Nowadays, many 3D printers come with a heated bed. But if you’re working with PLA, would you even need one?

Polylactic acid (PLA) doesn’t need a heated bed. Heated beds increase the temperature to improve adhesion and prevent warping, but since PLA is used at relatively low temperatures, it doesn’t need it. However, using one may be advantageous.

Want to know more about PLA and 3D printing? Read this article as I’ll discuss PLA and its applications, especially in 3D printing. I’ll also discuss why a heated bed for PLA is unnecessary, when you need one, and how to avoid warping without using a heated bed.

PLA in 3D Printing

PLA is a popular choice for filament in 3D printing. The filament is the material melted by the machine and applied in layers to create the target model or product. It’s a recommended starting material for beginners because it’s easy to work with and comes in various colors.

Would a PLA Need a Heated Bed?

Heated beds help make the printing process easier. However, since PLA is used at relatively lower temperatures, around 60°C (140°F), there are a few issues like warping. Thus, you can often do without one. However, there may be cases where you would need one.

But before we go in-depth into what scenarios you might use a heated bed for, let’s talk first about what a heated bed is and why it’s not needed.

What Is a Heated Bed?

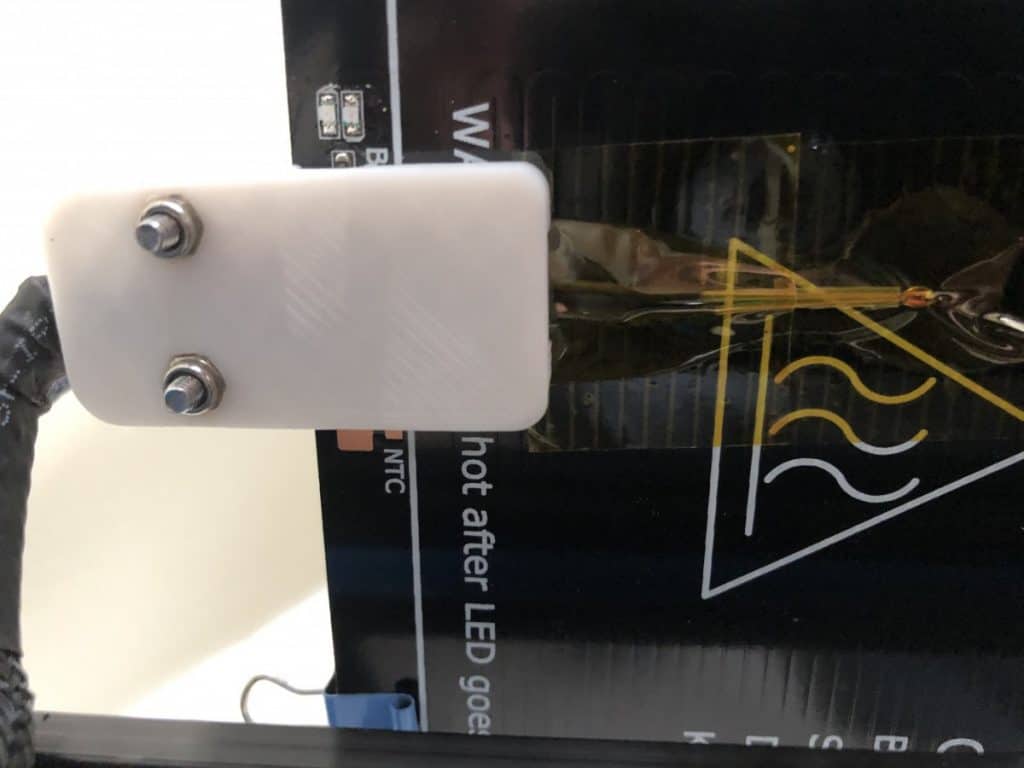

Nowadays, a heated bed is a (nowadays) common, additional component to a 3D printer. They can be made of circuit boards or PCBs that heat the printing bed. They lay on top of the printing surface and may have a spreading surface to dissipate heat.

Some heated beds may also come cheaper than others. Certain types may also be more durable and suited for complicated projects.

Types of Heated Beds

Here are a few common types of heated beds:

- PCB heater/heat bed. One of the earliest and most common types is the Printed Circuit Board (PCB) heater/heat bed. There are a few issues with this heated bed. First, they take quite some time to heat up. Next, some uneven heating can cause some sides to heat faster than other sides. Also, they can’t be exhausted or used that much, especially for complicated projects, since they’re vulnerable to damage.

- Heater mats. Heater mats can be made of aluminum and silicone. Heating elements are sandwiched between two layers of silicone, which is an excellent insulating device.

- Kapton (polyamide) film heater. A Kapton heater consists of polyamide films that are thin enough to heat and cool down quickly. This is a great feature because while we want the print to warm while printing, we also need to cool down efficiently to remove it. Also, PLA sticks nicely to it.

Why Would PLA Not Need a Heated Bed?

PLA doesn’t need a heated bed because of its low glass transition temperature. This is the temperature at which the material turns from rigid to rubbery, allowing it to stick better to the bed.

The reported glass transition temperature for PLA varies, with sources stating 50°C (122°F), 55°C (131°F), and 60°C (140°F).

Also, PLA retains heat better than other filaments. As such, it stays warmer than others, allowing it to stick better even without a heated bed.

When Do You Need a Heated Bed?

Even though PLA doesn’t often need a heated bed, there are cases when you’d need one. For instance, large, complex projects would need it for easier printing and adhesion. Relatively cold places may also need it.

In general, many recommend getting a heated bed. It makes 3D printing easier and reduces mistakes.

How Does a Heated Bed Help?

A heated bed keeps the first layer hot, which makes it sticky. Being sticky, it adheres better. A stable and sticky first layer is critical for a successful model since this is the project’s base. The layers build on it; thus, you need it to be as stable and as sticky as you can.

Next, adding hot layers onto a cooled first layer causes it to warp. Thus, you need to keep the first layer warm throughout the whole printing process. A heated bed achieves this effect and so keeps your model from warping.

Also, it helps in the easy removal of finished pieces, especially when the optimal temperature is set. The bed gets warm enough to adhere but not so much as to make it hard to remove. Thus, when it has cooled down, you can just pick it up without scraping anything.

Disadvantages of Heated Bed

Having a heated bed is highly recommended, but there may be things you should know about before getting one. These are:

- Pre-heating may take a long time. Before starting the printing process, you must make sure the heated bed is warm enough, and the heat is spread evenly. It’s like baking – too cold, and the product will be ‘uncooked’ all the way through. If heating is uneven, it may also induce warping.

- Need optimal temperature range. A study has found that while PLA adhesion may increase with temperature, after 60°C (140°F), the reverse happens. The material adheres less to glass when the temperature exceeds 70°C (158°F).

- The base may expand. Heat makes objects expand. A heated bed constantly warms the bottom layer and allows it to grow wider than you may want.

- The base may bulge or have an “elephant’s foot.” Too high temperatures can cause an “elephant’s foot.” This is when the first layer swells or grows bigger. It may also happen if the product is too large.

How To Avoid Warping Without a Heated Bed

If you’re just making fun, little, and simple projects using your 3D printer and PLA, then getting a heated bed may not be a priority. You can turn to some easy (and inexpensive) hacks to mimic the effects. Here are some ways:

- Use tape. Instead of laying the extruded layer directly onto the printing bed, lay down some tape. You can use masking, Kapton, or painter’s tape. Generally, blue painter’s tape is recommended. It keeps your first layer stuck to the bottom, preventing warping and failed products.

- Use glue sticks or hairspray. Spread a thin layer of glue stick or hairspray to keep your layer from peeling off and warping. Hairspray is often used with glass. The residue film from the spray can be easily peeled off afterward.

- Use specalizd adhesion options. Specalized options like Beld Weld, availabel on Amazon, work greate as well. This is what i personally use and have had great success with it. It will also last a long time. I bought one bottle over a year ago and still about 80% full.

Related Articles

- PLA vs PLA+ – What’s the Difference?

- All About 3D Printer Plastic

- Can You Drill Into and Cut 3D Printed Plastic?

- Does PLA Need to Be Kept Dry?

- Can You Spray Paint PLA? Details Inside!

- Best PLA Glue – The Answer Inside!

Final Thoughts

If you’re just starting with PLA and doing small projects, you may not need a heated bed. But, if you get into it for the long run, consider getting one or having a 3D printer that it comes with. It makes life easier and allows you to explore more possibilities.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.