There are two broad options for 3D printers: resin or filament 3D printers. Each is good in their own right but there are trade-offs to using one over the other. Today, I will explain if it’s cheaper to print on a resin 3D printer or a filament 3D printer.

On average, printing with resin is about 50% more expensive. The cost to print an object is based on the volume of printing material used to print it. Resin costs about $50 per liter (kg), whereas filament costs $20 per kg. To print two identical objects is 50% more expensive with resin.

To help you better understand the cost difference between printing with resin compared to filament I will provide a side-by-side breakdown of how much it costs to print different kinds of objects.

I’ll also cover the costs difference between buying a resin 3D printer compared to a filament 3D printer. As well as, additional costs involved with printing on one over the other to give you a very clear picture of exactly how much it costs to print with one compared to the other.

Side by Side Price Breakdown: Resin vs Filament

Let’s take the example of printing a figurine like those used in the game Warhammer, or a figurine of Batman or Captain America from the Marvel and DC comics. A small figurine would require about 3g of printing material.

Here’s a table that shows how the cost differs if you print the exact same object on a resin 3D printer compared to a filament 3D printer:

| Cost | Filament 3D Printer | Resin 3D Printer |

|---|---|---|

| Printing material | $0.06 | $0.15 |

| Electricity | $0.01 | $0.01 |

| Margin for error (failed prints) | $0.01 | $0.03 |

| TOTAL | $0.08 | $0.19 |

From the table, you can see that a resin 3D printer costs about twice as much to print the same sized object. The main cost that impacts the difference in price is the cost of the filament. When 3D printing it’s possible to have failed prints every now and then.

It’s important to note that 1 liter of resin doesn’t equal exactly 1 kg of resin. This calculation applies to water – which isn’t as dense as resin. But, resin is close enough in density to water that the difference in weight is minor. And 1 liter roughly equals 1 kg.

This is where some problem arises when 3D printing which causes the 3D print to have an imperfection that won’t allow it to finish. Or, the print needs to be discarded because it didn’t come out perfect. When this happens the additional cost is the printing material – either filament or resin.

Because resin is more expensive than filament the cost when you have a failed print is also higher. Overall, though printing on either a filament 3D printer or a resin 3D printer is fairly cheap. Coming in at under $0.20 total for a small figurine-sized object.

The other costs involved are the cost of buying the 3D printer initially. Here are some average costs for some of the most popular resin and filament 3D printers so you can see how they differ.

| Filament 3D Printer | Avg. Price | Resin 3D Printer | Avg. Price |

|---|---|---|---|

| Creality Ender 3 Pro | $275 | Creality LD-002H | $225 |

| Original Prusa Mini | $400 | Voxelab Proxima 6 | $200 |

| Voxelab Aquila | $175 | Elegoo Mars 2 | $225 |

| Biqu B1 | $300 | Nova3D Bene4 Mono | $300 |

There are many more models of 3D printers than this. But, overall you can see that a resin 3D printer and filament 3D printer both cost about the same. And range from about $150 to $300.

So it’s reasonable to say that you can buy a resin 3D printer or a filament resin printer for the same price. Therefore, the main consideration between a resin 3D printer and a filament 3D printer is the cost of the filament. But, then why choose one over the other.

Pros and cons of printing with resin vs filament

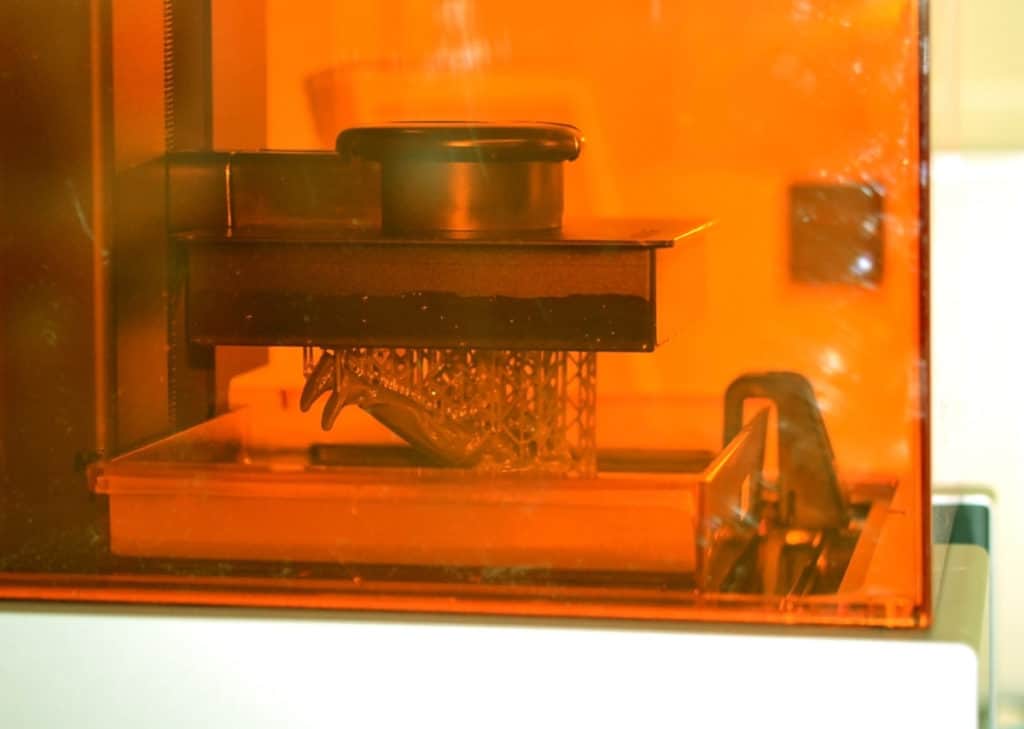

The main pro of printing with resin is that the prints have much more detail and are of better quality. If you compare a resin 3D print to a filament resin print you can easily tell the difference. After doing a 3D print you generally you’ll do some finishing which includes sanding away any imperfections and adding a layer of primer.

But, the end result of a resin 3D print is much cleaner, has smoother edges, and the finer details are much clearer. It’s kind of like the difference between an image on a low-quality camera compared to a photo taken with a very expensive high-quality camera.

Why 3D Printing Resin Is So Expensive

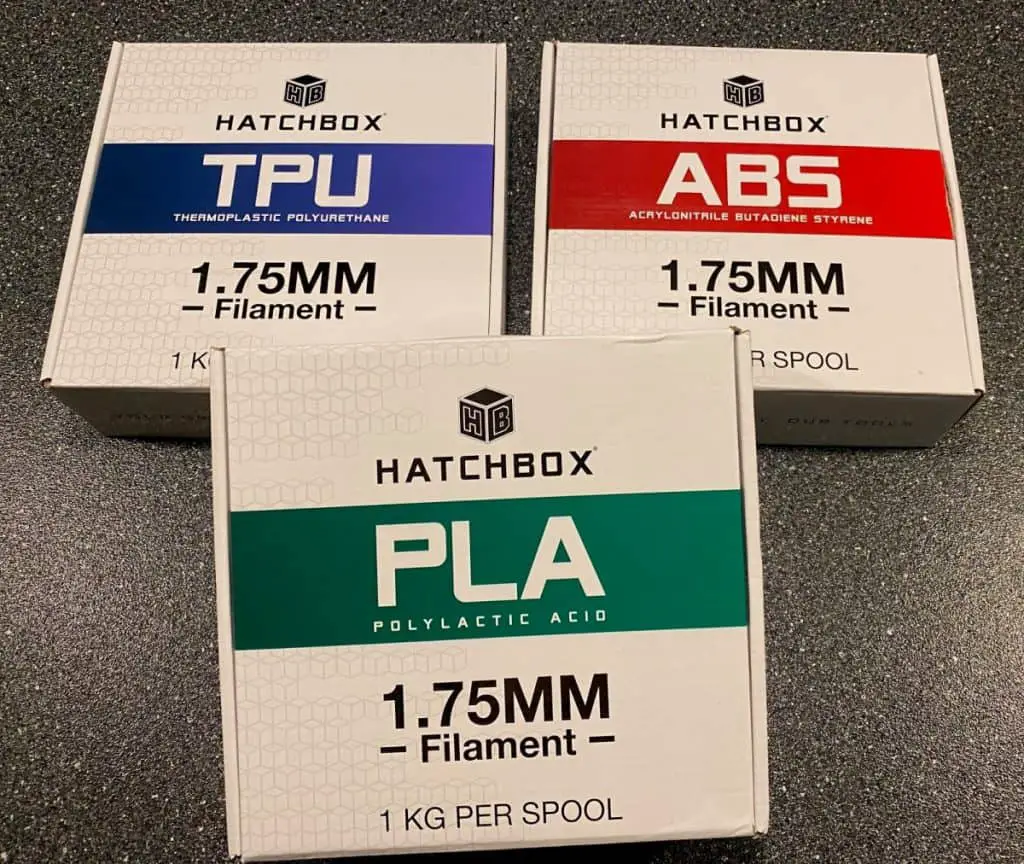

The material used to print with resin is more expensive. To print on a resin 3D printer you need to buy resin. Resin is about twice the price of filament. But, why is resin more expensive than filament.

Resin is specially formulated to cure with UV light. The technology and materials used to make it is more difficult and expensive to produce. This cost to produce it is reflected in the price to buy resin. Filament, by comparison, is made of plastic which is easy and cheap to make.

Resin is a common name for the material used in resin 3D printers but another name for it is stereolithography or SLA for short. Many people are familiar with the word stereo meaning sound or types of speakers. The word stereo in stereolithography comes from the Latin language where stereo means solid and generally relates to 3D objects.

Lithography means to print onto a surface. Although the term stereolithography can apply to both filament and resin 3D printing it’s commonly only used to refer to resin 3D printing.

I explained how both types of 3D printing material are made in this article about why 3D printing with resin is so expensive (Coming Soon).

How Much Does Resin Cost for 3D Printing

The ongoing costs of 3D printing with a resin 3D printer are electricity, resin, and any other materials you use to finish your 3D prints such as primer or paint. Resin is not only the most consumable product used in resin 3D printing but is much more expensive than the negligible electricity costs of running a 3D printer. Here’s how much resin is for 3D printing costs.

On average, resin for 3D printing costs $50 per liter. 1 liter of resin will print about 1kg of 3D printed objects. The time to 3D print this amount of resin is about 150 hours or 7 days of continuous printing. Resin is around twice the price of filament.

Although resin is the most expensive ongoing cost, on balance it’s not too expensive compared to how many 3D objects you can print. As an example printing a small model about the size of a matchbox from a cartoon or comic book costs around 20 cents to print with resin.

To print the same sized model on a filament 3D printer costs about half the price or 10 cents. To buy a similar model online can cost around 50 cents. But, with a 3D printer, you can print virtually anything. There are many libraries of models online. These can be used to download the 3D print files for free.

Other costs involved in printing with resin vs filament

Printing with resin is also more expensive than printing with filament because of the extra equipment you need.

When printing with filament the extra equipment you need is only:

- A glue stick – to help with adhesion to the print bed

- A scraper – to help remove the completed print from the print bed

Both of these are fairly inexpensive and last for quite some time. A scraper will last almost forever. Whereas, you’ll need to get another glue stick from time to time depending on how much 3D printing you’re doing.

Printing with resin, however, has a lot more equipment you’ll need. Here’s a list of what you’ll need and why they’re needed.

| Equipment | Use |

|---|---|

| Nitrile gloves | Handling the resin and isopropyl alcohol can irritate your skin. So its best to stop it from making contact with your skin. Nitrile gloves create a solid barrier so the resin and isopropyl alcohol don’t make contact with your skin. |

| Isopropyl alcohol (IPA) | Resin is made of a complex chemical mixture that won’t come off easily using water or soap. Isopropyl alcohol completely dissolves resin. Therefore, it’s the most effective at cleaning up any minor spills, the tools you use when 3D printing with resin. As well as, cleaning/prepping finished prints. |

| 2 tupperware containers | When a print is finished you should dip it in a tupperware container filled with IPA. They should be filled enough that you can easily dip the finished prints and completely cover the model you’ve printed. Dip completed models once in one tupperware container. And again in a second tupperware container with cleaner IPA to thoroughly clean completed models. |

| Tongs | Handling completed 3D prints with tongs is the easiest. That way you don’t need to dip your hands in the IPA bath. And any resin residue can be isolated to the tongs. This makes it easier to not spread resin residue around your work area. |

| Metallic baking trays | After you’ve dipped a completed print in IPA you should place it into a metallic baking tray to dry. Generally, it’s best to put some paper towels at the bottom of a metallic baking tray and place the ‘washed’ models onto it. The paper towel will absorb the excess IPA, as the model dries. |

| Paper towels – blue shop towels are the best | These are used in the base of the metallic baking trays to absorb the minor excess IPA. They are like normal paper towels but have a softer finish that won’t cause minor scratch marks on the surface of a 3D print. They also tend to be more absorbent than regular paper towel. |

| Sticky clear shelf liner | This is a clear shelf liner that you stick on to the top of the desk that you use for your resin 3D printer and to finish the completed prints. It makes it much easier to clean up any resin that’s spilled, and protects your desk from stains caused by the resin. |

| Face mask | Resin and IPA have a very strong chemical smell. A face mask can really help to reduce the smell. There are specialist face masks that do a really good job at reducing strong smells. But, try a regular disposable face mask with good ventilation and see if it’s enough for how much the smell bothers you. |

How Long Does 1kg of Filament Last

As you may know, 1 liter of resin is roughly equivalent to 1 kg of resin. Because filament is a solid it’s measured in kgs rather than liters. 1kg of filament is a common amount that is sold, but how long does 1kg of filament last and how soon will you need to buy more?

On average, it will take 166 hours to print 1kg of filament. How long in days and weeks depends on how often you print. 166 hours is equivalent to 7 days of continuous printing. 1kg of filament will also print 1kg of print material.

But, many models have supports that require extra filament. These supports ensure the print doesn’t collapse as it’s printing. On average these supports account for about 10% of the total print.

Therefore, the numbers above can be adjusted by -10% depending on the type of models you’re printing. So, 1kg of filament will last about 150 hours of continuous printing.

Related Articles

- 3D Printing Actual Costs with Examples

- Is 3D Printing Cheaper than Molding?

- Why is 3D Printing Via Shapeways So Expensive?

- How to Print a File from Thingiverse (The Easy Way!)

- Best 3D Printer Under $300

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.