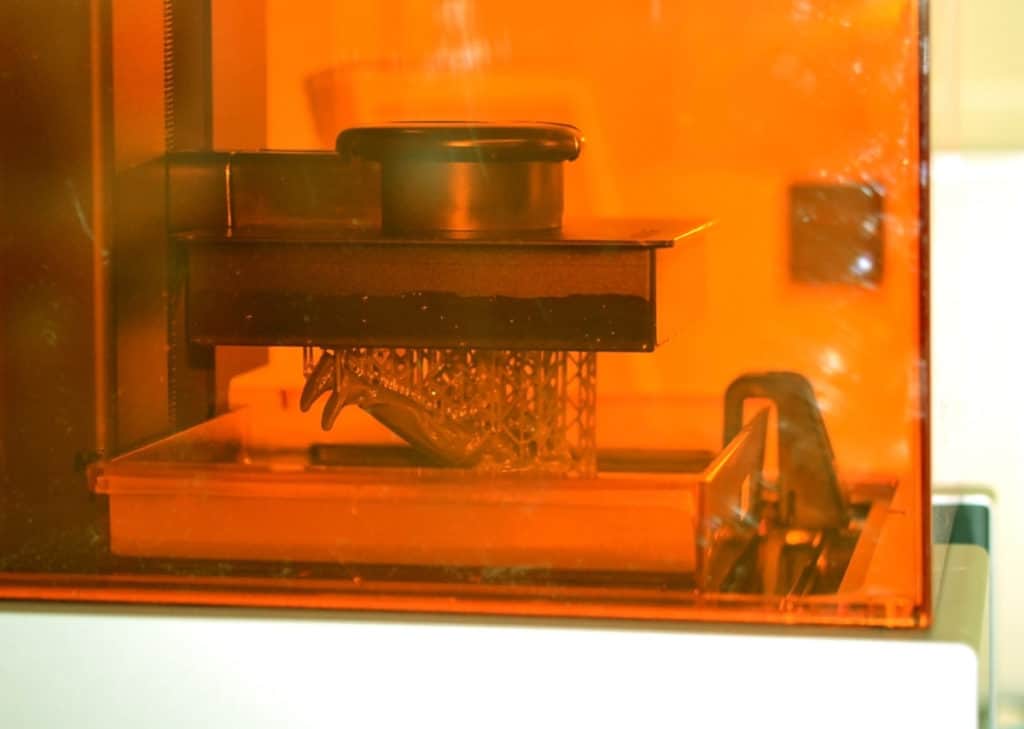

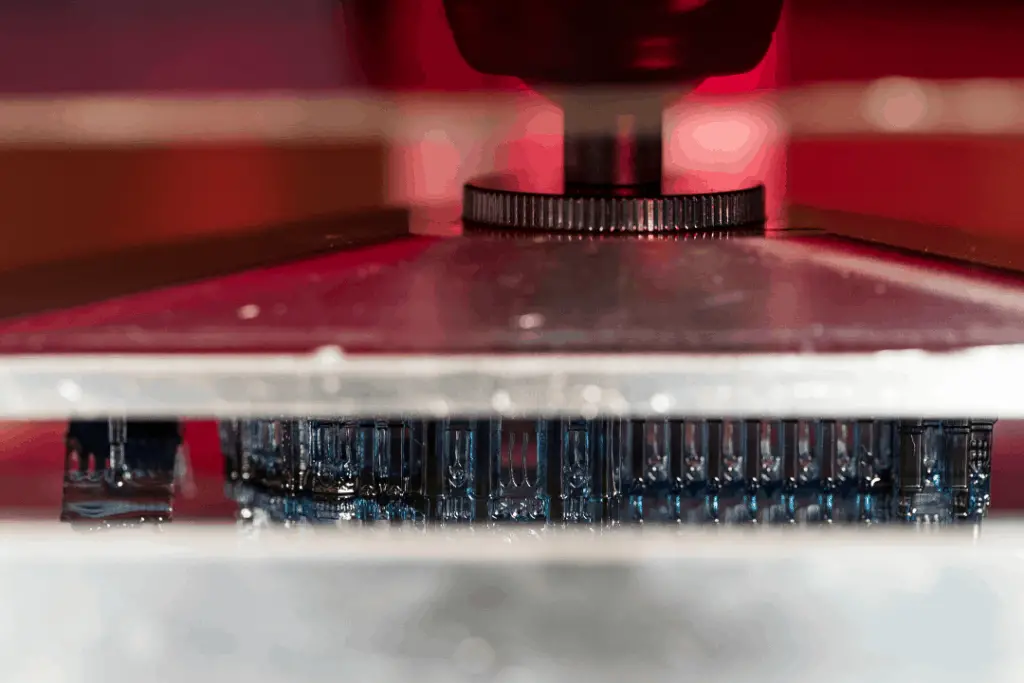

SLA and DLP printers are two of the original types of 3D printers to hit the market. Created in the early 1980s, they’ve been upgraded and improved through the years. However, the speed of these printers is something every 3D printing enthusiast needs to think about before making a purchase.

So, what do you need to know about resign printer speed and other components of these machines? There are two types of resin printing processes, both of which can take a toll on the speed. Using either a laser (SLA) or projector lighting (DLP), you can determine how quickly your resin printer will move along.

Numerous other factors need to be taken into consideration, as well. The rest of this article will discuss some essential topics related to resin printer speed:

- What factors affect resin printer speed?

- SLA print speed vs. FDM print speed

- How to calculate Resin print cost

What Factors Affect Resin Printer Speed?

Here are a few things that can affect resin printer speed.

Object size

Larger objects tend to use more resin and increase the time required from start to finish. The object size is made up of the overall volume of the object, not just the height. You’ll need to ensure that you’re using the correct amount of resin to prevent further issues.

Object detail

When an object is detailed with divots, strings, and other unique features the result is that it slows down the print tremendously when compared to a solid, uniform project.

Object resolution

The resolution of the print plays a significant part in the print time of the object. The higher the resolution the more layers are required to be printed. This results in an overall better print but takes more time. You can save a significant amount of time by printing at a lower resolution if the detail isn’t important to you.

Printer quality

The only factor that can’t be changed is the quality of the printer. In most cases, high-quality machines will have a higher speed than cheap models. There aren’t any modifications that you can do other than completely upgrading the system. When the system moves from one layer to the next, you’ll notice a decent change between a cheap printer and a high-quality printer.

SLA Print Speed vs. FDM Print Speed

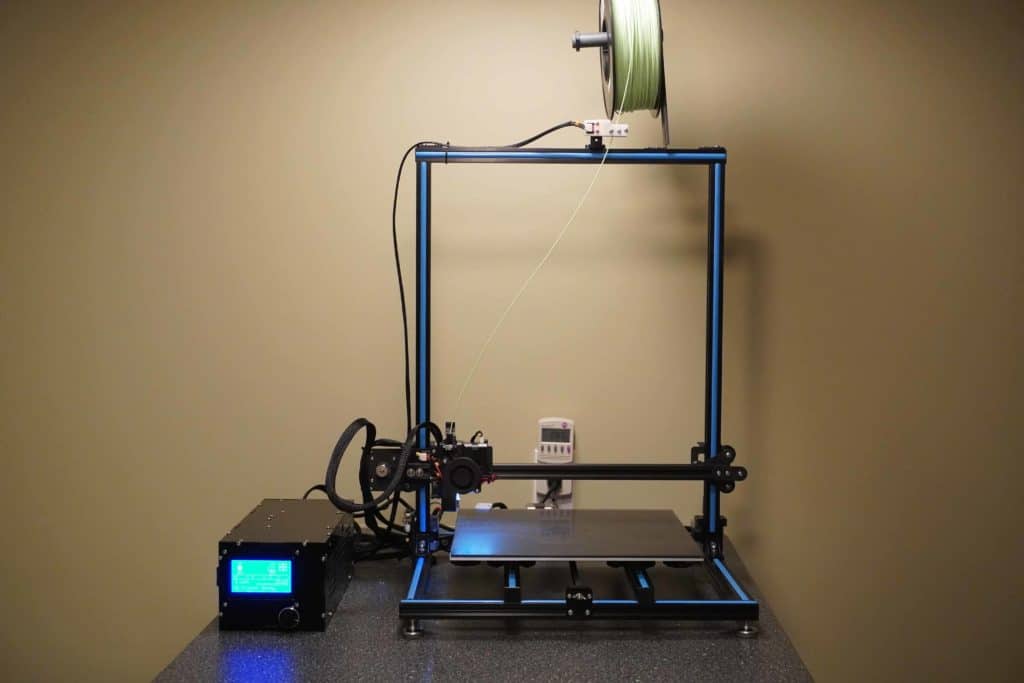

The problem with comparing SLA printers and FDM printers is that they use completely different technologies, processes, and materials in most cases.

FDM printers use a wide range of colors and materials, while SLA printers are specifically designed for the unit. Each brand makes its own material packages that are exclusive to the model and can increase the cost to print things.

SLA printers don’t seem to be nearly as popular as FDM printers for this reason. However, they do boast a few features that make many people consider them.

First of all, SLA printers compare well with FDM printers when it comes to speed. The material largely determines the speed of each machine, which means it’s practically the same in most situations.

However, when compared side by side, FDM printers tend to be a bit faster than SLA printers but they print at a much lower resolution.

If all of the settings are equal and the materials are the same or at least similar, the advancements of FDM printers is the winner here. In more expensive models of each, different equipment could change the result.

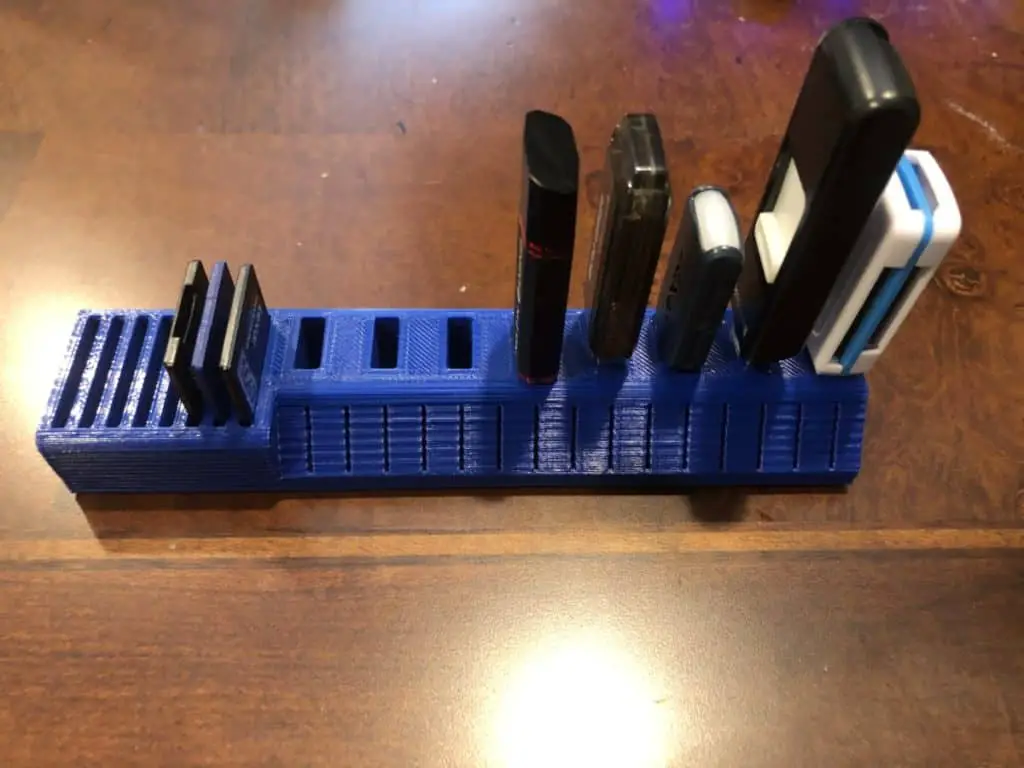

FDM printers are also much more available, resulting in a lower price point. This availability primarily exists because they use softer materials than SLA printers, but is also due to the exclusivity mentioned above. The materials usually aren’t as tough, making them less useful when compared to SLA printers for various applications.

A quick comparison of the two popular 3D printers will show you the following details:

- SLA printers produce much more durable products thanks to the resin used.

- FDM printers are usually significantly cheaper than SLA printers.

- FDM printers are also usually much quicker when the settings are the same as an SLA printer.

- FDM printers can typically print much larger objects than SLA printers as its easier to create larger printer because of the technology used.

- SLA printers use exclusive materials for each model, whereas FDM printers have a broader selection.

There are pros and cons to both machines. When it comes down to a speed test, FDM printers are the way to go in most circumstances.

SLA Print Cost: How to Calculate

There are two costs to calculate when you’re looking into buying an SLA printer.

- How much does the actual machine cost?

- How much do the materials cost to print?

The price of the machines was briefly touched on earlier in the article. SLA printers aren’t cheap compared to other 3D printers. It’s not uncommon to see one of them selling for $5,000 or more for commercial applications, you can get small home printers for a couple of hundred dollars. Here is my list of the current top 5 SLA printers under $500.

Almost all demonstrations and training videos use an FDM printer since so many people stray away from the price but this will likely change over time.

However, if you can get beyond the initial price, these printers are some of the best around. The durability mentioned above alone is well worth the investment for many potential buyers. After using an SLA printer for about 2 to 3 projects, you’ll have to replace the resin tank. Otherwise, it’ll produce low-quality work.

Resin tanks cost an average of $60, but they can be a little bit more or less depending on the make and model of the machine. Another costly repair is the construction platform. After several uses, it tends to become damaged by the user. However, the replacement time varies from machine to machine.

As far as the cost of printing goes, it costs about $80 to $150 per liter of resin. The detail and size of your projects will determine how often you need to replace them. In comparison to an FDM 3D printer (which costs about $25), it’s a bit pricier.

If your interested in how much it cost to print an object with an FDM printer check out this article I wrote a couple of months back. I go over all the cost factors in more detail.

You should determine the types of objects you will be printing and weigh the pros and cons discussed above and before making a purchasing decision. If you looking to print larger objects or don’t need objects to be printed at a very high resolution I would recommend getting an FDM printer as they print faster and are cheaper.

SLA printers are a development that took place over several decades. These days, we’re able to enjoy the high-tech, long-lasting results of these multi-use high-resolution resin 3D printers.

Summary

Here are the key points you should take from this article:

- Many factors can affect SLA print speed. The most common include object size, object detail, object resolution, and printer quality.

- FDM printers are typically a bit faster than SLA printers. However, the resolutions are typically much lower and the difference is quite minor. This shouldn’t be a major factor in choosing a printer.

- Two factors go into calculating SLA print cost: The cost of the machine and the cost of the materials.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.