You might have noticed the motors in 3D printers are not like traditional motors. These motors can perform the same action continuously. In this article, we will explain the reasons why 3D printers use this kind of motor.

3D printers use stepper motors because they are more efficient and precise to create small patterns when compared to other motors such as servo motors or brushed motors.

Stepper motors are cheaper and don’t require a feedback system to work. These electromagnetic devices are great for machines that perform the same operation over and over. Let’s take a deeper look at what stepper motors are, how they perform in 3D printers, and what other industries use these motors.

What Exactly Are Stepper Motors?

Stepper motors are electronically commutated motors that use electricity and magnetic principles to create movement. This type of motor requires a direct current supply.

Parts Of A Stepper Motor

The stepper motor is composed of the following parts:

- A rotor

- Stator teeth

- DC power sources

How Does A Stepper Motor Work?

The stator teeth are placed around the rotor. The teeth in the rotor and the stator will never be the same. It is done on purpose to be able to create movement.

Initially, part of the rotor teeth will be aligned with the stator teeth. The rest will be positioned differently to allow movement to happen. The next set of stator teeth gets electrified to attract the rotor. This causes the rotor to move clockwise or counterclockwise, depending on how it was set.

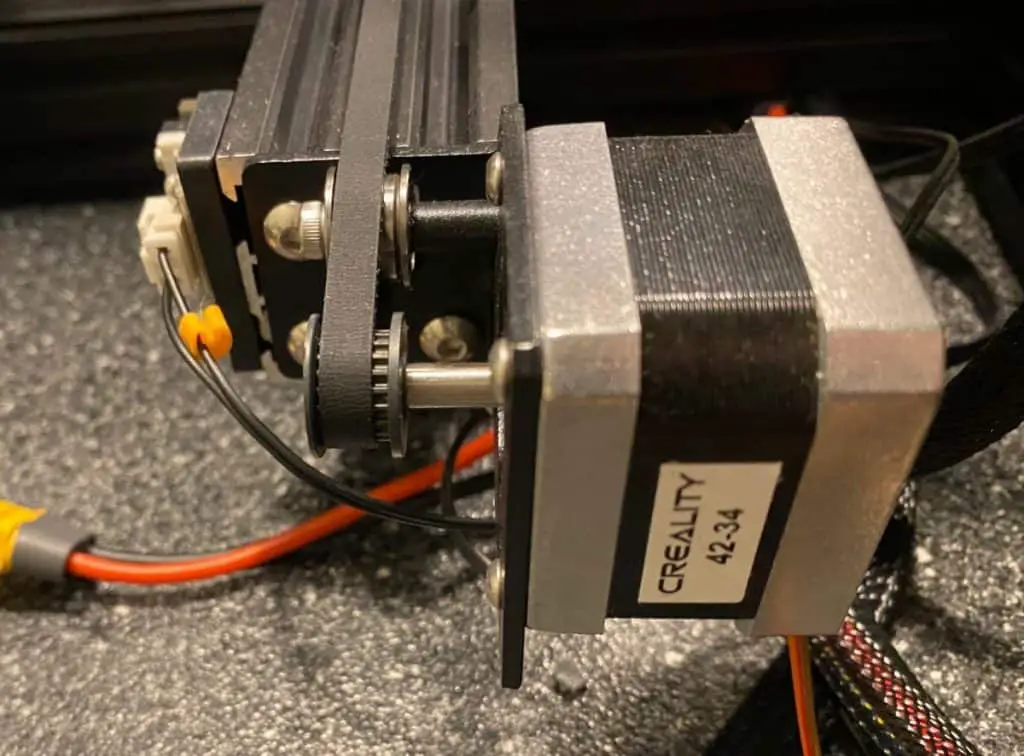

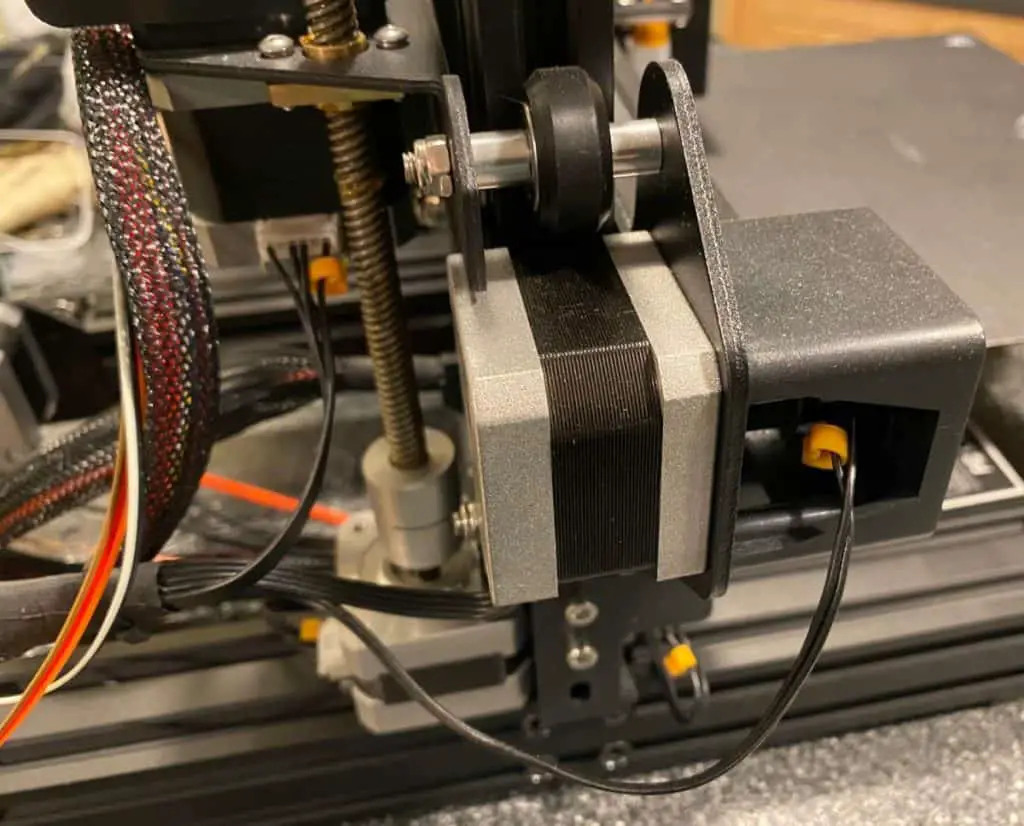

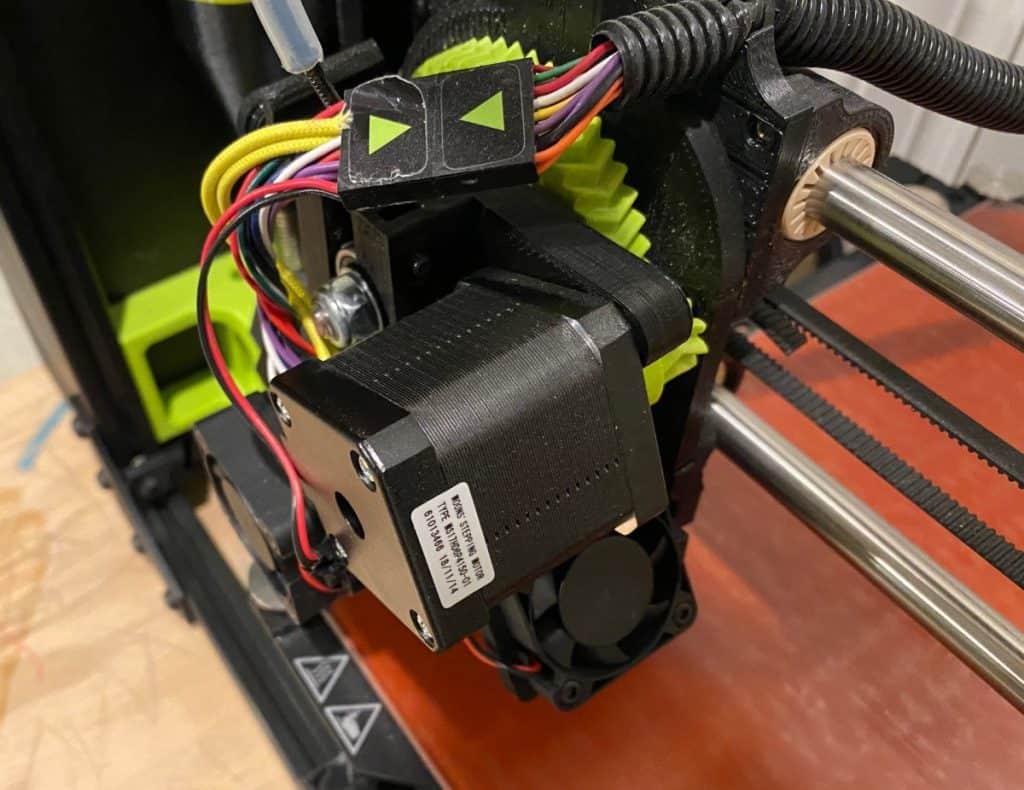

Stepper Motors In 3D Printers

Now that you understand the basics of how these motors work. Let’s see how they are used in 3D printers.

How Many Motors Does A 3D Printer Have?

A 3d printer has a minimum of four stepper motors and uses them to:

- Move the build platform up and down, called the Z motor.

- Move the build platform forward and backward, called the Y motor.

- Move the build platform left and right, called the X motor.

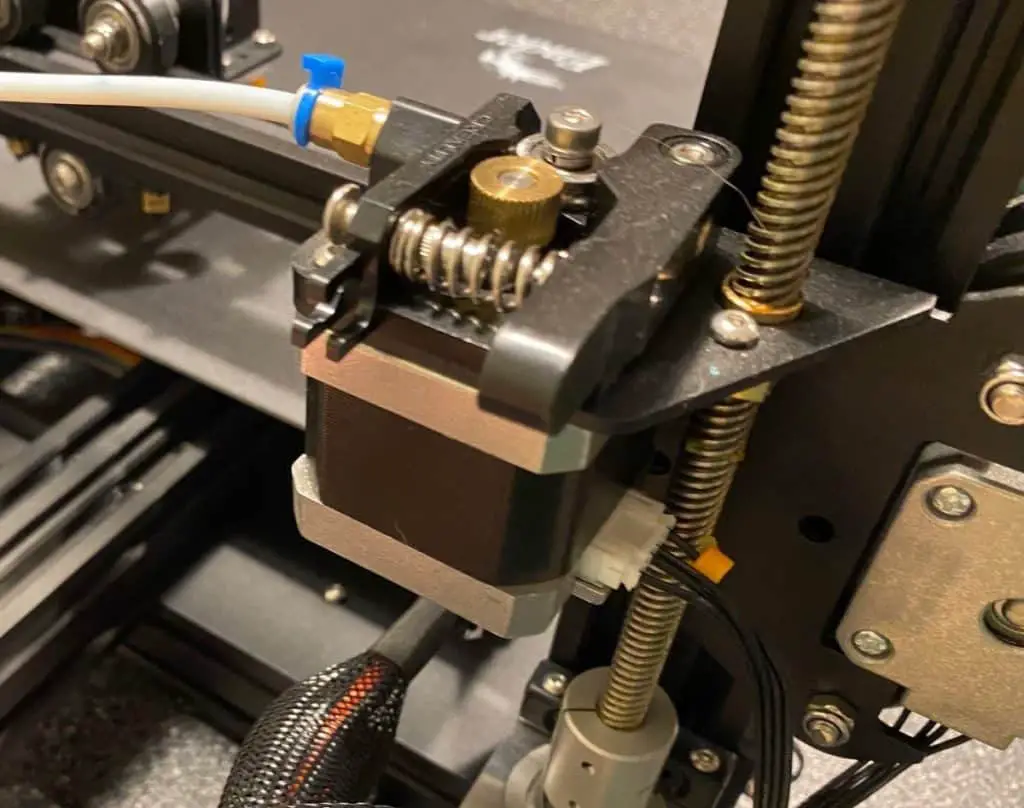

- Load the printing material, called the extruder motor.

Why Use Stepper Motors In 3D Printers?

Stepper motors offer many advantages, which could be why you find them in most 3D printers nowadays. Some of the benefits of stepper motors include:

- Reliability. You can count on a long-lasting motor which, under regular use, can work for years.

- Availability. These motors are cheap to manufacture, and there are many units available on the market. It is because of this combination that they have an affordable price.

- Precision. These motors work in steps, and it is great for 3D printing because you don’t need a feedback system to know which steps have been completed. Also, they can do micro-steps, which is a fraction of the whole movement.

- Torque. If you compare it to other motors, stepper motors don’t have a strong torque. However, it is an advantage in 3D printing because it helps with precision. Another positive thing about its torque is the holding torque. Stepper motors can keep their original position after force is applied.

- Consistency. Stepper motors don’t vary much in size from one manufacturer to another.

The Drawbacks Of Stepper Motors

As they say, where there’s light, there’s shadow. The stepper motors are not great at everything. Listed below are some of the disadvantages of using electric motors.

- Feedback is not received from the control system regarding possible missed steps.

- Low torque speeds. It is a critical factor that affects the time needed to deliver a finished printing. It can take days to print a complex figure.

- They can reach high temperatures due to their high electric consumption.

Other Uses Of Stepper Motors

Stepper motors are not exclusive to 3D printers. These types of motors serve other purposes. Some examples include:

- Robots

- Antennas

- Hard disks

- Toys

Other Motors In 3D Printers

Stepper motors have been the go-to option when we talk about 3D printing. However, servo motors are also trying to make their way into the market.

What Is A Servo Motor?

A servo motor is just another type of motor that uses electricity to create movement. One of the features that defines a servo motor is its encoder. It uses an encoder to provide feedback about the steps the motor skipped.

Another important aspect about servo motors is that they can run on DC or AC electricity.

Parts Of A Servo Motor

The internal components of a servo motor include:

- Gears

- Potentiometer

- Motor

- Circuit

- Servo case

Differences Between A Servo Motor And A Stepper Motor

As you already know, servo motors are designed differently than stepper motors. Different designs mean different performances. Some of the main differences between these two types of motors include:

- Servo motors provide feedback about any missing step in the process.

- Servo motors can be more accurate than stepper motors.

- If you want high torque and high speeds, servo motors work much better than stepper motors.

Interesting Facts About 3D Printers And Stepper Motors

- The first known reference to a stepper motor dates back to the 1930s.

- The development of the stepper motor has been closely related to tech developments such as the transistor.

- Stepper motors have been widely used in robotic arms for medical purposes, factory development, and office development since the late 1970s.

- 3D printing renders the image as several horizontal layers stacked one on top of the other. That’s why you need motors to move the hot end.

Frequently Asked Questions

How long do stepper motors last?

They can last up to 10,000 hours of continuous use. It is the equivalent of using it eight hours a day for five years.

Can stepper motors run continuously?

Yes, they can. It is one of the advantages they offer. That is the reason why you find them in machines that perform the same movement.

Do you need an encoder with a stepper motor?

No, you do not. Stepper motors are very rigid and stable. But, it can be added as a backup unit.

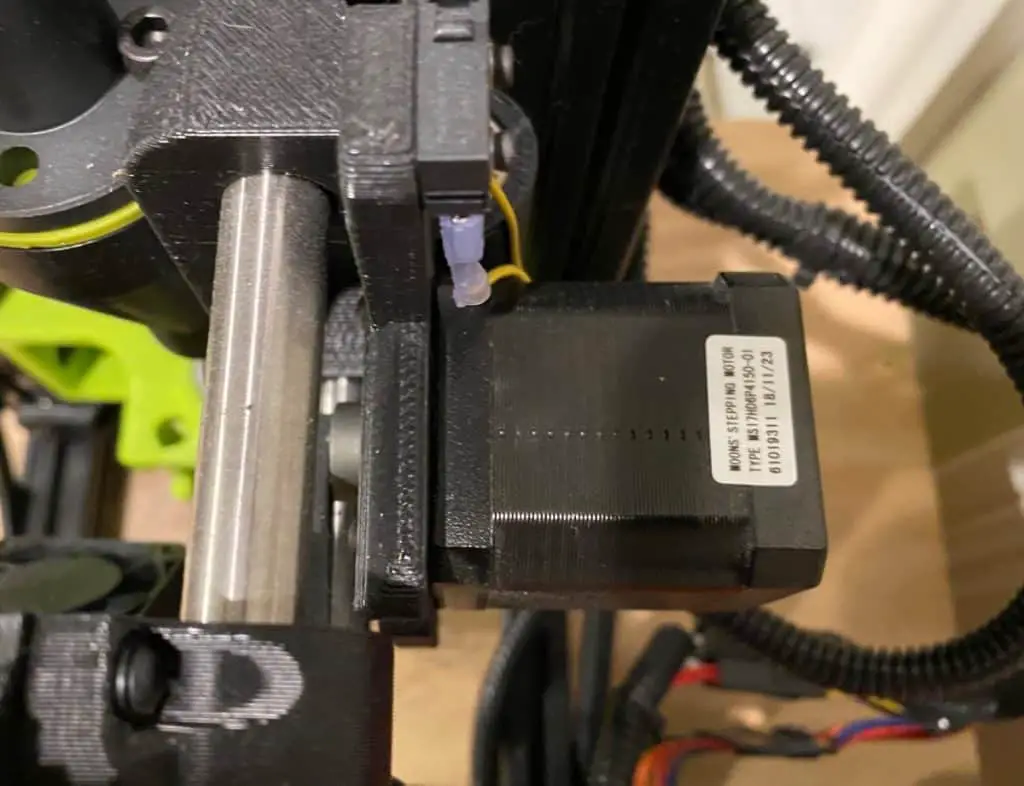

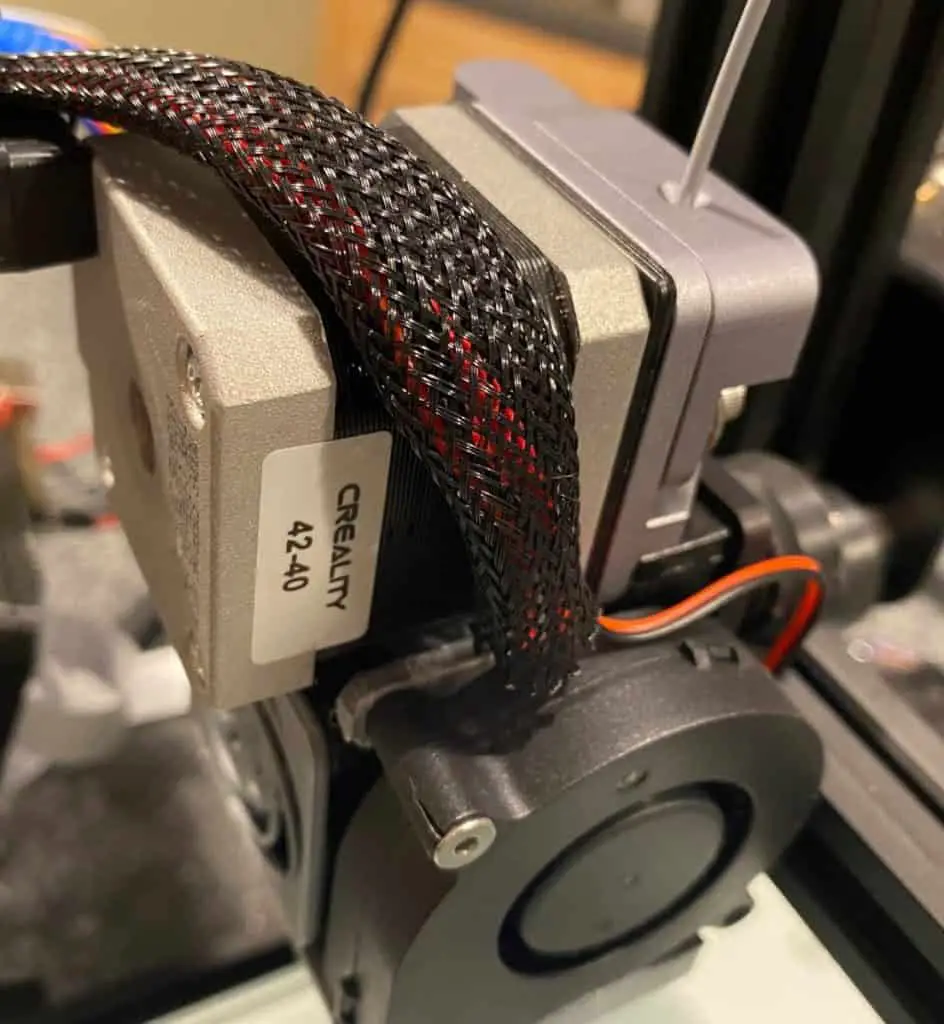

What are the most common stepper motors in 3D printers?

The most common motors in 3D printers include:

- NEMA 14

- NEMA 17

- NEMA 23

- NEMA 24

What does NEMA mean?

NEMA is an acronym for the National Electrical Manufacturers Association, which is the organization in charge of defining standards for electrical products.

What is the strongest stepper motor?

The winner here would be the NEMA 23 with a 3Nm holding torque.

Which is the most common motor for 3D printers?

The most common stepper motor is the NEMA 17. Most machines use this model because it is cheaper than the rest and is very easy to find.

What is a “pancake motor”?

It is a stepper motor with a torque rating of 20 to 25 N⋅cm. You can find these motors in portable or small 3D printers.

What is a “standard motor”?

It is a stepper motor with a torque rating of 40-45 N⋅cm. It is the most common category of 3D printer motors.

What is a high torque stepper motor?

To consider a stepper motor as high torque, it should exceed 50 N⋅cm. High torque motors are also known as Big Beef. You can find these motors in large 3D printers.

Related Articles

- How to Print a File from Thingiverse (The Easy Way!)

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

- Create a Temperature Tower Using Cura – The Easy Way

- What Shapes Cannot Be 3d Printed? – Details Inside!

- Why Is 3d Printing Slow?

Final Thoughts About 3D Printers Motors

3D printers are refined pieces of machinery, exact and accurate in their designs. This preciseness is thanks to their stepper motors.

Stepper motors are great for repetitive actions. Even though they are not as fast or forceful as other motors, they are great for 3D printing. After all, when it comes to sacrificing something, everyone would agree quality is not negotiable.

Other motors are trying to make their way into the 3D printers business. But, at this point, competing against stepper motors would be a fun challenge to witness.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.