For many years machining or CNC machining has been the primary method for precision manufacturing. CNC machining uses computer programs to move tools and machinery to create all the parts or objects needed. The fact is that we now have a new contender for the position of the best manufacturing system. This contender is 3D printing. The rise of this type of printing is due to its versatility and multiple advantages.

Can 3D printing replace machining? The answer is no, for now. Printing is an option or complement to the manufacturing process of objects. In some cases, the most convenient method will continue to be machining and, in others, 3D printing.

However, we must be attentive to technological advances.

3D printing has gained many fans very quickly due to the significant advances in technology that it has had in a short time. There is a strong belief that 3D printing will displace machining and other production processes completely. However, there are many types of objects and techniques that you cannot replace with 3D printing at the moment. But to understand a little more about this fascinating technology segment, let’s continue reading this article.

Let’s Define CNC Machining

CNC machining (Computer Numerical Control) is a process of manufacturing parts or objects in which pre-programmed software controls the tools and machinery in the factory.

This computerized process can control machines that are too complex to operate manually. With CNC machining, the system can do three-dimensional cutting jobs with a few instructions on the computer.

One of the highlights of this process is that it does not have the limitations of manual manufacturing. In traditional production, you will need workers to operate all the tools and machines.

At first glance, CNC machining may look like a standard computer system. Still, the reality is that the programs it handles and its consoles are entirely different from other types of computers.

The Origin Of CNC Machining

CNC machining appeared in 1940 thanks to the work of the American engineer John T. Parsons. Parsons had the idea of using punched cards as a coordinate system to control a machine.

This machine made small movements that could achieve a good finish on the machined part. John introduced CNC machining to the U.S. Air Force after eight years of use. After several years of research, the Massachusetts Institute of Technology (MIT) manufactured the first CNC machining prototype in 1952.

Soon many machine and tool manufacturers had CNC machining in their facilities. MIT continued their research and discovered that they could use automatic programming with CNC machining. This breakthrough facilitated direct communication between the programmer and CNC machining.

Advantages And Disadvantages Of CNC Machining

It is essential to analyze the CNC machining system comprehensively. Understanding the pros and cons will help you to make a personal opinion about its permanence in the future of our lives. Below we will review some of its advantages and disadvantages.

Advantages Of CNC Machining

- The main advantage of CNC machining is the precision with which these machines work.

- The precision of these machines ensures that the uniformity in the finishing of parts or objects is almost perfect.

- It is safe equipment since you can operate it from a computer.

- You can carry out, thanks to its high precision and reliability, highly complex processes.

- With this machine, there is very little metal waste or scrap during the process.

- No operator is needed.

- The program it uses is elementary to use.

- It has excellent speed to produce what is needed.

Disadvantages Of CNC Machining

- The tools used by the machine are costly.

- This process needs to have an advanced computer programmer to achieve the required precision in the production of parts.

- The maintenance of CNC machining is *20

- costly.

- If the computer operator is inexperienced, it can have negative consequences on the finish of the objects.

What Is 3D Printing?

3D printing is a system that automatically produces parts and objects designed by a computer. 3D printing uses a layering technique. A layering process means adding materials layer by layer to enable the creation of the object.

The big difference with CNC machining is that the 3D printer builds the part without using machines or tools.

In recent years, 3D printing has become a great alternative to traditional processes. 3D printing is already present in numerous fields of daily life. It is anticipated that this presence will continue to grow.

Origin Of 3D Printing

Reviewing the origins of 3D printing, we find that the first patent application for this device occurred in 1981. It was Dr. Hideo Kodama of the Nagoya Municipal Industrial Research Institute who introduced it. Unfortunately, he abandoned this project due to a lack of budget.

Also, in the 1980s, French engineers Alain Le Méhauté, Oliver de Witte, and Jean-Claude André became interested in 3D manufacturing technology through resin solidification.

They presented this project to the French National Center for Scientific Research, but it was not approved. The argument was that they did not see what the applications of this idea could be. They also abandoned the idea due to a lack of budget.

It was not until 1984 that Charles Hull invented a printing process that made it possible to create a 3D object from digital data. He used the technology to make a 3D model from an image.

Advantages And Disadvantages Of 3D Printing

As we did with CNC machining, we will now review the advantages and disadvantages of 3D printing.

Advantages Of 3D Printing

- It is a process that reduces the margin of error to the maximum.

- Customization of objects is another strength of 3D printing.

- In a sense, it is a lower initial investment than CNC machining. You don’t have to buy expensive tooling to run the printer.

- The manufacturing process in 3D printing is quite fast.

- This type of process allows for greater design freedom. Any 3D printer can print any parts

- 3D printing has a vast field of applications in everyday life. You can make objects or parts with this technique. It is already present in medicine, dentistry, architecture, engineering, construction, design, art, entertainment, and there are even foods created with 3D printing technology.

Disadvantages Of 3D Printing

- 3D printing is not the best technique when the final product must have a smooth and perfect finish. This technique adds layers of material on top of layers of material. Because of this, you can observe the application directions of the different layers in the final product.

- 3D printed parts are not as vital as traditionally manufactured parts. The capable manufacturing technique is not entirely uniform in all parts of the object.

- The accuracy of 3D printers is good but not superior to CNC machining.

- For producing large quantities of products and in a short time, traditional manufacturing may be the best option. 3D printing can take hours or days to complete a single part.

- There are some drawbacks associated with 3D printing. When producing an item in 3D printing, there is no economy of scale. This type of technique is currently not functional for producing large quantities of objects of the same kind. This fact means that in the long run, it can be an expensive technique.

Will 3D Printing Replace Traditional Manufacturing?

Many people claim that 3D printing will replace CNC machining and manufacturing. We think that this moment has not yet arrived.

On the contrary, traditional manufacturing still has a long way to go and contributions to modern society. Moreover, what is already happening is that factories combine both techniques to manufacture different products. Below we will list the reasons that make both methods coexist in parallel.

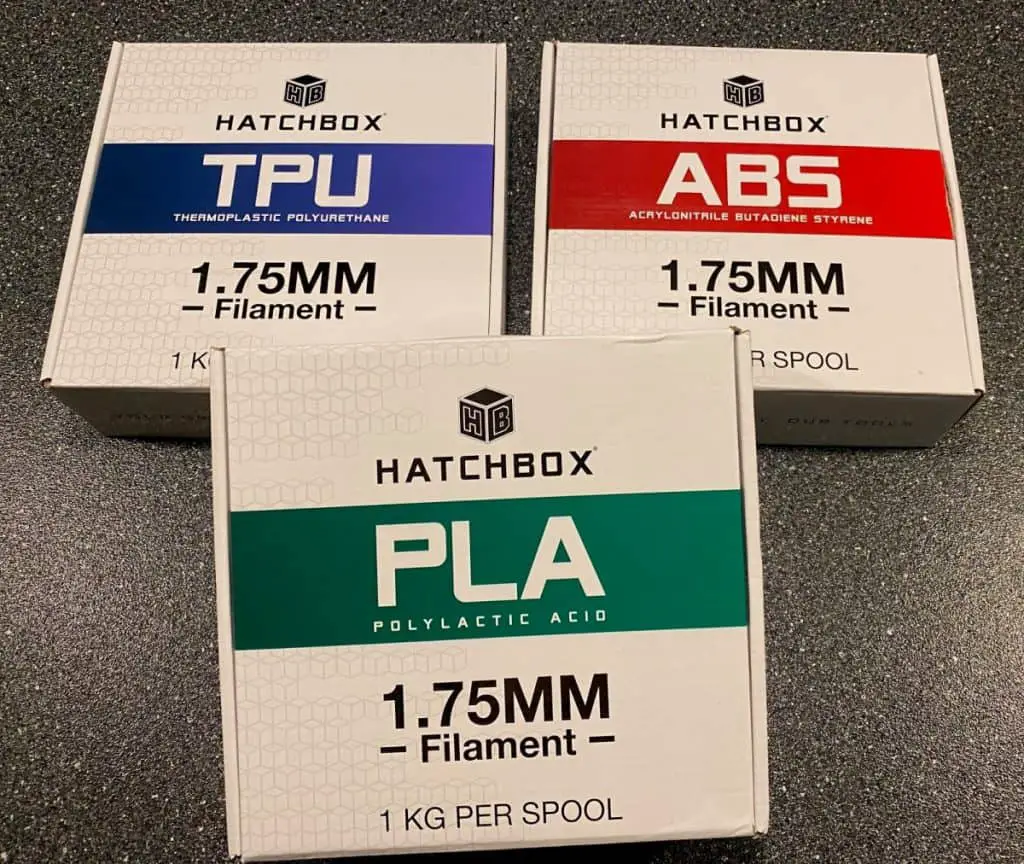

- 3D printing works best with plastics, nylon, polycarbonates, and acrylics. In contrast, traditional manufacturing works very well with materials such as metals, aluminum, stainless steel, and titanium.

- 3D printing manufactures product samples or prototypes that then serve as models for mass production in traditional manufacturing.

Related Articles

- 3D Printing vs. CNC Machining: What’s the Difference?

- What Is 3D Printer Engraving?

- Can You Drill Into and Cut 3D Printed Plastic?

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

A Final Thought On 3D Printing And Machining

It is an evident fact that 3D printing is here to stay and continues to grow. It is a process that has many advantages but also has limitations. It is impossible to 3D manufacture everything we design with the required quality of finish and speed.

This reality still offers many possibilities of permanence for machining and traditional manufacturing. It is excellent news for generating an environment of coexistence that gives us the best of both worlds.

But as in the world of technology, there are no immutable truths; what is one way today may be completely different tomorrow. The best thing to do is continuously read current information that keeps us as updated as possible on the various technological advances.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.