3D printing is an exciting new technology that is revolutionizing many industries. But what is a 3d printing and how does it work? If we understand the answers to these questions, we can use this technology to change our lives as well.

What is 3d printing?

3d printing is a process in which a 3d file from the computer is printed into a real 3-dimensional object. This technology is used in different industries to print out products and use them in business. It can also help print out things that we use every day. For example, you can print out a comb or really anything else you can think of.

Why would you want a 3d Printer?

3d printers enable you to make create items that are too difficult to make by hand in a relatively short amount of time for cheap. Considering that, it’s easy to see why people would want one. (You can check out my article here if your interested in seeing how much it actually costs to print something.) That said, make sure you get a decent printer so you don’t end up needing excessive bad prints or having to do a lot of cleanup work afterwards.

Why are there different types of the printer?

Print results can vary based on the type of printer you have but common factors include;

- Printer type

- Print speed

- Slicer settings

- Filament type/quality

- Resin type/quality

Due to these factors, there are different types of printers, to meet the demands of the users.

How do 3d printers work?

When the printing command is given to a 3d printer, the printer works in layers. Each layer is set out to produce the final object as it is guided by the computer file. From the printer, cross-sectional layers are printed out. The layer prints fit together to form the model that was there on the computer.

What is needed to use a 3d printer?

If you want to use a 3d printer, you need to know some information about the 3d printer. Once you understand how 3d printer prints and form the final model. Once you understand that 3d printing becomes an easy task. Before you print out a model, you must have the following;

- CAD file of the object

- You can get a lot of designs from thingiverse

- Slicing software such as Cura

- SD card or computer to connect to the printer

- Filament/Resin

- And of course, a 3d printer

Parts of 3d printers

Since there are various types of 3d printers, it is best to understand the parts of the 3d printers first. So, you can understand the mechanism of 3d printers.

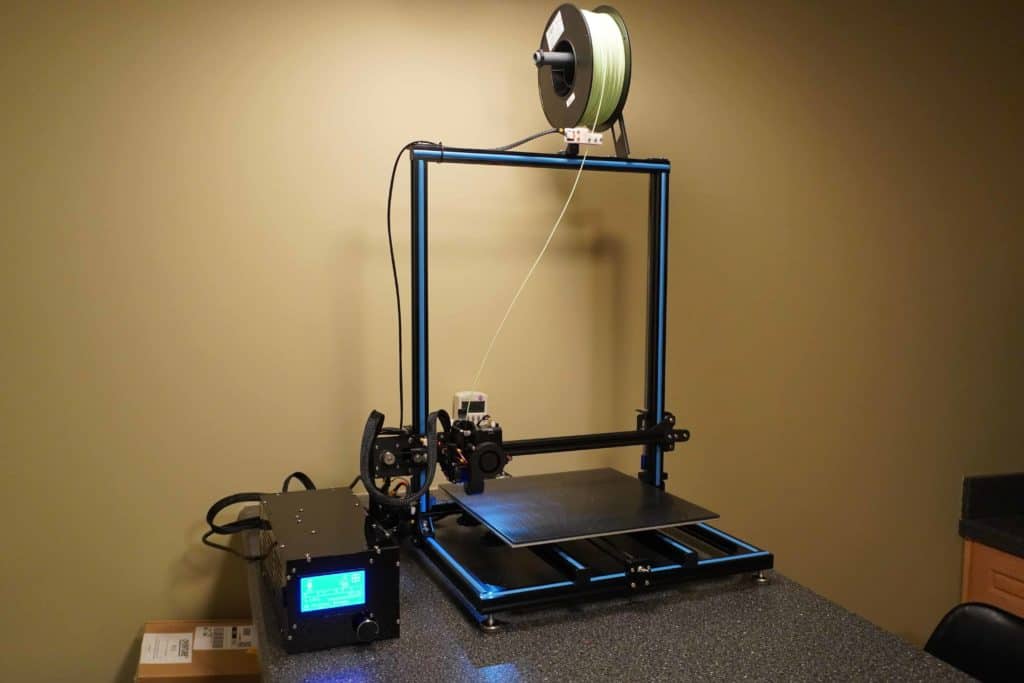

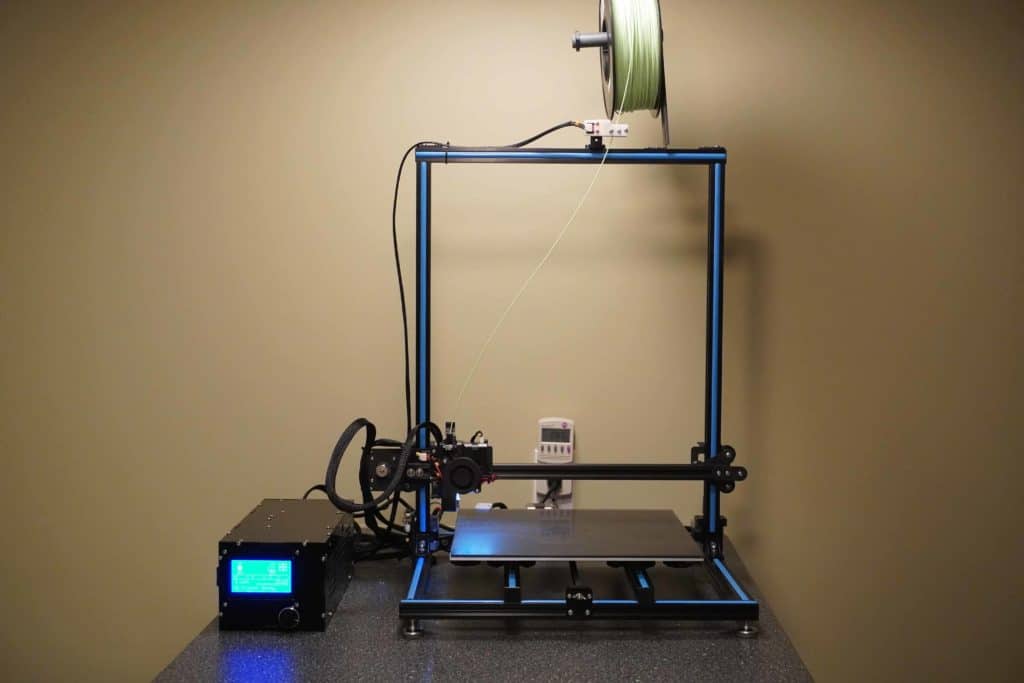

- Head movement: It moves in different directions concerning the print bed.

- Frame: It holds the machine in one piece.

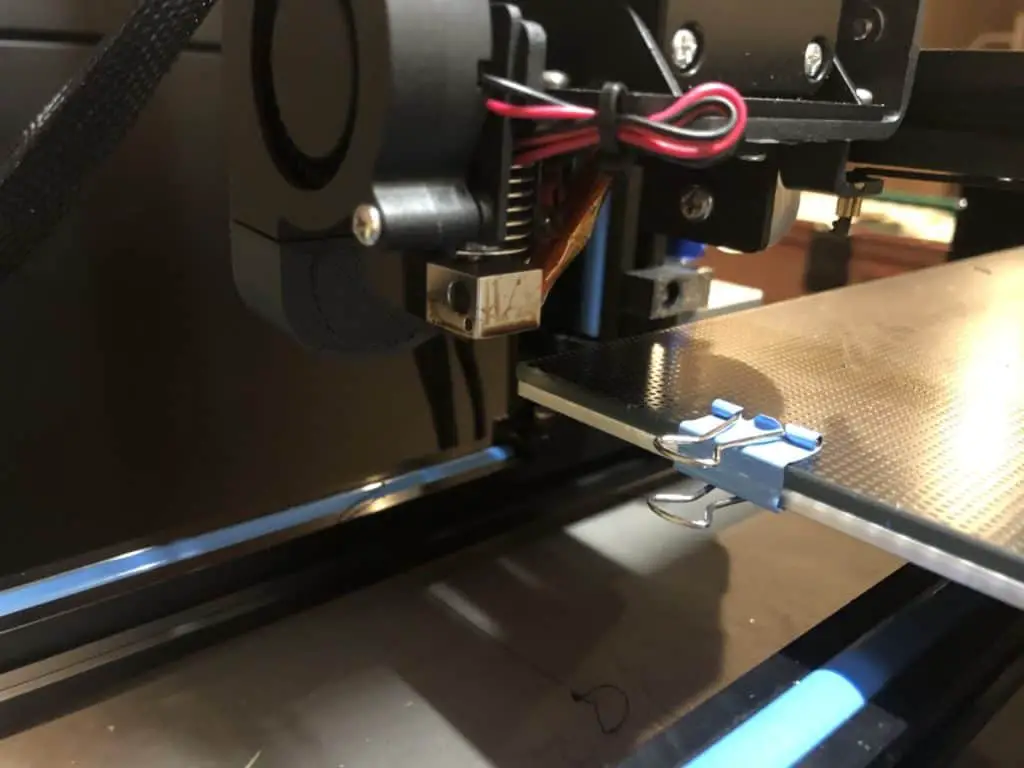

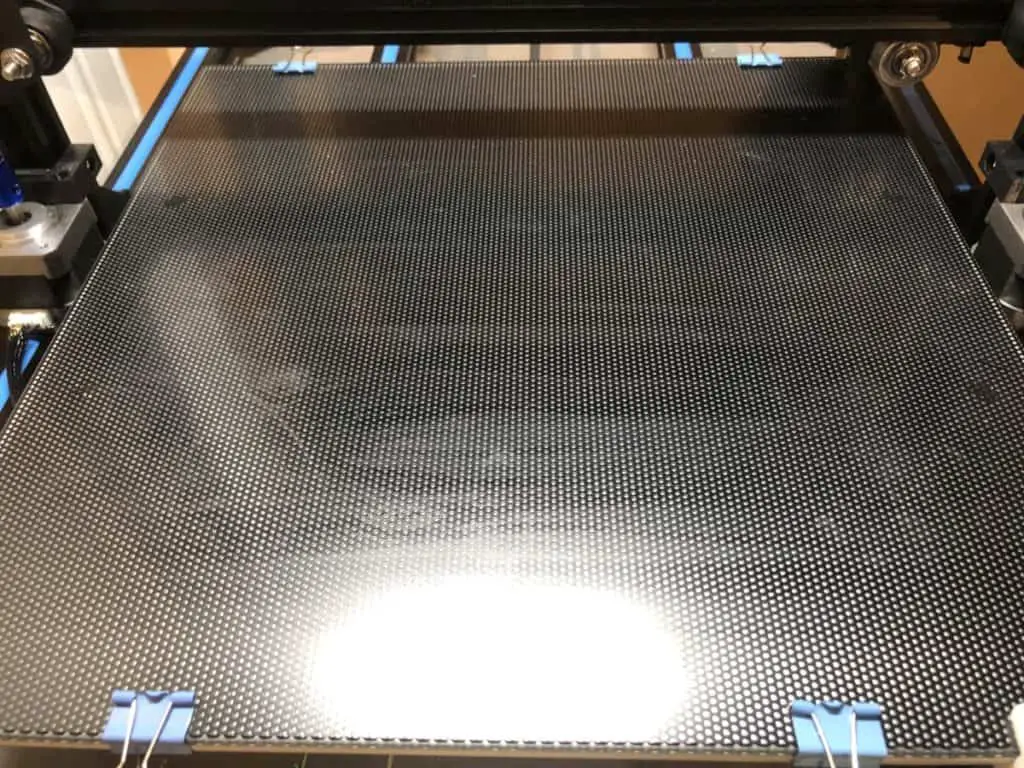

- 3d build platform/ the print bed: The place of the device where the printing is done.

- 3d printer head: It is a nozzle with which liquid is applied to the print.

- Stepper motors: A 3d printer at least need 4 stepper motors. It makes sure the printing is precise and controls the printing speed.

- Firmware: For any printer, some particular printing firmware is needed.

- 3d Software: This is mentioned before that for printing and 3d modeling software in needed where the data about the model lies. When printing command is given, the printer unfolds this information to make the real-life model as it is directed by the file.

How many types of 3d printers are there?

As 3d printing technology has developed over the years, there are seven different types of 3d printers. You will find out about them in the following paragraph.

Stereolithography (SLA) Technology

It is a fast 3d modeling technology, it can print out complex models in hours. Although the technology is fast, the outcome model is precise and accurate in measurements. You can expect to see SLA in production parts or similar uses.

The print out is made by using liquid photopolymers. When the printer is turned on it, read the information from the 3d file and heat the liquid inside.

The information about the shape of the model comes from the Cad file given on the computer. The printer than sets out liquids according to the data which solidifies in contact forming a precise prototype as directed by the files.

Inside the printer, there is a liquid photopolymer. When the printer reads information from the CAD file, this liquid is heated for printing. An ultraviolet laser is used to gain high accuracy while preparing the model which is directed by X, Y scanning mirrors.

Layers of liquids are dropped as it solidifies and a blade comes out and moves across each layer to make sure the model is smooth and accurate. This way continuous layers form the entire model from printing.

After the printing is complete, the model needs to be removed carefully. Sometimes a chemical bath is used to improve its shape. Extra resins are removed from the chemicals this way.

In some cases, the model is treated in an ultraviolet oven. The model gains more strength and becomes stable. Some people may add a final touch to the model by sanding.

The SLA printer has become popular in several industries. For example, medical, automotive, entertainment, product making uses SLA 3d printers.

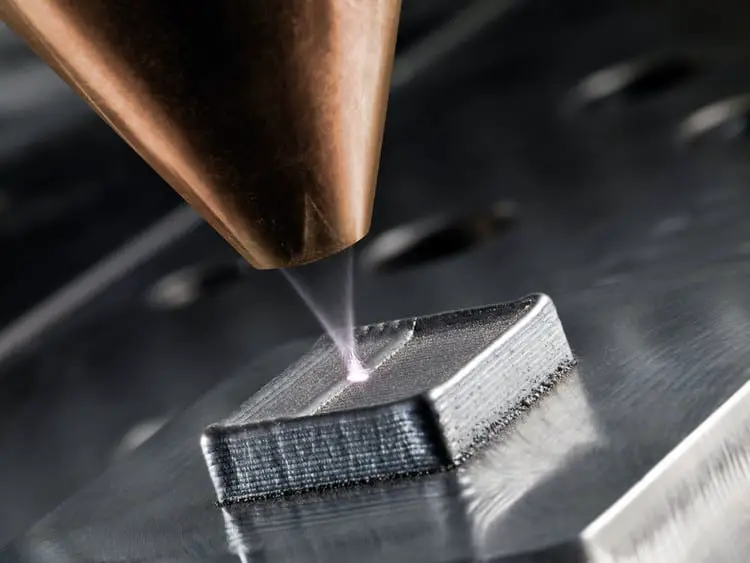

Selective Laser Sintering (SLS)

It is a technology where powdered materials are fused together with a laser to form and an object. The laser used here is a carbon dioxide laser. Although metal is the most common raw material here, other materials like glass, nylon, ceramics can also be used for printing.

In the printer bed, the powders are supplied to make the prototype. The bed starts from a height while printing. As each layer is printed, it lowers a level to form the next layer.

The model is made through sintering the powder at high pressure. The pressure is enough to liquidify the powder and gives it shape.

It is formed according to the file in the model. The sintering of each layer continues until the model is formed from the bottom to the top.

After the model is made, some powder is left in the bed. The excess powder is removed after removing the model from the platform. Since the model starts off as a pile of raw materials, the powder itself forms a medium for the structure formation. There is no need for additional support for making the model.

The prototype formed from the SLS technology is durable and precise. Both the SLA and SLS are similar in away. They produce sturdy and durable models. The only difference between the two is the raw material used for making the model. One uses powdered material while the other uses liquid resins. Even the printing speed of both technologies is the same.

When one needs to choose between SLA or SLS printing, he has

to choose via the material he wants for the model.

Fused Deposition Modeling (FDM)

In this type of 3d printing, thermal plastic materials are used to make the prototype. The technology is the most popular and known for producing precise models as well as models with more strength. It produces a quality object with more strength to weight ratio.

Here to print out something with FDM a sliced CAD file is needed. The file must use multiple layers to slice the data. When sent to the printer, it reads the file and starts building the object one layer at a time.

Inside the printer, the thermoplastic is heated inside the nozzle and poured in layers to form the object. It also contains the supporting material for printing. As the raw material, the supporting material also comes out when it is needed during printing.

When the supporting material is necessary for the shape, it is poured instead of the raw materials. Later upper layer is formed above the supporting material by flowing thermoplastic filaments. The supporting material dissolves on its own when the printing is done.

The printing time depends on various factors such as the form that needs to be printed and the size of the print. If a large object is printed, it will certainly take more time than a small one.

Once the model is printed, some objects might need cleaning. Since the entire body is made out of filaments, it may leave marks on the final product. Some artists may fancy it, but for a finished, smooth product needs sanding.

The products of FDM printing are durable, hence it is used in the engineering and manufacturing industries. Many famous companies use FDM technology to make their products and sell them.

Direct Metal Laser Sintering (DMLS)

You have learned SLS before which is sintering technology.

DMLS is also a sintering technology. It is based on using metal powder to

produce objects direct from the printer.

After manufacturing the metal particles range from 20 to 40

micrometers. The metal shape and size affect the print resolution. If the

particle sizes are similar, they produce prints with higher resolution.

Similarly, if the particles have a smaller size, they produce high-resolution objects. Hence, the size and shape of raw materials are very important in this type of printing.

Additional factors that affect the 3d printing resolution are the size of the layers and laser point. Usually, the printing height limit of each layer is the maximum size of the powder particle. All these factors affect how the metal structure resolution will be in the end.

Electron Beam Melting Technology (EBM)

A powerful electron gun is used to make 3d models in this 3d printer. Electrons are projected with high power in a vacuum space. It lands on the metal surface melts the metal changing its shape in the process.

As it is with all 3d printers, EBM works in layers to complete the structure. Each melted part changes its shape in layers on its ways up to form the final product. You can expect the product to have high-quality curves and bends that finishes as a perfect print.

The technology gives the freedom to form any type of structure from metal. Complex structures are formed in detail with EBM. The resulting products are strong, durable and dense. Hence many production companies that need strong parts use this technology to produce them.

If you compare the models made from EBM and other technologies these are some benefits you are going to get;

- EBM technology produces products fast in a short time. So, if you are a businessman, you will make more money fast with EBM technology.

- It does not need additional materials to complete 3d printing.

- Useful, durable and complete parts can be made from the system.

- High efficiency in using raw materials and producing the desired model.

Laminated Object Manufacturing (LOM)

Here the raw materials for printing are layers of plastic or paper. They are placed together in layers to form the shape and then heat and pressure are applied to form the structure.

When the printing begins the plastic layer is set, a cutter from the printer cuts out the layer in shape. If cutting this layer is complete, it moves to the next layer which is 1/16th inch below. The cutters come out again to shape the model.

This way as the entire model is cut to complete the form, heated rollers come out. They roll over the model to smoothen it and give it a final touch. The heat melts the layers just enough to join them and form the final structure.

Inside the printer, the command sets in the following ways;

- The sheets are heated with a roller.

- A laser is used to drawing the shape of the object on the material.

- The laser forms hatch to mark the unwanted areas of the material.

- If the shaping is done, the platform moves down.

- Another sheet is placed for the next layer.

- The entire process is repeated.

Digital Light Processing Technology (DLP)

This is one of the oldest 3d printing technologies there is. The printing process is similar to SLA technology. In this technology, instead of ultraviolet rays, traditional lights are used. As a result, the printing process is extremely fast in DLP.

The liquid plastic is poured in a translucent container where it gets shaped. Here the layers are cut and shaped after that light is used to harden the liquid.

In DLP arc lamps are used for the hardening process. The entire process is really fast. If SLA and DLP printing are compared together DLP is much faster. This is because to achieve perfection is shaping the model SLA cuts out each layer. But in DLP the entire model is cut out at once which saves time. So, the product comes out of the printer with high speed.

Although the technology makes models quickly, and it is one of the oldest 3d printing there is, it does not sacrifice quality. The models made form DLP have high resolution.

Apart from that, the technology is cheaper. You can use cheap materials to make models with good quality. Any other technology needs costly materials for production. It reduces waste materials and saves money in the process.

Final words

These are some of the most know technologies of 3d printing that are used in various industries. As 3d printing technology is developed, it is changing many industries. It helps in making products fast and efficiently which is great for everyone.

As further innovations are introduced in 3d printing who knows how much we can advance with the help of this technology. In the coming years, we may notice more innovations in 3d printers with new materials for model-making options.

Since the demand for 3d printing is rising, its price will fall very soon. So, 3d printers will be more accessible to the people in the market. Perhaps at that time, 3d printers can have a greater effect on our everyday lives.

If you would like any additional details or have any questions please leave a comment below. If you liked this article and want to read others click here.