3D printing is here to stay in our lives. Its current utility goes through buildings, the aerospace sector, medical prostheses, and even food production. But to achieve all these wonders, is it necessary to know how to code to do 3D printing?.

The answer is no and yes. Suppose you are a casual user; you probably don’t need to know a single coding command. The slicer or slicing software will do it all for you. But suppose you aspire to be a professional in this area. In that case, you must know coding or G-Code.

Although 3D printing is taking its first steps, it has become an essential tool in manufacturing objects and parts in just a few years. The potential of this technology is fantastic. This article will discuss various aspects of 3D printing and the importance of coding.

What Is 3D Printing?

3D printing is a technology where a printer creates a three-dimensional object, thanks to a previously designed digital model. This type of printing is a layering technology. Layering is nothing more than producing products by printing layers upon layers until the desired object is ready.

The value of this technology is that it allows the creation of an infinite number of objects. From works of art, construction parts, prototypes of all kinds, car parts, biomedical devices, or even a biological organ.

We can create objects of high complexity, which would be impossible to achieve under any other manufacturing process. Everything will depend on the 3D printer model and also on the user’s knowledge of coding. Multiple software or slicers can do the coding work for us to create particular standard objects. The reality is that the more complex creation we want to make, the more coding knowledge is necessary.

3D printing is also called additive manufacturing. Other names we call this technology are:

- Additive processes.

- Additive techniques.

- Layered additive manufacturing.

- Layered manufacturing.

- Solid free-form manufacturing.

- Rapid prototyping.

What Is G-code?

It is impressive to observe the technological advances experienced by 3D printers in a short time. Today’s 3D printers are not only surprisingly small and precise, but they also perform almost all of their processes in an automated fashion.

Automation benefits us from knowing that the latest equipment is less likely to make mistakes related to manual operation. Every automated process has a standard programming language. In the 3D printing technology, this language is coding or G-Code.

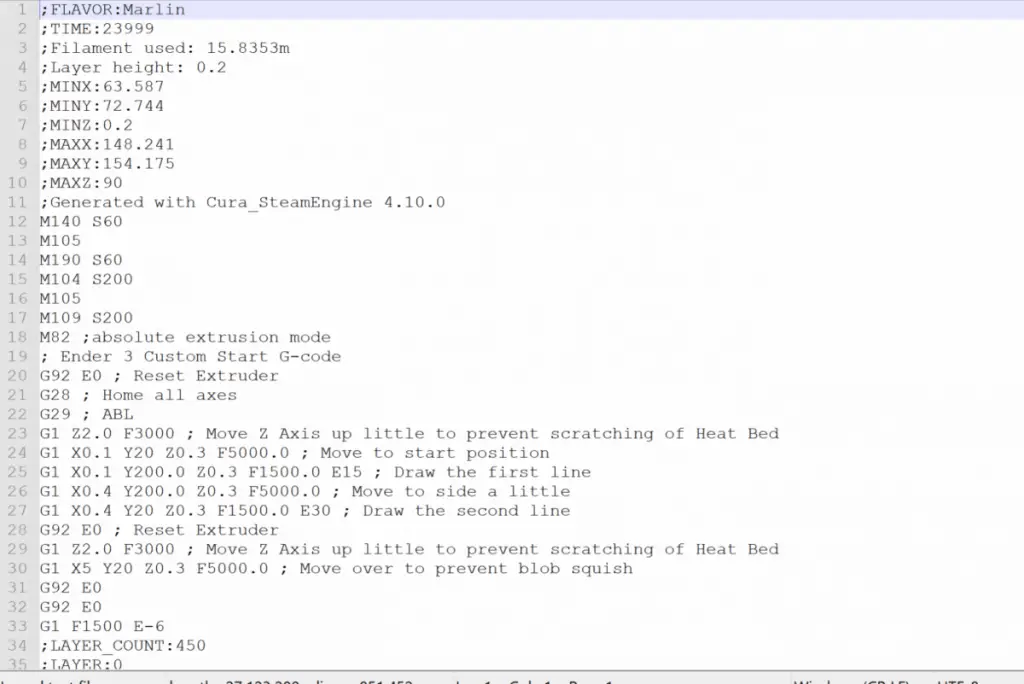

The G-Code is the programming language in numerical codes necessary to give commands to a machine through the computer. In other words, it is the language that is compatible with the computer that drives the machine and communicates all the necessary instructions for the device to do the movements and actions required.

G-Code is the standard language for many industrial or portable machines. Still, you are likely more familiar with this term, thanks to 3D printers. However, it is also possible that you have no direct activity with the coding of such equipment, which is quite common.

There are many software or slicers available whose primary function is to generate the G-Code automatically. So, a person who starts in this technology casually would not need to know coding to manufacture some objects. However, suppose you are interested in developing a deep and professional knowledge of this printing technique. In that case, it is necessary to learn all about G-Code.

By knowing G-Code, you will be able to solve printing problems. You will also be able to control the process better. You are also opening a new professional field to develop a career that will generate economic dividends.

The G-Code is a set of sequential command lines that tell the 3D printer what tasks to perform. The printer performs these instructions one by one until the sequential code is ready.

The term G-Code is the generic name for the whole 3D printer coding process. However, the reality is that there are two types of coding: the general commands or G-Code and the miscellaneous commands or M-Code.

The G-Code is responsible for the various movements of the printer. It also controls the three axes of the print head and for the extrusion of the filament. The M-Code is responsible for instructing the machine to perform non-geometric activities. These activities include nozzle heating, bed heating, and fan control.

So, What Is G-code In 3D Printing?

G-Code is the language we use to be able to print 3D models on the printer. If we want to achieve this, converting the design file (most likely an STL format file) into a G-Code sequence is necessary.

In many cases, the slicer software does this conversion for you. The slicer converts the STL design file into a G-Code sequence compatible with the 3D printer. The slicer will indicate the instructions for movement, extrusion, heating, and detection, which will make it possible for the printer to manufacture the 3D object.

Is It Essential To Know To Code In 3D Printing?

It is pretty common to find people who have been working with 3D printers for a long time and do not know what G-Code is. The explanation for this is that the slicer cutting programs take care of converting design files to G-Code and generating the sequence of instructions to the printer.

This process happens automatically, so the operator never directly sees all the G-Code commands and sequences generated by this software.

With all these elements clarified, it is pertinent to say that the absence of knowledge of G-Codes will not prevent you from using the 3D printer. However, understanding the coding process and its creation will allow you to use this device better. You will be able to create complex objects or parts and can dedicate yourself professionally to 3D printing.

The slicer makes the conversion process to obtain the G-Code invisible to the operator. However, this software also allows us to export the code to review and correct it manually. This code review option will optimize printer performance, catch errors and solve problems intelligently and in advance.

A person who knows G-Code will be able to bring highly complex designs to a successful conclusion. For example, complex geometric models with protruding areas have a high probability of failing during printing when using an automatic slicer. If you know G-Code, you can go deep into the design and manually make necessary adjustments.

But the idea is not for you to worry about this topic. You don’t have to be a computer whiz to learn G-Code. There are programming and G-Code courses that are very easy, and many of them are aimed primarily at beginners with little or no knowledge of the subject.

The Future Is In Coding

Coding is a precious skill today, and we are sure its importance will continue to grow day by day. There is an impressive shortage of programmers in the world. Many countries already have coding as a subject that is part of the curriculum of some careers. There are even schools that teach it to children from an early age.

In addition, another important aspect of coding is that it contributes to the development of logical thinking. The ability to code allows us to access additional unseen features of a device, which opens up the possibility of advanced and unique creations.

Related Articles

- Create a Temperature Tower Using Cura – The Easy Way

- 3D Printing Blobs and Zits: Tips to Avoid Them

- How to Print a File from Thingiverse (The Easy Way!)

- Cura VS Simplify3D – Which is Right for You?

- Cura Hacks – My Picks!

A Final Thought On Coding In 3D Printing

In many cases, people who want to 3D print will not have to worry about learning G-Code; the slicer software will cover all the coding. However, knowing how to code is indispensable to achieve innovative and advanced results in 3D printing when it comes to reproducing complex objects.

Make sure you check out my YouTube channel, and if you’d like any additional details or have questions, please leave a comment below. For more 3D printing articles click here.