The 3d printing hobby is fun when things are going well but can be frustrating when things go wrong. On more than one occasion, I have come home to a print that has stopped mid-way through, and in most cases, the print ended up being ruined. In this article, I plan on covering five common reasons your 3d printer stops mid-print and go over ways to reduce the risk of them occurring.

Here are five common reasons your 3d printer may stop mid-point.

- Thermal cutoffs

- Power Issues

- Filament Issues

- Clogged Nozzle

- Pause command in the g-code file

There is a lot more to each of these issues than you may think, so keep reading to learn more about them and ways to help reduce the risk of one of them happening.

Power Issues

If you live in an area where the power frequently goes out or has brownouts, running a 3d printer may be challenging. This is especially true if you like to print larger objects that take a long time to print as a common issue that will cause your printer to stop mid-print is losing power. There are some ways to mitigate this problem, but they still have limitations.

How to fix this?

Resume from power loss feature

If you already have a 3d printer, the first thing you can do is check to see if your printer has the resume from power loss feature. It should be in the documentation for the printer but you can also test this by kicking off a small print and unplugging the printer. When you plug the printer back in, you should get the option to resume the print if the feature is there. If you are looking to purchase a printer, you will want to make sure that the feature is explicitly called out.

While this feature is useful, it still has issues. First, if you accidentally hit the wrong button on power-up, there is no way to go back and resume the print (I’ve done this before ☹). Second, any time you stop a print, you risk there being quality issues in the area it resumes at because the printer has to re-purge the nozzle and hope no extra filament was left on the print from the nozzle still being hot when it lost power.

Battery Backup or Uninterrupted Power Supply (UPS)

The second option, which can be combined with the first one, is you can have the printer connected to a battery backup. You will need to make sure the battery backup is capable of handling the wattage called out on the printer’s power supply, but that typically won’t be an issue as they don’t use that much power. The larger the battery backup is, the longer it will be able to run the printer when the power is out.

If the power goes out where I live, its typically for either a couple of seconds or a couple of hours. The latter situation is pretty rare, so I don’t try to account for that. Having a battery backup that can last 5-10 minutes is typically all I look for (even for my computer). Right now, I have a larger one on my printer (shown below) because I had an extra one available.

Here is the battery backup I recommend. It provides plenty of coverage at a fair price. The only thing I don’t like about it is it doesn’t tell you the remaining run time.

CyberPower EC850LCD Ecologic Battery Backup

Clogged Nozzle

Another issue that can cause your printer to stop mid-print is the nozzle getting clogged. The behavior of a clogged nozzle will vary based on the severity of the clog. If it’s just a slight clog, you may still see some filament come out, but it will be inconsistent and can lead to a full nozzle clog. If it’s a completely clogged nozzle, you will not see any filament come out, and you would probably hear the extruder motor grinding the filament because there is nowhere for it to go. If either of these happens, I would stop the print and work on clearing the jam if you can. That said, it’s possible that the nozzle will need to be replaced.

Common Causes of Clogged Nozzle

Here is a list of common causes of clogged nozzles.

- Low-quality filament with an inconsistent diameter

- Swollen filament from excessive exposure to moisture

- Hot end temperature too low for the filament type used

- Nozzle being to close to the build plate

- Dust or other debris in the hot end

How to fix a clogged nozzle?

There are a couple of ways to clear a clogged nozzle, but the success will depend on how bad the clog is. A common method for a partially clogged nozzle is the cold pull method, but I haven’t had much success with it. I could write an article on this alone, so I don’t want to go into to much detail here.

Another method is to use a nozzle cleaning kit with needles to help push the stuck filament through. You will want to make sure you heat the hot end to help melt the filament unless it won’t go anywhere.

The last option which is what I tend to do when the nozzle is completely clogged, is to just replace the nozzle. The process isn’t complicated, and assuming you are using a brass or copper nozzle, the replacement cost is typically less than 50 cents. If you are using a hardened or stainless nozzle, I would still attempt to clear it before going the replacing route because they are a lot more expensive.

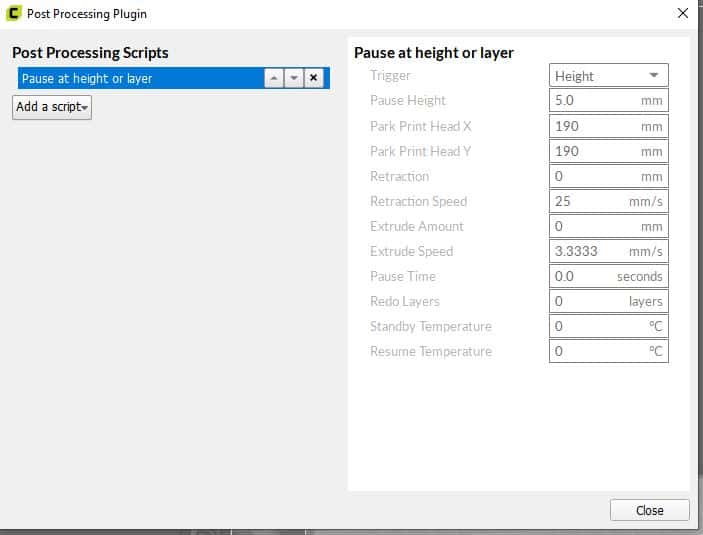

Pause Command in G-Code

This is one that many people tend to overlook and has caused me issues more than once. In most slicers, including Cura, there are built int post-processing plugins that are capable of having your printer pause at a specific height or layer. If you have never worked with the plugin before, then its probably not the cause of any issues you may be having, but if you have, then its possible it is.

The plugin works great. It does what it’s supposed to and can be helpful when you need to change between filaments mid-print. The problem I have run into is if you leave Cura open and start slicing another object, those settings will still be there. So if you forget to manually remove the settings, it can end up in the next object you slice.

How can I fix this?

The only real way to prevent this from happening is to either not use the plugin or make sure you disable it after you use it. It’s easy to forget about it when you slice another object, especially if it’s a couple of days later.

Filament Issues

Filament issues can also cause a 3d printer to stop mid-print, but in most cases, these issues can be prevented. I’m going to go over the most common filament issues and talk about how they can be prevented.

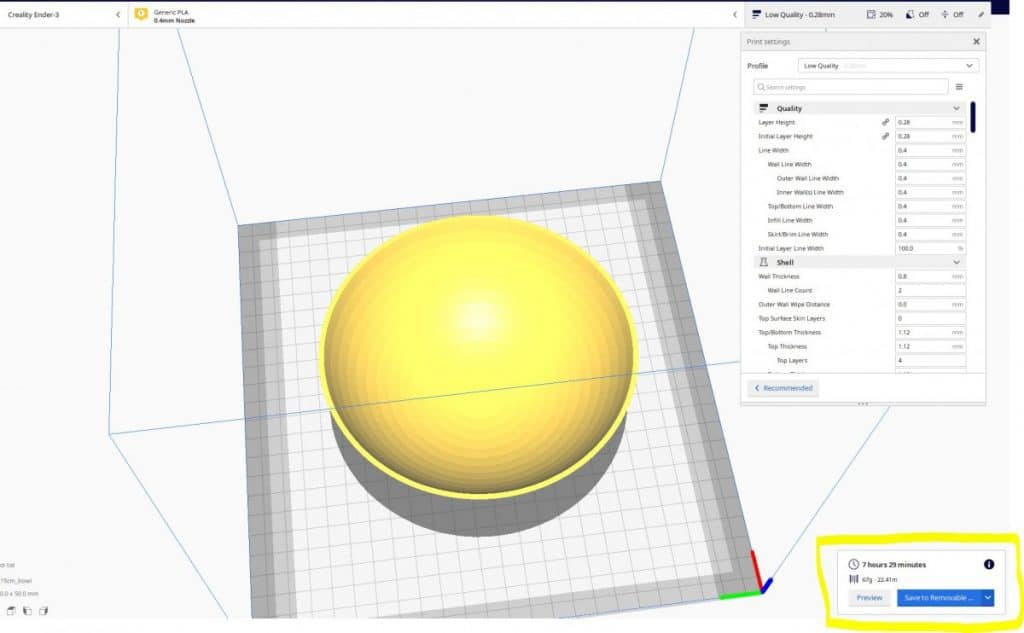

Out of filament

The most common issue related to filament is running out of it. There isn’t much you can do once you run out, but you can take a couple of steps before starting a print to make sure you have enough. Before I start a print, I look at the estimated filament requirement called out in the slicer. If I cleary have enough filament, I will just start the print. If its not a clear answer, I will weight the filament spool I’m using (subtracting the weight of the spool its self) to see how much I actually have. You will need to have an extra empty spool to weigh, or just have the weight.

Another option would be to have a filament sensor that will pause the print when you get close to the end of a roll. Some printers come with the sensor, but many do not. If the printer you are working with doesn’t have a sensor, you can always buy an add on one like the one below.

The last option here is to use a plugin for OctoPrint to track how much filament you have used and how much should be left on the spool. I have used this before, and it’s a good free option but requires OctoPrint and additional setup.

Grinding Filament

Filament grinding can happen when the extruder motor gear grinds against the filament. This can occur when there is a clog in the nozzle or something else causing resistance to the filament. The only way to fix it would be to clear the clog or fix whatever is causing the resistance.

Scraped Filament

Scaped filament can happen when the filament grinds against the frame or something else along the way. You can typically prevent this by tracing the filament from the spool to the extruder to make sure it’s not touching anything and isn’t kinked.

Snapped Filament

There are several things that can cause filament to snap, including mechanical stress, too much moisture, or its just low quality. This can be prevented by making sure you buy quality filament, storing it properly when not in use, and making sure there isn’t much pull on the filament during the print.

If the filament does snap and you catch it, you can possibly save the print by pausing it and replacing the filament past the snap. If you don’t catch it, you will probably end up having to start the print over again.

Here is a video I made covering how I store my filament when it’s not used.

Thermal Cutoffs

Thermistor Issues

A thermistor is basically a probe that is used by the 3d printer’s firmware to keep the bed and hot end at the set temperatures. It will tell the firmware to engage the heating element when under the set temperature and turn it off once the temperature is reached. Assuming the printer has a heated build plate, it will have two thermistors, one for the hot end and one for the build plate.

Most firmware will have a thermal runaway feature that will stop the printer if there is an issue with either thermistor to prevent damaging the printer and possible fires. Typically thermistor issues present themselves as a MINTEMP error, meaning the temperature has dropped below the temperature defined in the firmware. As annoying as this error may be, it’s not something you want to play around with or try to bypass.

Can this be Prevented?

The number one casuse of thermistor issues is a break in the circuit somewhere. In some cases, this can be caused by accidentally damaging the cables. In other cases, it may just happen randomly. The only thing you can do to help prevent thermistor issues is to be careful when working around the cables and make sure no wires have excessive tension on them, especially when printing.

How can I fix a broken thermistor?

The short answer is you cant reliable fix a broken thermistor. If you have issues with one you will want to make sure all the wires are intact and connected correctly. If you are still having issues after that you will most likely end up needing to replace the thermistor. The process isn’t too hard but may be intimating to someone that hasn’t done it before.

Here is a video I did covering how to replace the hot end thermistor on my Taz 6. There are some things that are specific to that printer, but most of the process will be the same on most printers.

Overheated extruder Motor driver

The extruder motor is the most heavily used motor in your 3d printer. It’s responsible for all filament movement and is constantly making quick moves to push or pull the filament based on the needs of your print. This can put a lot of strain on the printers’ electric components, causing them to heat up.

Most mainboards have a thermal cutoff that will cause the overheated driver to stop working. If this happens, the printer will continue to behave like its printing by moving the other axes, but no filament will actually move through the hot end. If this happens, there is very little you can do to try to resume the print. You could try to measure the height and reslice starting at that point, but I have not had good luck doing that.

Why does this not happen to the rest of the motor drivers?

The rest of the motors do not have anywhere near as much movement as the extruder motor. The X and Y-axis may seem like they are moving a lot, but their movements are typically longer and more spread out. In comparison, the movements on the extruder motor are tiny and basically continuous.

How can I prevent this from happening?

You can help prevent this from happening by following doing maintenance, having proper cooling, and making sure you have a heat sink on the drivers.

Proper Maintenance

Doing proper maintenance on your 3d printer will help prolong its life span and keep it running well. I don’t want to go into to much detail on all the maintenance required, but I did a video covering what I do (shown below). One maintenance task you would want to focus on to prevent overheating the motor driver is blowing off the dust on the mainboard. Over time the dust will build up and will cause the board, and drivers, to run hotter.

Proper Cooling

Most 3d printers on the market today have a fan somewhere around that mainboard that will blow the hot air out of the enclosure. You will want to make sure your printer does have that fan and that it works. If your printer has a fan and you are still having issues, you can look at buying a more powerful fan, though if you go this route, make sure you get a fan that runs quietly (like this one), or it will end up just annoying you.

One thing to note is that depending on your mainboard, the fan may not kick in until it’s needed. So if you have a fan and it’s not running, it may just not be required at that time.

Heat Sinks

Most decent mainboards have four motor drivers with heat sinks of some sort on them (quality may vary), but if you have one that doesn’t or you replaced the mainboard forgot to add them, you will want to correct that. They are not very expensive and will mage a considerable difference in the temperature of the driver.

You will want to make sure you measure how much space you have and get the ones that will fit. I added a link to a standard-sized one below. The install process is typically just peeling off the plastic and sticking the heat sink on the chip/driver and doesn’t take much time. Just make sure you don’t have the printer plugged in when doing it.

Recap

Troubleshooting issues with a 3d printer can be a challenging task but once you understand what the printer is doing, it becomes easier. Thermal cutoffs, issues with power, filament issues, a clogged nozzle, or a pause command in the g-code file can cause your 3d printer to stop mid-print, but as I mentioned in the article, there are things you can do to reduce the likelihood of them happening to you.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.

Very helpful Rob, you outlined the possible causes and solutions so well. I had lost many prints most likely because of filament (Dremel) issues, despite my taking good care of storing them. I’m new in 3D printing and I don’t know to measure (accurately) and reslice starting from where it stopped. Is there a printer out there that has a feature of resuming it from where it stopped? That way we don’t lose lots of filaments esp. if it is a big part.

Thank you.

Hi. Thanks for the feedback. There are a lot of 3d printers on the market that have power loss recovery, including the Ender 3 v2, but I’ve haven’t had the best of luck with it overall. If you have a lot of short power outages in your area, I would look at getting a battery backup for it.

Hi Rob,

I wonder if you could give some advice. I have an Anycubic Mega 3 that I bought about six months ago. Yesterday my filament stopped but the print kept going, so it was printing in midair for an hour or so. Today It happened again, and I noticed that the hotend was cold, so the filament had plugged up the nozzle. It was hot and printed beautifully for about 4 hour previously. I changed the hotend and Bowden tube about 2 weeks ago and the nozzle is brand new yesterday.

Thanks for any advice you can provide!

Larry.

Hi,

If the hotend is cooling down for whatever reason mid-print it will cause the filament to stop flowing and you will see a lot of grinding on the filament at the extruder. If everything is heating up properly to start with the hotend thermistor may be going bad, but it’s hard to say for sure.

Hi Rob, Thanks for getting back to me. Do you happen to know where the thermistor is? On the motherboard? I replaced the hotend a few weeks ago. Best regards! Larry.

It’s at the bottom of the board under where the endstops connect.

OK thanks, appreciate it! Larry.

Hi Rob,

I am having an issue similar to this, on longer prints or ones I have overnight they will fail at random points without any sign of what fails, it will suddenly stop and the recover print message come up on the screen, would it be a cooling issue or something else?

Hi,

I don’t think the board will pause the print if it’s overheating, but I cant say that for sure. Do you have a runout sensor anything like that connected? I’m thinking it may be triggered by that or possibly a brownout (not sure how good the power is for you).

Thanks,

Rob

Hey Rob, I’ve been having an issue with my Ender 3 v2 and of everyone I’ve asked and everywhere I’ve searched there hasn’t been a related problem or solution. Glancing over your posts I haven’t seen anything that might be in relation to it either

I bought my printer about 2 weeks ago and had a few prints come out fine. At some point I had prints that would get about 80% done and then it would stop and exit to the menu screen without the option to finish the print.

Now it will get about 1% or 3% into a print and do the same thing, every single time I try to print.

Has anyone come to you with this problem? Any idea on a solution?

I haven’t seen this before but it may be from corrupt firmware or EEPROM. I would update the firmware, clear out the EEPROM, and try again.