3D printing may seem like an invention for the elite and over-qualified intellectuals of our society, but the days of 3D printing being mainstream are more near than you may even realize. If you thought it was mind-stumping to ask Alexa to play a song and have your command obeyed, imagine telling a printer to create a pair of shoes for you and then going out to dance in your new design.

How do you get started in 3D printing? You will need to purchase a 3D printer and get a slicing program like Cura. Once you decide what you want to print, you will need to find a model of it or learn how to use modeling software.

3D printing is projected to grow from a $5.8 billion industry in 2016 to a $55.8 billion industry by 2027 with an ‘aggressive annual growth rate of 23%’ according to Smithers. If you are curious about this revolutionary tool that could replace manufacturing altogether, stick with us for this quick read and learn what you need to start 3D printing.

What is 3D Printing?

If you are curious about what 3D Printing is, it is “the manufacturing of solid objects by the deposition of layers of material (such as plastic) in accordance with specifications that are stored and displayed in electronic form as a digital model.”

Essentially, 3D printing is exactly what it sounds like! You can make tangible objects from a printer that formerly only had the power to minorly alter paper. The days of minor alterations are over because 3D printers can fundamentally create anything which can be drawn.

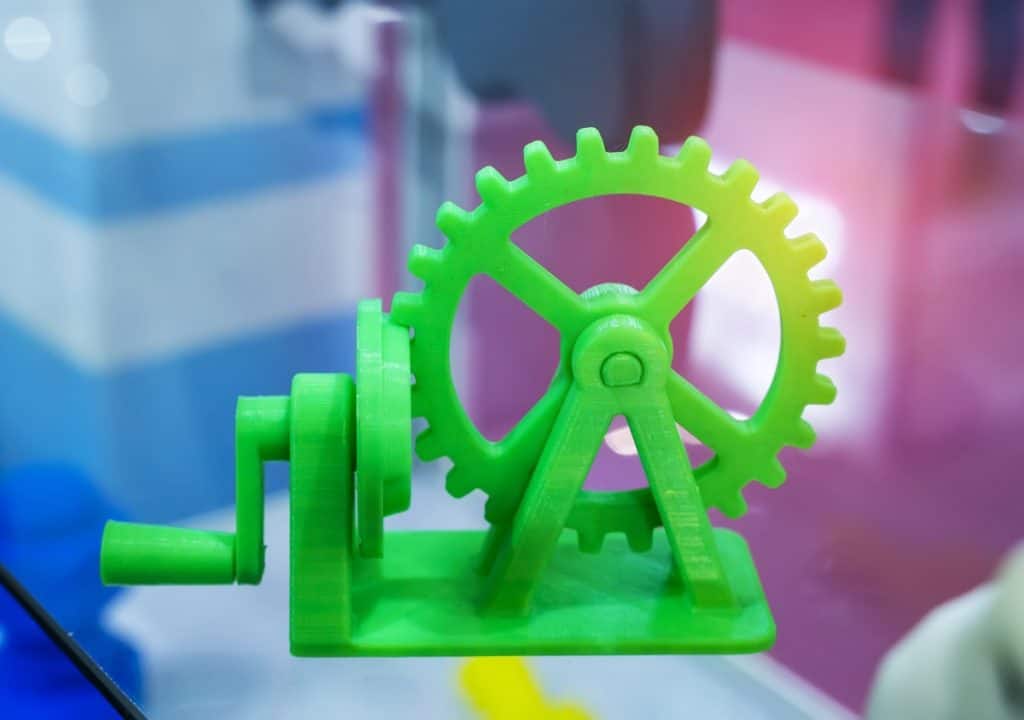

What Can You Make With a 3D Printer?

If you drew out a tiny squirrel character, using the proper 3D software, printer, and printing materials – you could print out that squirrel. You can even print a bridge, check out The World’s Longest 3D-Printed Concrete Bridge, located in Shanghai with 800 layers of concrete.

“Imagine dreaming up a toy for your kids, sketching it out on your computer, and minutes later—voilà!—you’re holding the real thing in your hand.”

Bre Pettis, Entrepreneur and CEO behind the 3D printing company, Makerbot Industries.

What are some items you can make with a 3D printer?

- Bridges

- Toys

- Musical Instruments

- Shoe Racks

- Camera Accessories

- Factory materials and large-scale engineering parts

- A coffee cup

- A 3D rendering of a 2D drawing

- High Heels

- Even a fully-functioning gun!

The possibilities are quite endless with this radical invention that may have the potential to run factories, businesses, and entire enterprises out of business.

If everyone can print everything at home, why wouldn’t they?

It’s a fascinating thought that already has brick and mortar shaking in their collective boots after the digital revolution. This exact point is covered in the title of this piece by Pymnt.com titled, ‘Is This The End Times for Brick and Mortar Retail?’

What most people can gather as the rules for printing regarding this new artform is that – ‘If you can draw it, you can 3D print it.’

How to Get Started in 3D Printing

When it comes to getting started with a 3d printer, you really have two options. You can choose to work with a model that has already been created or you can create your own. I would recommend you start with pruning models that have already been created.

The most basic way to break this down into bite-sized pieces will be as follows:

Print an Existing Model

- Decide what you want to print.

- Purchase the materials that are cohesive with your design concept and printer

- Download a model from sites like Thingiverse

- Slice the model using Cura or another slicing software

- Save the g-code file to an SD card and insert it in your printer

- Start your print

Create a New Model

- Design it on a 3D modeling software. Some of the best are:

- Google Sketchup – Free and easy!

- Tinkercad

- Openscad

- Blender

- Learn these design programs and how to scale things from 2D to 3D, keeping in mind the 3D dimensions with their exact measurements and gravitational physics relative to your chosen printing material. Considering this throughout the process will avoid multiple re-prints which can get expensive and time-consuming.

- Then follow the steps under the “Print an existing model” section

When it comes to actually printing the model, you have a couple of choices as well. I personally think the first choice is the best but wanted to make sure you were aware of both.

- You can either:

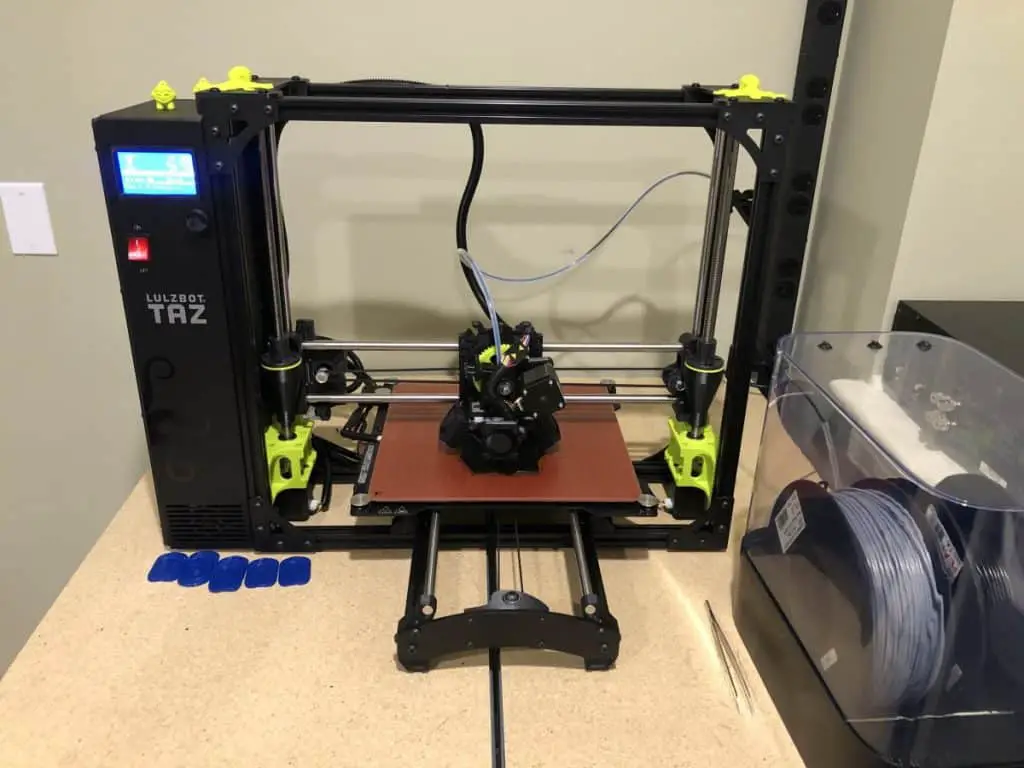

- Purchase your own 3D printer and print it at home

- Hire a 3D Printing Service to print it for you.!

How Much Do 3D Printers Cost?

3D printers cost between $300 to $10,000+ depending on the scale at which you are printing. The average cost for a hobbyist printer is around $700 for an average-quality 3D printer that will suit most home projects.

You can find one for as little as around $200 like this Monoprice Mini and then upwards of $10,000+ on Higher Quality and Commercial Scale 3D Printers.

You will also need to account for the material’s cost within your printing which is around $25 per Kilogram. I have been using Overture PLA filament which is a little cheaper but still great quality.

What You’ll Need for 3D Printing

By this point, you’ll already have the design software to get your idea on paper.

If you are printing these designs, then essentially all you will need is:

- A 3D printer (we will offer recommendations later) or hire a 3D Printing Service

- The materials for whatever it is that you desire to print. The most commonly used materials are:

- Generic APA PLA Filament

- Specialized Filament (ASA, PETG, Nylon, Flexible or Polycarbonate)

- stereolithography materials (epoxy resins)

- Polycarbonate

- Steel

- Wax

- Silver

- Photopolymers

Your printer will need to be compatible with this material so you may want to understand your purposes for printing before you make any ill-thought-out investments. Be sure that the material you select binds or functions with your printer. Do not purchase materials too large, dense, or incompatible with the 3D printer you’ve purchased.

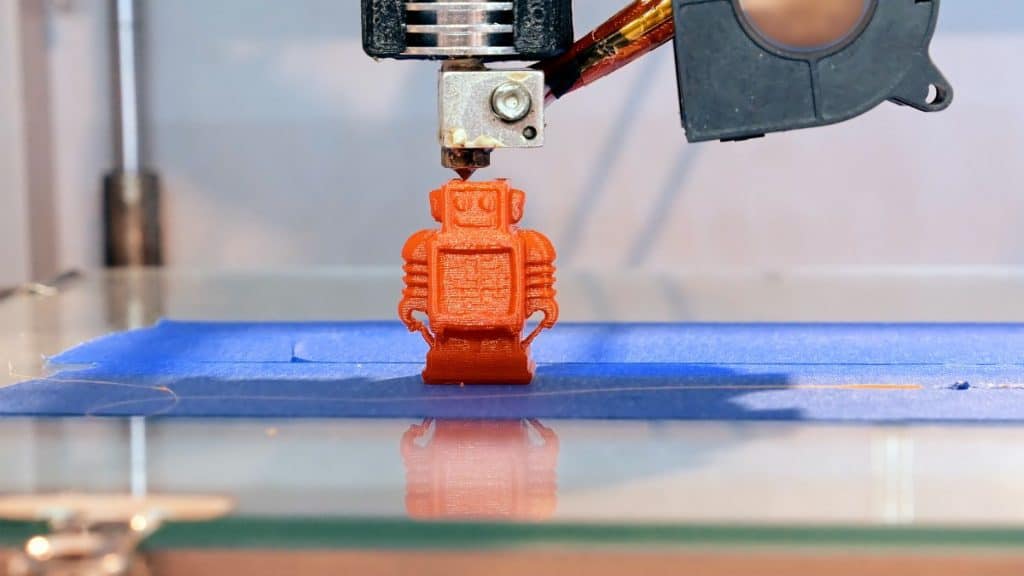

How to 3D Print

What you need to understand and visualize about 3D printing is that it’s like a printer printing words on the page, except layered upwards. Each layer gets printed vertically instead of horizontally or on a 2D/flat-dimension.

Layers pile over one another, building vertically to create a design that literally jumps off the page and stands as a physical item.

The steps to actually print your design will be as follows:

- Design your Model

– Use websites like Thingiverse that is a playground for 3D creatives! They offer up templates and people share models, tools, ideas, and much more! Other great resources we recommend that are repositories for 3D models include:

- My Mini Factory

- Know your exact measurements. Including:

- Length

- Width

- Height

- Arc across

- Radius

- Diameter if circular

- The scale between your design and the printed product

- You will most likely use millimeters as your measurement in printing so be sure all settings in your design software and rendering program match your finished product’s goals.

- Use mirroring, splicing, copy tools and shortcuts as you work to simplify the steps you need to take.

- Utilize Video Tutorials on 3D Printing Software to get a more visual idea of what this software is like. It will take lots of visual representations and practice to get good at these, so take your time and don’t rush the learning process. Taking your time to become familiar with whatever software you have chosen will only make your printed designs that much more successful!

- Load up your printer with the material you are printing with and allow it to heat up.

- Follow your instructions on the 3D printer you’ve purchased and allow it to print as slowly or quickly as it requires. Some printing jobs will take a few hours while others can take a few days. It will all depend on the scale of the design, materials being used, and the quality of the printer.

There are dozens of steps we could add into this list but it’s equivalent to learning code. Just as with any practice you can get a 4-year degree in, we do not have time to cover it here. Our advice would be to learn about:

- What you are specifically seeking to print

- Printer you purchase

- What you need to study

Best 3D Printers for Beginners

Some of the top-rated brands that we recommend for those new to printing are the following 3D printers:

For home printing projects:

- Monoprice Mini Printer 3D

- MiniMaker 3D Printer

- Creality CR-10 V2 *Personal favorite for the price

- Dremel Digilab 3D Printer for Hobbyists and Tinkerers

It is simple to purchase your 3D printer by simply knowing the purpose for which you want to print. Read reviews, set a budget that warrants the quality you are seeking to make, and go from there.

Final Tips for Successful 3D Printing

Some parting words of wisdom as you go off into your printing endeavors include:

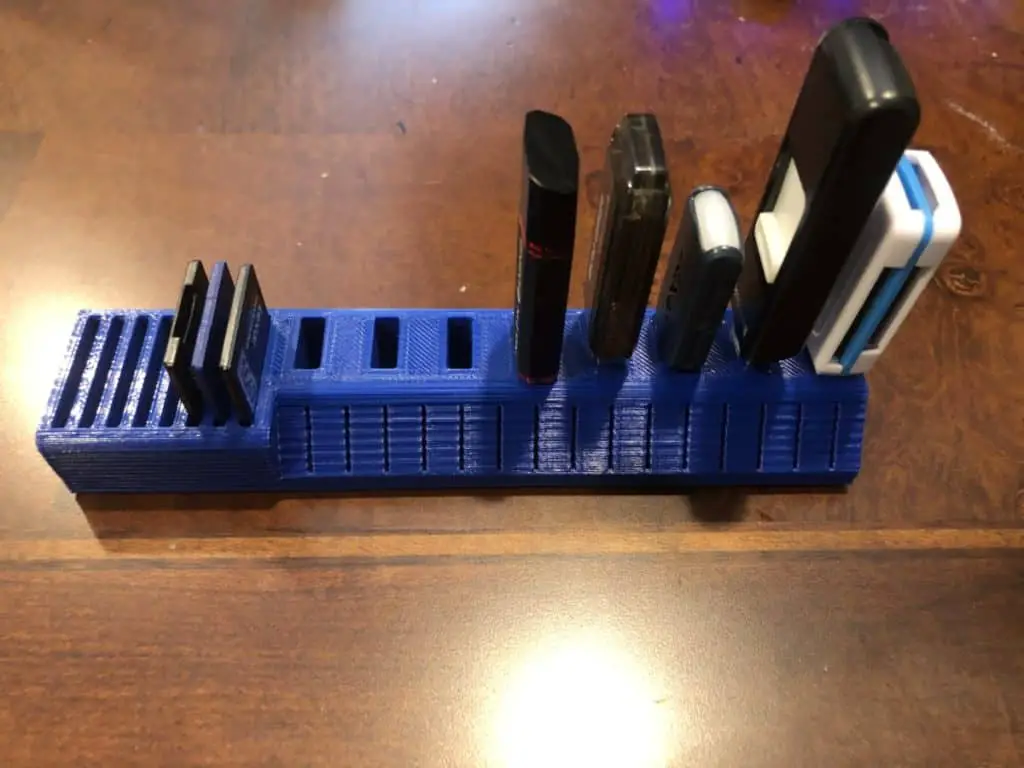

- Larger surfaces with larger bottoms will be stronger and more well-supported. You need a strong base to build from or your design may easily topple over. Keep in mind how lightweight the materials can be and how your design should work with this instead of against it.

- Since building layers vertically is an aspect so quintessential to the process, the layers will of course be the most difficult part for you to nail in printing. This may take some practice and time to get familiar with the software.

- Learning how to print 3D can take years to become an expert. Be patient with yourself and give yourself time to learn and make mistakes.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.