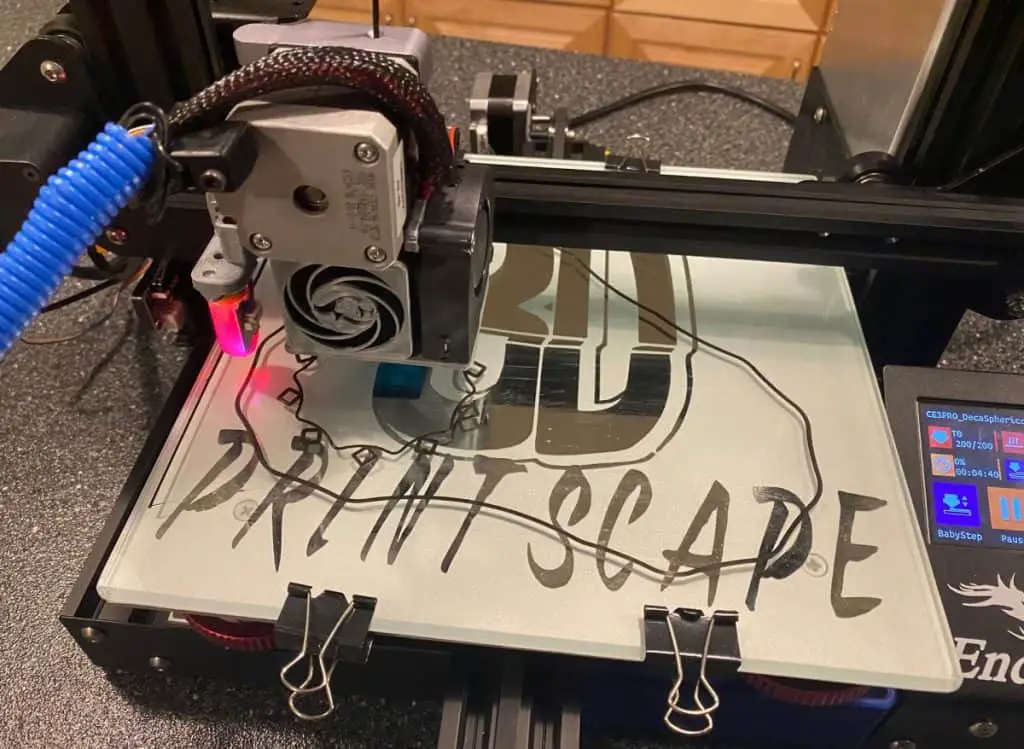

3D printing is an innovative way of manufacturing structures and shapes that can otherwise be impossible to achieve. While 3D printing has many great applications, it’s not without its flaws. Deformities can occur during printing which is primarily due to issues with the first layer and the height used for the first layer.

0.20mm (0.009 in) is the best height for the first layer in 3D printing for a 0.4mm (0.015 in) nozzle. Some people compact the first layer to 90% the size with the same amount of materials, although this can lead to later issues. Therefore it’s best to use a 0.20mm (0.009 in) nozzle for the first layer to ensure a stable print.

Keep reading to learn more in detail about the first layer in 3D printing. I will examine the importance of getting the first layer right and the steps to ensure you get a good first layer. By the end of this article, you’ll have a clear idea of how you can improve your 3D printing by improving your first layer.

Why Is the First Layer So Important?

If you’ve ever looked into 3D printing, you’ve likely seen dozens of articles and opinions about the first layer. You’ll see different settings for different materials and a bunch of conflicting information. As a result, you’re probably wondering what’s so important about the first layer?

The first layer is so crucial in 3D printing as it’s the foundation that the rest of the print is built upon. The first layer of printing is also one of the most common sources of printing issues, with as much as 90% of printing issues attributed to mistakes made with the first later of the print.

Several things can go wrong during the initial layer of a print. The first layer can go wrong if the temperature is off, the machine is not effectively calibrated or if any contaminants are on the printing surface. Therefore you should pay extra attention to ensure you get the first layer right.

How To Guarantee You Get a Great First Layer?

Now that you know why getting the first layer is essential in ensuring a successful 3D print, you’re probably wondering how you can improve your prints by getting the first layer right. Below are some critical steps to ensure that you get a tremendous initial layer in every print.

Here are the steps to follow for a great first layer of your 3D print:

- Leveling

- Temperature

- Layer Height

- Layer Speed

- Calibration

Leveling

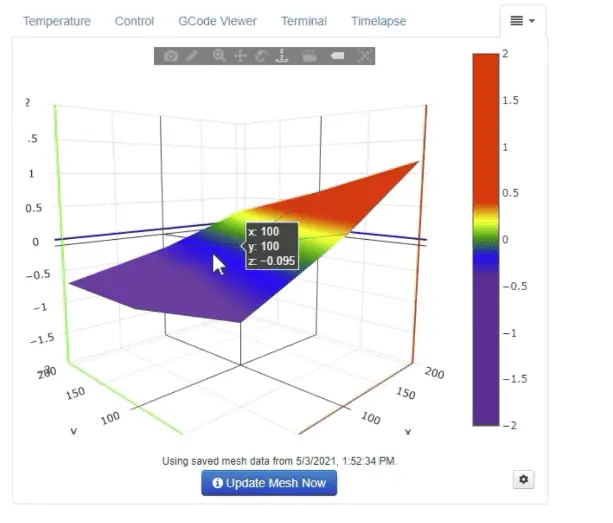

Leveling is essential when getting the first layer right in 3D printing. If your printing surface is off by even a few millimeters, it can significantly impact the finished print. Investing in a high-quality printing surface with self-leveling software can ensure that you get an even first layer every time.

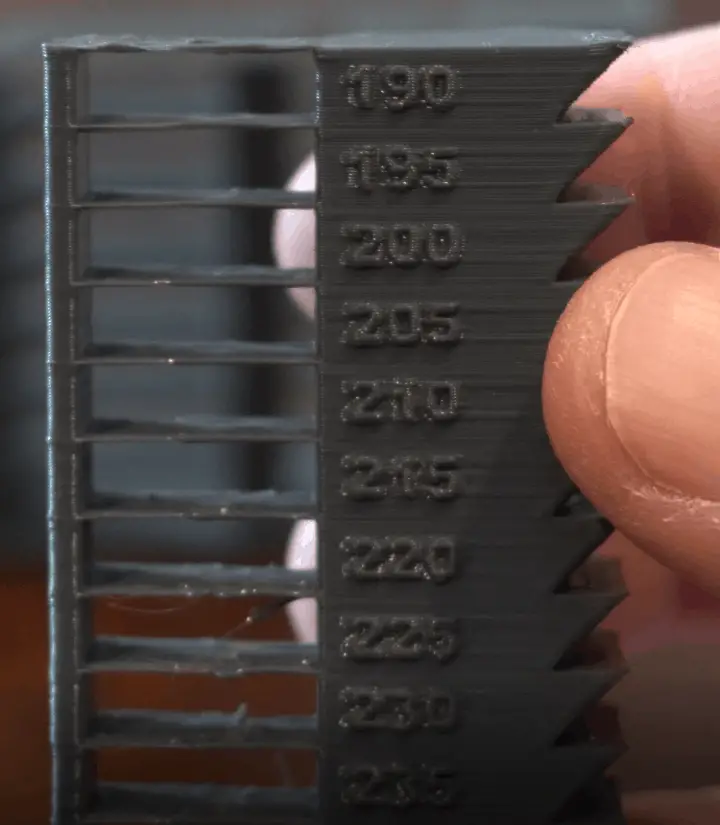

Temperature

Getting the temperature right for the initial layer is another crucial aspect. The temperature you choose can determine the layer adhesion and the first layer adhesion to the build surface. Different printing materials require different temperatures, so research which temperature is ideal for the materials you use.

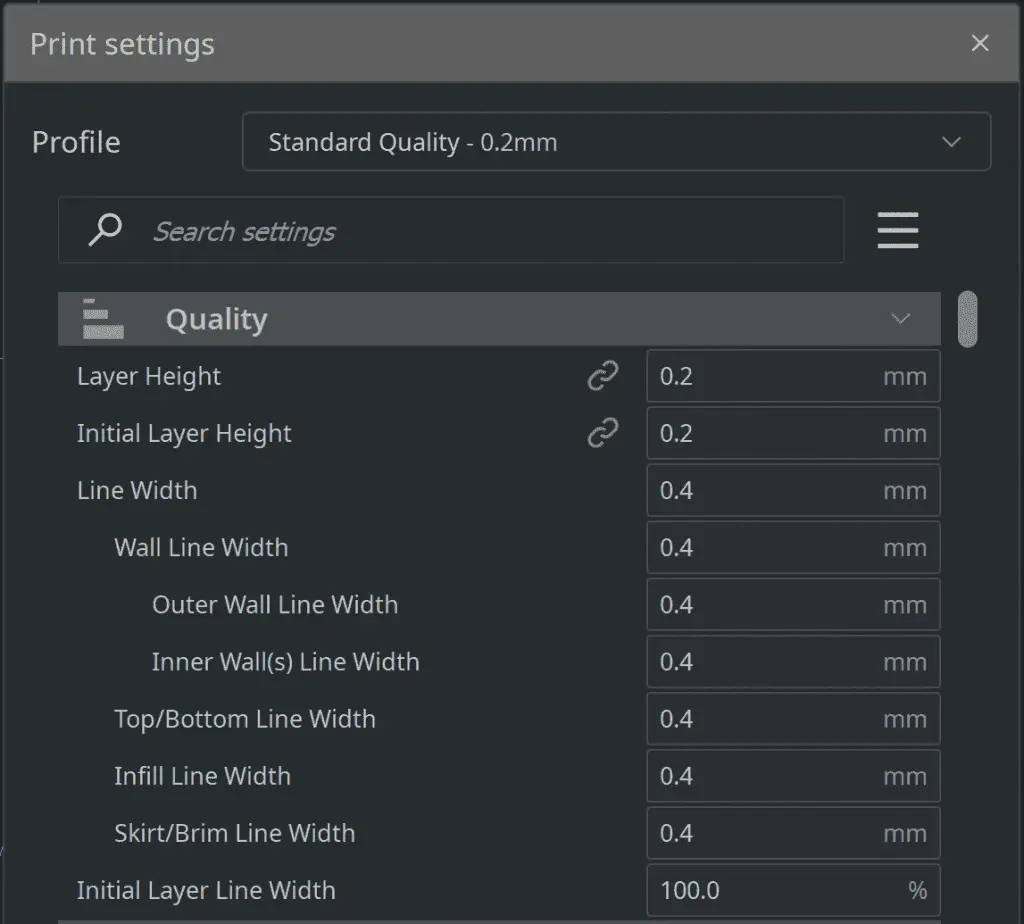

Layer Height

The wrong layer height can have disastrous consequences for your print. Therefore you should research what layer is best for your build and materials. If you’re using a .4mm (0.015 in) nozzle, you should choose a 0.20mm (0.009 in) initial layer for best results. However, some materials such as PETG may require a higher initial layer.

Layer Speed

The speed that your initial layer is laid has a significant impact on the result. If the speed is too fast, your layer may not set correctly, or the adhesive may not dry. As a result, a speed of around 15mm (0.59 in) per second is ideal for the initial layer. However, some materials can be laid at a higher rate.

Calibration

Another common source of problems for the initial layer is poorly calibrated printers. Ensuring that your 3D printer is adequately calibrated is vital. Check with the manufacturer of your 3D printer to learn how you can accurately and effectively calibrate your make and model of 3D printer.

If you follow the steps above, you should achieve a perfect initial layer in every print. This will significantly reduce the risk of deformation occurring during your print and vastly improve the results of your designs.

Does Lower Layer Height Affect Strength?

We’ve already established the importance of getting the initial layer height right when 3D printing. However, we haven’t explored what height you should use for the rest of your print layers and whether lower layer heights affect the print strength.

Some people claim that lower layer heights result in more robust builds. This is due to the fact that layers can bind together better while still hot. However, others argue that using a higher layer height enhances strength in 3D printing.

The layer height is typically associated with the detail required in the printing and not the strength of the overall build. Lower layer heights are best suited to more points, although it increases the print time.

Whereas high layer height produces less detailed prints that are completed much faster. As a result, the printed item significantly influences the layer height as complex pieces will require smaller layers.

Similarly, different printing materials work best with varying heights of layer, so make sure you choose the appropriate layer height for your fabric choice to ensure a strong build that does not take longer than is needed.

Related Articles

- Cura First Layer Settings

- Does Cura Work With Any Printer?

- Cura Speed – Everything You Need to Know!

- Cura Brim Build Plate Adhesion – Everything You Need to Know!

- Cura Hacks – My Picks!

Final Thoughts

3D printing is a fantastic way of creating unique and extraordinary items and products from the comfort of your own home. However, 3D printing can be complex when you first start, especially without the right skills and experience. Most issues occur in 3D printing due to problems with the initial print layer.

The first layer height is significant. The ideal first layer height varies depending on what materials you are using; however, for most materials, 0.20mm (0.009 in) is perfect for a 0.4mm (0.015 in) nozzle.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.