Very silent printers can be as quiet as 30 decibels and others can be over 60dB. Sometimes, if your printer is getting progressively louder, there could be a part that’s malfunctioning. 3D printers can be loud for many reasons.

The most common causes of loud noises in 3D printers are the motors that control movements. Including the extruder motor that feeds the filament. Other reasons are improper calibration, cheap or worn-out components, worn out fans or bearings and the design of the printer. (Loud stepper drivers)

Some models are known to be louder than others, regardless of how well they are calibrated or maintained.

To make your 3D printer quieter, there are a few things you can try. But first, make sure that your printer components, like the rails, are properly aligned, and that belts and screws are tight. This can greatly reduce the amount of noise it makes.

Upgrades That Reduce The Noise Of Your 3D Printer

There are several upgrades that can help reduce the noise produced by a 3D printer. Here are a few examples.

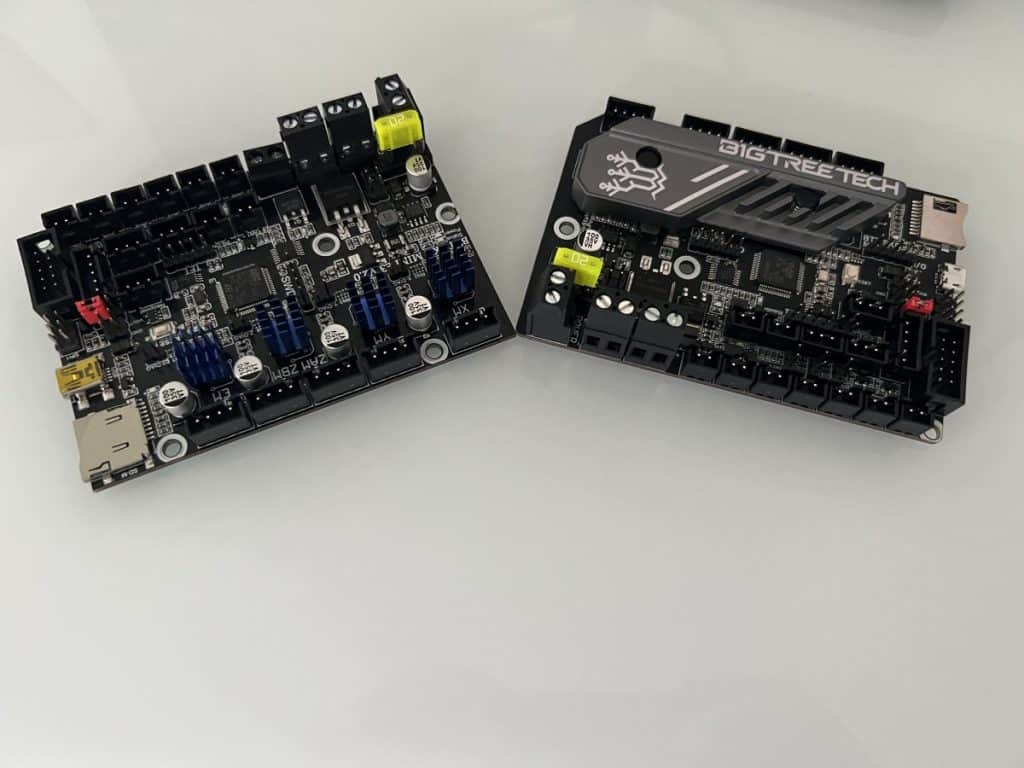

Upgrading to high-quality stepper drivers is one of the best options to reduce the noise of your printer. I wrote an article about very quiet TMC2208 stepper drivers you should consider.

Upgrade the printer’s firmware. Some newer firmware versions may include features that can help to reduce noise, such as adaptive layer heights or variable layer speeds.

Install a different extruder. Some extruders are designed to be quieter than others, so upgrading to a quieter extruder can help reduce noise.

Cover your printer in a sound-dampening enclosure, which can help reduce the amount of noise that escapes from the printer. But monitor the temperature inside to make sure it doesn’t get too hot.

You can also try replacing old parts with high-quality components, such as smooth, well-maintained bearings and belts, which can help reduce the amount of noise the printer makes.

Replace the fans to low-noise fans.

Overall, there is no one-size-fits-all solution for making a 3D printer quiet. The best course of action will depend on the specific model of printer you are using, as well as the specific issues that are causing it to be loud. It may take some experimentation to find the right solution for your printer.

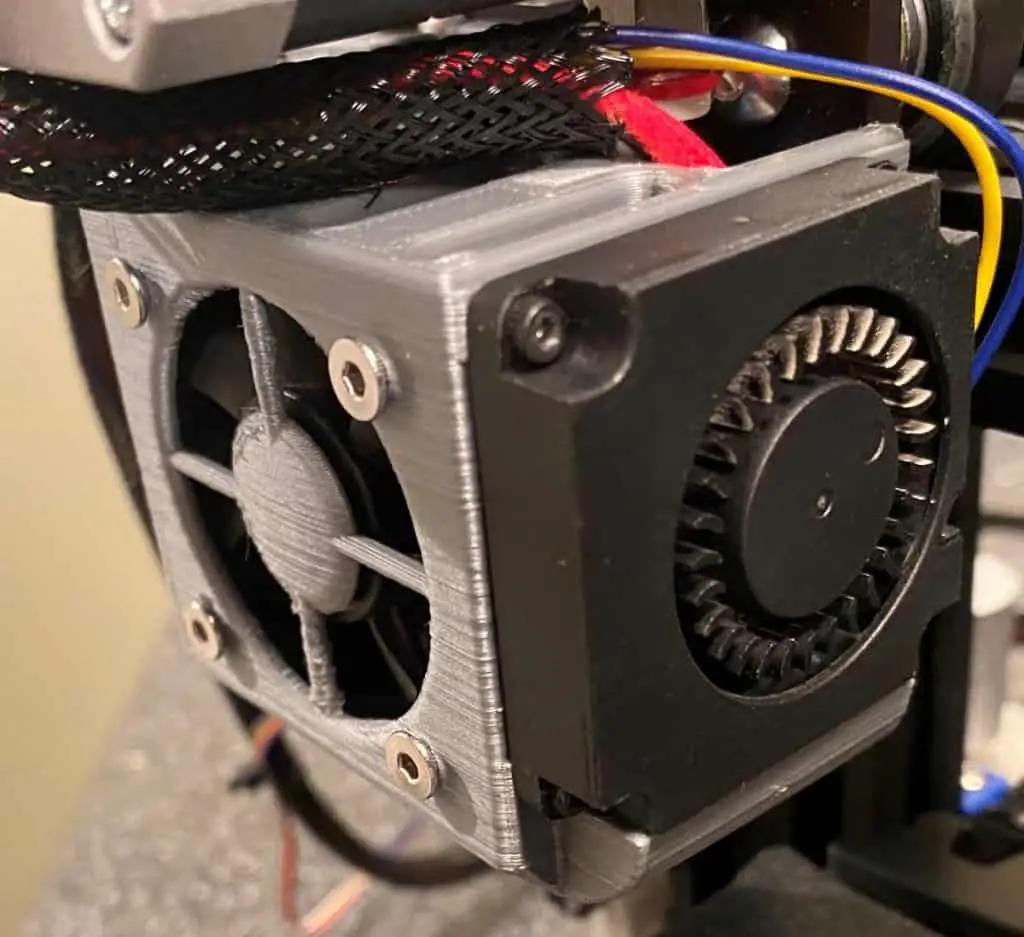

Why Is My Printer Fan So Loud?

It’s possible that your 3D printer fan is loud because the design is not optimized to be quiet. Of course, the larger the fan, the louder it will be. However, a larger fan can also move more air and cool your printer more effectively.

One way to reduce the noise of your 3D printer fan is to make sure it’s properly installed and tightened to the printer. If the fan is loose, it can make a lot of noise as it vibrates against the printer. You can also try using rubber mounts or silicone fan mounts to reduce the amount of vibration and noise.

Use a fan with a different speed or airflow. Some 3D printer fans are designed to operate at a lower speed and make less noise, while others are designed to move more air at the expense of being louder. You can try experimenting with different fans to find one that strikes the right balance between cooling performance and noise level.

It’s also worth noting that some 3D printer fans are noisier than others because of the materials they are made from and the way they are designed. If you’re unhappy with the noise level of your current fan, you may want to consider purchasing a different fan that is designed to be quieter.

Here are some printer examples with noise levels:

Open FDM printers are a type of 3D printer that does not have enclosures, allowing you to see the moving components while the printer is in use. These are the loudest, with a noise level of around 60 decibels.

Enclosed FDM printers have an acrylic hood that covers everything, resulting in minimal noise, as the noise from the moving parts is blocked off. These printers have a noise level of about 54 decibels.

Resin printers have enclosures to protect the photocuring resin and are quieter than open FDM printers, but louder than other enclosed printers, with a noise level of 55 decibels.

Quiet Stepper Motor

To reduce the noise levels of your 3D printer, look for stepper motor that are specifically designed to be quiet. These motors are typically made with high-quality materials and are built to run smoothly, which helps to reduce the amount of noise they produce.

One type of stepper motor that is known for its quiet operation is the hybrid stepper motor. These motors combine the best features of both permanent magnet and variable reluctance stepper driver, which allows them to run smoothly and quietly.

Another option is to use stepper motors with built-in damping or damping mechanisms, such as stepper motors with magnetic or mechanical damping. These motors use special features to reduce the amount of vibration and noise they produce, which can help to make your 3D printer much quieter.

In general, it’s a good idea to research and compare different stepper motors to find one that is designed to be quiet and will meet your needs. It’s also important to make sure that the stepper motors you choose are compatible with your 3D printer and are the right size and type for your application.

Stepper motor dampers are used to reduce the noise produced by stepper motors, which are commonly used in printers and other precision devices. They work by absorbing vibrations and noise generated by the stepper motor’s operation, which helps to reduce the overall noise level of the printer. Here’s how they look on amazon.com.

Is A 3D Printer Too Loud For An Apartment?

It’s possible that a 3D printer can be too loud for an apartment, depending on the size and type of printer you have, as well as the sensitivity of your neighbors. 3D printers can produce a significant amount of noise, especially when they are printing large or complex objects through the night. The motors and fans used in 3D printers can also be quite loud, which can be annoying to people who are nearby.

If you live in an apartment and are considering purchasing a 3D printer, it’s a good idea to consider the potential noise levels and whether they may be a problem for you or your neighbors. You can also look for 3D printers that are specifically designed to be quiet, or that have features that help to reduce the amount of noise they produce.

In general, it’s always a good idea to be considerate of your neighbors and to take steps to reduce the noise your 3D printer produces. This might include using noise-dampening materials, installing your printer in a well-insulated room, or using it at times when it is less likely to disturb others, like when they’re at work.

Can You Run A 3D Printer For Over 24 Hours?

Yes, you can run a printer for over 24 hours because they use electrical motors that are designed to operate at a constant speed and load. This means that they can run for long periods without overheating or experiencing mechanical failure.

However, it’s important to note that all motors, including electrical motors, will eventually wear out and need to be replaced. The life of a motor can be affected by factors such as the type of motor, the quality of the materials it is made from, and the operating conditions it is subjected to.

To ensure that an electric motor can work continuously without needing a break, it’s important to maintain the motor properly. This involves regular cleaning and lubrication. It’s also a good idea to monitor the motor’s performance and check for signs of overheating or other problems. By following these steps, you can help your motor to run smoothly and reliably for a very long time.

Quiet 3D Printer Bearings

Bearings made of high-quality materials, such as ceramic or stainless steel, are quieter than bearings made of cheaper materials. Additionally, bearings with low levels of friction and properly aligned shafts can also help to reduce noise.

Mechanical components called sliding linear bearings are often used in 3D printers. These bearings allow the printer’s moving parts, such as the print head or bed, to move smoothly and precisely. The bearings work by making the moving parts glide along their tracks rather than grinding or scraping against them.

Using sliding linear bearings can help reduce noise in a 3D printer in several ways. For one, it can decrease the vibration and friction that occurs as the moving parts move. Both vibration and friction can be significant sources of noise in a 3D printer, so reducing them can make the printer quieter. Additionally, using high-quality bearings with low friction coefficients can further help reduce noise by allowing the moving parts to glide smoothly with minimal resistance.

Do Linear Rails Make A 3D Printer Quieter?

Linear rails are mechanical components that guide the movement of a 3D printer’s moving parts, such as the print head or bed. They are made of a smooth, hard material like steel or aluminum and allow the moving parts to glide smoothly along their length.

Linear rails can reduce noise in a 3D printer by decreasing vibration and friction as the moving parts move. Using high-quality linear rails with low friction coefficients can further help reduce noise by allowing the moving parts to glide smoothly with minimal resistance.

Use A Stable Table

The stability of a 3D printer’s workstation can affect its noise level in a few different ways. A stable workstation can help to reduce the amount of vibration that the printer produces, which can in turn reduce the amount of noise that the printer makes.

Additionally, a stable workstation can help to prevent the printer from moving around or shaking during printing, which can also help to reduce noise.

To properly set up your printer, first place it on a stable and level table, leaving enough space around it for proper ventilation and movement of its parts. Depending on the size and weight of the printer, you may need to secure it to the table using bolts, screws, or other fasteners to prevent it from moving during printing. Add dampening pads under the printer’s feet or wheels to absorb vibrations and reduce noise.

Related Articles

- Why Do 3D Printers Make So Much Noise?

- 3D Printer Power Supply Silent Fan Upgrade – Install Guide!

- 3D Printer Enclosure – Do I Actually Need One?

- Ender 3 Fan Upgrade – My Choice and Install Guide

- How to Control 3D Printer Vibrations

Conclusion

many factors can contribute to the noise level of a 3D printer. The most common cause is the motors that control the movement of the printer, including the extruder motor that feeds the filament. Other factors include improper calibration, cheap or worn-out components, worn-out fans or bearings, and the design of the printer, including loud stepper drivers. Some models are inherently louder than others, regardless of maintenance and calibration.

Make sure that all components are properly aligned and that belts and screws are tightened.

Replace worn-out components or add dampening materials to absorb vibrations and reduce noise.

It’s also worth noting that some printers are simply quieter than others, so if the noise level is a concern, you may want to consider purchasing a model that is known for its low decibel output.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.