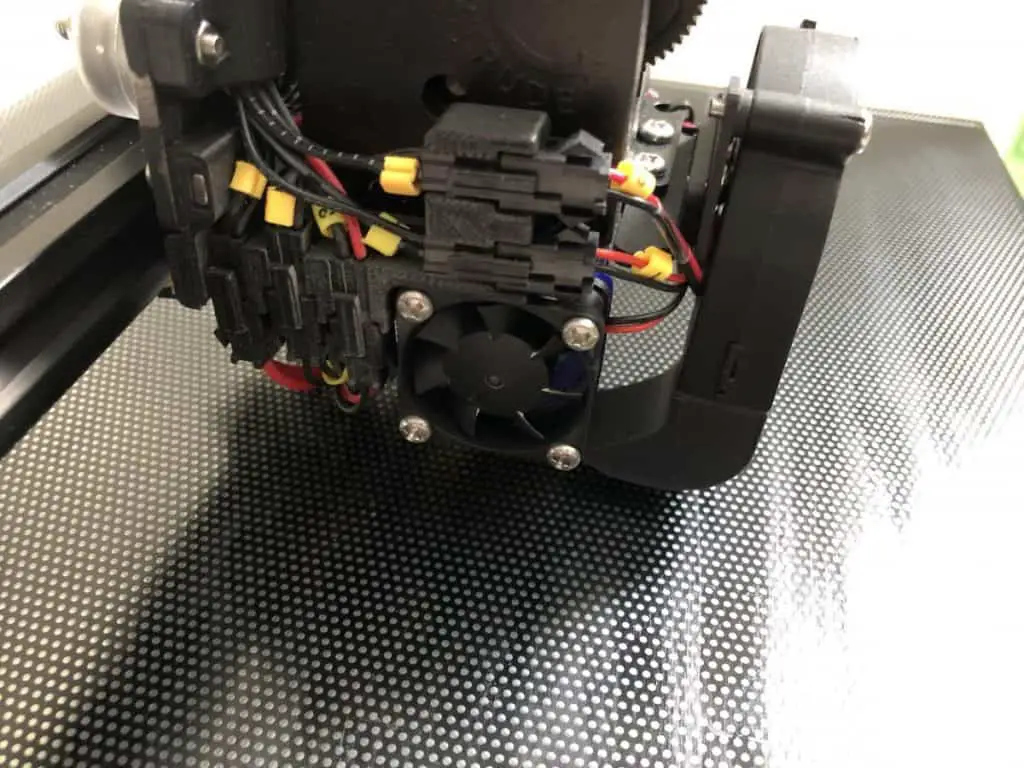

The extruder is one of the most crucial parts of a 3D printer. It is the component of the 3D printer that draws in, melts, and pushes out the filament. However, do you know how to go about fixing it?

When fixing a slipping extruder, check whether your nozzle is too close to the print bed, the printer can’t keep up with speed, the extrusion temperature is too low, and there’s a blockage in your nozzle or tube if dust is stuck in your extruder. Once the issue is identified, it’s easy to solve.

In order to really understand the troubleshooting process of fixing a slipping extruder, we need to understand the meaning of this piece and its use.

What’s an extruder? What’s its function in a printer?

You might come across an extruder while using additive manufacturing, especially if you’re 3D printing on your own with a desktop 3D printer. This 3D printer component plays such an essential part in your additive manufacturing projects that we believe you should know everything there is to know about it!

The extruder is a component of a 3D printer that ejects liquid or semi-liquid material. Within the 3D printing volume, it is found as a layered deposit. In addition, the extruder is sometimes used to deposit a bonding agent. This bonding agent is also utilized to harden the powdered substance.

Types of extruders

There are two basic types of extruders on the market right now: Bowden and Direct are two of the most well-known names in the printer industry.

BOWDEN:

A Bowden extruder is not connected to the hot end directly. Instead, a tube connects the extruder body with the hot end. A Bowden tube is what this is called. The tube holds the filament in place as it travels to the hot end.

DIRECT:

The small distance between the drive mechanism (hobbed pulley or gear) and the hot end is one of the critical advantages of a direct extruder. Extrusion and retractions are more sensitive when the space between them is shorter. It also requires less torque to extrude the filament through the hot end than a Bowden extruder.

So, which is the best option? It would be ideal if one of them were significantly better than the other, but they each have their own set of strengths and shortcomings.

Basic Troubleshooting To Fix Slipping Extruder

Before you can determine the reason your extruder might be slipping, it is suggested you follow these basic troubleshooting steps, which wouldn’t come as a challenge regardless of your level of expertise because there is plenty of information online and in the manual.

Nonetheless, these steps, if followed in order, would be a pivotal determinator to understand the correct reason behind the slipping and not confuse them with another error:

- Adjust extruder tension:

- Replace the PTFE tube

- Reduce retraction

- Change speed

- Adjust hot end temperature

- Level your bed

- Clean your hot end

Following these steps and examining the causes will significantly increase your chances of resolving and preventing this problem. Other factors can also play a role, so keep an eye out for unusual or unusual issues.

Possible reasons for slipping + How to fix them:

When determining how to proceed with troubleshooting a slipping extruder, we must understand the following possibilities that could lead to such:

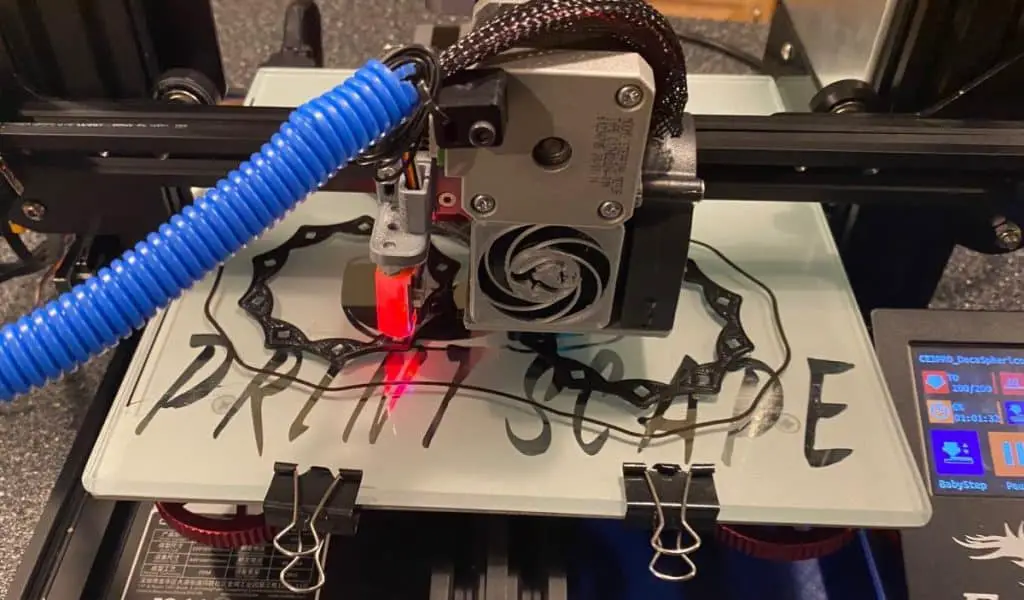

Printing Speed Or Temperature Are Either Too High Or Too Low

To test if one of these fixes the problem, try increasing the heat by 5° -10°C and slowing down the feed rate while printing. Print temperatures are generally suggested to be lower than those required.

How to fix it?

If this is the case, the simple solution is to raise the temperature of your printer, and everything should be back to normal.

Loose Tube Assembly or Hotend

To determine if your end is too hot or if the tube is loose, you need to consider the following:

- If your Hot End Coupling has any play in it, and the Bowden tube can move up and down.

- If between the Bowden tube and the heat break inside the hot end, there is no gap.

- If the heat break and the nozzle, or any fitting, molten material can get into that gap, swell beyond the diameter of the tube, and make it difficult to move, this can result in jams or complete obstruction.

Clogged Hotend or Nozzle

If you have a clog, you’ll need to disassemble the entire hot end assembly. To test, squeeze the extruder arm to compress the spring when the hot end is thoroughly heated. If you can’t push the filament through, and it doesn’t come out of the nozzle? It’s very likely it’s clogged.

Bowden Tube Or Pathway Interference

Always verify your PTFE clearance before breaking down your entire hot end and replacing the nozzle.

Remove one end of the tube from the hot end (leave the other end in the extruder) and manually push filament or filament past the extruder and into the PTFE tube with your extruder arm squeezed to test. If the movement is smooth, the problem is somewhere else.

How to fix it?

Give your nozzle a good cleaning, and if the obstruction is severe enough, a cold pull. Reduce your temperature or replace your heat sink if you have a thermal break or a poor-quality heat sink.

Tampered Extruder

To test whether the spring applies enough pressure to the hob gear and bearing to compress the filament, squeeze the gears together manually while feeding. If these don’t work, you can assume the extruder is tampered with.

How to fix it?

Make sure the power connections are secure and the cables are free of snags or damage. Check that your printer’s power cable is sturdy enough to handle it and that the voltage is correct.

If you feel this is the problem, you can get a new power cord or power supply. However, if the issue persists, it is safe to assume you’ll need a replacement.

How to prevent slipping?

It would help if you considered raising the force of the roller bearing onto the filament and extruder wheel, or increasing the temperature, to prevent filament slippage. This could potentially be due to a (partial) clog.

You may attempt a “cold pull” or “atomic pull”;

Cold pull:

This approach uses a strand of filament and temperature variations to unclog or clean a nozzle without completely disassembling it.

Atomic pull:

This method entails picking up a glob of material and other small debris, with a molten tip on a strand of filament, clogging the nozzle, and then pulling the strand out, ideally bringing the clog and debris with it.

These steps involve heating the filament to print level, push a bit through by hand, let the nozzle cool to approximately 60% of the printing temp, and then slowly take the filament out of the extruder, which should remove all muck inside. A layer height that is too low can put the filament extrusion under strain.

Related Articles

- Quick Guide to Change the Nozzle on a 3D Printer

- Five Reasons Your 3d Printer Stops Mid-Print

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

- Cura Profiles

Conclusion

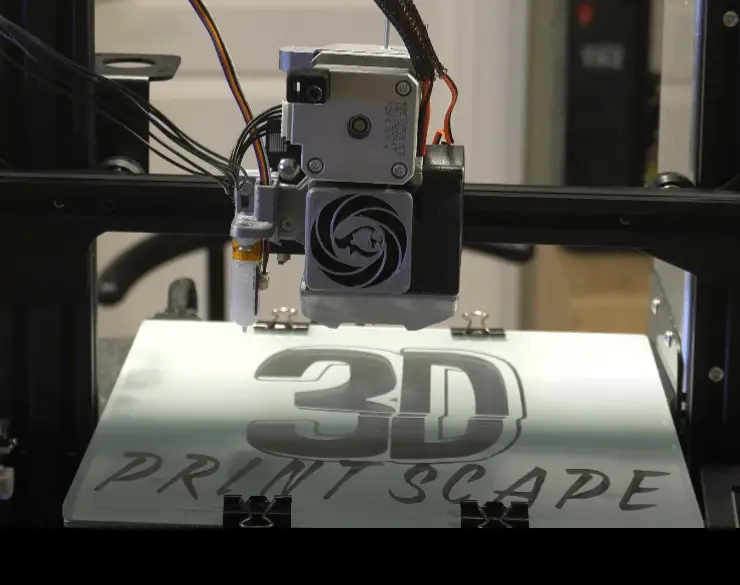

To round everything up, it is imperative one understand the possible issues that might lead to a slipping extruder and the importance of understanding how these pieces work in addition to their heat limit.

Knowing the fundamentals of a 3D printer extruder is critical because it is where the “real printing” occurs. It is here that the filament is sucked in, melted, and then pushed out.

Furthermore, most 3D manufacturers and amateurs nowadays use 3D printers with extruders (material extrusion method).

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.