With technology getting better each day, some tools, systems, and methods are getting out of date and may become obsolete. But sometimes, it might not be the case, especially if the new technology is way too new and it is still experiencing major improvements on almost a daily basis. But what is the case for 3D printing and injection molding?

If you have been wondering if you can replace injection molding with 3D printing, the answer is no. Injection molding is faster than 3D printing with more efficiency and, in most cases, with more dimensional accuracy.

This is pretty much the summary of the reasons why 3D printing cannot substitute injection molding. But in the following paragraphs, we will look deeper into the differences between these two, pros and cons, and what they are, so you will have a deeper understanding of how each works.

What are injection molding and 3D printing?

First, let’s dig into what 3D printing and injection molding are.

What is 3D printing?

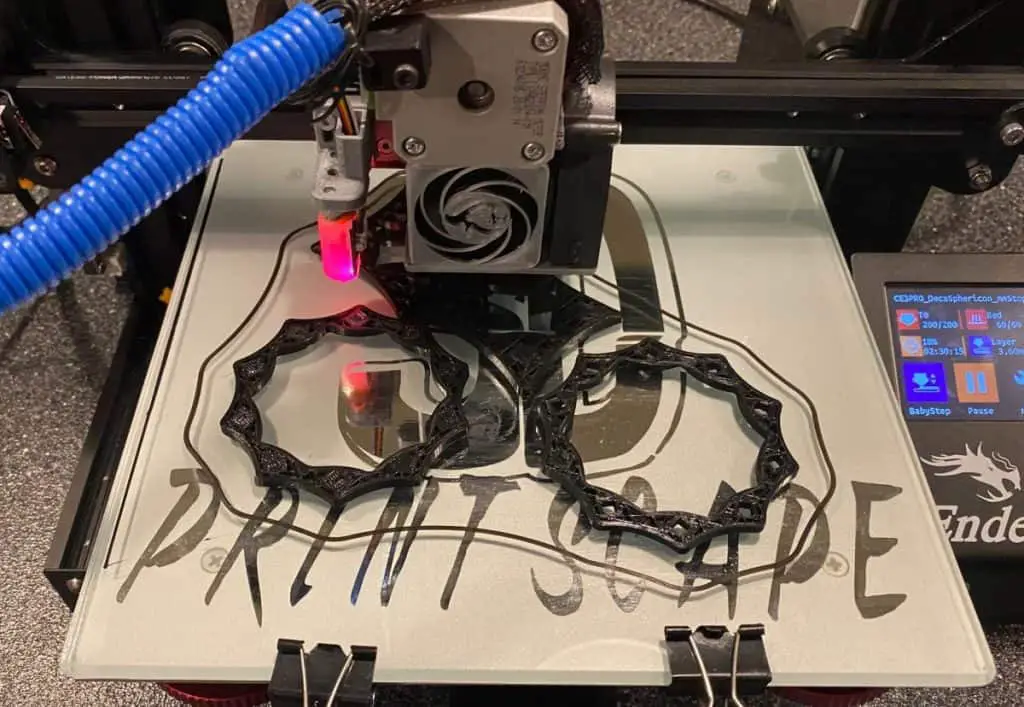

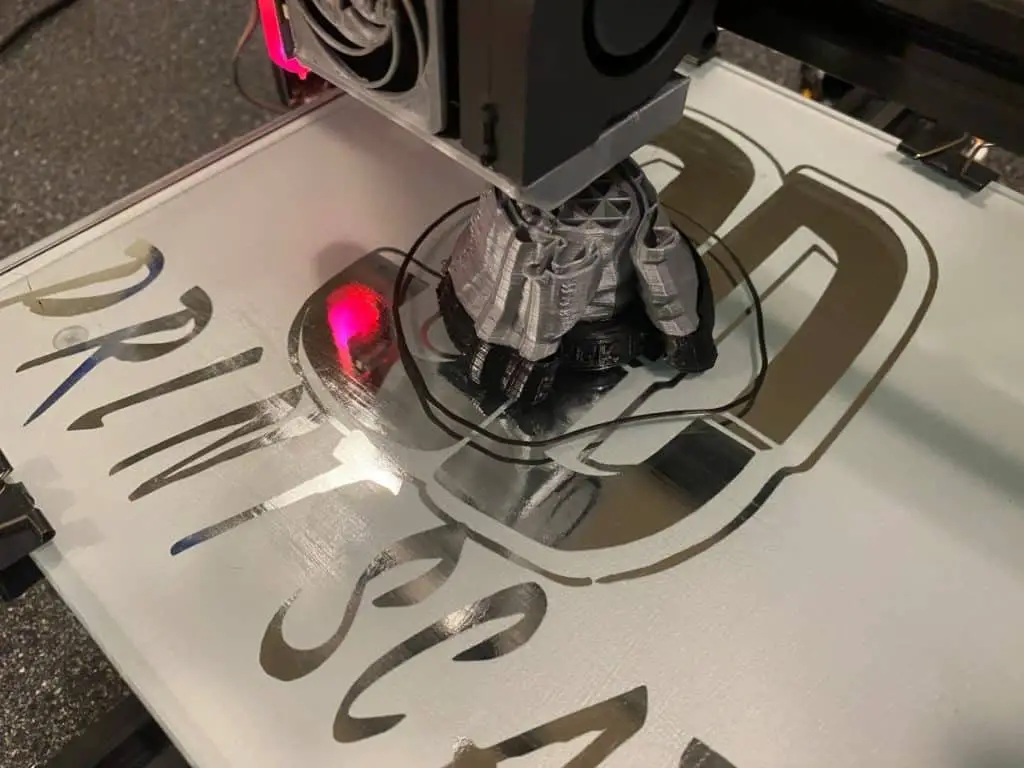

3D printing is a production method that uses the 3D printer to build objects based on computer-generated model files using raw material and one of many different processes, such as FDM (Fused Deposition Modeling), Resin (SLS, DLP, SLA), PolyJet, among others.

The process starts with manufacturers designing the objects on a computer, using a specialized program, and then sending them to the 3D printer. The printer will use the raw material to transform the model file into a physical object by building it up layer by layer, putting the material on a bed. But this is not the only method; there is another one that is less used. With this other method, the printer melts metallic powders with a high-density laser and will then fuse the particles together.

What is injection molding?

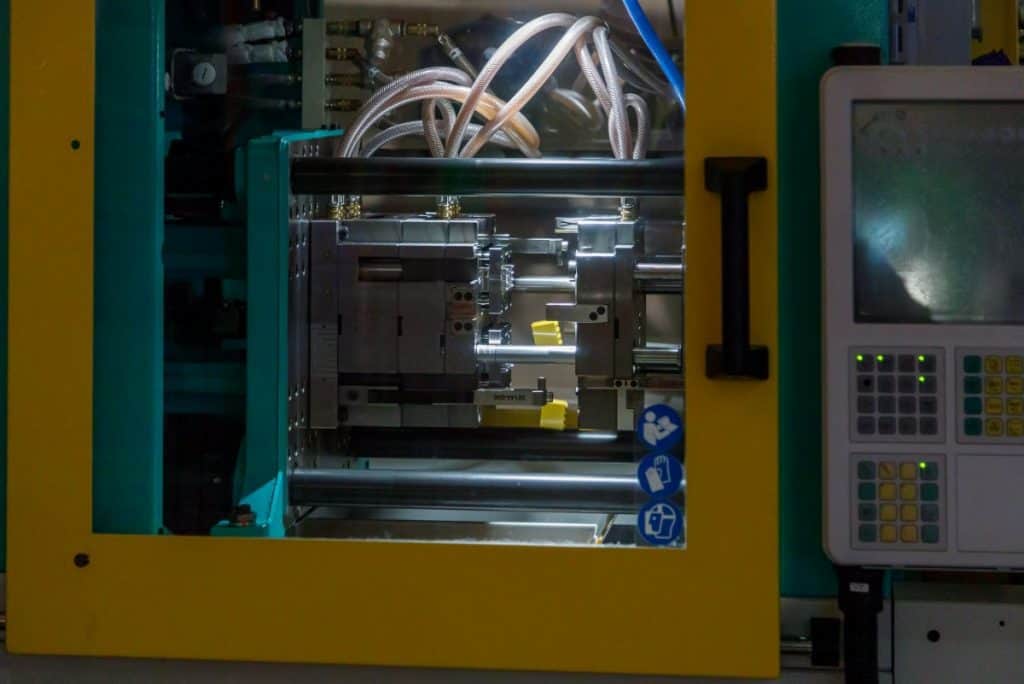

Injection molding is a molding method that consists of injecting plastic that has been previously heated into a mold. This method can also be used with many different materials; however, plastic is used more often. The material will take the shape of the mold. Once cooled and hardened, the newly created object is withdrawn or ejected from the mold.

Pros and Cons of 3D printing

Like many other things in life, 3D printing is not perfect, and even though it has some outstanding advantages, which we will mention below, it also has some disadvantages that we will learn about.

Pros

- More flexible designs. More traditional designing processes have restrictions that are not present in 3D printing.

- Faster designs and prototypes. Creating a prototype can take days; with 3D printing, this is reduced to a few hours. Which also helps to complete the whole process faster. In the case of any modification needed, users can do it quicker and easier when compared to machining prototypes.

- Print on demand. A lot of space for storage is not needed; the designs are saved in a virtual library, so once required, the design can be printed.

- Little stock space. 3D printing does not require a lot of room to keep an inventory. The designs are stored virtually and can be edited before printing, so it does not need to invest in tools and have a drain on inventory.

- Sturdy but lightweight. Even though metal can be used in 3D printing, plastic is lighter, perfect for the automotive and aerospace industries. Users can also create by using materials tailored to their needs with properties like heat resistance or waterproof.

- Reduced cost. 3D printing has less waste on materials; the material used in the printing is all you need. No big chunks of non-recyclable materials will be wasted, which can be translated into cost savings. In addition, we could mention that 3D printing only requires the raw material and the 3D printer, which also reduces cost.

- Accessible. Day by day, there are more local service providers for 3D printing, saving users a lot of money in transportation and time.

- Medical uses. 3D printing is helping in the medical field to save lives; doctors are attempting to print organs for humans. And more advances are coming to get more out of this technology in the healthcare sector.

Cons

- Limited types of material. 3D printing cannot use any plastic or metal, as not all of these materials can be controlled in meanings of temperature. Also, many of the materials are not recyclable, and just a few are food safe.

- It cannot print on every scale. The chambers of 3D printers are small, this does not allow printing in large sizes, and users will have to print the design in pieces.

- Post printing processes. Once the printer is done with a piece of the design that is being printed, that piece needs to be cleaned to remove extra material and make the surface smooth to ensure the desired finish.

- Higher cost for large volumes. The first investment and lower volumes of 3D printing are more cost-effective than other methods. But for larger volumes, the cost of every unit does not reduce as it would if injection molding is used.

- Less manufacturing jobs. With 3D printing, the need for human skills is not necessary for a large number, which causes a conflict in countries’ economy based on low skills jobs.

Pros and cons of injection molding

Not only does the 3D printing method have some good advantages and a downside, but we can also name a few from injection molding so you can compare them with the 3D printing.

Pros

- Fast and efficient. With injection molding, you can produce a good amount of pieces in one hour. The speed of a full cycle time can be between 15-120 seconds.

- Low cost. Injection molding is an automatic process; therefore, it can be done faster than a human manufacturing process; this automatization helps to reduce production costs.

- Flexible designs. The high pressure the molds are subjected to helps the plastic inside them to be pressed harder, and this assists in getting highly detailed and complex structures.

- A large variety of materials. Users and manufacturers have an extensive catalog of materials to choose from.

- Low post-production cleaning. There is no need to scrap many material excesses with injection molding, and any waste can be recycled.

- Better color control. Any design can be done in the desired color without much trouble.

- Consistency. Injection molding is an automated and repetitive process, which means every piece will be identical to the previous one.

Cons

- High cost of tools and long setup time. The initial costs are high due to testing the designs and finding the correct tools needed to get the desired finished product.

- Design restrictions. With injection molding, you need to follow certain rules like avoiding undercuts and sharp edges and irregularities in the cooling process. Also, using a consistent wall thickness, draft angles are good for de-molding and many others.

- It can be pricey for small badges. The tools are complex, and cleaning the machine and setup time can be long, causing small badges to be thought of as expensive.

- Tools are made of steel or aluminum; this makes it difficult to make design changes.

Comparison table

The following table will show some differences between 3D printing and injection molding side by side.

| 3D Printing | Injection Molding | |

|---|---|---|

| Quality | Sharp edges, prototypes parts, rough surface. | More rounded edges, more homogenous material, smooth surface. |

| Time | Fast for a limited quantity; very details-oriented to help create and adjust, but might take a lot of time; easy to set up. | Fast for large productions; longer time in mold building; long set up time. |

| Delivery | More complicated process; best to deliver prototypes instead of the final product; more flexible to changes and modifications; supports more complex designs. | Simple steps process; the product delivered is usually the final product; not suitable to make changes in the design as it can trigger costs. |

| Material Options | Can use plastics, resins, and metals which allows creative manipulation of material. | Can use nylon, acrylic, polycarbonate, polyoxymethylene, polystyrene, metal, among other materials. |

| Cost | Suitable for low quantity and prototypes. High cost for larger quantities. | High cost for low quantities and trials. Low-cost for massive productions and final products. |

Related Articles

- What Shapes Cannot Be 3d Printed? – Details Inside!

- Will 3d Printing Replace Machining? (We Find Out)

- How to Print a File from Thingiverse (The Easy Way!)

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

Final thoughts

Even though you cannot replace injection molding with 3D printing, the latter can be used to get the prototypes as it saves costs in small productions compared to injection molding. But for the final product, if it is going to be a really large production, it is best to use injection molding. So at the end of the day, each has its own applications and uses.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.