Whether you are new to 3D Printing or an expert, resin printing without support is something everyone should know about, whether it is possible or not. Resin 3D printing has become more and more popular as technology advances. Can you do it? Can you use water-soluble supports? What are other things to consider for this process?

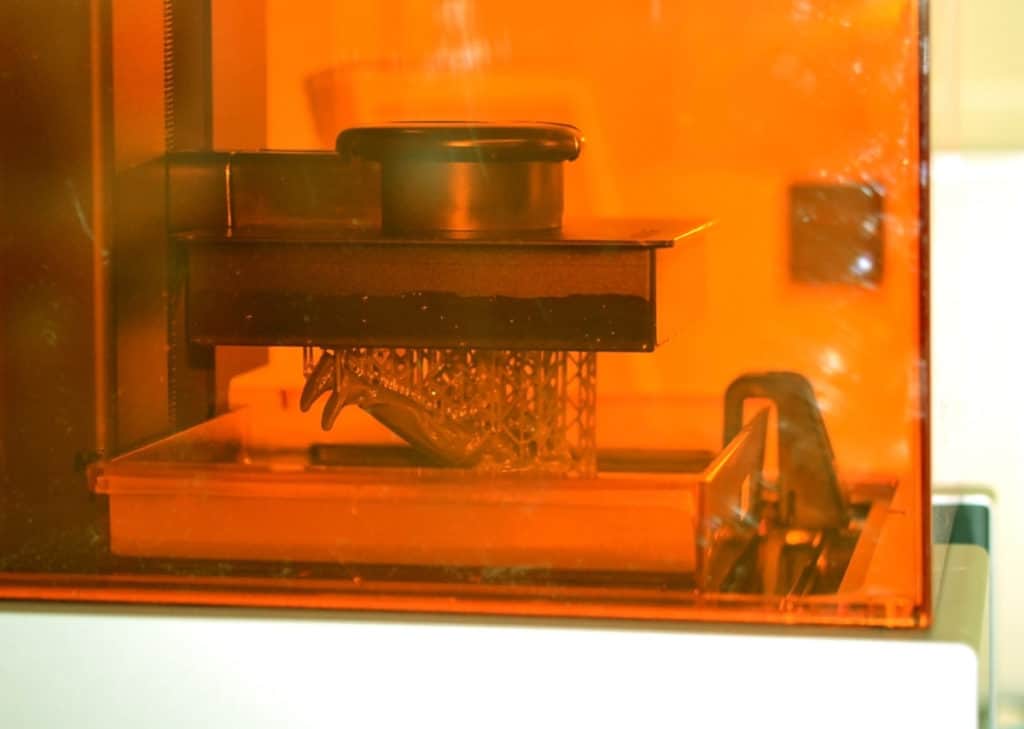

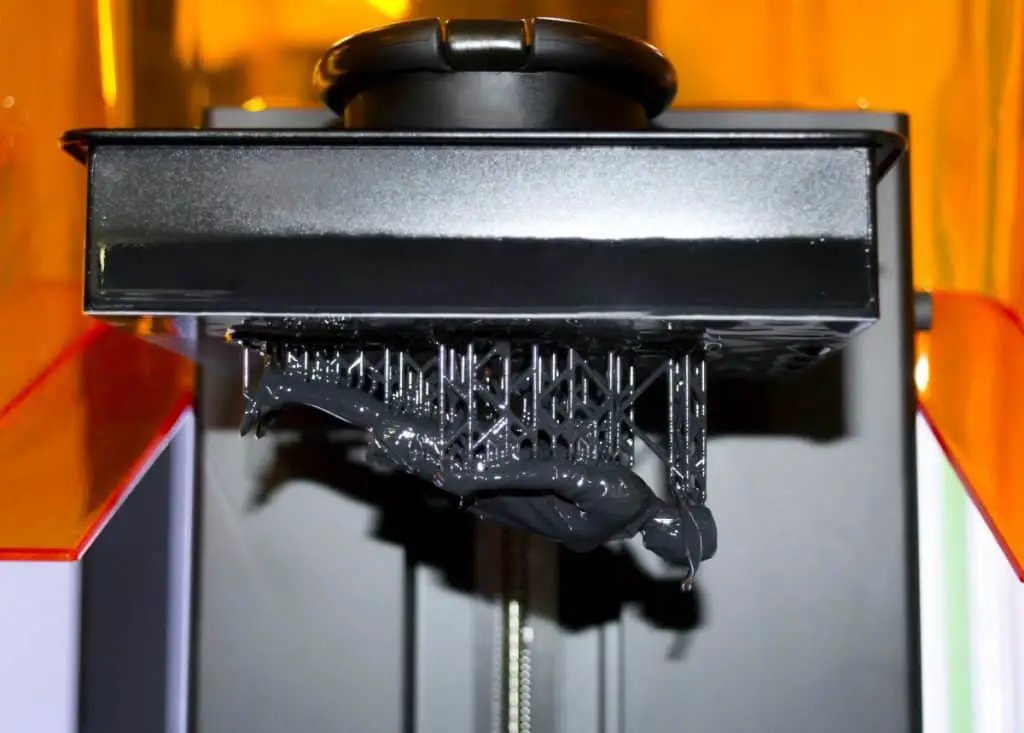

Although it is possible to print resin without supports, it is typically recommended not to do so. If your designed item contains prominent overhanging elements like axes, swords, or limbs, resin prints will require supports. Supports are added to give such portions of the model a solid basis.

Even if it is possible, it is a good idea to take into consideration some tips and information that will help you succeed with your model; in this article, we will discuss a few.

What Are Supports For 3D Printing?

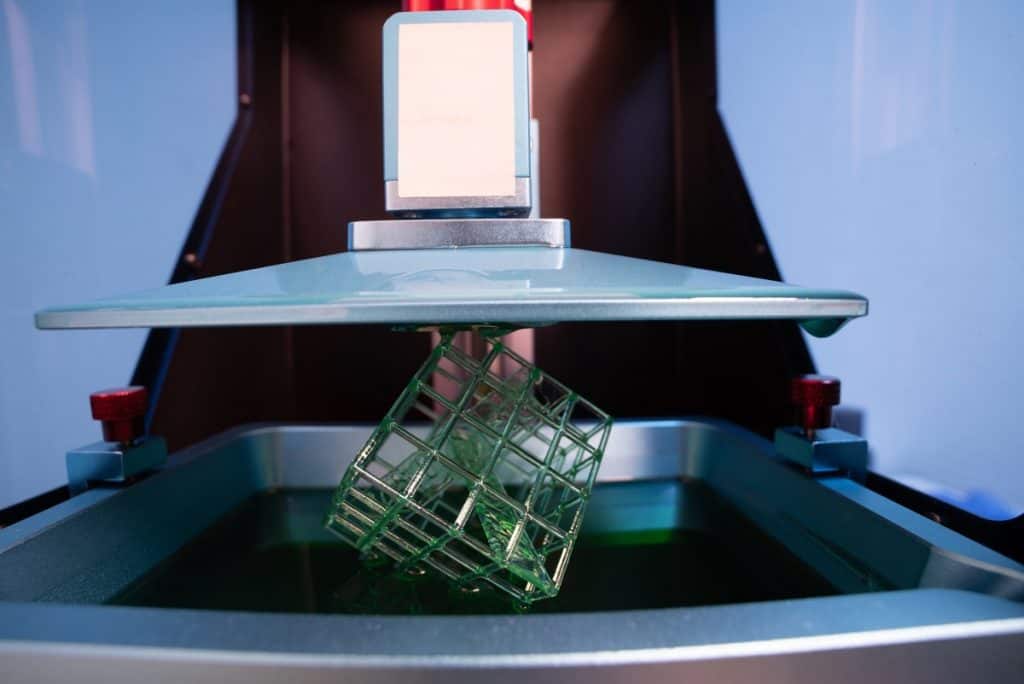

These are parts of a model that act as support, to help ease the process when building your models. Support Material comes in different forms like soluble or insoluble. When starting with these products, it is important not to confuse them because one wrong move may cause damage to your model.

What To Consider When Printing Without Support?

There are many factors to take into consideration when printing without support. Printing with support is often easy and efficient. However, sometimes it can be extremely challenging or even impossible depending on the model you’re attempting to print. Generally speaking, a slicer should generate some sort of supporting structure for your object that considers how material needs to flow through your printer and allows for enough infill density in areas where the unsupported sections have been bridged over open space.

Here are some tips and tricks for printing without supports:

Mid-air 3D Printing

Mid-air printing is a way to print objects in mid-air. The technology was developed after some experiments conducted by the University of Illinois. It uses an advanced robotic arm to create complex shapes that would otherwise be unprintable using traditional manufacturing techniques. This printer can also use different kinds of material for each part of the object being created, which means you could have one side made out of rigid plastic while having another soft rubber on the other side.

3D Printing: Under 45 Degrees Rule

With no supports at all, any model with angles less than 45 degrees can be 3D printed by anyone. It’s a real-world solution that needs some additional time and effort when it comes to designing or cutting your 3D printing model in slicing software. But the time spent following the restriction is worthwhile.

When you 3D print without supports at an angle of less than 45 degrees, the 3D printer builds layer by layer, with each new one offset by no more than 50 percent. It implies that at least half of the area of the new layer engages the prior one and stays put because there is enough groundwork for it to adhere to.

3D Printing: Background as Support Rule

Supports are used in 3D Printing to keep a model from falling apart. Despite the fact that complicated 3D printing models generally require supports, you may always include them as part of the print. Background and extra objects may be used to conceal supports and minimize filament use since there will be no support systems to remove after completing the manufacturing process.

Backgrounds can also be used as support. For example, if your figure has cushions or folds of clothing supporting its arms or legs, they can work as support. The hair easily supports the character’s chin. Supports for the legs might be incorporated into a long gown to conceal them.

The Bridge Rule

If you create a 3D printing model with bridges, you will most likely need a supporting structure. Using a bridge is the most challenging technique. However, to avoid relying on supports, there is a restriction for bridges: any bridge less than 5mm in length may be printed without the help of any support materials.

When it comes to bridges, take your time. The slower your 3D printer operates, the smoother the end product will be. The layers will stick better, and the bridge will become stouter and neater.

Take a close look at your project. When seen vertically, the model may look complex and demanding. However, when rotated 90 degrees and printed on the reverse, it may appear simple and straightforward to create.

To use this approach, you must first determine the direction of your print bed. Changing the printing orientation can help create a magnificent bridge that does not require the use of supports. Of course, this method will not work for unleveled bridges that need many layers of filament.

Some Other Tips

- Using a circular base can help avoid warping.

- The addition of epoxy or 3M tape to the base improves the model’s adhesion to the bed.

- With fewer supports under its base, rotating a model with a horizontal arm to 45 degrees takes less time.

- Cheating angles that break the 45-degree rule by employing a chamfer might occasionally be acceptable.

- Slowing down the printing speed might improve the quality of your model.

- Moisture may cause your 3D prints to deteriorate if you don’t know how to store filament.

- Some supports may be necessary when cutting a model in half. However, they can also be eliminated if enough glue is applied.

Can You Use Water-Soluble Supports For 3D Printing?

For almost any kind of support, there are specific products that can be used to print them. However, if you want to use water-soluble supports for your next project, you need to be sure it will work fine. Water-soluble supports are very useful in many cases. Below you can find some benefits of this type of material.

- Surface quality is greatest with soluble support materials. Soluble supports dissolve rather than needing to be manually removed, leaving clean, perfect surfaces behind.

- It provides a firm foundation and excellent dimensional precision, as well as complicated geometries that dissolve.

- Some of these materials prevent thermal distortion after cooling down.

- A few of these materials can dissolve quickly.

But not everything is perfect. Water-soluble supports also have some disadvantages:

- First of all, you need to be sure that the water will dissolve them because if not, it can make a mess on your model and ruin the printing process.

- Second, there might be times when this kind of support is more challenging to remove than others, depending on how well it adheres to your printer’s build plate or the geometry in which you want it to print.

- Third, using water-soluble material during a project adds up cost-wise since most filaments with these properties tend to increase their price compared to other types of materials used by FDM printers.

Although we recommend trying out water-soluble filament at least once, you should keep in mind that this material is not always the best solution.

Related Articles

- Why Is My UV Resin Sticky After Curing?

- How Long Does It Take For UV To Cure Resin?

- Why Are My Resin 3D Prints So Brittle?

- SLA Printer Resins

- Choosing SLA Printer Resin

- Resin Printer Speed: What You Need to Know

Conclusion

We encourage you to try the method that might suit your design next time you create a new model; check which one will be better for your design if you are using supports.

Even if having all of these issues, it is still worth trying out water-soluble filament with your 3D printer since you might find yourself in a situation where this material can be beneficial. However, keep our warnings about the potential problems that may come up when using it.

Hope this article has helped you get some insights into how to print without any support or support material.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.