the print, body parts are just too big, unless you’re printing a side mirror cover. On the inside, you can fit 3D printed trimmings over the rear-view mirror and air vents.

Car parts like custom gear knobs or unique interior trimming are perfect for 3D printing. Phone and cup holders are also popular 3D printed car parts.

Bike parts are ideal for 3D printing because they are so much smaller than car parts. Mirror back covers or trimming around the speedometer. You can print a custom fuel tank cap as well.

Related Articles

- What Are FDM Printer Fumes?

- Can You Drill Into and Cut 3D Printed Plastic?

- What Computer Do I Need for a 3D Printer?

- Cura Profiles

Recap

There are a lot of options when it comes to 3d printer filament, but by far, the most commonly used material is PLA. That said, it may not always be the best option for what your printing, so it’s essential that any hobbyist understand what options are available and when each should be used.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.