PLA filaments can go bad if you do not store them properly. Moisture, heat, sunlight, and ultraviolet radiation can damage all PLA filaments to varying degrees, not to mention that you may have a bad quality PLA filament from the manufacturer. So, what can you do with a bad PLA filament?

Here are the five best things to do with bad PLA filament depending on its condition:

- Return new spools for a refund, credit, or exchange.

- Use low heat to restore moist and brittle PLA filament.

- Use the bad or restored PLA filament for experiments.

- Run tests and calibrate the printer with bad PLA filament.

- Recycle the bad PLA filament.

These recommendations will not serve every scenario identically. So, you must choose a solution based on the exact condition of your PLA filament, the cause, and if the spool has degraded in time. Read on to see which approach works best for you.

1. Return New Spools for a Refund, Credit, or Exchange

There is no universal formula or global standard for all PLA filaments. Every 3D printing filament manufacturer has its distinct approach. The PLA apart, these filaments contain dyes and other materials for specific colors, strength, and performance.

Thus, PLA filaments are not identical. The differences in composition are why one PLA filament may print well at 410 °F (210 °C) while another needs 428 °F (220 °C).

Also, PLA filaments of questionable quality may have substantial dust or substances that should not be present. Not every manufacturer making PLA filaments has impeccable facilities. Hence, you cannot do much with a PLA filament that is not just mildly bad but defective and unusable.

If the subpar filament is new, return it immediately and seek a refund, credit, or exchange from the manufacturer. All credible brands have a return, refund, and exchange policy. However, most policies have a specific duration and process, so check these and proceed accordingly.

2. Use Low Heat To Restore Moist & Brittle PLA Filament

You can’t return a bad PLA filament to a manufacturer and ask for a refund, credit, or exchange after the stipulated time per the company’s policy. Also, your PLA filament may become brittle if it is not stored in a sealed bag or container to protect it from humidity or moisture.

Most 3D filaments or thermoplastics absorb moisture. Nylon absorbs much more moisture than others in humid settings, but PLA is not immune. Your PLA filament will be brittle and almost unprintable if it is exposed to moisture or high humidity for a prolonged period.

3D PLA filament swells as it absorbs moisture and the saturation point is usually around 40 microns. Hence, a PLA filament’s diameter can increase by as much as 40 micrometers if it is exposed to sufficient humidity or moisture.

The only solution is drying the bad PLA filament. Low or moderate heat will dry the filament, alter its brittleness, and you will have a printable thermoplastic again. However, you must exercise caution not to overheat the filament. Otherwise, it will melt and be unusable.

Here are the steps to dry and restore bad PLA filament:

- Get a food dehydrator that is large enough for your PLA filament spool.

- Place the spool inside the food dehydrator. Remove or modify the trays as needed.

- Set the temperature at 104 °F (40 °C) and let the filament dry for 4 to 6 hours.

- Dry the bad PLA filament longer if it is still brittle.

Note: You can increase the temperature up to 122 °F (50 °C), but not any further.

PLA’s glass transition temperature is from 140 to 149 °F (60 to 65 °C). So, you should not heat the filament at those temperatures. Also, your filament is not pure PLA, so the glass transition temperature may vary.

Some people heat and dry moist and brittle PLA filaments in an oven. But that is tricky. Many ovens do not have a temperature setting as low as 104 °F (40 °C) or 122 °F (50 °C). If you use a temperature higher than 140 to 149 °F (60 to 65 °C), a PLA filament may become gooey.

If you must use an oven, preheat it, and dry the PLA filament for a brief period. Decide this duration based on the heat setting. For example, if your oven does not go below 170 °F (76 °C), allow the temperature to start dropping, and keep a moist PLA filament for 30 minutes or so.

3. Utilize the Bad or Restored PLA Filament for Experiments

You can restore moist and brittle PLA filament and use it normally. However, if you have a PLA filament that has been damaged by heat, sunlight, or ultraviolet radiation, the thermoplastic may no longer be suitable for quality prints. UV can discolor PLA and affect its melting point and performance.

You can use this degraded PLA filament for experimental prints. The discoloration should not affect your prototypes as it is only a cosmetic or aesthetic issue.

Also, the effects of UV on unprinted PLA filament’s melting point and thus the heat settings are minimal. Therefore, the nozzle, hotend, or extruder settings do not require significant changes.

However, prolonged UV exposure may make PLA filament brittle. And there is nothing you can do to restore such a spool. Plus, a significantly brittle PLA filament is unprintable.

4. Run Tests and Calibrate the Printer With Bad PLA Filament

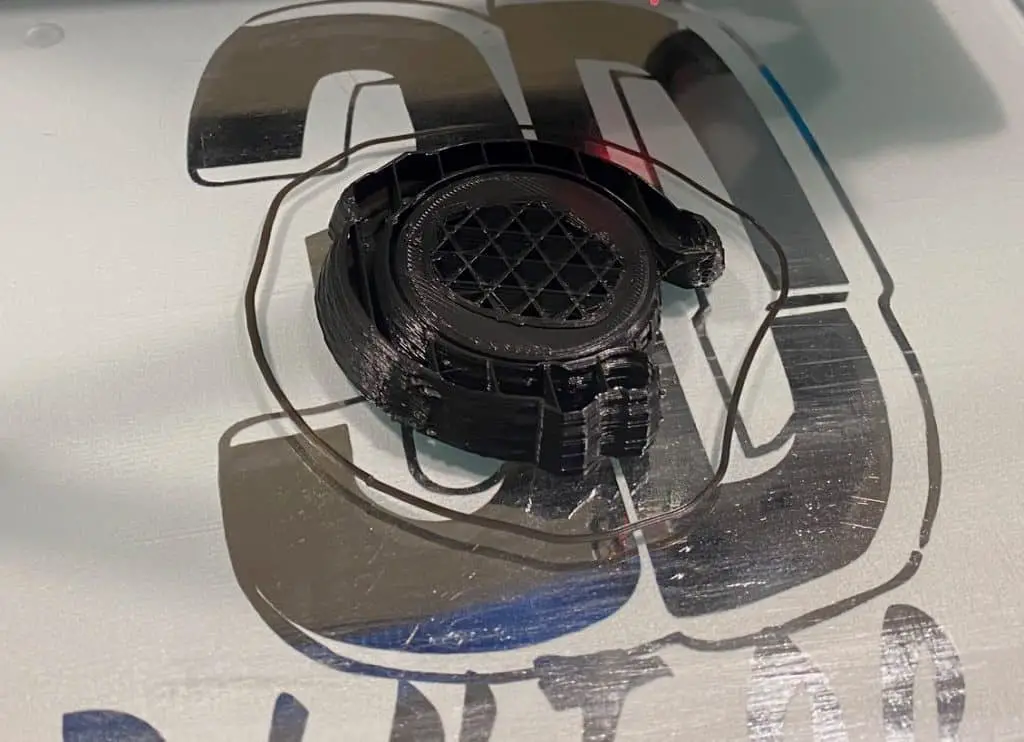

If your PLA filament is beyond restorable, use it to run tests and calibrate your 3D printer.

Check for over and under extrusion. Increase the temperature and extrusion multiplier to flush a clogged nozzle. Print quaint shapes or try the settings you have not used, say, fillet, chamfer, or anything else. Change the diameter and layer height for a model and see what happens.

A moist and brittle PLA filament will snap or break and stop a 3D print. But a failed print is not a concern for experiments, tests, or calibrations.

5. Recycle the Bad PLA Filament

Last but not least, recycle a bad PLA filament if there is no way to salvage and use any of it.

Like many 3D printing enthusiasts, you may wonder if there is a way to salvage an unusable PLA filament. A few people have tried to recycle their failed PLA prints and discarded supports, among other wasted filaments.

However, doing so requires effort, time, resources, and money. Also, there is no certainty that you will have a tangible return.

Related Articles

- Does PLA Filament Need To Be Dried Before Use?

- How To Tell if PLA Filament Has Gone Bad

- PLA vs PLA+ – What’s the Difference?

- All About 3D Printer Plastic

- Does PLA Need to Be Kept Dry?

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.