If you are in the manufacturing business, there are plenty of different ways for you to form different products that are made out of plastic. Two of the most popular ways are vacuum forming and injection molding, and both of these methods have their own uses and advantages. However, is vacuum forming the cheaper method of production compared to injection molding?

Vacuum forming is indeed more affordable than injection molding because of how the initial costs tend to be lower compared to injection molding. The start-up costs of vacuum forming tend to be lower compared to injection molding because of how less complicated they are.

While there are some advantages when it comes to injection molding, the advantage of vacuum forming is that it tends to be better off for those who are merely starting up and are looking to produce fewer goods at a much cost-efficient method. But for you to understand the costs associated with these methods, let’s talk more about them in a nutshell.

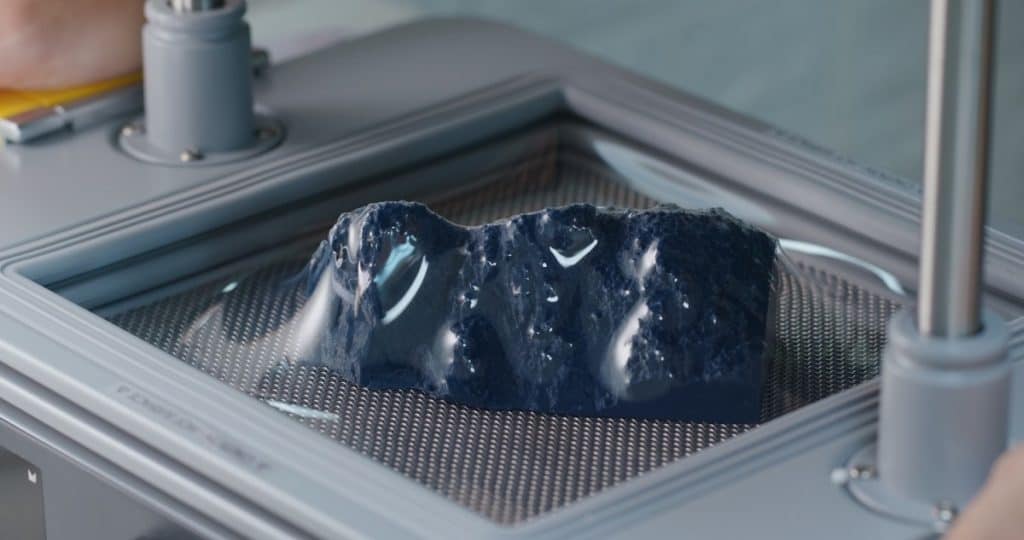

What is vacuum forming and how much does it cost?

One of the most popular methods of manufacturing products made out of plastic is vacuum forming. And the reason why vacuum forming is as popular as it is can be connected to the fact that it is one of the most economical thermoforming technologies out there. But what exactly is vacuum forming?

In vacuum forming, what happens is that a sheet of thermoplastic is heated in an oven or through any other means that would allow the plastic to soften. From there, the sheet of plastic is set on a mold, where a vacuum pulls air out of the mold to pull the sheet against it. What happens after the vacuum pulls the sheet against the mold is that it will shape it based on the shape of the mold. The sheet is then allowed to cool down and harden before it is removed from the mold and then trimmed.

The reason why vacuum forming tends to be cost-efficient and economical is that the costs of entry tend to be quite cheap. Because of how vacuum forming doesn’t involve plenty of different complex methods of forming the plastic, it is easier to have a mold constructed.

However, it is still important to take note that the cost of vacuum forming will still depend on a lot of different factors such as the design and the materials you need for your product. On top of that, you also need to pay for the labor involved when it comes to constructing the mold and the product itself. That said, you can expect to spend around $2,000 to $10,000 on a vacuum forming mold. Meanwhile, the cost per product will depend on the size and the materials.

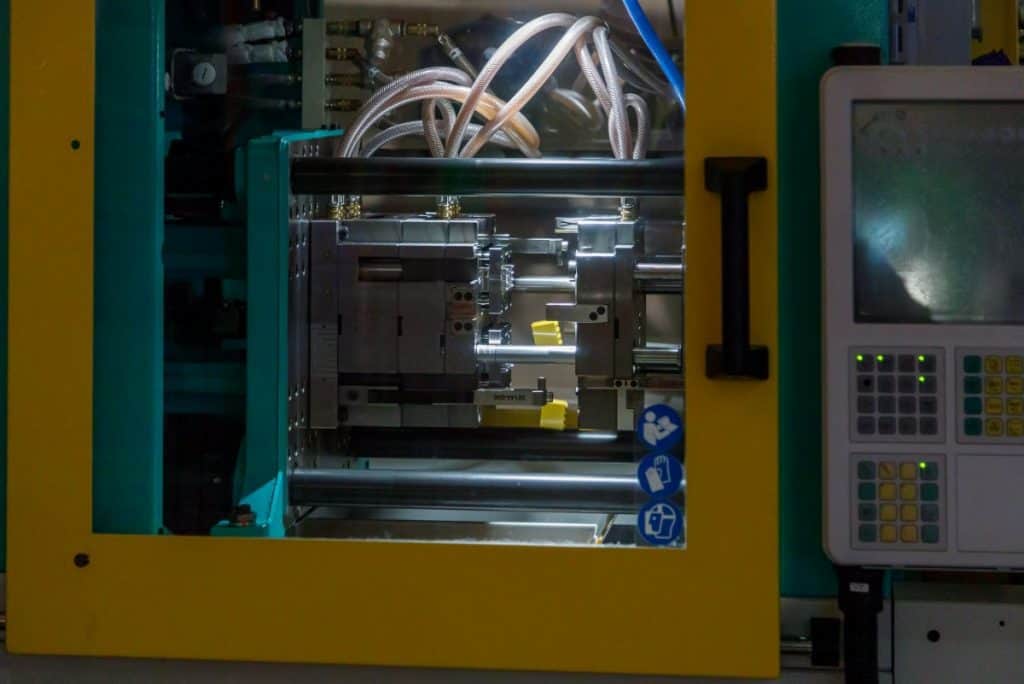

What is injection molding and how much does it cost?

Another popular method of production when it comes to plastic products is injection molding. Like vacuum forming, injection molding uses a mold to form the product. However, there are some differences.

In injection molding, what happens is that the product is formed through injecting hot plastic into a mold and a core using high pressure. From there, the plastic is allowed to cool down before it is ready to be ejected from the mold.

Injection molding is also pretty popular among small to medium-scale businesses because of how efficient it is at getting the job done. Of course, it is also an economical way of producing different products.

In most cases, the cost of injection molding depends entirely on the materials used, the size of the product, and the complexity of the product’s design. However, a single mold in injection molding can cost somewhere between $1,000 to nearly $100,000. Take note that the range is so wide because of how designs that tend to be more complex tend to be more expensive. Still, the good news is that injection molding is quite cost-efficient when it comes to production scales that range in the hundreds.

Is vacuum forming cheaper than injection molding?

Now that you know more about vacuum forming and injection molding and how much they cost, does that mean that vacuum forming is the more affordable method of production?

In most cases, yes, vacuum forming is cheaper than injection molding when it comes to smaller scales of production. And when we compare the two, we are talking about similar products here so that it would be easier for us to look at which one is cheaper.

The reason why vacuum forming is more affordable is that the cost to enter the industry tends to be cheaper due to how vacuum forming and its molds are not too complex when compared to injection molding. Because the process and the molds are simpler to create, vacuum forming won’t cost as much as injection molding.

On the other hand, the reason why injection molding tends to be the more expensive method of production can be tied to the fact that the initial investments are quite high. You might end up spending as much as $100,000 when it comes to injection molding.

However, the thing you need to know is that injection molding seems to be the more preferred method when it comes to large-scale production. That’s because injection molding is more time-efficient due to how it can produce more products in a limited amount of time. This explains why 60 to 70 percent of the different plastic products in the market are made using injection molding.

But if you are merely starting, it is better to go with vacuum forming because of how the initial investment tends to be a lot lower. Then there is also the fact that vacuum forming is capable of forming larger plastic products that injection molding cannot do. For example, injection molding cannot produce a large plastic canoe, which is something that can be produced using vacuum forming.

As such, because vacuum forming and injection molding do have their advantages, most manufacturers don’t necessarily prefer one over the other as long as they can afford to invest in both methods of production.

Related Articles

- Will 3d Printing Replace Injection Molding?

- Is 3D Printing Cheaper than Molding?

- What Shapes Cannot Be 3d Printed? – Details Inside!

- Will 3d Printing Replace Machining? (We Find Out)

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.