3D printing encompasses a variety of technologies that achieve the same result but at varying levels of quality and integrity.

3D printers take a longer time to print because they print every detail of your 3D model in thousands of layers. The filament used in 3D printing is not made of ordinary materials that can be quickly published like a sheet of paper. Slower printing, on the other hand, yields superior results.

3D printing operates on power and opens up new possibilities. Additionally, it brings added value and the potential for exponential growth to companies involved in the manufacturing of goods. It can increase productivity, broaden reach, and serve as a source of tremendous creative energy and business expansion.

Why Is 3D Printing Slow?

Once you have adequately optimized your 3D printer, lower speeds generally make 3D printers better quality. When you have good stability and have removed slack from your 3D printer’s parts, a high speed has less impact on print quality. Upon its optimization, flow rates are the main thing that slows down speed.

However, achieving this is not so simple because numerous factors influence 3D printing speed. Although speed does not always imply lower quality, generally, the higher the print speed, the lower the quality of the printed part.

How Fast Is 3D Printing?

To create an exquisite 3D model, you must adjust the printing speed based on the type of 3D printer you are using; however, the amount of filament that the 3D printing speed uses determines your printer’s extruder deposits on the 3D printer bed.

Most 3D printers possess a maximum setting of about 150 mm/sec for expediting the extruder assembly capable of laying down the filament on the building terrace. The speed determination is based on the quality of the 3D print desired and the type of filament used.

Some filaments must be heated at higher temperatures before melting, demanding more time in the heated end nozzle. With these constraints, you can set your printing speed to between 80 and 100 mm/s.

A 3D printer can make a nut, but it must be precise to fit the screw. The complexity and precision of the models determine how long it takes to print them. Models that require high precision, such as mechanical components, will take longer to print, while simpler models will take less time.

Regardless of exceptions, most 3D printers measure printing speed in millimeters per hour (mm/hr). A fused deposition modeling (FDM) printer, for example, has a 3D printing speed of about 100 mm/hr on average. FDM printers can be tweaked to increase 3D printing speed. Some FDM printers can print at speeds of up to 500 mm/hr, making them five times faster than the average.

Speed setting on 3D printers

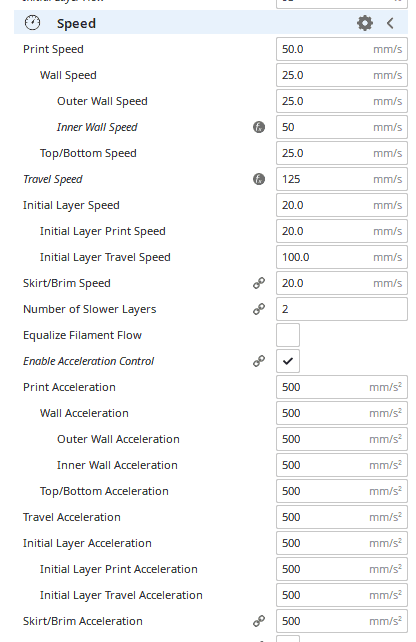

When used broadly, the term “speed” refers to various settings other than the default movement speed.

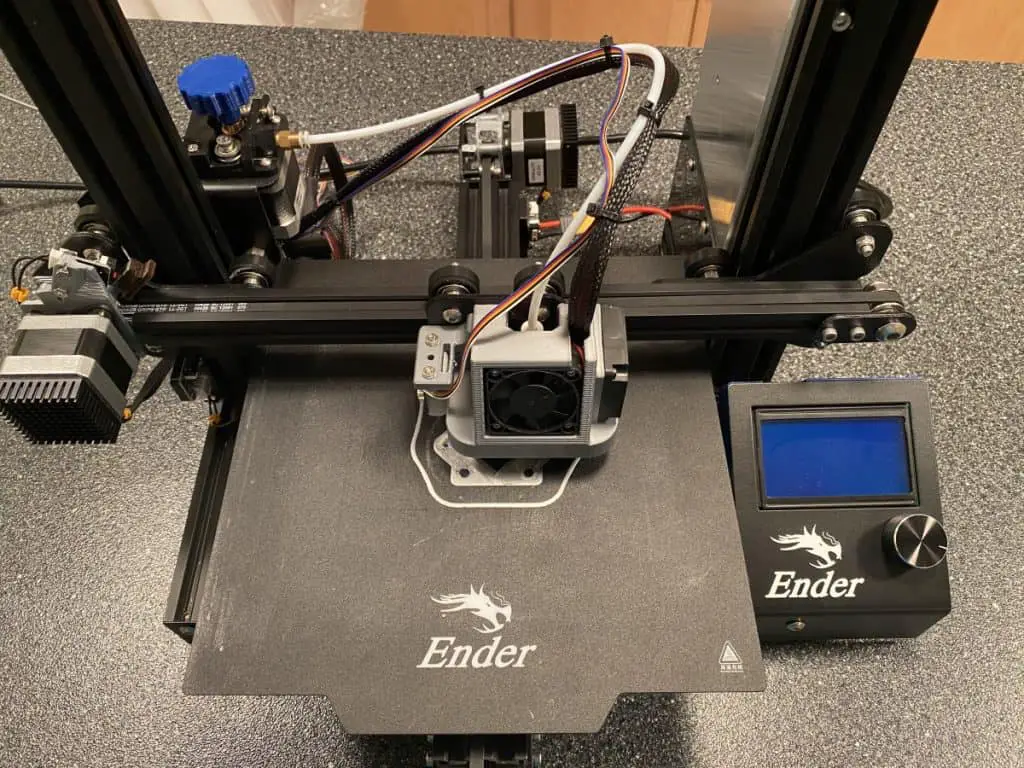

Currently, three different sets of printing speeds are available with 3D printers. Initially, the most common 3D printers have print speeds ranging from 40mm/s to 50mm/s. The Ender 3 for example has a default speed of 50mm/s in Cura, which is the speed I typically use for that printer.

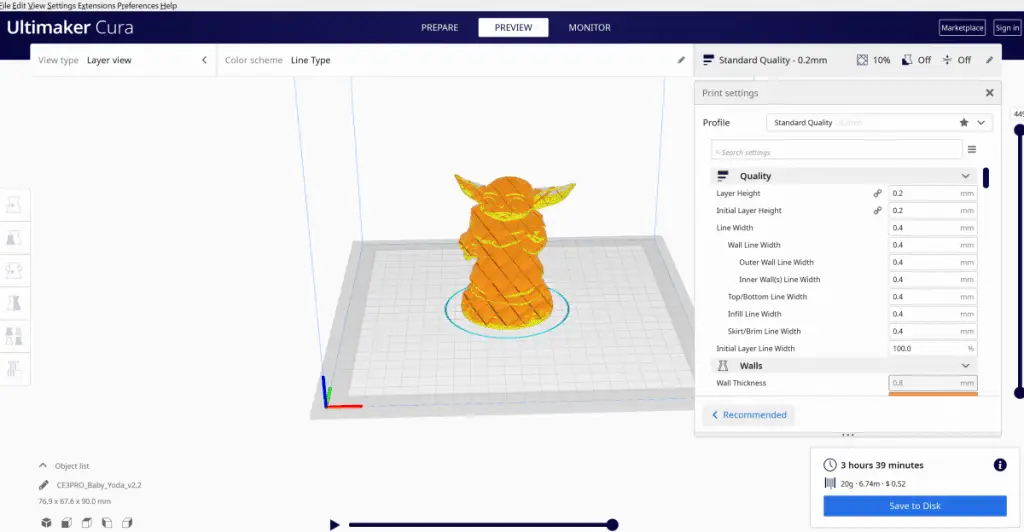

To change the 3D printing speed, you must first understand the slicing software settings. The slicing software is the application used to prepare the 3D model for 3D printing.

You can alter the print speed by entering a value in the Print speed field. If you are not using the most recent version and are using one of the previous ones, you must switch to Advanced mode.

It is preferable to leave specific speed settings alone and only change the default speed. Most slicers will choose a rate based on your layer height and material, but if you believe your printer is capable, you can experiment with increasing print speed to reduce print times.

Can You Accelerate The Speed Of Your 3d Printer?

Speed settings in your slicer will help more depending on the print size, with larger objects benefiting more from reduced printing times.

You’ll have multiple speed settings for specific parts of your object, such as perimeters, infill, and support material, so it’s a good idea to tweak these to get the most out of your printer.

When discussing 3D printing speed, layer height is the most important setting to consider. The print time is significantly reduced when the layer height is increased, but the print quality suffers.

The line width can be changed in your slicer to increase the speed of your 3D printer. You can change this value to fit your model. Extra printer moves are required in some cases to fill the gap between the lines, which increases the print time required to complete a model.

Another essential factor to consider when attempting to increase the speed of your printer is changing the nozzle. The most common nozzle size is 0.4 mm because it provides a good balance of print speed and quality; however, if you want to print faster while retaining detail, I recommend fitting a 0.6 mm nozzle. It is possible to go even higher with a 0.8 mm or even 1 mm nozzle, but the details would suffer.

You can go above and beyond to make it go faster, even though your 3D printer will usually have speed limits.

You can find out how far you can stretch by increasing the speed value. Most of the time, there is room for improvement in print speed, which will undoubtedly affect the overall print duration.

Where Did 3D Printing Come From?

Since their inception, additive manufacturing technology and 3D printing have evolved tremendously.

Charles W. Hull invented the first 3D printer, which used the stereolithography technique, in the mid-1980s. Stereolithography has traditionally been a costly commercial technique, with machines costing five and even six figures. Still, in recent years, desktop professional stereolithography printers costing a few thousand dollars and consumer systems starting well under one thousand have appeared.

Advantages Of 3D Printing

- From the medical field to the production of consumer goods, mass customization can be advantageous in various industries. It is simple to adapt a 3D design using 3D modeling software and print different iterations of the same product when using digital manufacturing.

- As more competition has entered the space, the explosion of interest in 3D printing has resulted in easier-to-use software and hardware for consumers.

- 3D printing is faster than standard production techniques such as injection molds and subtractive production. Consider the difference between the speed of a sports car and the speed of a horse cart. Both will arrive at their destination, but the time difference is enormous.

- Traditional manufacturing methods are prone to producing poor designs and, as a result, poor-quality prototypes. 3D printing enables a step-by-step assembly of the object, resulting in improved techniques and, eventually, higher quality objects.

- Habitual prototyping methods, such as production runs and injection molds, are expensive because they require more human labor. Labor costs are a significant factor in determining how much money is spent on developing a prototype. Labor in 3D printing can be as simple as one person issuing a print command.

Fastest 3D Printers

If you’re looking for quality 3D printers that will allow you to get the best/fastest production result and value for your money, don’t worry. We’ve searched the internet and compared client reviews to bring you the best rated and fastest 3D printers:

Uniz Slash Plus LCD 3D Printer: The Slash Plus’s liquid cooling system and 2K high-resolution screen allow users to print models quickly and accurately but that speed and accuracy comes at a steep price.

FLSUN Mini Delta 3D Printer with Heated Plate: The FLSUN QQ is an excellent printer for a first-time user because it comes pre-assembled primarily, with only the uprights fitting between the top and bottom. Overall, it takes about 15 minutes from opening the box to turning on the printer and getting it ready to print.

Creality Official 3D Printer CR-6 SE Upgraded Auto Leveling Silent Motherboard: The Creality CR-6 SE 3D printer is equipped with an intelligent pressure sensor to truly automate platform leveling, significantly improve bed adhesion, and solve the uneven printing problem.

Related Articles

- How to Print a File from Thingiverse (The Easy Way!)

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

- How to Get Your Print to Stick to the Build Plate

- Create a Temperature Tower Using Cura – The Easy Way

- Cura Profiles

Conclusion

Regardless of how knowledgeable you are about the subject, it is safe to say that it is a shared assumption when we believe that 3D printers are from the new wave of modern gadgets beneficial for all businesses. However, this has been around for some time. With an ongoing improvement approach to the majority of the models, this machine offers new and practical solutions.

The speed of such is crucial to understand since you want to have a good grasp as to the outcome you are going to obtain. Therefore as long as you read the user manual and do your research as to what to avoid and what to do to improve upon, you’ll be good to go!

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.