Nowadays, the significant advantages of 3D printing are well known. It is no secret that this technique is gaining more and more fans every day. Many believe that it will replace the traditional manufacturing process in a short time. There are many things we can achieve with a 3D printer. But is it a technique without limitations?

This technique still has some limitations to overcome, especially to be capable of printing some specific shapes and forms. The shapes that still cannot be printed without support in a 3D printer are certain kinds of spheres, shapes with thin walls, oversized objects, or thin structures that protrude from their direct base.

The 3D printing process, though, gives us many advantages over traditional production techniques. Its ability to create rapid prototypes is unique. However, the use of this technology has several challenges to be solved to correctly state that it will be the primary manufacturing technique for parts and objects of all kinds. Stay with us to find out more about all the challenges ahead for 3D technology.

Can All Types Of Materials Be Used With 3D Printers?

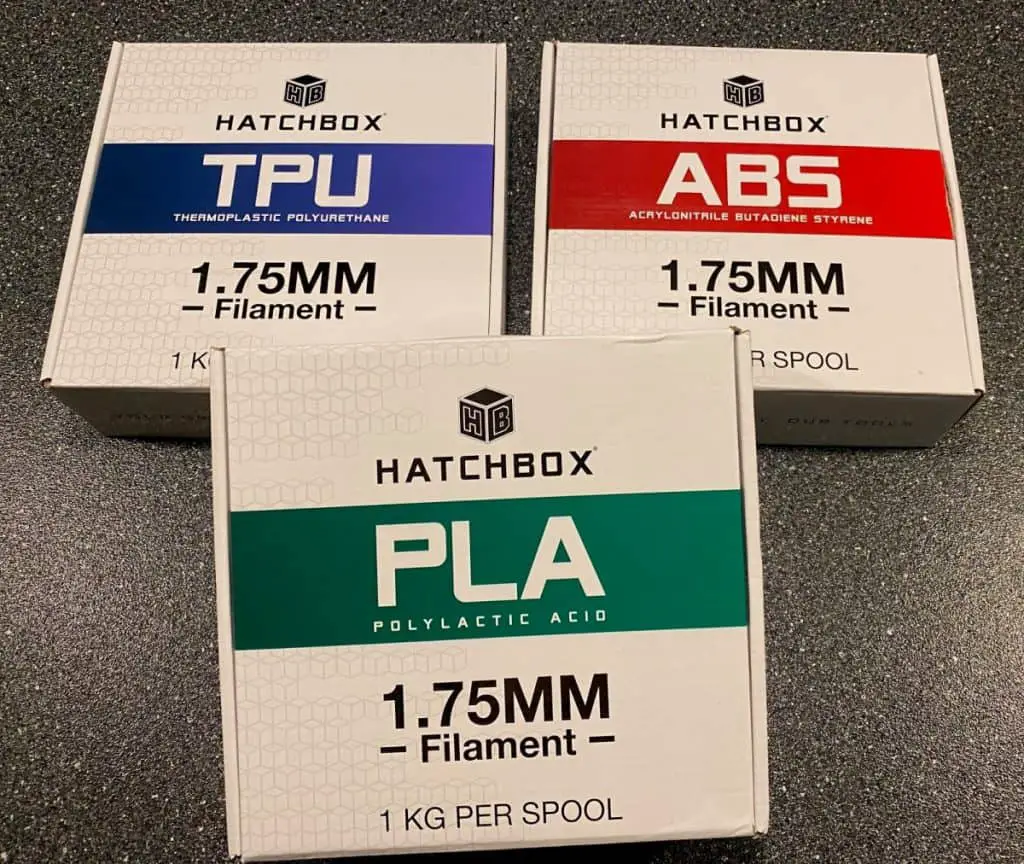

It is important to emphasize that 3D printers allow the use of a wide variety of materials. On the other hand, there is also a small group of materials that you cannot use in this equipment.

The central aspect to consider here is that we will not print materials that we cannot melt. Since there are materials that, instead of melting, they burn, we must be cautious when selecting the element to use. If we are not sure, the smart thing to do is consult a specialized store.

The key is to ensure that the material you want to use meets the technical specifications of semi-liquid state and tolerances that will allow 3D printing. Some of the materials that we cannot use in 3D printers are:

- Stones or rocks.

- Paper.

- Real wood

- Fabric or textiles.

What Are The Shapes That We Cannot 3D Print?

The truth is that nowadays, there are not many shapes that a 3D printer cannot print. This technology has had tremendous advances in just a few years. But please note, this does not mean that all shapes are possible to manufacture with this technique. Below we will review some of these exceptions.

We Will Not Be Able To Create Shapes That Have Little Contact With Their Base

A 3D printer will have great difficulty creating large or small shapes with thin or delicate contact with their base.

The explanation for this situation is that there is a high possibility that the object will detach from its base when having such a thin connection. This is where the answer to why we cannot create spheres with the 3D printing technique lies. There is only one tiny point of contact with the base for this shape, while the object’s body is enormous. This combination would make it easy for the sphere to peel off at any time. That said, you can add a brim, or raft, and add supports to help out.

Objects With Too Thin Edges

We have to keep in mind that printing an object that is too thin, like the thickness of a knife, with the 3D technique is very challenging. One way to be able to print thin objects is to use a raft or a brim.

The raft helps stabilize too thin objects creating a stable base to build the top layers of the object. When the print finishes, we remove the raft without any risk of damaging the model.

The brim holds the edges of the part. This action avoids deformation and helps the adhesion of the object to the base. The brim is often a preferred alternative to the raft because the brim prints are much faster and use less filament. Once the printing is complete, we remove the brim from the object and discard it.

Objects That Have Large Overhangs

Objects that have overhangs are challenging to achieve with the 3D printing technique. The explanation is simple; if these protrusions are medium or large, they may break before the printer completes the fabrication of the object.

The alternative option is to build supports underneath these protrusions so that they can stabilize the structure. The support is a printing material that we use to hold the overhangs of the designed object. When the support is in place, the printer can continue the placement of the upper levels of the object. Once the printing is ready, we can remove the support.

The downside is that sometimes these supports will somewhat modify the original design.

Objects That Are Too Large

3D printers are limited in size. When we want to print an object that exceeds these dimensions, we have a problem. We are not going to find equipment that can print a large object in one go. The alternative is to print the piece in several separate parts. Then we can join them together with specialized glues.

Recommendation To Take Into Account When Designing The Shape Of An Object

This recommendation is not to develop objects with small or curved sides. When an object has small or curved sides, the printer will need additional support structures to have an acceptable result. When dealing with minimal parts, the addition of these supports is also not a guarantee of success.

If the parts are extensive, you may need many supports, and the final result may not be as expected.

Supports are like building scaffolding for 3D printing. Supports are additional plastics that the printer puts in place to support the object’s structure as it makes it.

The advantage of the supports is that you can easily remove them when the object is ready. Another critical aspect of the supports is that the printer software generates them automatically. So we don’t have to worry about creating them, but we have to worry about removing them.

Note that supports also do not guarantee success in producing minimal parts. The critical moment is when you try to remove them, as there is always the risk of breaking the object.

What Are The Limits Of 3D Printing?

We know that the 3D printing technique has more benefits than limitations from everything we have studied so far. However, we must wait with patience for technological advances to continue to make their contribution and thus overcome the technical challenges that still need to be solved. We will now look at some of them.

The Limitation Of Mass Production

3D printers have a limited production speed. To fulfill numerous product orders, we would have to have a fleet of printers at our disposal.

If you have a business and plan to switch from conventional production techniques to 3D techniques, think very carefully before doing so. The other option is that you start with low-demand items so that you can fulfill all requests. The key point is that you are clear that 3D technology is not yet ready for mass production.

The Limitation Of Non-model Objects

This point is a considerable limitation for 3D printing. If we don’t have the model of the product object we want to print, there is no way to get started.

An example that clarifies this limitation is if we want to print a component of a motorboat engine:

- We would have to know the exact part that does not work.

- We would have to be experts in computer design and programming.

- The object must have the characteristics that make it a realistic printing option.

The Limitation Of High-precision Items

It’s no secret that 3D printers have significant limitations regarding the accuracy of the output. Depending on the item you need to print, the 3D printer is not the best option. Small parts that require precise and detailed reproduction may not be achievable with this technique.

The Limitation Of The Materials That We Can Use

Every day there are more and more materials that you will be able to use with this type of printer. But reality also tells us that there are still various items that we cannot use with this technique.

The Limitation To Adjust The Printer In A Simple Way

An aspect that is a bit tricky is the adjustment of the 3D printer to be able to achieve the designs made. Specialized 3D printing of objects demands advanced knowledge of software and logarithms. If we do not make the proper adjustment to the printer, we can get a completely different object.

The Limitation Of The Shapes That We Can Make

This aspect we already reviewed extensively. However, it cannot be overlooked as one of the current limitations of 3D printing.

Related Articles

- How to Print a File from Thingiverse (The Easy Way!)

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

- How to Get Your Print to Stick to the Build Plate

- Create a Temperature Tower Using Cura – The Easy Way

- Cura Profiles

A Final Thought On The Limitations Of 3D Printing

All technologies have limitations, and 3D printing does not escape this reality. While it is true that today there is a lot of interest in this technique, and the information circulating is that you can print almost anything with it. The facts tell us that this is not entirely true.

It seems that we are indeed heading in the direction of significant technological advances in 3D printing. But we are not there yet. What is certain is that this technology is capturing consumers’ attention, and companies are investing resources to offer high-quality equipment.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.