If a 3D printer can print details in any direction, why would you want to engrave it? Although 3D engraving also becomes useful to add fine detail to already completed projects, it’s used more for creating new art on different materials like wood.

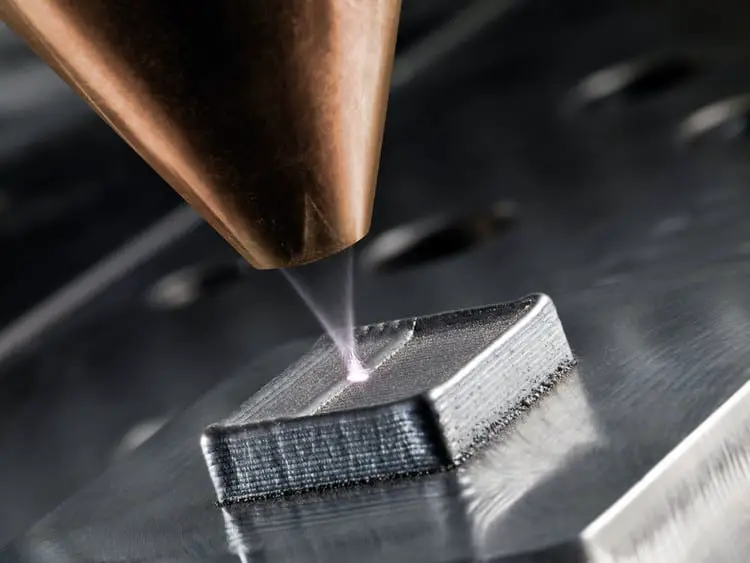

3D printer engraving involves burning images or words into wood and other materials with precise detail. This is done by attaching a laser engraver to your 3D printer. 3D printer engraving technology means that you can engrave in every direction, including varying depths for unique sloping angles.

The laser engraver shoots out a laser beam, aiming at a specific point below the surface of the material. As soon as the laser has removed all the material in its path to that point, it moves to the next point and repeats the process.

Wood is what most people are engraving on these days because it’s soft and reactive enough for the laser to easily vaporise and discolor. Plywood is relatively cheap and makes for a perfect artwork material.

3D engraving is perfect for creating logos and pictures on surfaces like wood, acrylic, leather, cork, and other soft materials.

Advantages Of 3D Engraving

These are the advantages of having that third dimension to move around in:

- It’s easier to target and achieve different colors in the engraving because the laser can move down or up to the optimal height to shoot the laser out. 2D printing lasers lose some energy when they travel far down to reach the target area.

- 3D printer engraving usually provides a bigger area to engrave in.

- You can engrave on different shapes with 3D printers, spheres, or other curved objects. 2D laser printers are limited to flat surfaces.

- You can engrave deeply with 3D printers because of your programmable Z-axis to move up and down.

- Because you can move so close to the material, you can get better results from lower-powered lasers. You can also make markings that stand out more for the same reason.

What Is Laser Engraving?

Laser engraving is the process of burning away sections of a material with a laser beam to create pictures or text with extreme accuracy. Kind of like drawing a line in the sand with a stick, but instead of displacing the material, the laser vaporizes it.

Laser engraver attachments are available for 3D printers to connect and operate with your software.

Low Priced 3D Laser Engravers

If you’re just looking to experiment, there are laser engravers that are very affordable. This one on Amazon will allow you to cut thin wood and acrylic given enough time. Even though the laser is daily low powered at 500mW, it still works great to engrave on wood.

If your passion for 3D engraving grows bigger, you can upgrade to a higher-powered laser to use on harder materials. High-powered lasers also get the job done quickly, but that’s something you have to pay for.

Can A Laser Engrave Metal?

You can’t laser engrave metal the same way you do wood. The lasers you attach to 3D printers aren’t powerful enough to vaporize the metal. However, laser etching on metal is possible. Laser etching involves shooting a laser onto the metal, causing a chemical reaction which changes the color of the material.

If you have a laser with more than 60 W of power, you should be able to etch beautiful artwork or fine print onto metal surfaces. Depending on the hardness of the metal, the image can fade away, soft materials lose the image quicker than hard metals. The stronger the laser, the longer the image will remain. If the etching is done with the right amount of power on the right hardness of metal, it can last forever without fading.

3D Laser Wood Engraving

Wood is perfect for laser engraving. It’s soft enough for the laser to vaporise instantly as it passes over. Laser engraver upgrades range from a couple hundred dollars to many thousands of dollars, but if you’re only planning to engrave wood, you can definitely get a decent engraver at a reasonable price.

Can A 3D Printer Cut Wood?

Yes, any 3D printer with a laser engraver can cut wood. The higher the wattage of the laser, the quicker and deeper it will be able to cut. A 100W laser can cut 20mm deep into plywood.

3D laser engraving is ideal to use on wood. The laser easily cuts straight through the wood if required, but is also accurate enough to only slightly discolor certain spots.

Hardwood is the best type of wood to laser engrave on, but is a bit more expensive than plywood. If your project is less than 1mm deep, plywood will be fine because you’ll probably only be going into the top layer. For engravings that are 2mm or deeper, solid wood is ideal as the wood is consistent all the way through.

3D Laser Engraving Safety Advice

You need to wear safety glasses that are rated to protect against 455nm long laser beams. Wear the glasses from the moment before you switch the laser on to the moment you switch it off.

Keep the laser lens clean with an alcohol swab to avoid any reflections from dirt.

Laser engraving is essentially burning materials. Make sure you’re engraving in a well-ventilated room, especially when engraving wood as there will be smoke coming from the burning materials.

Since you’re working with something that can cause a fire, keep a fire extinguisher in the room and make sure it gets serviced regularly.

3D Printer 3-In-1 Machines

3-in-1 one machines have the capabilities of 3D printing, laser engraving, and laser cutting. These machines, with all the technology they sport, are quite pricey, starting in the region of $1500 to $2000.

The Snapmaker 2.0 is a prime example of a capable 3-in-1 machine. It handles 3D printing, laser engraving, and CNC cutting. The A350 model boasts a 320 x 330 x 350 build volume for all three functions.

Can A 3D Printer Do CNC Work?

Yes, 3D printers can do a certain amount of CNC machine work. But some parts are simply too big for 3D printers to take on, that’s where large CNC machines come into play. 3D printer laser engravers don’t work on metals as effectively as CNC machines do.

Related Articles

- 3D Printing vs. CNC Machining: What’s the Difference?

- How to Print a File from Thingiverse (The Easy Way!)

- What Is 3D Printer Resolution?

- What Computer Do I Need for a 3D Printer?

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

- Cura Profiles

Recap

So 3D printer engraving is essentially carving pieces out of an object with the use of a laser upgrade for your printer. With the 3D printer being such an accurate machine, it only makes sense to attach different tools to it. You can print a part with your 3D printing material and then add some high-level detail to the exterior with the laser. But most people use 3D lasers to create new artwork, mostly on flat surfaces.

3-in-1 machines have lasers included, but you can upgrade your machine with an add on laser engraver at a much cheaper price. Even if you buy a 3D printer and laser engraver, it will still be cheaper than the 3-in-1 machines.

If you’re interested in using a laser engraver on your 3D printer, you can get a low cost one to test the waters, you can get them for under $100 and they perform very well on wood.

Remember to be cautious when working with any laser, wear your eye protection while the laser is powered up.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.