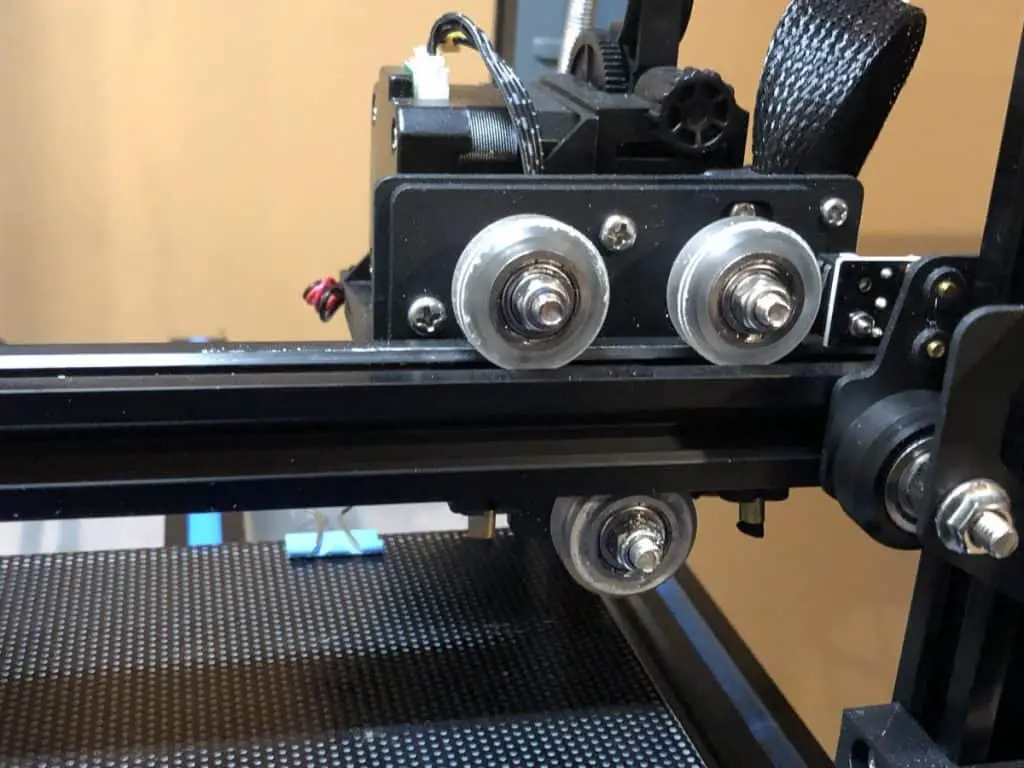

When it comes to guiding the movements of your printer, wheels running on linear rods is the cheapest solution and gets the job done well. But if the wheels aren’t installed properly, they will wear down quickly.

3D printer wheels are most commonly made from POM, which is a semi-crystalline thermoplastic and turns on a bearing. POM is a strong and rigid plastic ideal for printer rollers. But if you tighten them too much, the rails will carve grooves into the wheels.

Most of the time, grooves in the rollers aren’t an issue, but sometimes, they can cause the movement along that axis to get bumpy. This is when you’ll need to replace the wheels. They aren’t very expensive and if you don’t tighten them against the rod too much, they should last hundreds of hours without needing to be replaced. Black Creality rollers are the most popular choice on amazon.com and fit most 3D printers. Just make sure to check the sizes if you don’t have a Creality printer.

Not tightening the eccentric nuts on the wheels will cause the carriage to wobble on the rail. Some nuts are fixed while others are adjustable (eccentric). I’ll go over that in more detail later in the article.

Many people think that the debris around the wheels is dust that’s collected because of static building up on them. This is not accurate. POM shavings just look like dust once it’s been shaven off by the axis. I’ll link to a video proving this later in the article.

Polycarbonate wheels (available on Amazon) are slightly stronger, but will also wear down if you tighten them too much against the axis.

Can 3D Printer Wheels Be 3D Printed?

It may be a novel idea to print rollers for your printer with your printer, but it’s definitely not a good idea. POM and polycarbonate are much stronger than most materials you’ll be able to print with using a hobby-grade printer and they aren’t expensive enough to justify trying to print them.

Tightening 3D Printer Wheels

If the carriages on your 3D printer are wobbly, you need to adjust the eccentric nuts. Eccentric nuts have an off-center hole through the middle of them. This causes the wheel to move closer or further away from the rail depending on the orientation of the hole when you turn the nut.

Not all the wheels have eccentric nuts to tighten, so check your manual to be sure which ones do. Don’t over-tighten the fixed nuts because they won’t do anything to get the carriage closer to the rail.

Once you’ve located the adjustable nut, turn it in any direction to see if it moves closer or further from the rail. The direction could be clockwise or counterclockwise, depending on how the hole is orientated at the time.

Tighten the eccentric nut until all the wheels are touching the axis and there is no wobble in the carriage. Be careful not to overtighten them or you can dent the wheel as shown below (I learned this the hard way).

When To Replace 3D Printer Wheels

You need to replace the wheels on your 3D printer if there are any deformities on them. If the wheels are deformed, they will cause defects like ribbing on the models you print. Here’s a video on how to replace the wheels on a 3D printer.

3D Printer Wheel Dust?

If there appears to be dust building up on your 3D printer wheels, it’s probably not dust and they’re being worn away by the rails. The reason that wheels are worn down is because they usually don’t fit perfectly into the rail. Here’s the video explaining everything.

Are Linear Rails Worth The Money?

Linear rails aren’t worth the money for most people because linear rods and bearings get the job done at a fraction of the cost. Linear rails are more sturdy, easier to install, last longer, and have many other benefits. But considering that you could buy hundreds of wheels for the price of a linear rail, and the fact that linear rods already work fairly well, makes me believe linear rails aren’t worth the investment.

3D Printer Wheel Lubrication

You only need to lubricate the bearings of the 3D printer wheels once a year. As for the debris around the wheels, just clean it up with a damp cloth after every long project to keep the rollers and rails free and clear.

Related Articles

- Fix A Slipping Extruder – Details Inside!

- Quick Guide to Change the Nozzle on a 3D Printer

- Five Reasons Your 3d Printer Stops Mid-Print

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

In Summary

Installing the wheels correctly will go a long way in making sure they don’t wear down quickly. But if they’re damaged to where they are causing artifacts in the prints, you can replace them at a low cost. Both POM and polycarbonate wheels work perfectly, with POM being the slightly weaker of the two

Rollers work very well to move carriages around a 3D printer and they’re extremely cheap compared to linear rails.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.