When a 3D printer starts to print really thin layers, most people might feel frustrated, but this is an issue that many experience, and it is called under extrusion.

Under extrusion may be caused by a number of different factors. It could be due to stuck filament spools, too little pressure on the filament feeder, blocked nozzle, too high printing speed, low printing temperature, clogged extruder, among others.

One of the best ways to fix a 3D printer is to increase the nozzle’s temperature, which helps the filament get enough liquid consistency, so the extrusion through the nozzle can happen easily. But if you are using a different material, you might consider increasing the flow rate in the slicer settings.

As the reasons for under extrusion vary, there are also several ways to fix them. In this post, we will talk about the reasons you might be experiencing under extrusion with your 3D printer, a few ways to fix them, and things you can do to avoid under extrusion.

What Is Under Extrusion?

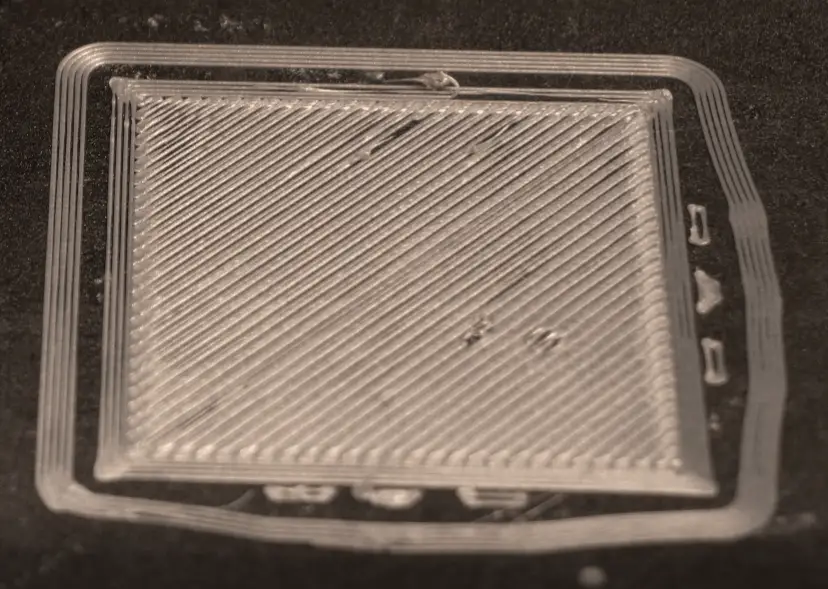

Under extrusion is a situation where the 3D printer is not able to provide sufficient material through the nozzle. This issue not only messes with the esthetics of the 3D print but compromises the structure and dimensional integrity of the 3D print. The layers might not stick together, could warp, or the whole assembly might break down since the structure might not be solid or sturdy enough to hold itself together.

Other signs of under extrusion are extremely thin layers, cracks, holes, and dots on the layers. Sometimes the structure might even be missing a few layers.

Reasons For Under Extrusion In A 3D Printer

As we have mentioned, there are several reasons for under extrusion. Here we point out the most common reasons for this situation:

E-Steps are Not Set Correctly

The extruder steps (or e-steps) are set in the firmware by default but there is no real one size fits all and if you start modifying your printer, there is a good chance you will need to calibrate them.

The reason it’s important to get the e-steps set right is if your e-steps are too low, you will end up with under extruding or gaps in the print. If the e-steps are too high, you will end up using more filament and will have a lot of blobs/zips on the surface of the print.

The Filament Spools Might Be Stuck

Due to improperly winding, the filaments could get stuck, and this could also happen when the 3D printer does not roll off the threads correctly. This blockage creates friction that might cause a loss of grip on the material when the motor feeds it into the printer.

This situation might be the reason for a reduced flow on the materials, which causes the under extrusion. Unwinding and rewinding the spool is an excellent way to ensure that any unwanted knots are removed, so you could avoid the printer stopping a proper function.

Low Pressure On The Filament Feeder

A few 3D printers in the market allow you to adjust the pressure settings of the filament feeder, which controls the strength put into the filament but the motor to get a firm grip of the material. When this pressure declines, the engine loses its grip on the printing materials.

The filament pressure can be checked by hand; when printing, you can hold it down while the motor rotates; if the filament is slipping, the pressure needs to be increased. As the diameter of filaments may vary from manufacturer to manufacturer, you must adjust the feeder pressure every time you change filaments.

The Nozzle Might Be Blocked

If you do not clean the nozzle from time to time, the residual material could build up and block the passage hole, which leads to an obstacle in getting the 3D printer ready, on time, and perfect.

One of the most common causes for under extrusion is a blocked nozzle, but you want to make sure this is why your 3D printer is printing out way too thin. You will have to push the filament material manually; if it passes through with little to no resistance, the nozzle is clean; on the contrary, if you feel some resistance or the material not coming out at all, you need to clean the nozzle.

The Printing Speed Is Too High

The flow rate should match the print speed. If the print speed exceeds the flow rate, not enough material will be passing through the nozzle, making weak and thin layers. You have to sync the flow rate and printing speed by decreasing the speed by 20 mm/s and observing the results; you might have to do this until you get the desired result.

The Printing Temperature Might Be Low

It is better to make sure you have the correct printing temperature. When the nozzle is not hot enough, the filament may not melt correctly and at a rate suitable for the material entering the nozzle, resulting in under extrusion.

The Extruder Is Clogged

The extruder might get stuck by remains of old filament, which will cause additional friction when a new thread of material is passing through the nozzle. This friction slows the printing material from entering the nozzle.

The clogging could happen in the feeder motor. You will have to make sure the nozzle and the feeder motor are not contaminated with filament leftovers.

How To Fix 3D Printer Printing Too Thin

Below, we will mention how to fix the issue with your 3D printer printing too thin.

Calibrate The E-Steps

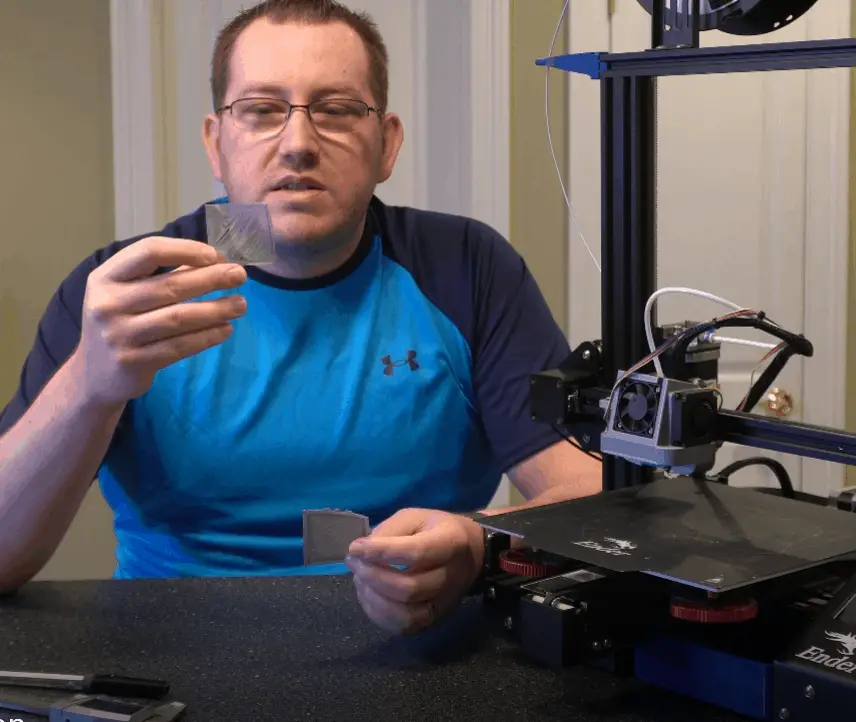

The calibration process isn’t difficult but there is enough to cover that I decided to create a video and write another article to cover the process. You can see the article here “3D Printer E-step Calibration (Step-by-Step Guide)” and the video below.

Adjust The Speed And Temperature

The temperature and the speed go well together. You should make sure you have the correct temperature set; you could increase the temperature by five degrees celsius until you reach the perfect temperature. Regarding the speed, try to maintain it at a slow pace to ensure accuracy and better results. The best way to get the optimal temperature for the filament you are using is to create a temperature tower.

Cleaning

As mentioned above, the nozzle and the extruder might get clogged, causing filament threads to get stuck, all of this due to residual material in these parts. Every once in a while, you need to clean these parts to avoid or fix an under extrusion on your 3D printer.

Check The Settings

Check the feeder settings related to the tension. The tensile settings of the feeder should be just right, so the process of taking the filament to the extruder is not too soft or too harsh.

Filament Diameter

Ensure correct filament diameter input so that the extruder can push the filament at an adequate rate; even a .1mm error might create printing problems. To determine the correct diameter of the filament, use calipers to measure it.

Deformations In The Teflon Tube

If you want a constant feed rate through the nozzle, the path through the spool and the extruder should be smooth and continuous; to achieve a smooth and continuous path, most 3D printers use Teflon tubes.

Constant use and extremely high temperatures could cause damage to the tubes. Even the tiniest damage could cause a delay in the flow of material through the nozzle. Try to check the status of the tube; if it is broken, you should replace it immediately or just remove it.

Related Articles

- Quick Guide to Change the Nozzle on a 3D Printer

- Five Reasons Your 3d Printer Stops Mid-Print

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

- Cura Profiles

Final Thoughts

A 3D printer printing too thin might be more common than people think, and most of the time is due to an issue that users could solve by themselves.

A smooth printing experience is only achievable when everything is put in place; that is why you should try to avoid under extrusion by checking your 3D printer every once in a while, checking the nozzles and extruder are not clogged, that there are no filament spools and that you are using the correct settings and the size of the filament, as well as keeping in mind to check the state of the Teflon tube.

We hope this post helped you to understand a little better why your 3D printer is printing too thin and the best ways to fix every failure.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.