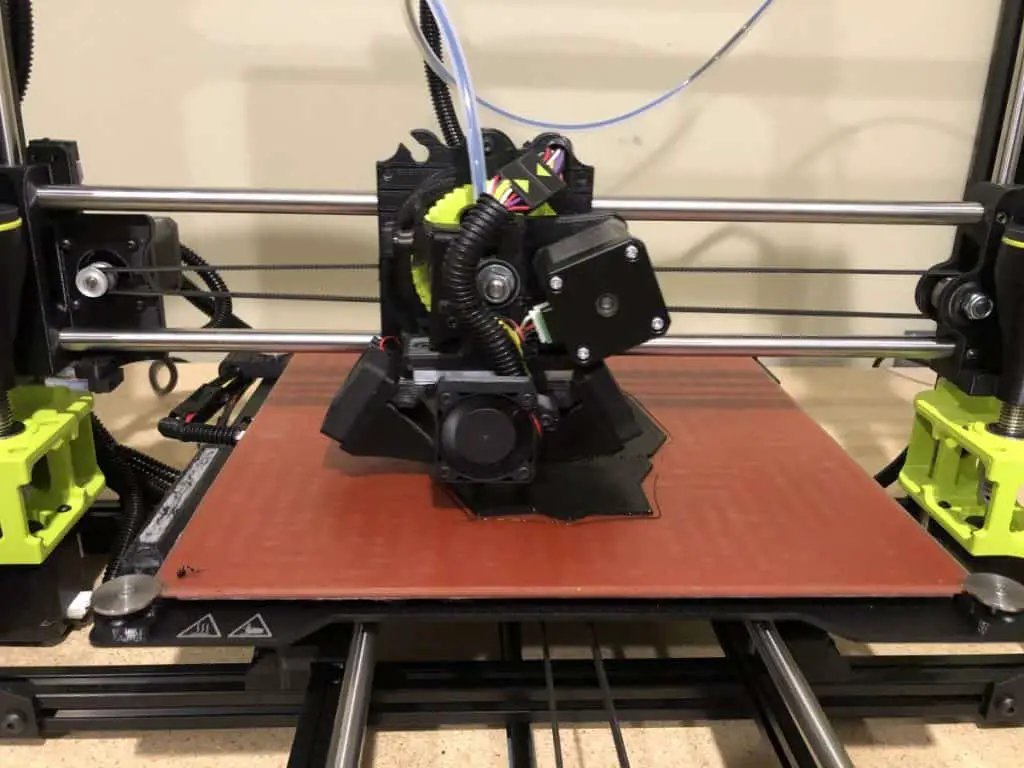

We all know that the 3d printing hobby isn’t exactly the cheapest one to be in. One of the most common types of questions I get from people with no 3d printing experience about 3d printers is how much power they use. Most people who haven’t worked with them, and many who have, just don’t know and are curious because of things they have heard. While a 3d printer can chew through power while heating the hotend and build plate, I think you will be surprised about how much power they actually use.

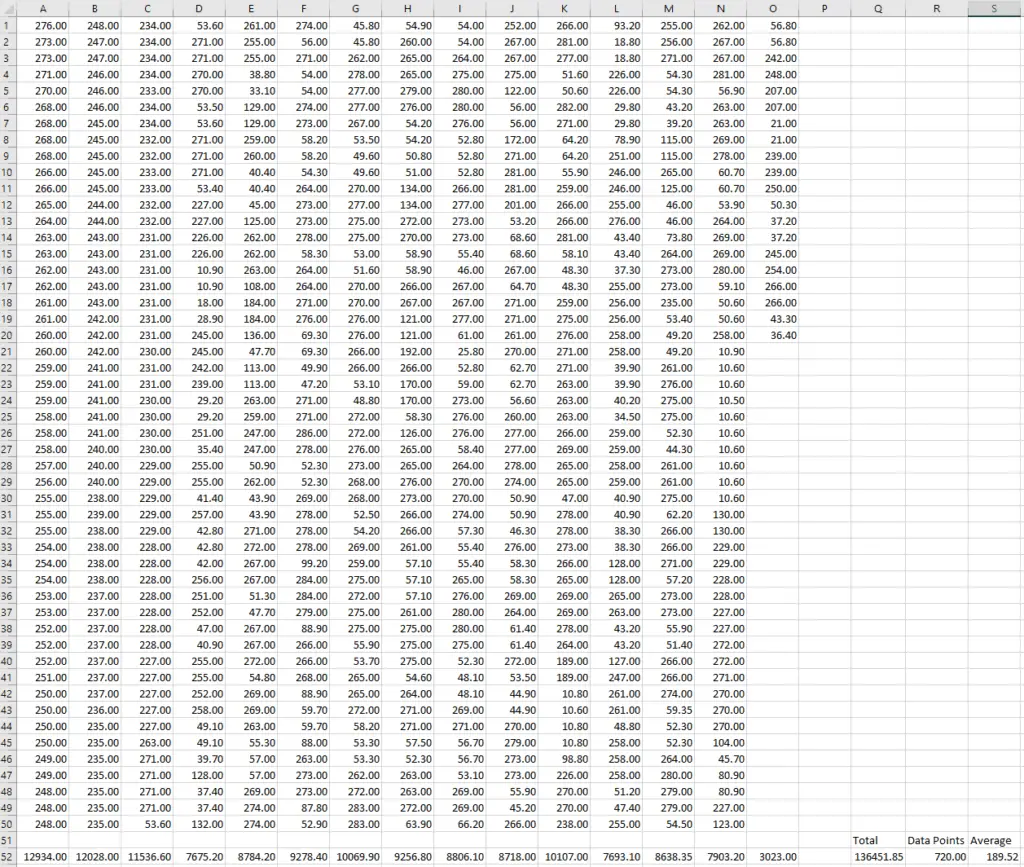

The short answer is that 3d printers don’t use as much power as you would think. Based on the test I did with a larger 3d printer, the average power consumption was 189.52 watts, or .018952 kilowatts, which means it would cost $0.023 to run the printer for an hour.

I used a Kill_A_Watt meter (available on Amazon) to capture the actual power usage of the 3d printer, but there are a lot of other factors that went into getting this average that I will talk about in more detail below.

3D Printer Power Consumption

I got this average by kicking off a one hour print on a 3d printer with the following specs/settings.

| Item | Specs |

|---|---|

| Build Plate Size | 300mm x 300mm |

| Hotend Temperature | 225 degrees celsius |

| Build Plate Temperature | 65 degrees celsius |

| Power Supply | Stock 360 Watts |

| Filament | HATCHBOX PLA from Amazon |

I captured the power usage every 5 seconds, for a total of 720 data points. The lowest reading was 10.9 watts, which would be for the mainboard, screen, one fan, and minimal movement from the stepper motors. The highest reading was 279-watts, which most likely had everything running at that point. The average power draw over the 1-hour print was 189.52-watts, which was actually less than I was expecting.

Now let’s compare that average to some everyday household items.

| Household Item | Power Used When Running |

|---|---|

| 3D Printer | 189 Watts |

| Ceiling Fan | 60 Watts |

| Light Bulb | 75 Watts |

| LED Light Bulb | 9 Watts |

| Space Heater | 1,200 – 1,800 Watts |

| ½ HP Furnace Fan | 800 Watts |

| Central AC Small Unit | 1,500 Watts |

| Microwave | 1,000 Watts |

| XBOX | 50 Watts |

| 49” LED TV | 85 Watts |

| Desktop Computer | 100 Watts |

As you can see, a 3d printer uses more power than a video game console and a low-end desktop, but it doesn’t use anywhere near as much energy as your appliances. I would consider the power draw similar to a mid level desktop.

Average Cost of Power

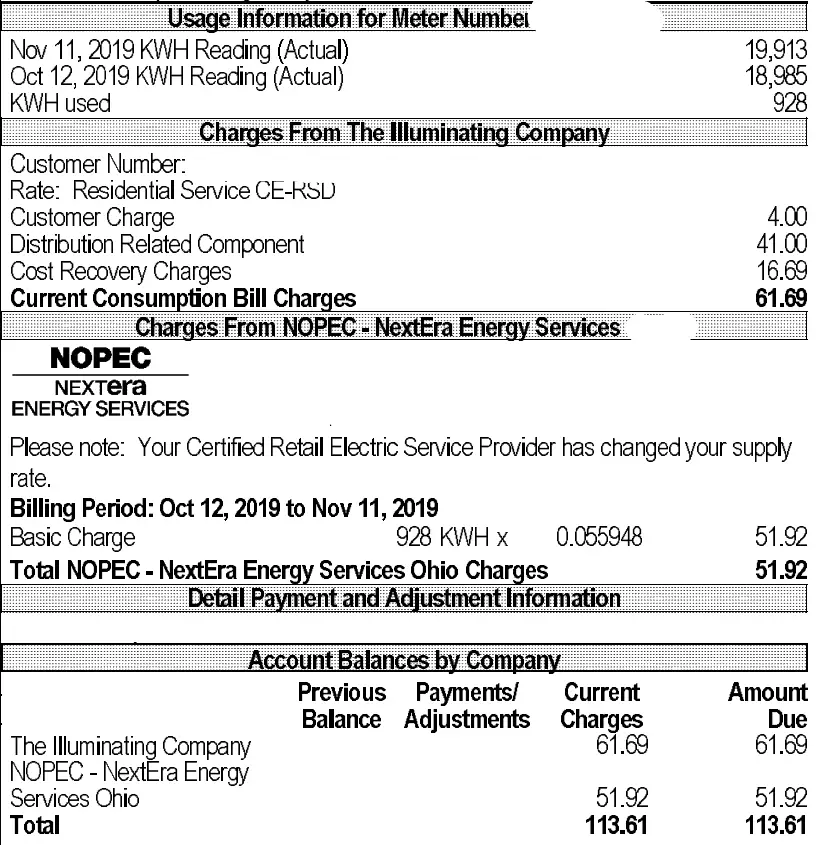

Now that we know how much power a 3d printer uses, I wanted to go into what that actually means to your electric bill. According to Choose Energy, the average cost per kilowatt-hour is 13.30 cents. The cost can vary significantly based on where you live, but in North East Ohio, I pay 12.24 cents per kilowatt-hour, factoring in all taxes and fees. If you are interested in figuring out what your actual electricity cost is, all you need is your electric bill and the formula below.

Formula: Total bill / KWH = Actual cost per KWH

Looking at my bill, you can see that I used 928 KWH for the month, and my bill was $113.61. Now, let’s plug those values into the equation.

113.61 / 928 = 0.1224

The end result shows that I paid 12.24 cents per KWH after all taxes and fees are accounted for.

Cost to Print

Now we can take that value to find out how much it costs to run a 3d printer for a duration of time.

Formula

- Watts / 1000 = kW

- KWH * Cost Per KWH = Total Cost

Example

- 189.52 / 1000 = 0.18952

- 0.18952 * 0.1224 = 0.023197248 or $0.023 per hour

Average Cost

- Per min: $0.00038

- Per Hour: $0.023

- Per 10 Hours: $0.23

- Per Day: $0.56

As you can see, it doesn’t really cost that much to run a 3d printer. You would be looking at using $0.56 if you ran the printer for 24 straight hours, which isn’t bad.

What Consumes All the Power on a 3D Printer

Before I get into how I calculated the average power consumption, I wanted to talk about what’s actually consuming the power. From a mechanical standpoint, a 3d printer is pretty simple and only has six types of devices that consume energy. So let’s drill into those.

Hotend

The hotend is what melts the filament as it’s pushed through the extruder. It’s heated to the print temperature defined in the g-code file by a heating element that is connected to a heat block.

That heating element uses a significant amount of power (caped by the mainboard and power supply) until it’s up to temperature and turned off. After that, it gets turned back on for short durations to maintain the temperature. When it’s off, it’s not using any power.

Build Plate

Most 3d printers on the market today have a heated build plate. The build plate is heated the same way as the hotend. It has a heating element connected to the bottom of it and heated to the temperature defined in the g-code file.

The heating element used a significant amount of power when on, but it’s only on when heating the built plate to the initial temperature and as needed to maintain it. It is important to match the temperature of the build plate with the filament requirements.

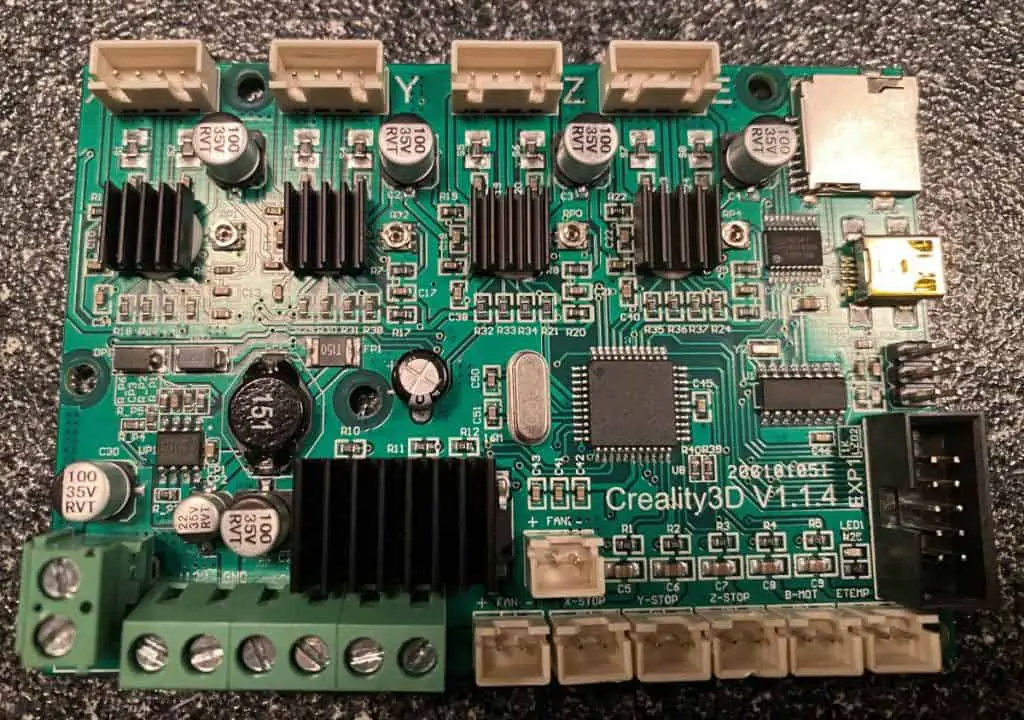

Main/Control Board

The mainboard, like the SKR Mini on Amazon, is essentially the brain of the 3d printer. It’s responsible for everything from tracking the print to turning the wheels on the stepper motors. Even though it’s the most critical part of the print, it uses very little power and can even be powered via USB.

The mainboard can be upgraded to reduce power consumption and noise while increasing performance. A good option would be the SKR Mini (on Amazon) if the 3d printer supports it. I have one of these in my Ender 3 Pro (on Amazon).

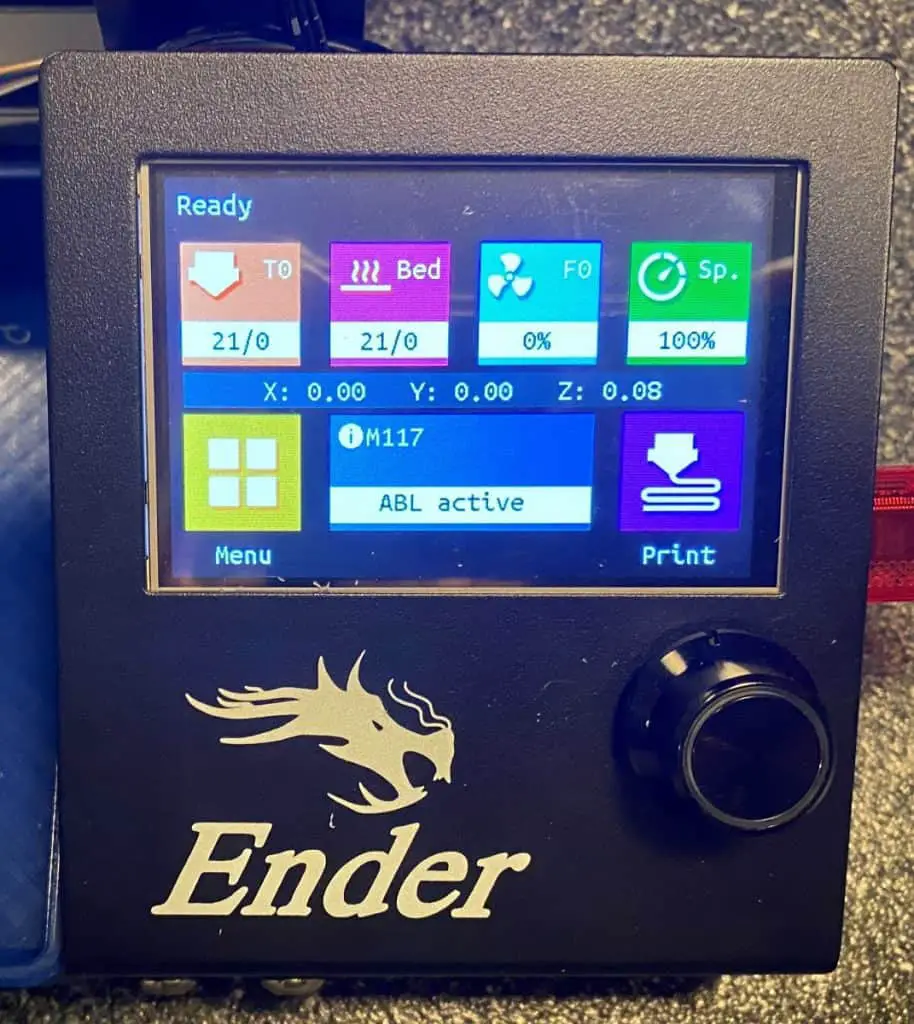

Display

The display uses very little power and is the interface you would use to control the 3d printer. It directly connects to the mainboard and can be as simple as a standard LCD screen, or it can be full color and touch screen.

Without the screen, you would have to have the 3d printer connected to a computer, or RaspberryPi (available on Amazon) with OctoPrint, in order to control the printer.

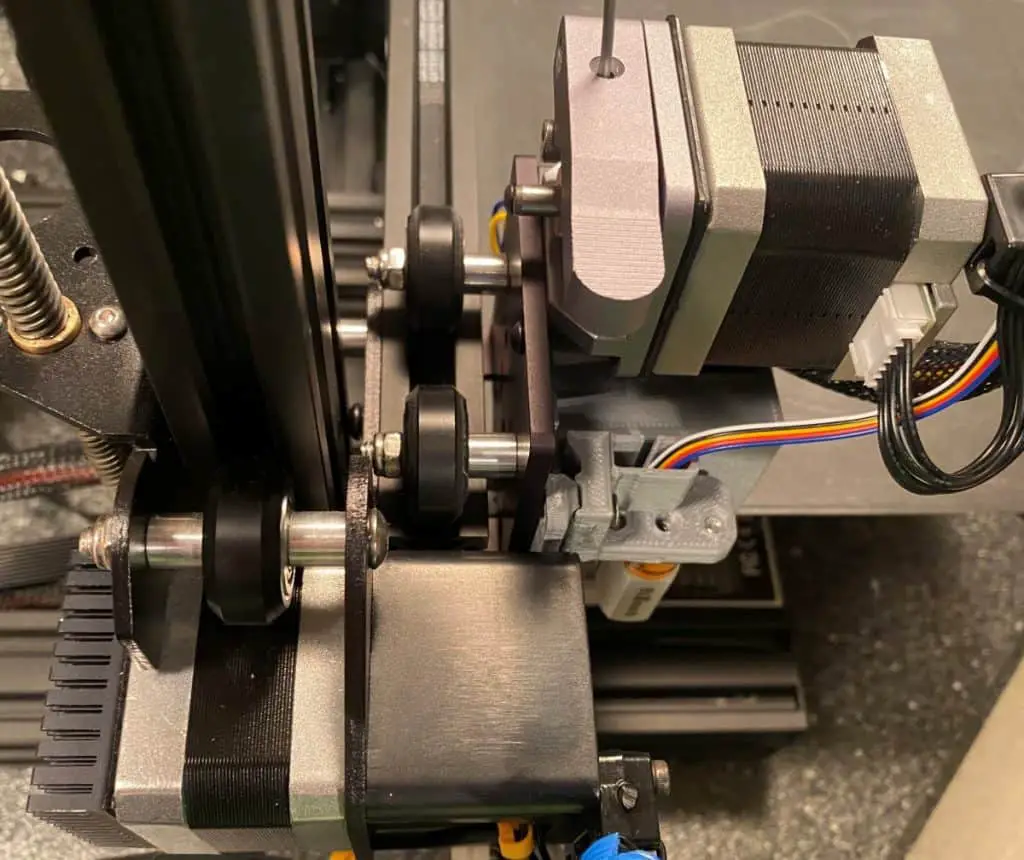

Stepper Motors

There are at least four stepper motors on a 3d printer. They are responsible for moving the build plate along the X, Y, and Z-axis and feeding the filament into the extruder. These motors typically use a couple of watts apiece, which is not much at all and without them, the 3d printer wouldn’t function.

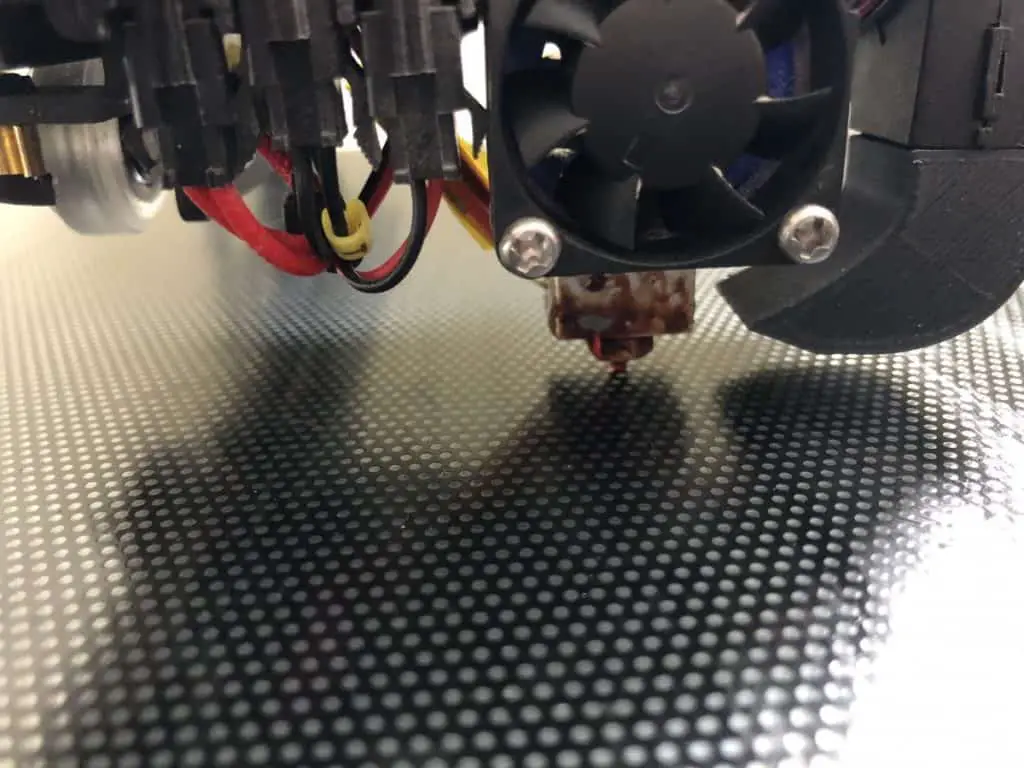

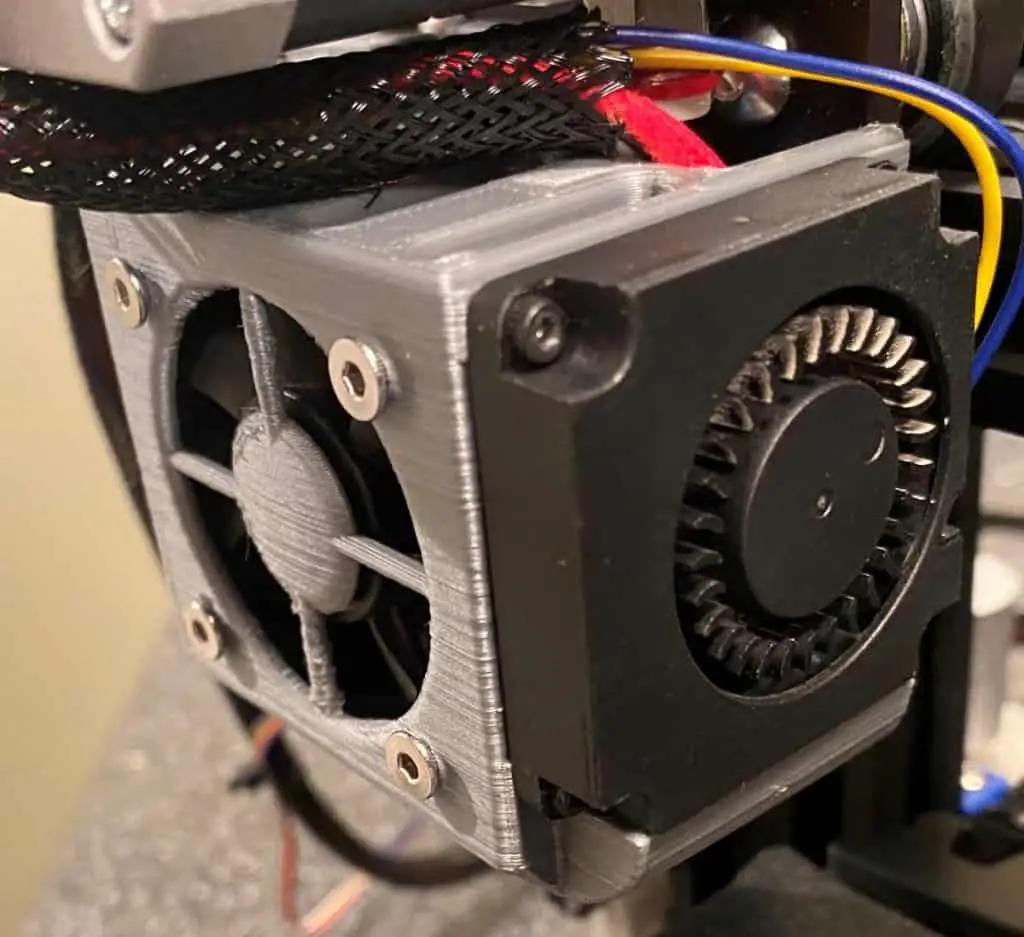

Fans

There are typically at least three fans, like these fans on Amazon, on a 3d printer (not including the power supply). One of the fans is used to cool down the heat sink on the hotend to help regulate the nozzle temperature, one is used to help cool the filament as it’s being put in place, and the last one is used to keep the mainboard temperatures in check.

Some printers use more than one fan for each of these functions. The fans are typically small and use very little power but have a considerable impact on the overall printer performance.

The combination of the mainboard, display, stepper motors, and fans uses about 40-50 watts, which is less than a third of the overall average power consumption. The rest of the consumption comes from the heating elements.

How to Get Better Efficiency

There are some things you can do to get better efficiency out of your printer, though the impact may not be that significant, so you will need to decide if doing them makes sense to you or not.

Use an Enclosure

The lower the room temperature is, the harder the heating elements will need to work to keep everything at the desired temperature. Running a 3d printer in an enclosure will help keep the temperature more consistent and won’t require the heating elements to be used as often, this is especially true in areas with a lot of breezes or buy a vent. It accomplishes this by blocking out the outside environmental factors that could impact the temperature of the heating block and build plate.

There are some printers that are sold with an enclosure but if yours didn’t come with one, which many of the popular ones don’t (including popular ones like the Ender 3 and CR-10 that you can get from Amazon) you can buy a pre-build enclosure (like this one for the Ender 3 from Amazon) or make one yourself.

Print With Lower Temperatures Where Possible

The higher the temperatures are, the more the heating elements need to work to reach and maintain them. If you can print at a lower temperature, the heating elements won’t need to be on as much and reduce the overall power consumption. In many cases, you can get away with lowering the temperature of the hotend by 5 degrees and the build plate by 10 degrees without any negative effects on the print.

That said, lowering the temperature is not always an option, and you must print at a temperature within the specs of the filament. I would recommend printing a temperature tower to get the best printing temperature for the filament being used.

Reduce Print Time

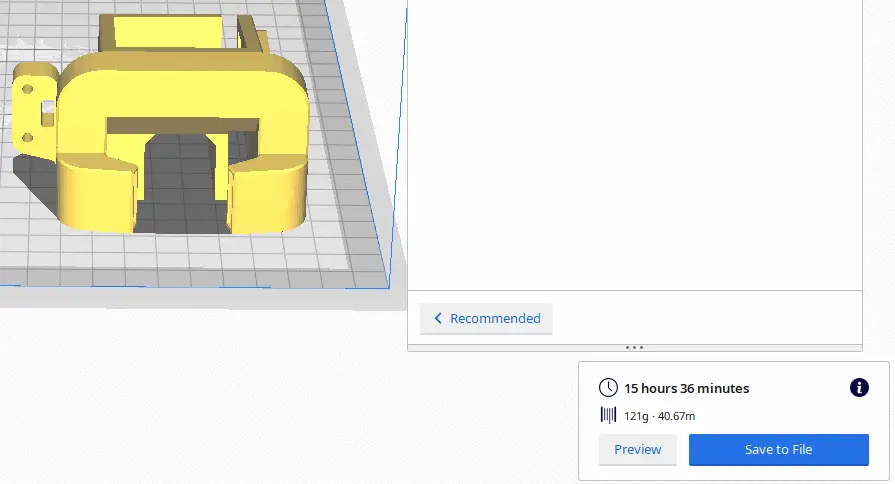

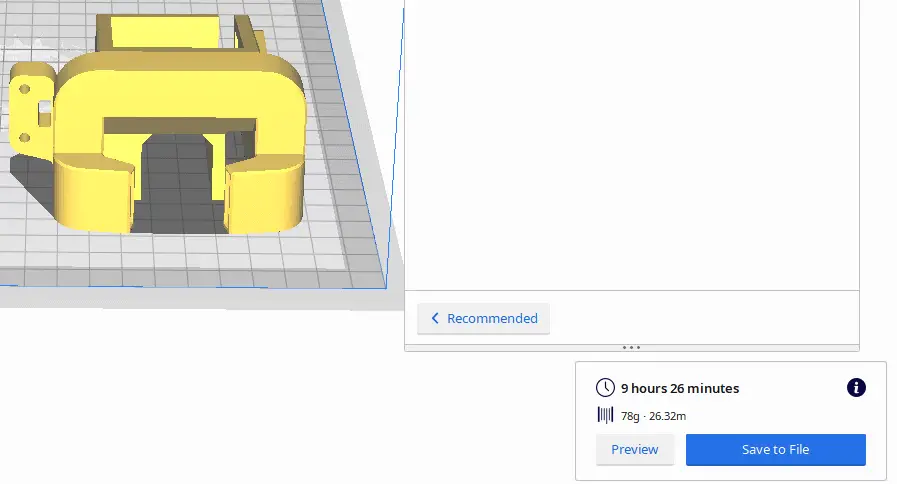

Before

After

Another option you have to reduce the power consumption would be to reduce the print time as much as possible. It simple, if the printer runs for less time, it will use less power. That said, you want to make sure you are printing an object correctly, and that you take into consideration what it will be used for. You don’t want to make any changes below if it means you will end up with a print that isn’t functional because you will probably end up having to reprint it and use more power.

Here are a couple of ways to reduce the print time.

- Reduce infill

- Change infill pattern

- Reduce or remove supports

- Increase the layer height

- Reduce wall thickness

- Reduce or remove supports

- Only use a raft if absolutely necessary

- Increase print speed

Get a More Efficient Power Supply

The power supplies that come with most of the 3d printers aren’t the most efficient, and switching them out with a more efficient one will reduce the overall power consumption. You would really need to move to a platinum-rated power supply to see much of a difference. Don’t make this change if you are looking to save money. Unless the 3d printer is running around the clock you probably won’t recoup the cost of the power supply within the life of the printer.

That said, there are not many power supplies that will work out of the box with a 3d printer, so you would need to make some modifications to make them work. I would not recommend doing this unless you know what you are doing and are comfortable making that type of change. If done wrong, you cond end up messing up the mainboard.

Get a Battery Backup

While this won’t directly reduce the power consumption, it can reduce the number of failed prints, which in turn will reduce the amount of power used for that print. This is especially true if you live in an area that has a lot of power outages or you have a 3d printer that doesn’t recover from power loss.

You would need a battery backup that is rated to handle the wattage called out on the 3d printer’s power supply. In this example, it’s 360 watts. You will also need to consider how long the power typically goes out for and how long you want the printer to continue when it’s out.

Here is the battery backup on Amazon the I recommend. It provides plenty of coverage at a fair price. The only thing I don’t like about it is it doesn’t tell you the remaining run time. If you would like that feature, the price starts going up considerably.

Final Thoughts

Even though the average power consumption of a 3d printer isn’t as much as I initially was thinking, with an average consumption of 189.52 watts, it’s still more than many common household items, including TVs and game consoles. That said, you could run this 3d printer nonstop for a month, and it would only cost you about $17, which isn’t bad.

As discussed in the article, there are some actions you can take to reduce the overall power consumption, but only you can decide if they are worth doing or not. That said, if you live in an area that loses power a lot, I would highly recommend getting a battery backup from Amazon.

*Disclaimer: These numbers are based on the power usage of my 3d printer, your results may vary. I ran the numbers using a larger 3d printer, PLA filament, and higher temperatures to show a more realistic high-end estimate. Printing with filaments that require a high temperature, such as ABS, will increase the overall power consumption.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.