Introduction

The number of businesses using 3D printing, which first served as a tool for rapid prototyping, has increased dramatically in recent years. While specific use cases and sectors vary, some common examples include functional and visual prototypes, tooling assistance, and even finished products.

As the technology’s potential uses expand, innovative business models and prospects are being developed as a result of 3D printing.

Five Prominent Industrial Applications Of 3D Printing

1. Automotive Industry

There has been rapid adoption of additive manufacturing technology in the automobile industry, with prominent businesses employing the technology. Everyone from professional racing teams to original equipment manufacturers (OEMs) for the world’s leading automakers are using the capabilities of 3D printers.

The initial benefits of the 3D printing sector for the automotive industry were concentrated on the creation of tools and fixtures to improve production. Most of the components printed by automakers are prototypes, cradles, and fixtures, all of which must be rigid, sturdy, and long-lasting.

However, high-strength, fiber-reinforced end-use components are now also printed with industrial 3D printers. For instance, Bugatti employs 3D printing technology to fabricate titanium brake calipers and exhaust finishes. Also, Garry Rogers Motorsport prints out steering wheels and other functional parts on a high-end 3D printer.

Some people even utilize high-end 3D printers to make new components for vintage vehicles. It makes sure there are enough parts for classic cars as well as for regular upkeep and repairs.

2. Education Sector

More and more classrooms are teaching students how to use 3D printers. Because it eliminates the requirement for costly tooling, 3D printing in the classroom helps the students effectively prepare for tomorrow by allowing them to produce prototypes. Students gain hands-on experience with 3D printing technology as they create their designs and print out physical models for science projects.

These days, it is not uncommon to see a 3D printer in a school or public library setting. Students at colleges and universities now have access to 3D printers for use in lectures and research. Several companies like Sculpteo and MakerBot are facilitating educational institutions with 3D printing adoption by offering their services and tailored certification programs.

Low-cost rapid prototyping in schools using 3D printing technologies and the fabrication of high-quality, specialized tools from open-source hardware designs radically transform the education system. By investigating design, manufacturing, and structural principles, students understand the many uses of 3D printing in the modern world.

Fossils and archaeological objects can be reproduced so that students can study them in depth without risking damage to the originals in museums and galleries. They can see topographical maps from a whole new, three-dimensional angle.

Thanks to 3D printing, models with intricate mechanisms are a piece of cake for graphic design students. Anatomical dissections of the body and other biological specimens are among the tools available to research students. Also, nanoparticles and molecules in chemistry can be modeled in three dimensions.

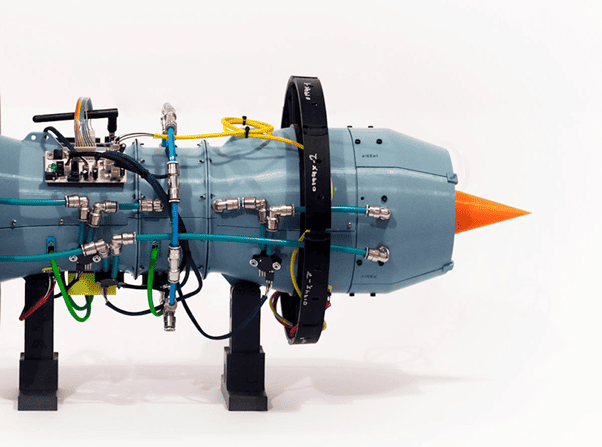

3. Aerospace Industry

The aerospace sector is known for having some of the most stringent requirements for component performance. Parts used in aircraft systems must tolerate intense heat and various chemicals, as well as endure recurrent loading while still maintaining as little weight as possible. Failures of individual parts frequently result in breakdowns of the entire system on aircraft transporting life and cargo.

Hence, failure is not a choice that may be taken. Because the precision of aviation parts is of the utmost importance, aerospace engineers have begun using 3D printing to produce inspection tools to cut costs for low-volume aircraft components. In the recent past, there has been tremendous growth in additive manufacturing, and developments in the field of 3D printing have contributed to developing improved systems for the aircraft manufacturing market.

Printing in high-performance thermoplastics supplemented with continuous fiber reinforcement (CFR) for increased strength is now possible with industrial 3D printers. One example of this type of material is ULTEM 9085 Filament. Additionally, industrial 3D printers can now print larger parts at greater speeds.

4. Manufacturing And Prototyping Industry

As opposed to the weeks or months it would take using conventional manufacturing methods, a prototype may be made in a matter of hours using 3D printing technology. Traditional manufacturing is the most economical only when producing in massive volumes. 3D printing is great when mass production is not in the cards because it enables low-cost, on-demand manufacturing of individual parts or prototypes.

Additionally, developments in RP technology have led to the creation of materials and techniques, such as Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS), that are appropriate for the fabrication of the final iteration of a product, as opposed to only the prototype.

Moreover, several manufacturing businesses are adopting a hybrid approach of leveraging 3D printers with CNC turning center setups to achieve excellent surface finish and superior dimensional accuracy for plastic and composite materials production.

Also, companies now provide mass customization services, allowing customers to design their products and have them 3D printed in a one-of-a-kind design.

5. Robotics Industry

Efficient robotics components connect nicely with 3D printing technologies due to their adaptability, lightweight, and customizability. For instance, grips and sensor attachments are both challenging to mass produce and make purpose-specific in design.

Robotics researchers employ 3D printers for everything from gripper hands to extensive robot systems to reduce product weight, allowing the equipment to move more quickly and carry more weight.

Robotics businesses can now design and create lightweight, complicated parts like end-of-arm gear at a tenth of the cost, thanks to technological advancements in the 3D printing sector. For instance, Boston Dynamics leverages 3D printing to produce lightweight and affordable humanoid parts.

Conclusion

Greater customizability, shorter time-to-market, and accelerated product development are just a few of the many advantages of 3D printing technology that are widely acknowledged by an expansive range of sectors.

Consequently, as additive manufacturing advances, we may expect several new industries and brands to follow in the footsteps of the industry’s early adopters, thereby driving the tech toward novel applications and innovations.

Co-Author Bio

Vincent Hua is the Marketing Manager at TSINFA. He is passionate about helping people understand high-end and complex manufacturing processes. Besides writing and contributing his insights, Vincent is very keen on technological innovation that helps build highly precise and stable CNC Machinery.