Single color objects are perfectly adequate for most 3D prints. If you want to add coloring and other details, most people just use paint. But what if your printer could extrude the appropriate color at exactly the right time so that you don’t need to paint it?

You can mix 3D filament colors by pausing the print and swapping out the filament feed. Another way is to feed your filament through a color blender which uses ink markers to color the plastic just before it gets extruded. Machines like the Pallet 3 do the best job at combining filaments.

Those aren’t the only ways to mix 3D filament colors, dual extruders also exist, we’ll cover those later. Another way of mixing filaments is by printing the parts separately and then putting them together afterward.

Here, we’ll go through all the methods so you can decide on whether to go for an exquisite filament blending machine or just tackle the job manually without buying anything.

Manual Color Changing (Layer Swapping)

Replacing filament during a project is nothing new to 3D printing. Normally when the current spool runs out, but you can also change filament colors if you want the top of the print to be different.

Pause the print at a certain layer height and load a different color filament for a multicolored effect. Of course this will limit the color change to certain layer heights, one color per level. If you want multiple colors on certain heights, you’ll need a Palette or dual extruder set up. We go over both later.

Having said that, this technique is particularly effective when the object you’re printing has different features at different heights. Here’s an example: you can print a figurine with a brown filament at the shoe level. Pause the print once the shoes are printed. Replace the filament with blue for the pants. Pause when the pants levels are done, choose your next color for the shirt, and so on.

One of the most common uses of this method is creating badges or logos on a base plate. Print the base of your design in a certain color, pause the print, swap the filament, and print the text and other graphics in a different color. This gives the print excellent contrast and makes the text pop out visually.

It isn’t the best way to mix 3D filaments but it won’t cost you anything extra and with some practice, you can produce some good looking multicolor prints.

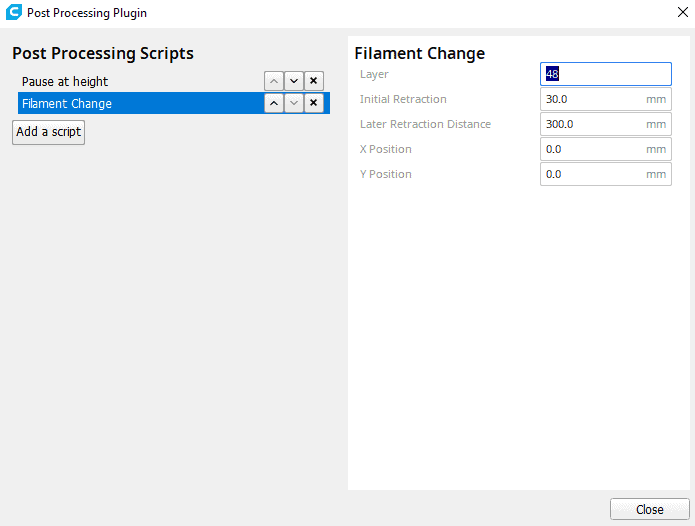

Create a pause in Cura:

- Hover over extensions.

- Click on post processing.

- Click on modify G-code.

- Click on Add a script.

- Select Filament Change.

- Insert the value of the layer height of where you want to swap filament.

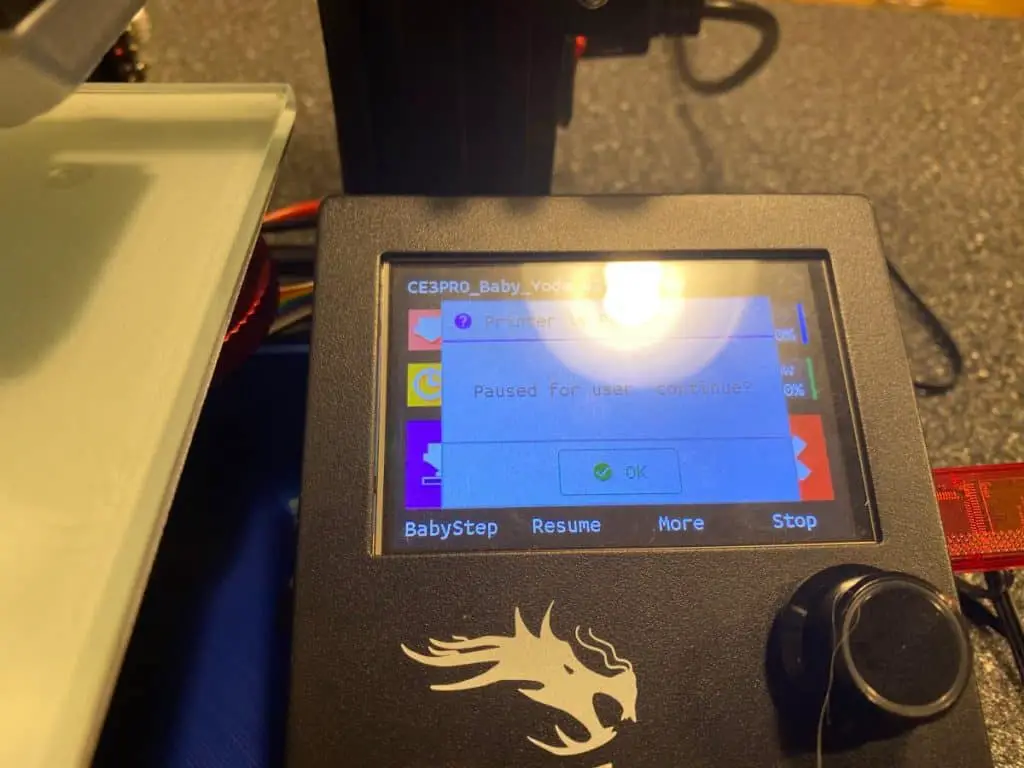

The print will pause at that level for you to change the filament color.

Pros

- Doesn’t cost you anything extra to do, except time.

Cons

- You can only print one color per level.

- Sometimes the new filament won’t stick to the previous levels.

Multi-Material Machines

There are a few options for multi-material machines, but we find that the Palette series from Mosaic is one of the very best. Here, we’ll go over their latest model, the Palette 3.

Palette 3

The standard Palette 3 can combine four different colors and the Palette 3 Pro can combine up to eight colors or materials.

Feed four different filaments into one end, and watch as one perfectly merged filament comes out the other side. These machines cut and join the different filaments so that it extrudes the appropriate color at exactly the right time. When the 3D printer needs to get to the next color, it extrudes the remaining filament in the nozzle into a separate “waste cube” so that it can get to the right color before continuing the design.

The Palette is very easy to set up. Clip the stand into the back and attach the filament pipe from the Pallet to your printer. The instruction manual lays the procedure out very well.

Download and install the free CANVAS software. Update the firmware and you’re ready to create a new project in CANVAS.

For inspiration, go to thingiverse.com to see all the multicolored designs.

The Pallet 3 works with most 1.75mm 3rd party filaments to create perfectly merged materials.

Have a look at the new Palette 3 on the official website.

Pros

- It can print any part of the object in a different color or material.

- Different colors or materials at the same layer height.

Cons

- Consumes more filament.

- The machine is very expensive.

Dual Extruders

You can mix 3D filaments by using a dual extruder. It’s just two extruders that work independently from each other. One at a time, the extruders lay down the material of each layer before moving to the next. One extruder parks on the side while the other does the work, basically like a relay race. As soon as one finishes, it parks to give space for the other one to come in and print.

So if you load different colors into each extruder, the result is a multicolored print. This method is very useful for printing support structures with a dissolvable material and printing the model using a different material. It makes it very easy to remove the supports.

Pros

- You can print two colors at the same height. Like brown hair over a head

Cons

- Dual Extruder setups are expensive.

Ink markers

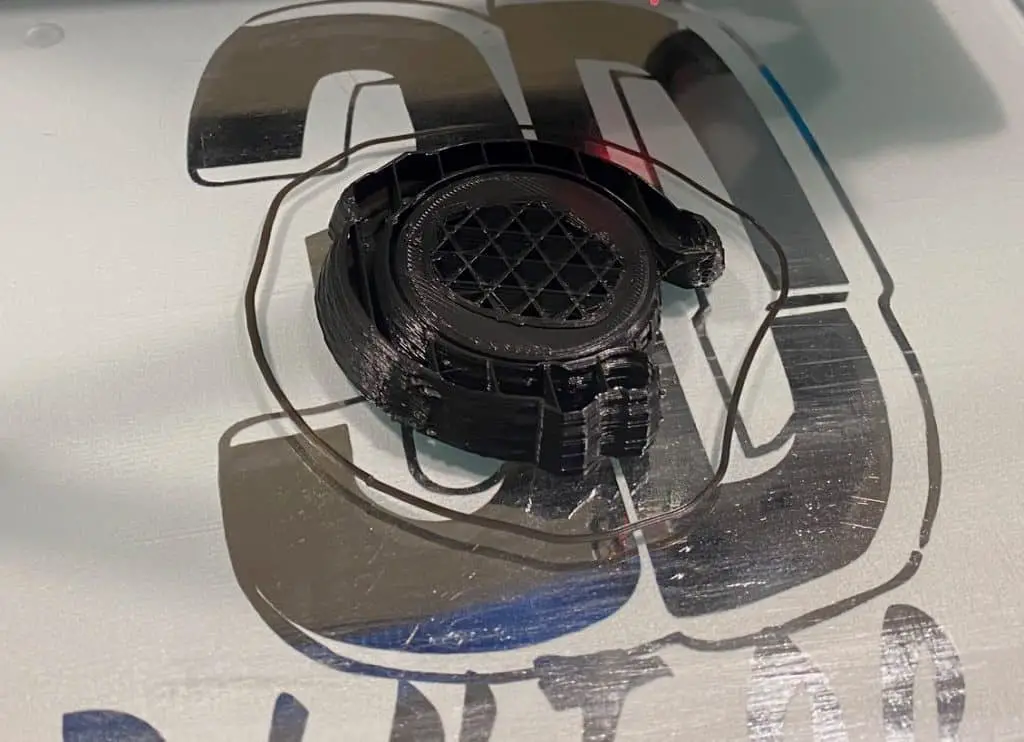

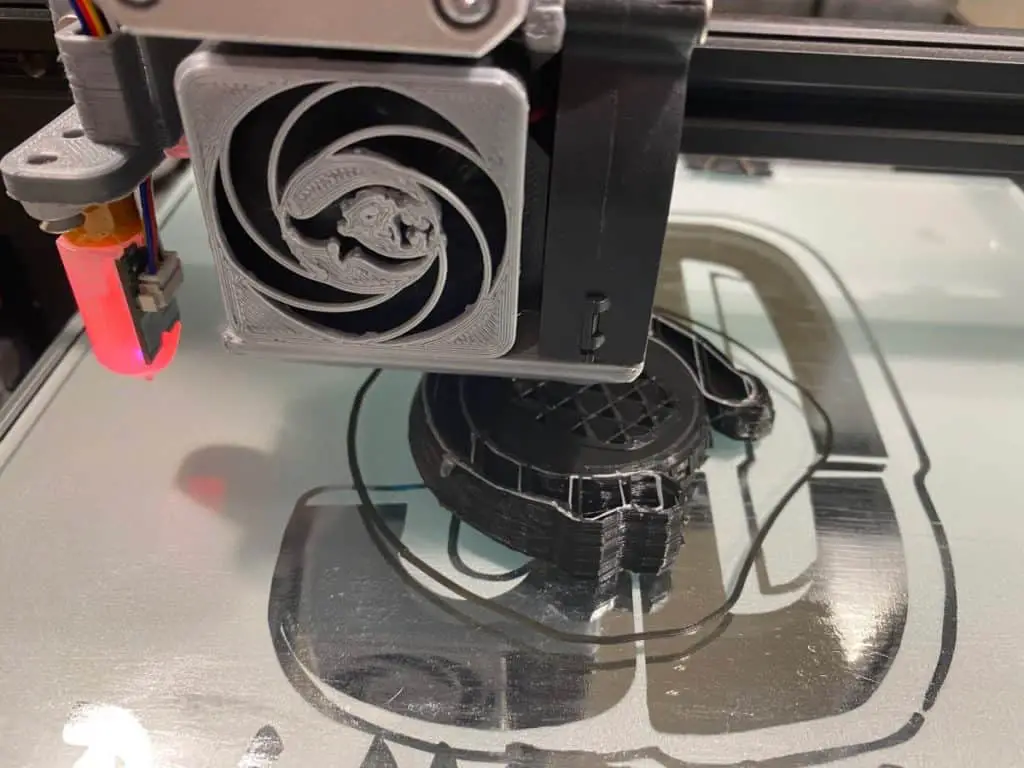

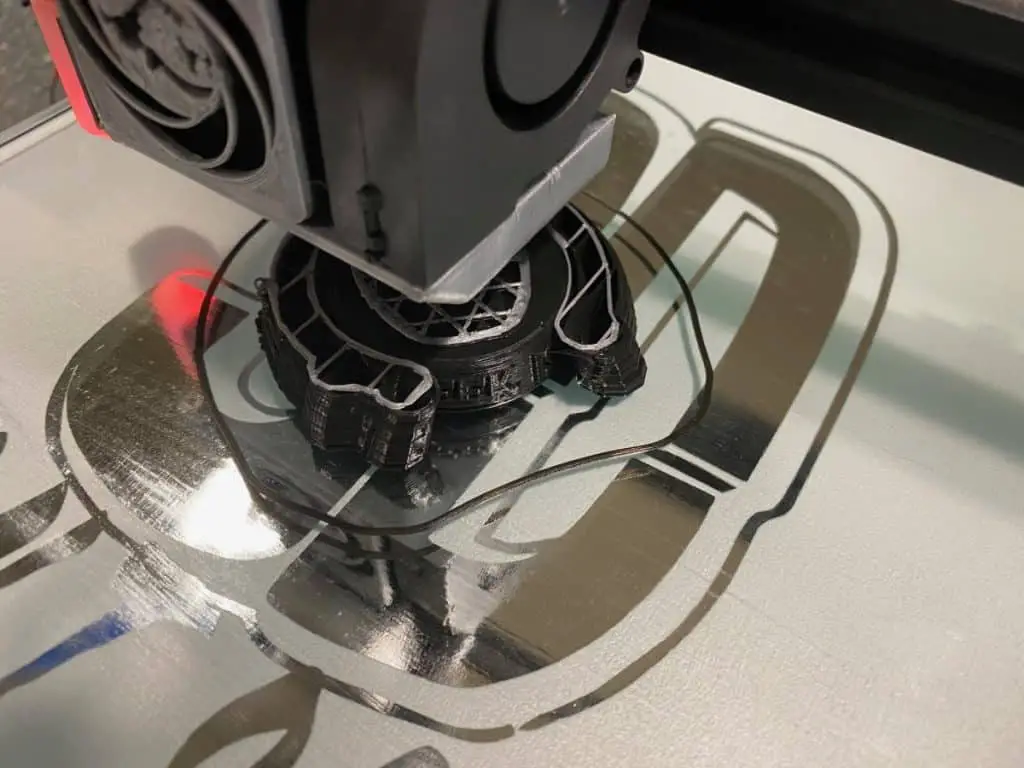

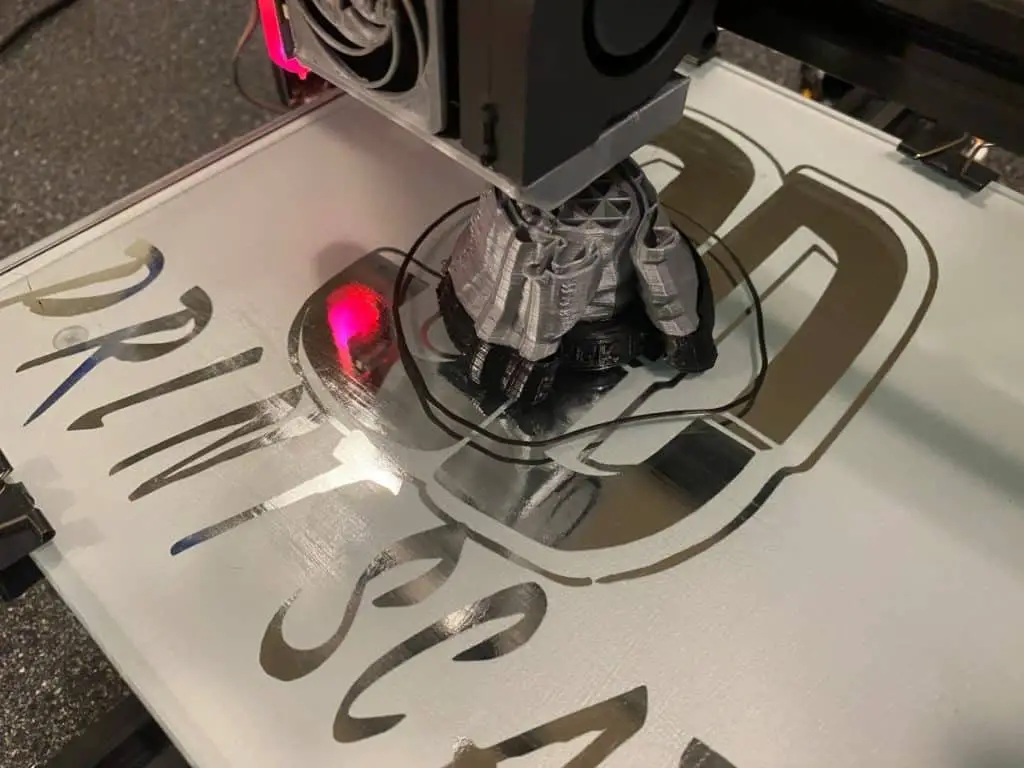

We’ve added this to the bottom of the article because it doesn’t involve mixing 3D filament colors. But it’s still on the list because it gets the job done of mixing different colors into one 3D print. You can color your filament with ink markers as it goes through your machine. Simply print this design out and attach it to your printer. (This design is for an Ender 3 and Ender 3 Pro)

Once printed, attach the color blender to your machine. Load up some Sharpies and they’ll color your filament as it moves through the attachment. This is such a simplistic 3D printing hack that you might wonder if it actually works, it does. Although you won’t get consistent results, the flow of the ink is not reliable, which results in varying gradients of colors. This is a good way to add specific colors to different levels of the print. As the job prints, insert the correct color sharpies for that level.

Keep an eye on the print as it goes and pop in the right colors as you see fit.

This technique works best with transparent and white filament.

Pros

- Minimal cost to get started.

- Easy to add and subtract color as you print.

Cons

- Inconsistent. You may get two different results using exactly the same colors.

- You need to change the colors manually, so be prepared to invest some hours into it.

- You can only change the colors of the layers, not specific parts of the print.

Related Articles

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

- What Computer Do I Need for a 3D Printer?

- Cura Profiles

Conclusion

You can mix 3D filaments in many ways. From manually swapping out filament during a print to using high-tech machines like the Palette 3 that do all the merging for you. Adding color to your filament with ink markers is an affordable and fun way to add color to your filament.

Dual extruders can print two colors on one level but are very expensive. The best way to mix 3D filaments is by using the Pallet 3. It can print four colors on one level and the Pallet 3 Pro can print eight. This is the only way you’re going to get precise color detailing on your prints without using dual or multi extrusion machines.

Most 3D printing enthusiasts are overwhelmingly excited about this technology, especially the ones who don’t want to spend time painting their prints. It’s far better to have the material of the right color as opposed to painting it because painting takes plenty of time and concentration. Paint also fades and wears off after some time.

There are already some 3D printers that have filament merging capabilities, but in a few years time there will probably be a lot more.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.