3D printing with a resin 3D printer is about twice the price of printing with filament. Resin 3D printers and filament 3D printers have completely different designs. Below is a summary of the reasons why 3D printing resin is so expensive.

To manufacture 3D printing resin is much more difficult than filament. Resin has a special formula of different chemicals that require many different chemical processes to manufacture. Filament, by comparison, is made by melting down plastic pellets which are very inexpensive.

To understand the difference in price between resin and filament in this article I will explain how both are manufactured in detail with some videos showing the process. As well as, whether it’s cheaper overall to print 3D models on a resin or filament 3D printer.

Costs Involved in Manufacturing Resin vs Filament

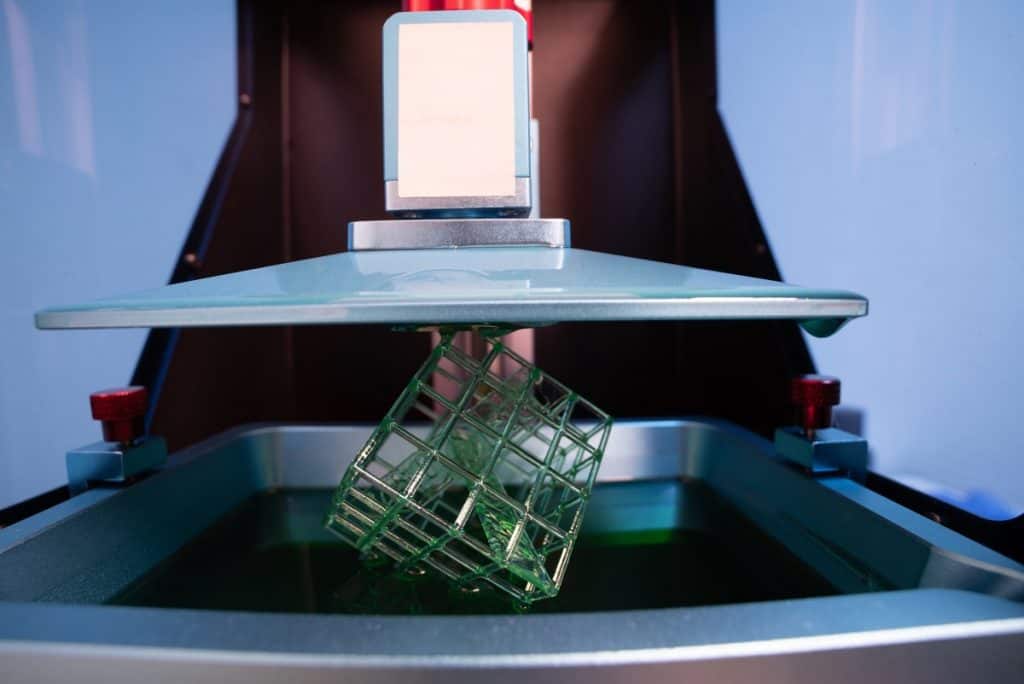

Resin is a liquid that forms into a solid when UV light is shone on to it. The chemicals required to allow resin to do this are more complex. Filament though is only melted plastic pellets that have been reshaped into a long thin plastic wire.

Plastic is used A LOT in many different manufacturing processes. Such as plastic bottles, and food containers. The machines used to make plastic products are also very common and easy to buy.

On the other hand, the chemicals involved in making resin are harder to source, are harder to manufacture, and are less common. Due to these factors making resin is more difficult and involves using ingredients that are more expensive.

Resin is made from the following chemicals and additives:

- 20% to 60% hyperbranched acrylate

- 10% to 55% polyfunctional alkoxylated acrylate

- 20% to 50% mono-functional acrylate

- 0.2% to 10% visible light initiator

- 0.1% to 5% sensitizer

- 0.1% to 3.5% fluorescent brightener

- 0.5% to 10% UV color paste

(source)

To buy the plastic pellets used to make filament costs a regular consumer $3.70 per pound (0.45kg). Filament is usually sold in 1kg rolls for about $20. The processes to make filament such as heating it and stretching it do have some operating costs. But, they aren’t so large especially when a company is working at scale.

This means they are producing large quantities of filament. Companies that make filament also have bulk discounts for buying raw materials such as the plastic pellets and the additives. So, the cost to produce filament becomes even cheaper.

The special UV additives in resin aren’t used a lot in other industries or for other products. I personally can’t think of any other products that are a liquid and go hard when exposed to UV light. Because of that, it’s harder to source these products which increases the price.

Here’s a video that shows how filament for 3D printing is made:

As you can see from the video the process to make filament is relatively simple. There are different thicknesses of filament that are sold to suit different nozzle sizes. To make thicker or thinner filament the melted plastic is stretched through a different sized hole. But, the overall process is exactly the same.

So overall the cost of the raw materials and process involved in making filament, make filament cheaper to produce compared to resin. This makes resin more expensive to buy. There is some other consumable equipment you need to 3D print with resin that aren’t required for 3D printing with filament.

These are relatively cheap ongoing. But, they do have more of an upfront cost compared to printing with filament.

Here’s a table that shows the additional equipment needed to print with resin as compared to filament:

| Additional consumables to print with RESIN | Additional consumables to print with FILAMENT |

|---|---|

| Nitrile gloves | Glue stick or hairspray |

| Isopropyl alcohol (IPA) | Paint scraper type tool |

| Tupperware containers | – |

| Tongs | – |

| Metallic baking trays | – |

| Paper towels | – |

| Stick on shelf liner | – |

| Face mask | – |

As you can see from the table there are more consumables used when printing with resin as compared to filament. These consumables add very little to the total cost to print. But, it does add an additional cost that isn’t needed when 3D printing with filament.

I explained how much these extra consumables add to the total cost to print, and why they’re needed in this article that compares the cost to print with resin vs filament.

Is Resin or Filament More Expensive

It’s possible to buy resin or filament 3D printer for about the same cost. But, the material that a 3D printer uses to print things does vary in cost. So, which is more expensive resin or filament.

Resin is more expensive than filament. Resin used to 3D print is on average twice the price as filament. 1 liter of resin is approximately equal to a 1kg roll of filament. A liter of resin for 3D printing costs about $50, whereas a 1kg roll of filament costs about $20.

Resin 3D prints are a higher ‘resolution’. Resin 3D printed models are more detailed and are smoother. This is the main advantage of printing with resin. With a resin 3D model, less work is required to finish it.

A 3D model printed using filament is still of good quality and you wouldn’t think that they are lacking in quality. But, 3D prints made with resin are of superior quality.

Is Resin 3D Printing Cheaper Than Filament

There is the cost of the material used to 3D print AND extra equipment you need to 3D print. Resin 3D printing uses a different technology to a filament 3D printer. So, all things considered, which is cheaper to print with a resin 3D printer or a filament 3D printer?

Resin 3D printing is not cheaper than filament. The resin used to print using a resin 3D printer is about twice the price of filament. There are also additional products you need to 3D print with resin such as isopropyl alcohol (IPA) that aren’t required when printing on a filament 3D printer.

The cost per print of the additional products you need to print with a resin 3D printer is not very much as a percentage of the total cost to print. But, there is an initial upfront cost involved in buying all these products.

All things considered, though on average printing with a resin 3D printer is about twice the cost per print as printing on a filament 3D printer. I’ve included a full list of the additional products you need in a table at about the center of this article.

Related Articles

- Resin vs Filament Cost Comparison

- What Kind of Light Do You Need for UV Resin?

- How Long Can You Leave Resin in a 3D Printer?

- Why Wash and Cure Resin Prints?

- SLA Printer Resins

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.