In 3D printing, fillets enhance the aesthetics of a model’s design for a fantastic finish. However, fillets are vulnerable to many issues, like most designing elements and slicer settings in FDM 3D printing. So, are fillets hard to 3D print?

Fillets aren’t hard to 3D print if they are along the X-Y axis with a radius or diameter suitable for the adjacent sides. However, fillets along the Z-axis are tricky because they have steep overhangs and thus require support. Also, you must consider variable layer height.

So, let’s talk about fillets and how challenging it will be to incorporate them into your 3D models and prints. I’ll tell you everything you need to know about fillets so that you can create the durable, aesthetically pleasing designs of your dreams.

Why Are Fillets Hard to 3D Print?

Fillets are hard to 3D print due to layer separation, warping, and imperfect rounding of the corners. These problems are more prevalent in 3D fillets with a Z-axis orientation. However, you can use supports, infills, and variable layer height to overcome the issues.

Fillets are like any other crucial design element in 3D printing. Thus, you must customize every critical aspect to ensure the part doesn’t fail or turn out with a flawed finish. The following are the typical reasons why fillets are hard to 3D print.

Imperfect Rounding of Corners

Fillets are round interior corners with no sharp edges, whether you orient them at 90º or other angles. So, your slicer should get the 3D printer to create a flawlessly round or curved corner when you incorporate fillets. However, you can’t have perfectly rounded corners if there’s a curvature issue.

This problem of imperfect rounding can happen on the X-Y axis, but the issue is more likely if the fillets turn towards the print bed, i.e., the curvature has a Z component.

Imperfectly Rounded Fillets Along the X-Y Axis

In theory, fillets should print easily if you 3D print them along the X-Y axis. You’re essentially printing a curved edge at selected parts of the model. Still, you may have an imperfect fillet if the curvature is too tiny or erratic regarding the adjacent sides.

A 3D printer nozzle should be able to make a perfect curving move along the X-Y axis. However, if your object is too small or the 3D design doesn’t allow you to get the geometry right, the fillets will not turn out as you desire.

Geometrically, the circumference of a 3D fillet or curved surface area (perimeter) should be proportional to the circle’s radius, as calculated using the mathematical constant Pi (π).

Imperfectly Rounded Fillets Along the Z-Axis

Fillets along the Z-axis have the same issue as those along X-Y if the adjacent sides, radius, and curvature aren’t proportional. Additionally, fillets with a Z-axis component have overhangs. Thus, these fillets may warp or have layer separation even with an accurate radius & curvature.

The other rounding issue along the Z-axis is due to the fundamental mechanics of 3D printing, especially FDM. You may be familiar with this problem if you’ve 3D printed a design with a hole or cylindrical port horizontally and vertically.

Suppose you want to 3D print a nut. You can do so horizontally or vertically. However, if you 3D print a nut vertically, the hole may have some bridging as the nozzle completes the curve at the top. Thus, the curvature will be flatter there. The same problem is likely with fillets on the Z-axis.

Here is a video illustrating this issue:

Plus, you will have to deal with layer separation and potential warping, among other problems, with 3D fillets along the Z-axis. However, there are effective ways to deal with all these challenges.

What You Need To Know About Fillets in 3D Printing

As is the case with several aspects of 3D printing, you have to customize the design and slicer settings to overcome the typical hurdles with fillets. Of course, the customization depends on the slicer you use and the 3D model you wish to print.

Some slicers allow you to combine cubes, cylinders, and other shapes for the curvature of 3D print fillets. Other slicers have built-in fillet functions that you can use to modify a 3D design.

So, let’s look at some important factors and steps to consider when you design and print fillets:

Choose the Right Radius or Diameter

3D print fillets should have an appropriate radius or diameter for the adjacent sides, regardless of the axes. A tiny radius may lead to an unexpected angular finish, not a smooth and rounded surface. In contrast, a larger radius than required may lead to an odd shape.

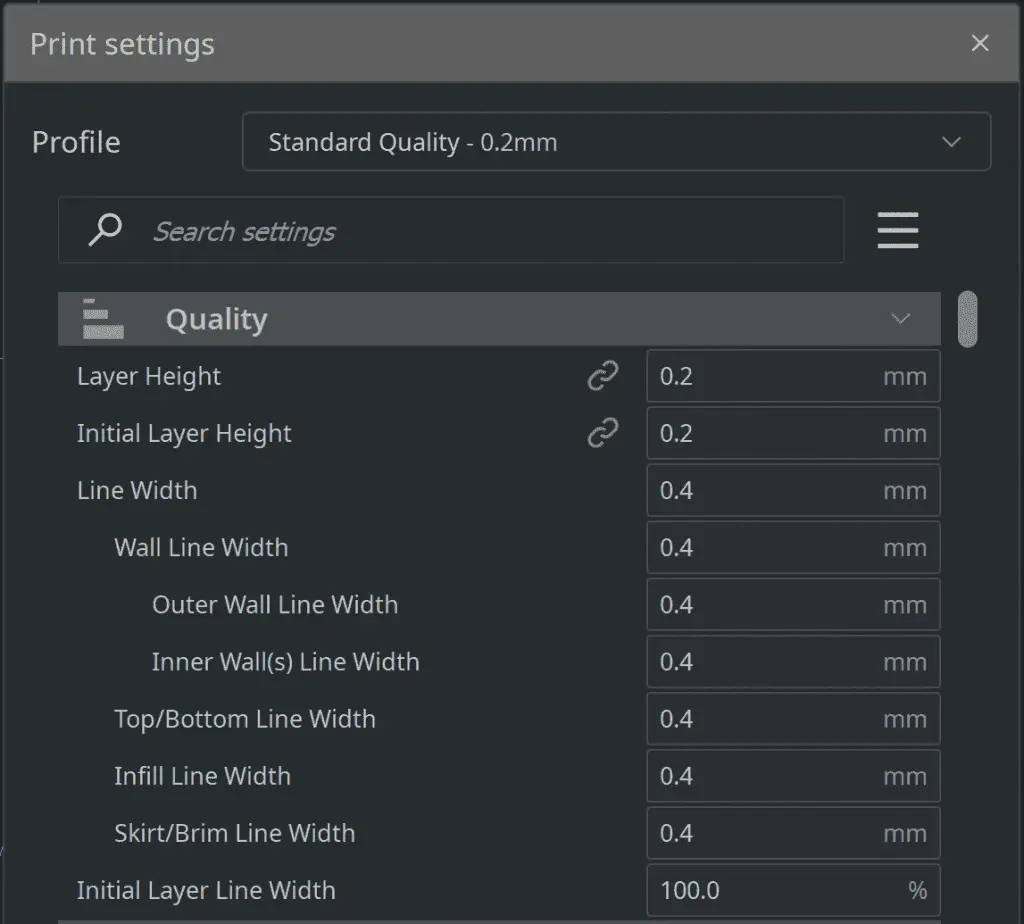

Use Variable Layer Height for Z-Axis

Explore your slicer’s variable layer height function when using 3D print fillets along the Z-axis. Technically, reducing the layer height can prevent separation and warping. Also, a smaller layer height will lead to a much smoother finish, especially for the fillets curving along the Z-axis.

Avoid Overhangs or Use Supports

When 3D printing them along the X-Y axis, you don’t need fillet supports because they don’t have overhangs. However, try to opt for a proper curvature, even if the 3D fillet is only a slightly rounded edge, such as a quadrant or smaller, so that you don’t have an angular finish.

3D fillets along the Z-axis are overhangs, so you must use supports. Also, using the fillet settings to round the outside corners along the Z-axis requires you to use sufficient infill to support those curved parts. Any outer corners using the fillet function are also overhangs if there’s no infill.

Understand the Slicer’s Fillet Settings

Last but not least, understand your CAD programs or slicer’s fillet settings before you finalize the design and its specifications. Your CAD may automatically incorporate supports for fillets or abandon them if it thinks the part or design is acceptable.

Likewise, some software may prevent you from using fillets for horizontal edges that don’t have two vertical sides or walls. Thus, you need to tinker with the fillet setting, modify the inside and outside corners as desired, and see how you can curve the surface you want.

Related Articles

- Should You Remove 3D Printer Filament Between Prints?

- Does PLA Filament Need To Be Dried Before Use?

- How To Tell if PLA Filament Has Gone Bad

- Can I Dry Filament in Microwave? (Details Inside)

- 3D Printer Filament Storage Options

Conclusion

Fillets aren’t hard to print as long as you know what you need to change to get them to work.

Use a proper radius for fillets on the X-Y axis for the best results. Also, use the variable layer height function for fillets along the Z-axis. Furthermore, use supports for fillets if they’re steep overhangs.

If fillets don’t seem ideal for your model when considering these factors, you may consider using chamfer. These offer a similar sloped finish but have some different design requirements.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.