Those in the manufacturing business would know that there are plenty of choices when it comes to the methods of manufacturing that they can use. 3D printing is quickly becoming popular because of how it minimizes wastage and allows you to produce products efficiently. However, molding has always been one of the most popular ways of producing products as well. But is 3D printing cheaper than molding?

3D printing is cheaper than molding only when it comes to small-scale production that requires you to produce fewer products at a time. However, when it comes to medium to larger scales of production, molding becomes more affordable when it comes to the cost per product.

The thing you need to know about 3D printing and molding is that both of these manufacturing methods have their own ups and downs in relation to their costs. As such, it would be great to know how much these methods will cost you with respect to the scale of your production so that you would know which method is the best for you.

How much do 3D printing and molding cost?

When it comes to those in the production or manufacturing business, there are plenty of different manufacturing methods that can be used to produce different types of products. Two of the most popular ways today are 3D printing and molding. Both of these production methods have their own unique pros and cons that manufacturers should know if they want to be able to produce the best products at the lowest possible costs.

In that regard, one of the things that manufacturers tend to look at when it comes to production methods is the overall cost that they will incur when they choose a certain method. That’s because the cost of production is where everything starts. Lower production costs can mean a higher profit margin. So, in that regard, how much do 3D printing and molding cost?

How much does 3D printing cost?

3D printing is quickly becoming a popular method of production because of how cost-effective it is and how it minimizes wastage. Plainly speaking, you will only spend and use the materials that you know you will use when you 3D print a certain product. That is why 3D printing tends to be quite cost-effective.

However, the thing you need to know about 3D printing is that the cost of production is so varied because of how different products have different sizes and materials required. That is why it can be difficult to truly tell how much 3D printing will cost, as there are plenty of different variables that we need to look at.

Then again, if you are a manufacturer, the cost of production when it comes to 3D printing has to be somewhere between $0.70 and more than a thousand dollars. This means that the cost can be anywhere, as it will depend entirely on what kind of product you intend on producing.

How much does injection molding cost?

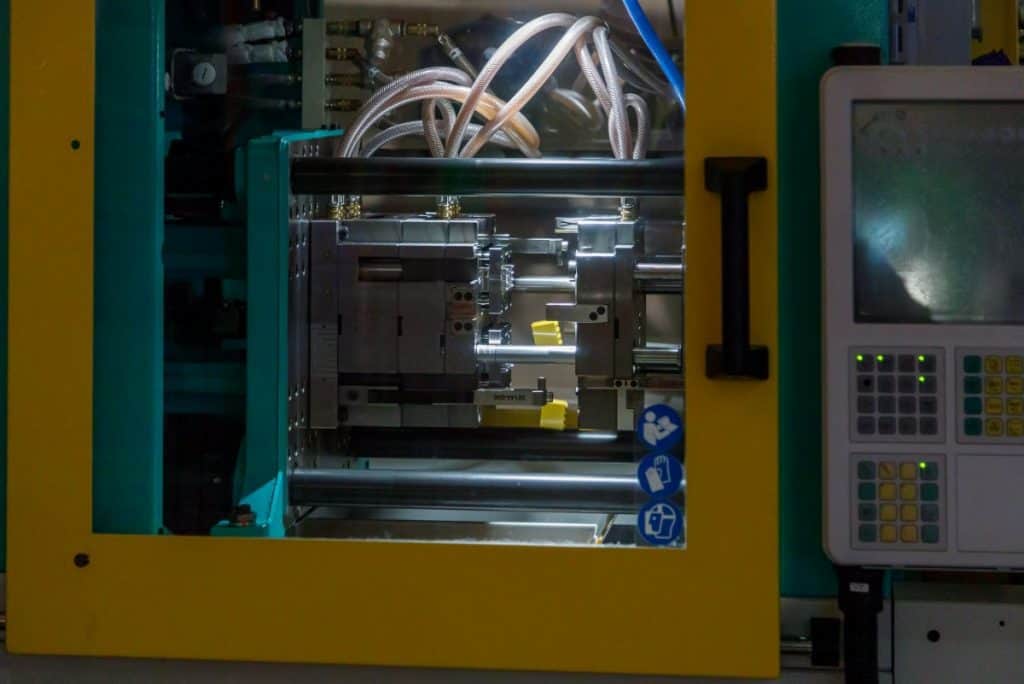

Injection molding or molding has always been one of the best ways to produce products in a way that is cost-effective and minimal in terms of wastage. That said, how much does molding usually cost?

The cost of molding will depend on the mold itself as well as other key factors, which include the size of the product, the materials used for production, and the complexity of the product. In a sense, it is quite similar to 3D printing because everything boils down to what the product is.

However, the difference maker here is the mold. Because you are using a mold that can produce a lot of products at the same time, you need to invest a lot of money to build that mold. That is why the cost of molding can be somewhere between $1,000 to nearly $100,000. Meanwhile, the cost per part in molding tends to be somewhere close to $0.20

Is 3D printing cheaper than molding?

Now that you know how much 3D printing is when compared to molding, let us now look at which between these two methods of production is the more cost-effective one.

At first glance, one would easily think that 3D printing is the cheaper method of production because the cost per product tends to be very affordable. And, other than the 3D printer that you will be using, the initial investments of 3D printing tend to be quite affordable for most entry-level and small-scale manufacturers as well. This is why 3D printing is quite popular.

On the other hand, when you look at molding, you will see that this method of production has a much higher initial investment but a lower cost per product. Most people would immediately say that molding is more expensive than 3D printing, and that is true to some extent. However, you have to look at it from a different perspective.

Plainly speaking, because of how low the initial investment is when it comes to 3D printing, it is actually true that 3D printing can be cheaper than molding. And this is mostly the case when it comes to small-scale production that only requires you to produce a few products at a time. That is why small businesses tend to favor 3D printing.

However, when it comes to business than need to produce more products at a time, that is where molding tends to perform better. It might be true that molding does require a higher investment because you need to have the mold created, but it becomes more cost-effective when it comes to producing more products.

Look at it this way. The problem with 3D printing is that, while it does only have a minimum cost per product of about $0.70, you need to understand that most 3D printers take time to print a product. And 3D printers usually do it one at a time. So, despite the low initial investment, the higher cost per product and the time it would take to produce the product are the downsides to 3D printing.

On the other hand, manufacturing at a comparatively larger scale needs to be efficient in terms of cost and time. So, despite the fact that molding does have a higher initial investment, it makes up for that with the lower cost per product. On top of that, you can produce more products at a time with molding because all you need is one single mold that can produce several products at a time.

All that said, if you are merely starting out as a smaller business that cannot afford a mold, it might be better for you to begin with a 3D printer. However, when you have a reason to believe that there will be a higher demand for your product, that is when you might want to use molding instead.

Related Articles

- Will 3d Printing Replace Injection Molding?

- What Shapes Cannot Be 3d Printed? – Details Inside!

- Will 3d Printing Replace Machining? (We Find Out)

- How to Print a File from Thingiverse (The Easy Way!)

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.