I was recently looking into getting an SLA 3D printer and realized the build volume was significantly smaller than that of their FDM printer counterpart. This led me to research what the average build volume is for this type of printer and what limitations the smaller build volume may impose on me if any.

I compiled a list of specs from the 10 most popular SLA printers on Amazon and here are the results. The smallest printer in the list (Sparkmaker) had a build area of 3.85(L) x 2.16(W) x 4.92(H) or 40.91 cubic inches. The build area of the largest one (KELANT S400) is 7.55(L) x 4.72(W) x 7.87(H) or 280.45 cubic inches. The average build volume of the 10 printers is 4.76(L) x 2.73(W) x 6.05(H) or 87.81 cubic inches.

Here is the data used to come up with the average build volume above, all values are in inches.

| Printer | Length | Width | Height | Volume |

| Sparkmaker | 3.85 | 2.16 | 4.92 | 40.91 |

| LONGER Orange 10 | 3.86 | 2.17 | 5.5 | 46.07 |

| QIDI TECH Shadow 5.5 S | 4.52 | 2.55 | 5.9 | 68.00 |

| Geeetech DP200 | 4.52 | 2.56 | 5.9 | 68.27 |

| ELEGOO Mars | 4.53 | 2.56 | 5.9 | 68.42 |

| ANYCUBIC Photon | 4.53 | 2.56 | 6.1 | 70.74 |

| EPAX X1 | 4.53 | 2.56 | 6.1 | 70.74 |

| ANYCUBIC Photon S | 4.53 | 2.56 | 6.49 | 75.26 |

| NOVA3D Elfin | 5.2 | 2.91 | 5.9 | 89.28 |

| KELANT S400 | 7.55 | 4.72 | 7.87 | 280.46 |

Keep in mind, there is more to a 3D printer than just the build volume so don’t make a decision solely based on that. Other factors you should consider include the cost, resolution, efficiency, build quality, etc. Keep reading to learn more about why SLA printers tend to have smaller build volumes and why you would want to buy one over an FDM printer.

Why do SLA printers have a small build Volume?

In order to explain why SLA printers have a smaller build volume than other types of 3D printers, we must first go into how they work.

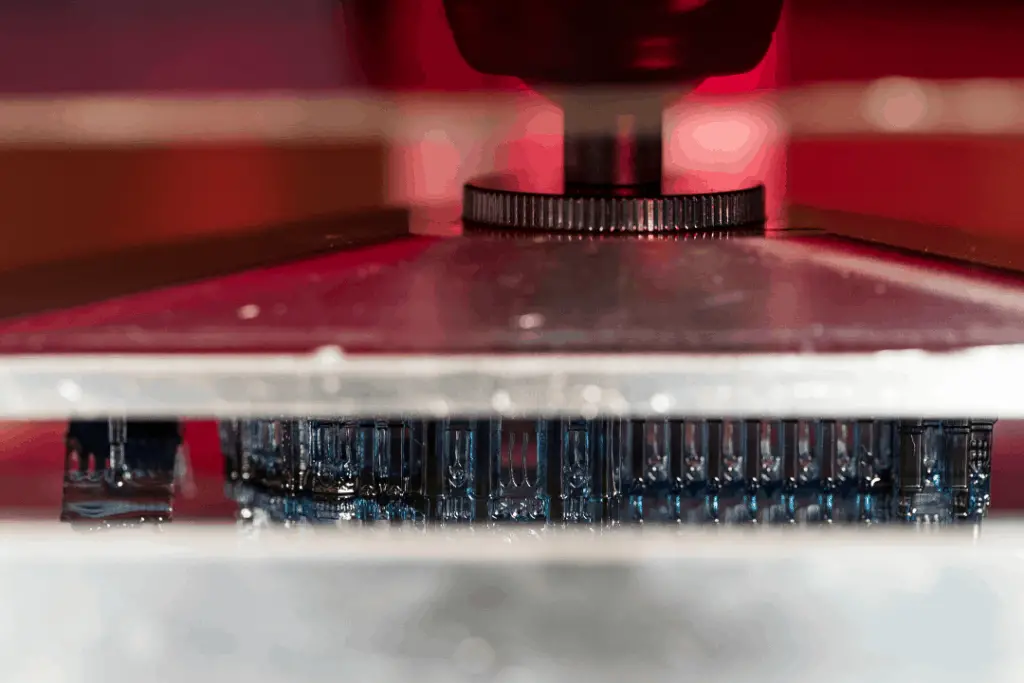

At a high-level SLA printers use a light (either laser or projection-based) to cure a polymer resin layer-by-layer during the print. The process would look something like this.

- A 3D model is created or downloaded from a site like thingiverse.

- That model is sliced and saved to an SD card or sent to the printer.

- There are several free slices available if your printer didn’t come with one, Cura being the most popular.

- The SLA printer has a tank that gets filled with a photopolymer resin.

- The print gets kicked off and the build platform is lowered into the tank.

- The SLA printer builds each layer one-by-one and raises the build platform as its going.

- Once the print finishes you remove it from the build platform and give it an Isopropyl bath.

- Finally, you cure the printed parts.

Note: I will go into more detail on how SLA printers work in another article as that’s not the primary intention of this one.

For this to work, the printer must be able to submerge the entire build platform into the resin and raise it to the max height of the print. Which means a larger build platform will need a larger resin tank. This not only costs more to produce but also means the consumer will need to purchase more resin to fill the tank, so you really need to consider what you will be printing when making a purchasing decision.

The other side of the equation is the height. The printer must be able to raise the build platform evenly to the max height of the printer. The higher the printer goes the more reinforcements are needed, not to mention the actual printer will be larger. The reinforcements are more of an issue with FDM printers because the print head is constantly moving but if there is movement on the Z-axis it will have a negative effect on the print regardless of type.

Why are SLA Printers Enclosed

SLA printers are always fully enclosed which is not the case for the more common budget FDM printers you see all over Amazon. The main reasons SLA printers need to be fully enclosed is because they working with lasers, special lighting, and open resin tanks. Any interference with the laser/light during the print will likely result in the print having imperfections or being ruined entirely. It also helps keep dust and other impurities away from the print and the resin.

There are FDM printers that come fully enclosed but they tend to cost significantly more as the enclosure adds to the cost of the printer and can get expensive as you go up in size. That said, the extra cost does also come into play with SLA printers as well. It’s just less impactful because of the smaller size.

When you’re looking at FDM printers, the two main advantages of having it fully enclosed are it helps with structural stability and makes it easier to vent fumes. Unless you plan on printing with ABS filament, having a fully enclosed print bed just isn’t needed.

Though if designed correctly it can help control vibrations and provide a better print as one of the biggest issues with budget gantry style printers is the vibrations on the Z-axis causing ghosting. You can also reinforce the gantry with somethings like this from thingiverse. Another point to mention is you can buy common size enclosures or build a DIY one for cheaper.

When to Buy an SLA Printer Instead of an FDM Printer

Choosing the right 3D printer can be a time consuming and possibly emotional process. Let’s face it, they are not cheap and there are a lot of options available.

To help decide what type of 3D printer to buy you need to first ask yourself what types of things you want to print. Here are some advantages and disadvantages of each type (yes I know there are other 3D printing technologies but you don’t really see those being used by hobbyists).

SLA Printers

- Pros

- Prototypes can be created at a very high resolution leading to a much more detailed print

- Extremely high accuracy in the print

- Smooth print surface (after Isopropyl bath)

- Cons

- Typically has a smaller max build volume

- Requires extra care when working with the resin

- Limited resin options

- Difficult to remove prints from the print platform

- Long print times

- Best used for

- Smaller parts that have a lot of detail

- Jewelry design/molding

FDM Printers

- Pros

- Affordable

- Easy to find parts and accessories

- Easy to remove the print from the print bed

- Many filament options (Both color and material)

- Cons

- Prints at a low resolution compared to SLA printers

- Best used for

- Creating low-cost models

- Parts not needing a lot of detail

- Larger parts

Summary

SLA printers typically have a smaller build volume than other 3D printers averaging 87.81 cubic inches. This is mainly due to how the printer works, needing to be fully enclosed, and requiring the resin tank to be large enough to submerge the build platform.

I think we will start to see more SLA printers with a larger build volume like the KELANT S400 as the technology advances and becomes cheaper. For now though, SLA printers can provide you very high-resolution prints at a reasonable price but if you need to print anything larger you will need to move to an FDM 3D printer. Here is a list of my top 5 SLA printers under $500.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.