Lubricating your printer is essential for many reasons. The primary reason is it prevents wear and tear caused by friction which ends up in damaged parts. It increases print accuracy by eliminating shuddering. It also reduces the load on the motors making your printer last longer.

Lithium grease works well to lubricate the bearings and rails on 3D printers. PTFE-based dry lubricants work well on screw rods without attracting much dust. Light machine oil works well in the extruder.

My recommendation is to use PTFE dry lubricants on the screw rods and lithium grease on the guide rail bearings. The reason grease is better suited for bearings is because it allows the bearings to roll. Grease is sticky enough to adhere to the bearings far better than other lubricants.

I recommend dry lubricants on the screw rods because is lubricates very well without creating a sticky mess.

Types Of Lubrication

Grease

Grease is the thickest type of lubrication and is a combination of oils and thickeners. Grease is very tacky which helps keep it on the parts but also collects dirt very quickly. Lithium grease is a good choice for 3D printer rail bearings. Lubricants with particles inside (dry lubricants) will cause the carriage to slide over them instead of rolling with them which creates flat spots on the bearings.

Although grease can lubricate screw rods effectively, I advise using PTFE-based lube to maximize the movement of the rod and reduce the amount of dirt build-up.

Oil

Oil is thin enough to get inside small spaces and lubricate parts without causing resistance. Lubricating oil has additives like antioxidants that protect the part from corrosion. Machine oil works well to lubricate but runs off the part due to its fluid nature. Oil also collects dust very easily.

If your environment isn’t dusty, machine oils like these will do the job but you’ll have to keep an eye on the parts and lubricate frequently.

Dry Lubrication

Dry lubrication is made up of tiny solids like silicone and graphite. Sometimes it’s suspended in alcohol or other fluids that evaporate after you apply it to the parts. This leaves the small particles behind to lubricate the part. This also means that dust doesn’t collect on it like oil and grease.

There are two main types of dry lubricants, PTFE-based and silicon-based. Silicon-based lubricants are better suited to rubber and plastic and PTFE is better suited for metal on metal friction. So PTFE dry-based lubricants are the best to use on your 3D printer. Don’t use dry lubes on rail bearings because it can cause slippage and flat spots.

This is one of the most trusted PTFE-based lubricants on amazon.com.

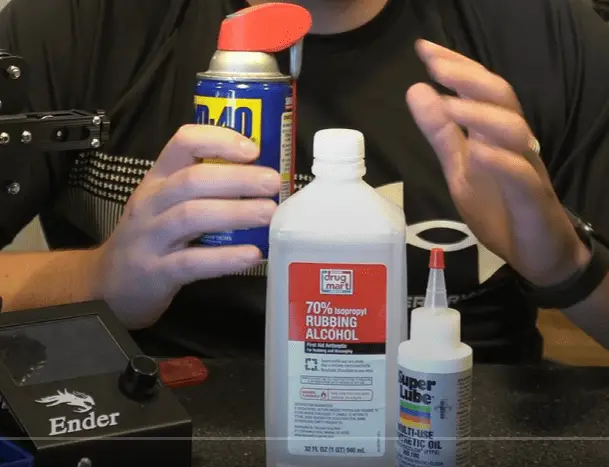

Penetrating Oil

Penetrating oils that you normally find in a spray can are not suitable to use on a 3D printer because they are too thin and run off the components easily. These types of oils, like standard WD-40, also have other chemicals that break down corrosion to loosen rusted bolts, these chemicals can cause damage to your printer. There are PTFE-based WD 40 options so make sure to use them over the standard “Multi-purpose” type.

WD 40 isn’t a good lubricant for any 3D printer component.

Do You Need To Lubricate A 3D Printer?

You need to lubricate your 3D printer for the same reasons you need to lubricate any machine with moving parts. Lubrication reduces friction and prevents seizing in machines. The most friction in 3D printers is between metal parts making PTFE-based dry lubricant and lithium grease the best lubricants to use.

You should use dry lube for the rods and extruder and grease for the rails and bearings. Grease is the best choice to make sure the bearings still turn properly.

Water-resistant greases and oils are definitely not required since your printer will always be indoors.

If you don’t lubricate your printer, parts like the screw rods, extruder gears, and pins could seize, rendering them useless.

What To Lubricate And How

Screw rods

The screw rods need the most amount of lubrication because of the metal-on-metal friction between the rod and the nuts they turn through. Unscrew the coupler from the screw rod to remove it from the nut. Apply grease to the thread of the nut and screw the rod back through it.

If you’re opting to use oil or dry lube, you don’t need to unscrew the coupler, just apply the lube to the top, center, and bottom of the rod and turn it manually to distribute it.

Wipe off any extra lubricant to avoid making a mess. If you use lithium grease you’ll need to wipe off the excess grease but with PTFE dry lube you normally won’t have to.

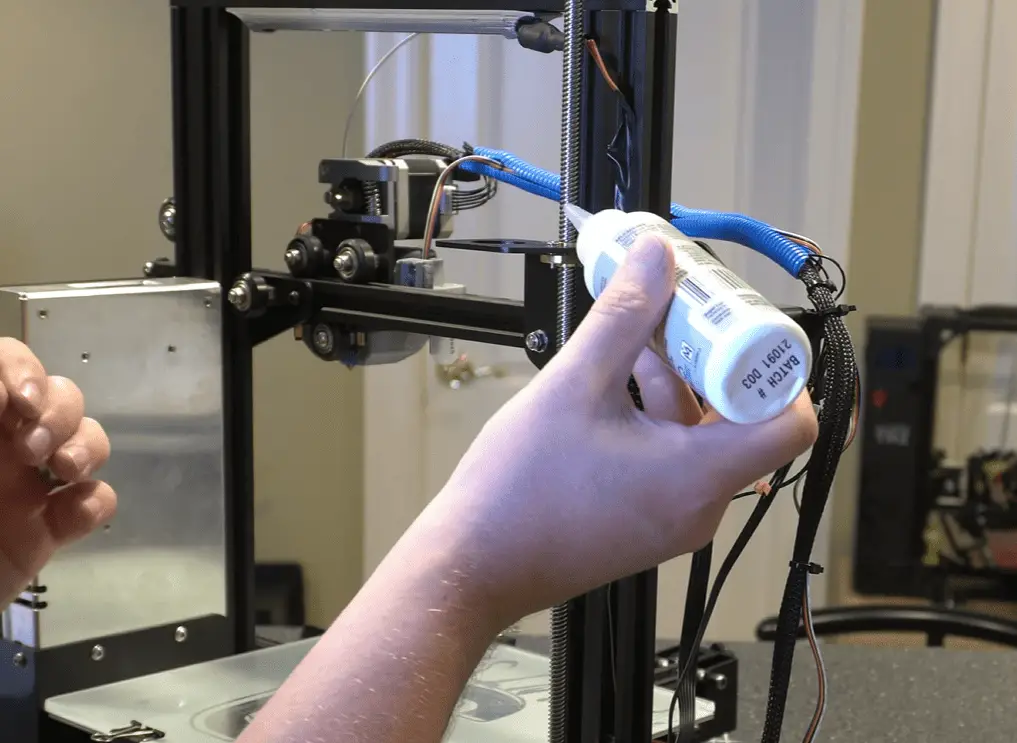

Guide rails and bearings

Lubricate the rail bearings with lithium grease. If the container doesn’t have a narrow opening, use a syringe to apply the grease. Apply the grease to each bearing as you roll the carriage back and forth.

Extruder

For the moving parts inside the extruder, I suggest using light machine oil or PTFE Super Lube. You need to lubricate the extruder if you hear squeaking coming from it. Unscrew the extruder housing and lightly lubricate moving parts.

Can I Use Lithium Grease On A 3D Printer?

Lithium grease is one of the best choices when lubricating bearings and rails because it sticks to the parts very well. Some people prefer not to use grease because it’s a bit messy, picks up dirt easily, and causes some resistance. White lithium greases like these on amazon.com work very well and is what I suggest when lubricating bearings and screw rods.

Is WD-40 A Good Lubricant For A 3D Printer?

Standard WD-40 isn’t a good lubricant for a 3D printer because the oil is too thin. It will run down the components quickly, requiring you to re-apply the oil after every print. WD-40 is made to be so thin that it can get into small spaces like the inside of a rusted lock. The chemicals inside WD-40 can be corrosive to certain parts of your printer.

WD 40 Specialist Dry Lube will lubricate your printer without eating away at any rubber or plastic. It’s a dry PTFE lubricant that will stick to the components and doesn’t leave an oily residue behind. So you can use this type of WD 40 if you have it laying around but Super Lube is far better if you’re going out to buy it.

How Often To Grease A 3D Printer

As a general rule of thumb, you should lubricate your printer after every 100 to 300 hours of use. Lubricate after 200 to 300 hours for parts that aren’t exposed to heat from the printer base and every 100 to 150 hours for parts that are exposed to heat from the base.

Having said this, if you can still see the lube on the parts and don’t hear any squeaking, you might not need to lubricate your printer for over 500 to 1000 hours of use. As long as the environment is dust-free because if the lube is dirty, you need to clean and re-lubricate to avoid damage.

Why 3D Printers Squeak

3D printers squeak when there’s friction between unlubricated parts like screw rods, bearings, and rails. Moving parts in the extruder are also one of the main causes of squeaking. Any part that rubs against another can cause a squeaking sound.

Try to identify where the squeaking is coming from and lubricate that part. If the squeaking continues after lubricating the screw rods and guide rails, open the extruder and lubricate it as well.

Related Articles

- Why Is My 3D Printer So Loud?

- How Do I Get Rid Of Layer Lines In 3D Printing?

- What Is the Best First Layer Height?

- Cura Speed – Everything You Need to Know!

- Cura Brim Build Plate Adhesion – Everything You Need to Know!

How To Clean Linear Rail Bearings

Apply some cleaning alcohol to a paper towel or clean cloth, squeeze the rail with it and wipe up and down the grooves and over the bearings until they are clean.

In Summary

The best type of lubrication for rails and bearings is white lithium grease because it adheres to the bearings and allows them to turn as they need to. Dry lubricants cause objects to slide over ball bearings.

My recommendation for screw rods is dry lubrication because it works well without collecting dust. Dry lubrication creates a slippery surface without adding much resistance compared to grease.

If the extruder is squeaking, open it up and apply some machine oil to the moving parts. Check your operating manual for specific locations.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.