PLA, or polylactic acid, is one of the most popular FDM filaments available since most printers take it, and it’s a cheap, reliable material. However, PLA tends to absorb moisture during storage. So, do you need to dry PLA filament before use?

PLA filament needs to be dried out before use since it absorbs moisture from the air. Using moist PLA could damage your printer nozzle and make your print brittle and stringy. So, using a dehydrator or oven to remove the moisture is a crucial step for PLA printing.

The rest of this article will teach you everything you need to know about working with moist PLA. I’ll tell you why PLA absorbs moisture and explain what happens when you don’t dry it before printing. I’ll then walk you through the steps to dehydrate and store your PLA properly.

Does PLA Filament Absorb Water?

Generally, when we’re talking about moisture and 3D printing filaments, the materials fall into two categories — hygroscopic and hydrophobic. Hygroscopic materials draw in water, whereas hydrophobic materials repel water.

PLA Filament absorbs water because it’s a hygroscopic material. In other words, the polymers PLA is made of naturally attract and draw in water, which can cause the filament to swell, possibly making your filament brittle.

PLA filament attracts moisture like a sponge. So, the more humid your filament storage area is, the wetter your filament will become.

That’s because PLA is a type of bioplastic, which means it’s semi-biodegradable. This material consists of starches from grains such as corn and rice. The starches are sanitized and refined to make PLA. They’re then combined with additives and preservatives to create a durable thermoplastic that you can melt to make 3D prints.

PLA is water-resistant, which means it won’t lose structural integrity when wet. However, although the filament will last underwater for several years without breaking down, there is a limit.

PLA is sensitive to heat, UV exposure, and microscopic organisms, which may feed on the organic starches in the plastic. Add water to the mix, and your PLA will degrade much more quickly.

When you expose PLA to any combination of these environmental factors, the plastic may start to become mushy, much like a potato does when you boil it. When this happens, the filament loses its structural integrity, permanently damaging the PLA.

Still, PLA won’t start to break down just from exposure to air humidity. However, over time (we’re talking years), it may become brittle as it absorbs ambient moisture.

What Happens When You Print With Moist PLA FIlament?

Since PLA absorbs moisture and is more sensitive to heat when damp, drying out your filament is a crucial step in PLA 3D printing.

When you print with moist PLA filament, steam forms inside the print nozzle, creating a crackling or hissing sound. The steam can reduce layer adhesion, form bubbles in your filament, create stringing and artifacts, or clog up your nozzle.

Steam and 3D printing do not mix well together. Keeping a constant stream of filament running is crucial to ensure that your print layers are even and smooth when your filament runs through the extruder.

However, if your filament is damp, it’ll produce steam as it heats up. Since 3D printers use vacuum-like suction to draw the filament out of the nozzle, that steam can get trapped in your printer, building pressure until it finds a way to escape.

Because steam easily gets stuck in your printer, it can add moisture to dry segments of your filament. This is never a good thing with PLA filament. As I mentioned before, heat and water can weaken PLA, changing the chemical structure. As a result, steamy PLA prints never have the strength of a dry PLA print.

Likewise, the trapped steam will try to escape through your print nozzle, potentially creating steam bubbles in your filament. If the moisture creates too much pressure, your model will have visible strings of filament where the steam has continued to push out the filament, even when the printer is off.

Other things can go wrong if you print with damp PLA, too, such as a rusted printer, completely failed prints, and more. Ultimately, it’s always best to dry out your PLA.

For some visual examples of what happens when you don’t dry your filament, check out this video by CNC Kitchen:

How To Dry and Store PLA FIlament

I always recommend drying out hygroscopic filaments the day that you get them to ensure that they haven’t absorbed any moisture in the shipping process. Also, if you haven’t used the filament within a few months of purchasing it, it’s always good to warm it up a bit again to remove any moisture.

To dry and store PLA filament, you can use a filament dryer, dehydrator, or oven to extract moisture from the plastic without melting it. After drying, always store your filament in an airtight container with some desiccant such as silica gel to keep the spool dry.

Although a 3D printing filament dryer can make the filament-drying job easy, most people don’t own one. So, hobbyists and at-home printers like me usually opt for the oven-drying method.

Here’s how to dry PLA:

- Place your spool of filament in the oven, loosening the filament a bit to ensure that the entire outer layer has room to get rid of the moisture.

- Leave the oven door open just a tiny bit to allow steam to leave.

- Bake the filament at 113 ºF (45 ºC) for 6 to 12 hours.

Optionally, if your oven has a dehydration feature as mine does, you can allow the filament to bake with the oven door closed for 6 to 12 hours.

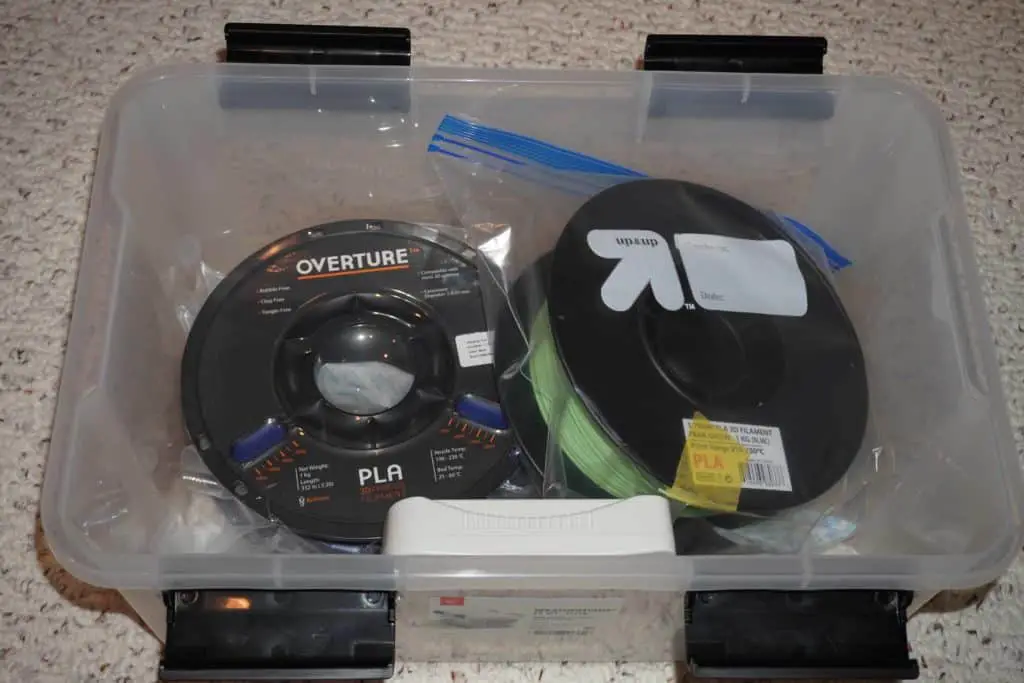

After you dehydrate your filament, allow it to cool in the oven. You can either use it right away or put it in an airtight bag with some silica packs or another desiccant. For good measure, I recommend putting these airtight bags into an additional airtight container to keep everything dry (and to prevent having to dry out the filament again later).

Next, store your filament in a dark, dry place until you use it.

Related Articles

- How To Tell if PLA Filament Has Gone Bad

- PLA vs PLA+ – What’s the Difference?

- All About 3D Printer Plastic

- Does PLA Need to Be Kept Dry?

- Can You Spray Paint PLA? Details Inside!

- Best PLA Glue – The Answer Inside!

Final Thoughts

Like any other hygroscopic filament, PLA needs to be kept dry to ensure that your print does not fail. PLA is sensitive to heat and moisture, which may combine in your print nozzle to create steam, messy artifacts, or strings in your print.

To prevent print failure, be sure to dry out your PLA in a dehydrator, filament dryer, or oven before using it and store it in an airtight bag or container with some desiccant.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.