I’ve been using a 3d printer for quite a while, and a question I had when I was first getting into it is whether a 3d printer uses data. So, I thought I’d summarize whether a 3d printer does or does not use data, and what for.

As a general rule, a 3d printer does not use data. A 3d printer executes instructions written in a special type of file – similar to a Microsoft Word document. However, these files are loaded from a computer onto a 3d printer using a USB cable or an SD card.

There are a few special types of software that you can use to create a 3d print, and there are also options to download files that other people have created.

But, it’s good to know how a 3d printer works, and why a 3d printer doesn’t need an internet connection so below I will explain that as well as everything you need to know about whether a 3d printer uses data.

Does 3D Printing Use Data?

So a 3d printer itself doesn’t use data, but you may be wondering whether a 3d printer uses data as it’s printing…

Printing a 3d print does not use data. As a 3d print is being printed it is following the step-by-step instructions outlined in the 3d print file. The print file is copied onto the hard drive of the 3d printer. The 3d printer then uses only filament and electricity to print the 3d print design.

You have the option to print a 3d print design you create, but there are online libraries of 3d prints that others have made that you can download for free. And there are also some paid designs.

All of this is done on a separate computer though. The computer you use will need to have an internet connection to download 3d print files. And certain 3D printing software is used in a web browser like Safari or Google Chrome. Therefore, they won’t work without an internet connection.

How Does a 3D Printer Work?

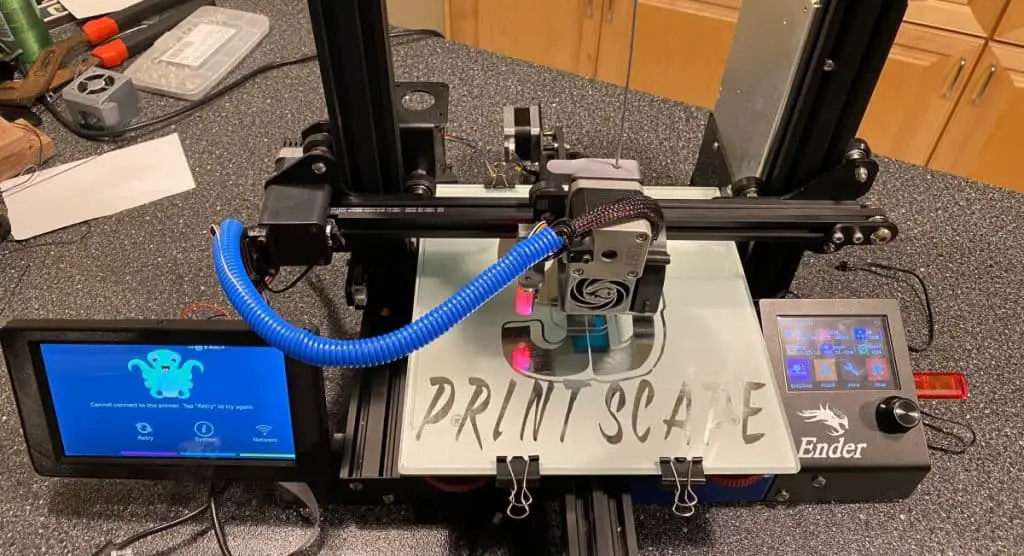

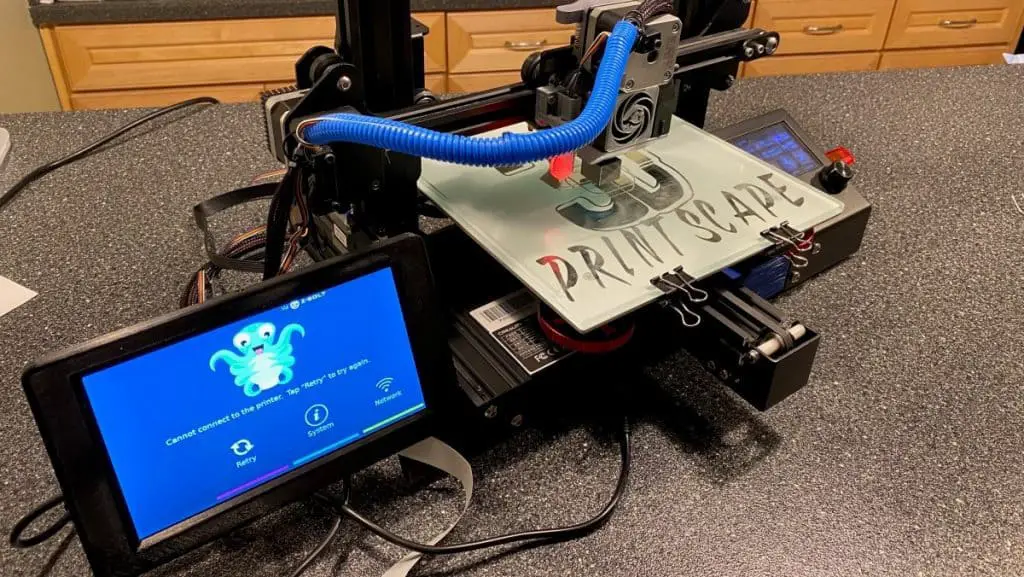

A 3d printer is a fairly new technology and unlike computers and smartphones, they aren’t that widespread. Therefore, most folks don’t know how a 3d printer works at a big picture level. Here’s how a 3d printer works.

A 3d printer prints one layer of plastic at a time. Each layer has a 2d design and all of the layers in a 3d print are the same thickness. A 3d printer prints each layer from a file that contains what each layer looks like.

A 3d printer uses computer code to give instructions to the 3d printer. These instructions and X and Y coordinates. The top left corner is the location 0, 0. If it goes a little bit to the right but not up or down it will be at a location of around (¼ inch, 0).

However, computer pixels are used for measurement on 3d print software. And as you may know on programs like Photoshop. So, the coordinates would be (4px, 0px) for example. Where px stands for pixels.

The 3d print file has instructions for the 3d printer to go to different locations around the 3d printer plate. And as it’s doing that it heats up the filament, and extrudes it at the right time so that it prints each layer until it is finished. Then, it moves on to the next layer.

For example, if you are printing a square cube, it will print the same shape over and over one layer after another until it makes a cube. But, a pyramid starts with a square but then prints a slightly smaller square each time until the final layer is only a tiny dot or filament. Which is the very top of the pyramid.

The filament is hard at room temperature and it’s heated until it melts. It’s then fed through what’s called the extruder where it draws each layer onto the 3d printing bed. After that, it will go hard and be a solid object.

3d printer compared to an ink printer

Both a 3d printer and an ink printer have the word printer in them. And they are remarkably similar. The major difference is that a 3d printer will print only one layer, whereas a 3d printer will print many many layers one on top of the other.

But apart from the fact that 3d printers print plastic whereas ink printers print with ink they are virtually identical and work in a very similar way.

The print file is sent to the printer. The printer then reads the file and moves a mechanical arm according to X and Y coordinates, and prints either ink or plastic. Depending on what kind of printer it is.

How Does 3D Printing Software Work?

3D printing software is used to create 3d print designs that a 3d printer can read. And then subsequently print a complete object from the 3d print design. But, how exactly does 3d printing software work?

3d printing software creates a 3d model. The 3d model is then sliced into layers. Each layer of a design is printed one by one in the 2d space. Each layer builds on the previous layer and creates a 3d object.

There are 2 different kinds of 3d printing software – one can be used to create the design – and the other is used to slice the design. The software used to slice the design is conveniently called slicing software.

A 3d print design needs to be sliced so that the 3d printer has the information it needs. And can then print each layer on top of each other until it has printed the entire design.

One of the most popular 3d printer designing software is TinkerCad. It is designed to be used by both school-aged children and adults. It has a tonne of lessons that explain how to create 3d print designs and best of all it’s completely free.

After you have a design you can slice it with Cura and is one of the most popular 3d printing slicing software. It’s also 100% free. Once the file has been sliced using Cura, then you send it to your 3d printer.

Some designs are very complex and the 3d printer nozzle needs to make a lot of back and forth movements. Whereas, in more simple designs the nozzle can print in long lines back and forward without stopping to reposition.

Because of that more complex designs tend to take longer to print, whereas simpler designs print a lot quicker. However, on a hobbyist type of 3d printer that most people would use at home, most prints don’t take longer than 12 hours.

Related Articles

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

- Can You Mix 3D Filament Colors?

- This Is How Much 3d Printer Filament You Really Need!

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.