SLA printers, or stereolithography printers, came to the desktop 3D printing market in 2011. Many believed that SLA desktop printers would offer a smaller and more affordable option for 3D printing than FDM printers. Since the introduction of the first SLA printers, there have been many advances in the technology and the resins available to the small form factor SLA printer user.

What are SLA Printer Resins? SLA printer resins are combinations of materials that, when exposed to some form of light such as a laser, cure into a hardened plastic. The basic varieties of resins available fall into four categories

- General-Purpose Resins

- Castable Resins

- BioCompatible Resins

- Engineering Resins

Each type of SLA resin has its characteristics and requirements. Selecting the right SLA resin is important to ensure that the finished product of your SLA printing process has the correct attributes and finish.

General Purpose Resins

General-purpose or standard resins are known for their low-cost and for producing finished products that exhibit a high degree of stiffness, high resolution, and a smooth surface. Current general-purpose resins are available in several colors, including the ones below.

- greens

- reds

- yellows

- oranges

- blues

- whites

- blacks

- browns

Each color of resin may display different finished properties. Some colors may be more brittle, while others produce finer detail and smoother finished surfaces. When selecting a general-purpose resin, be sure to consult the manufacturer’s specifications to make sure the finished properties of the resin match your needs.

Castable Resins

Investment casting techniques are the staple of many industries such as foundries, machine shops, and jewelers. The advent of small footprint SLA printers brought a new opportunity for small-parts investment casting. The SLA resin manufacturers responded by formulating resins that produce less ash residue for finished cast parts with fewer imperfections.

The newer castable resins available offer some qualities that other materials don’t such as:

- Low ash content

- Extremely fine detail

- Repeatability through the SLA printing process.

- Quick turnaround

There are a few downsides to using SLA printing for creating investment cast molds.

- Low impact and low wear resistance

- For optimal performance, the production piece requires post-processing.

Biocompatible Resins

Resins formulated for safe human compact are now available, making SLA printing an up and coming field in the biomedical industry. Dentistry has been the primary focus of the development of these types of resins, but more and more activity is occurring in the biomedical engineering field.

The SLA production of dental orthodontic appliances, as well as medical equipment, has spurred growth among medical and dental bioengineers. The newer biocompatible resins features include:

- High resolution and fine detail

- High resistance to fracturing and wear

- Extremely smooth finishes

On the downside, these SLA resins are expensive and feature only Class I and Class II biocompatibility.

Engineering Resins

SLA printing is a tool often used by engineers and designed to prototype forms and parts on a quick basis for testing and evaluation. However, standard resins often proved to be too brittle for these purposes. A new generation of SLA resins offers better properties in the finished products that allow engineers and designers a better product to test and evaluate.

New SLA resins can be purchased that offer some interesting characteristics to engineers and designers.

- Tough Resins – These resins feature a greater tolerance for wear and higher resistance to cracking than standard resins. Some manufacturers advertise SLA resins that have properties Comparable to ABS plastic.

- Flexible or Soft Resins – These resins, when properly cured, offer a flexible, almost rubber-like feel. These flexible resins give engineers and designers options for producing prototype parts that behave and feel like rubber or soft-plastic components.

- Durable Resins – This SLA printer resin creates wear-resistant parts with some flexibility, low friction, and a smooth finish. These durable resins have properties that simulate polypropylene.

- Heat Resistant Resins – SLA printing resins are not known for their heat resistance or ability to function in high-temperature environments. The recent introduction of high-temperature resins to the market have made it possible to produce parts or assemblies for industrial systems or testing that can handle hot air or fluids or prolonged exposure to relatively high heat sources without deforming.

SLA vs. DLP; How Do the Printers Work?

SLA and DLP printers are, in many ways, the same. However, the technology is different. The differences in the way the printing process works in an SLA and a DLP machine can cause differences in the finish, the details, and the quality of the finished piece. Also, the two processes use different resins due to the nature of the technology.

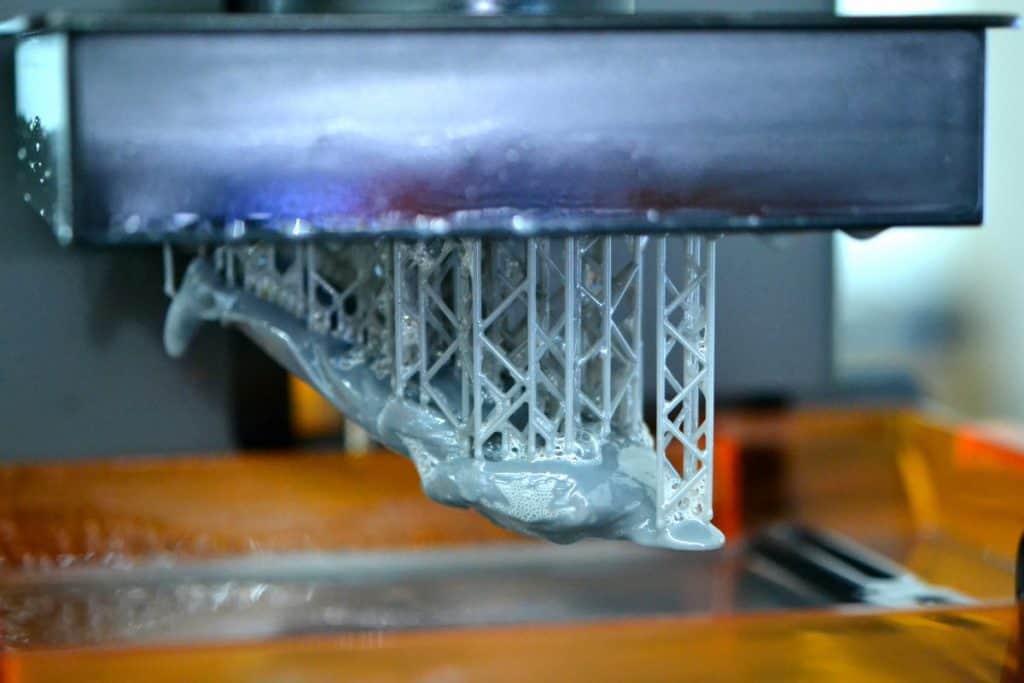

SLA Technology

SLA technology uses a vat of resin that is formulated especially for the SLA process. The resin is sensitive to UV light and begins to harden as soon as a UV light source focuses on the resin surface. In the case of SLA printers, the light source is a UV laser.

The software that drives the SLA printer guides the UV laser across the surface of the resin in the vat and fires the laser wherever the software indicates. As the laser fires, the resin fuses and begins to build up the project in the vat. The tray on the bottom of the vat is lowered incrementally as each layer of the model is created.

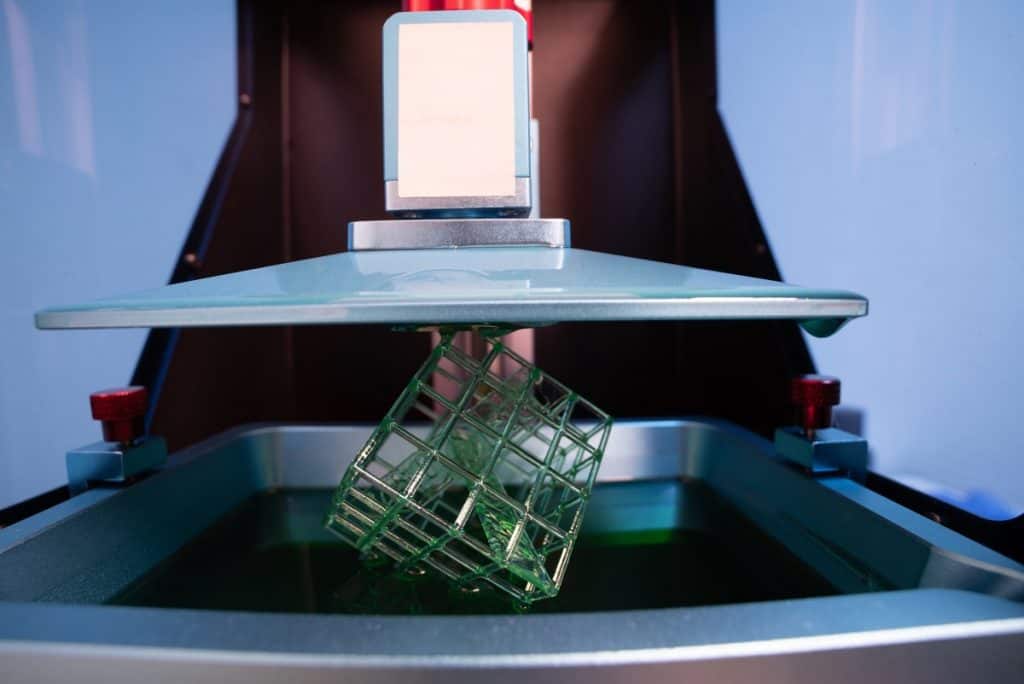

DLP Technology

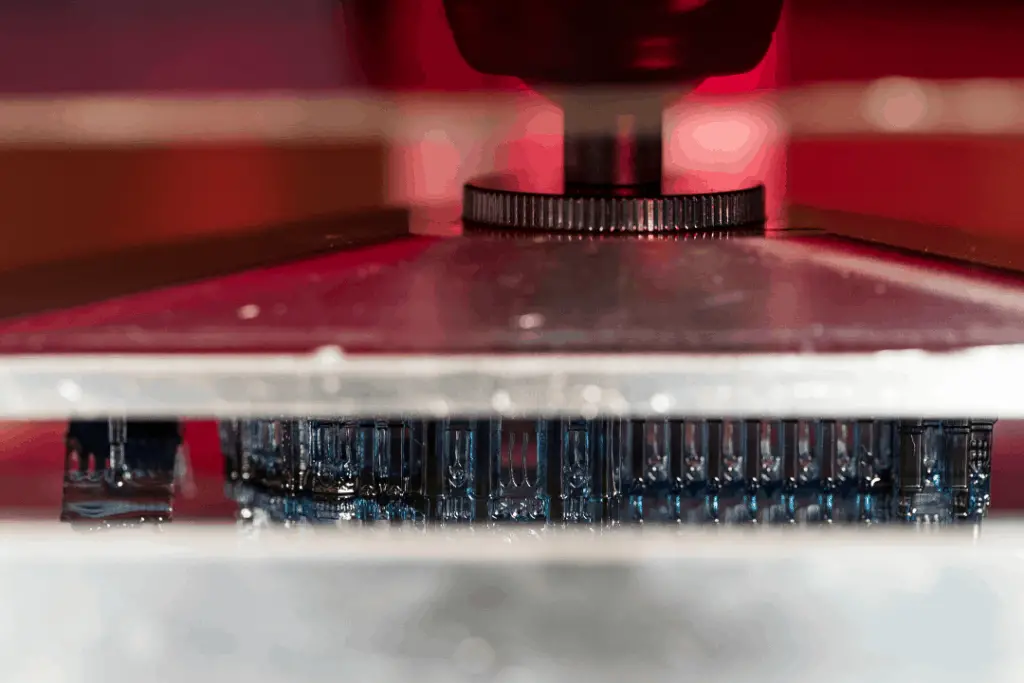

DLP, or Digital Light Processing, is much like SLA technology. Instead of a UV laser, DLP printers utilize a light projector screen to fuse the resins. The LED screen and the digital micromirror device are the heart of a DLP 3S resin printer.

Like SLA printing technology, the DLP printer also has a vat in which the printer resin sits. DLP printers use an LCD screen to project an image of a “slice” of the build project onto the surface of the resin in the vat. The entire “slice” of the model fused at the same time.

DLP LCD printing is much more power-efficient and doesn’t require as much precision tuning of the printer as an SLA device. The downside is that DLP printers have a bit less resolution. The difference precision can cause a loss of detail in the finished product.

Top and Bottom Printing

Both SLA and DLP printers are made to print from the top or the bottom.

Some SLA and DLP printers have a clear bottom on the resin vat and the light source sits below the vat. As the project builds, the vat moves up with each successive layer. A step in the printing process called the peel step, in which the fused layer of resin pulls from the bottom of the vat, can slow printing.

Printers designed for top-down printing have the light source above the vat. As the project builds, the vat moves down. Top-down printers eliminate the peel step and are a faster process.

There are some considerations when choosing which type of printer you purchase.

Pros and Cons of Bottom-up Printers:

- Bottom-up printers typically need less resin in the vat to produce a finished part. Less resin means less cost.

- Bottom-up printers need less resin, so smaller resin vats are needed. Bottom-up printers typically have a smaller footprint and fewer moving parts.

- On the downside, both vats and the windows in bottom-up printers are considered consumable items and do need replacing occasionally.

Pros and Cons of Top-down Printers:

- Top-down printers eliminate the peel step making them faster and more efficient.

- Parts are less prone to stress and fracturing than those produced in bottom-up printers.

- Top-down printers are usually larger and have a bigger physical footprint.

- Changing the resin in the vat can be time consuming and messy.

Most home and hobby 3d printers are bottom-up designs. To make this decision, you need to consider what you want to print, the size of the project, and how much you can spend on a printer.

SLA and DLP Resins

Contrary to some information available on the internet, printer resins for SLA printers and DLP printers are not interchangeable. The differences in technology require different formulas for the resins.

SLA printers use a UV Laser to fuse the resin. The measure of the energy delivered to the resin is energy density. The UV laser delivers a much higher energy density to the resin than the LCD technology used in DLP printers. The formulation of the polymers in the resins corresponds to the energy density the printer delivers.

While the products are similar, they do have some differences that make it critical that you make sure the resin you choose is compatible with your printer. The manufacturers’ specification sheet should make it clear whether the resin is compatible with the printer you are using.

Choosing SLA Printer Resin

A quick look at Google or Amazon quickly reveals a confusing array of printer resins on the market. Before you dive in and start buying printer resin, there are a few things you should know and consider.

- What kind of printer do you have? – Make sure that you have an SLA printer and not a DLP, LED/LCD, or LFS printer. The components and resins are different for each one.

- What wavelength of UV light does your printer generate? – Most SLA printers use a UV laser that emits light at 405nm. However, some printers use 350 nm up to 410 nm wavelength light. Make sure the resin your purchase will work with the wavelength of laser UV light your printer emits.

- What characteristics do you need in your finished product? – Do you need wearability, a super slick finish, great details, or high-temperature resistance? Make sure that the resin you buy will satisfy your goals.

Some printer manufacturers require proprietary printer resin. You must buy the resin manufactured by the company that built your printer. Some newer resins offer open compatibility, but you should be cautious. You could void your printer warranty if you use an OEM SLA printer resin.

10 Best SLA Resins

Here are the 10 best SLA printer resins available today (in my opinion and in no particular order). If you would like to know more check out my article on Choosing SLA Printer Resins.

- Siraya Tech Fast

- AnyCubic 3D Printer Resin

- eSun bio Resin

- Monoprice Rapid UV Printer Resin

- NOVA3D 3D Printer Resin

- ELEGOO 3D Rapid Resin

- Siraya Tech Tenacious

- Sparkmarker 3D Printer SLA Resin

- Monocure 3D Rapid Resin

- SainSmart Rapid UV

- Blu – Siraya’s Strong and Precise High-Res Resin

Finding SLA Printer Resins

Unfortunately, finding SLA printer resin can be a challenge. Many of the SLA printer manufacturers require that you use only their proprietary resin formulations with their printers. Some manufacturers design their printers to use disposable tanks to deliver resin to the printer, making it almost impossible to use an OEM printer resin with these printers. A few of the manufacturers of SLA printer resins include:

- Formlabs

- Peopoly

- PhotoCentric

- MakerJuice

These are not the only makers of SLA printer resins, but they are the most popular and the easiest to find.

How Much Can I Print with a Bottle of 3D Printer Resin?

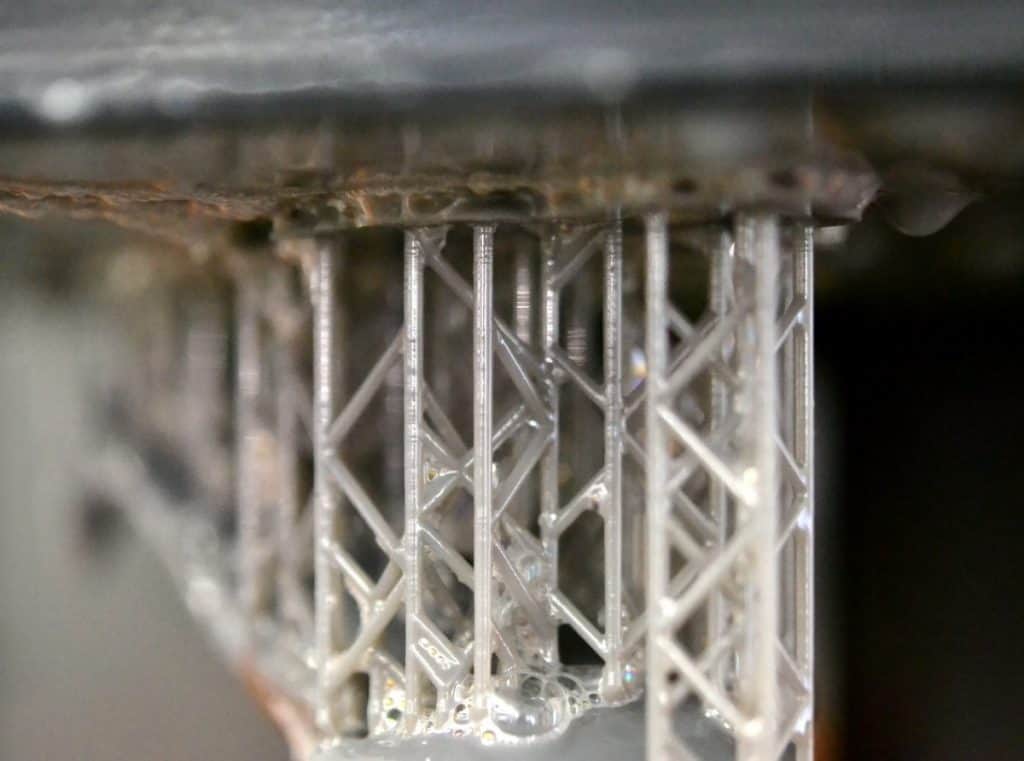

SLA printer resin is a bit on the expensive side, especially if you are using one of the specialty resins. Estimating how much resin a project will take can be on the tricky side. You should consider several things when estimating resin use for a project.

- The detail involved in the build.

- The amount of support structure needed for the build.

- The fill percentage of your design.

- The amount of resin needed to ensure that you don’t run out during the build.

It is always a good idea to have extra resin in your supply drawer. Mistakes happen and sometimes you need that cushion.

To get a much better idea of how much resin you need to complete a project, you should check your slicer software. Most programs have an estimating feature that will tell you approximately how much resin you need for a given project. Don’t forget to add in the support structure and a little extra in the vat.

Don’t fret. Leftover resin is reusable if properly stored. Keep it covered and away from any ambient light. Don’t be tempted to try and return it to the bottle, just in case it is contaminated, you don’t want to contaminate the whole batch.

Once you Print, you Aren’t Finished!

Once you have your project printed, the process isn’t complete. With either printing process, SLA or DLP, your printed project must have a post-printing cure. Most of the desktop size printers build this capability into the printer chamber by including a UV curing light source. The project rests in the chamber, bathed in UV light until the resin finishes curing to its final state.

If your printer doesn’t have a built-in UV curing light, you must still provide a means of UV curing your project outside the printer. There is specialized equipment for this and is an expense that you should include in your SLA or DLP printing plants.

Which is Better, SLA, or DLP?

- DLP printing is faster – The technology of DLP is slightly faster than SLA due mainly to the way the light focuses on the vat of resin. SLA uses a single point laser to cure individual points on the surface of the vat. DLP uses an LED screen to energize the entire surface of the resin at once, making the process slightly faster.

- Finishing SLA Prints is easier – Because the SLA laser moves during the printing process and the focus of the laser is a circle, the finishes on the products are typically much smoother and finer than those produced with a DLP printer. DLP printers print microscopic blocks that correspond to the pixels on the LED screen. These blocks can leave a less finished surface and make curves appear jagged.

- Maintenance Concerns – SLA printers need professional maintenance and calibration. Every moving part in the SLA printer is subject to becoming out of alignment and needs periodic checking to ensure the highest quality printing. DLP printers with no moving parts that affect the printing process are much easier to maintain. Except for the LED panel that must be periodically replaced, DLP printers seem to run forever.

- Costs – Operating costs for SLA printers and DLP printers are about the same. Printer resin is the biggest expense and the costs for resin for each kind of printer is comparable. Maintenance costs can be an issue with SLA printers due to the need for periodic adjustment and calibration. The only real maintenance cost for DLP printers is the occasional cost of replacing the LED screen.

What Else do I need?

A printer, resin, and a curing system are not the only things you will need to get your 3d printing project off the ground. You will also need some software and a computer on which the software will run and communicate with your SLA printer.

- Modeling Software – You will need to be able to construct the models of your projects in 3D. To do this, you need modeling software, sometimes referred to as CAD software (Computer-Aided Drawing or Drafting) The software must be capable of manifold modeling.

- Slicer Software – No, we aren’t talking about something for serial killers. Once you have your 3D model created in your modeling software, it needs translation into something that the printer can understand and use. Slicer software takes the 3D model and slices it into very thin pieces that the SLA or DLP printer follows to create each layer of the model.

- The Computer – Controlling the printer doesn’t take as much computer horsepower as you might think. Once you complete the modeling and slicing, the files that go to the printer are relatively small. However, if you intend to run modeling software and slicing software on the same computer, you are going to need some graphics and processor power. The software company that you chose will have recommendations on the minimum computer setup.

On to Printing

No matter what your project criteria, there is an SLA printer resin that will fit your needs. As SLA printing technology finds more and more possible uses, the range of printer resin formulations also grows. If you are a hobby user building models and small parts, a designer needing to test fit and functionality, or a production operator churning out part after part, someone is making an SLA printer resin that will give you the performance and characteristics you need.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.