Those new to using 3D printers often struggle to create solid, high-quality items with their printer. Fortunately, 3D printing enthusiasts and hobbyists can familiarize themselves with several printing techniques, such as skirt printing, to craft improved creations.

You don’t need a skirt for 3D printing before printing your primary creation. Use a 3D printing skirt only if you’re struggling with uneven printing beds, poor material adhesion, and slow-flowing printing material.

This article will discuss why a 3D printing skirt can be helpful and reasons you may want to start employing one before printing objects. You can use this information to learn more about basic 3D printing techniques and make an educated decision about whether or not 3D skirt printing might benefit your project. Let’s get started.

You Don’t Necessarily Need a 3D Printing Skirt

Understanding what a 3D printing skirt is can help you determine whether you need one for your printing projects.

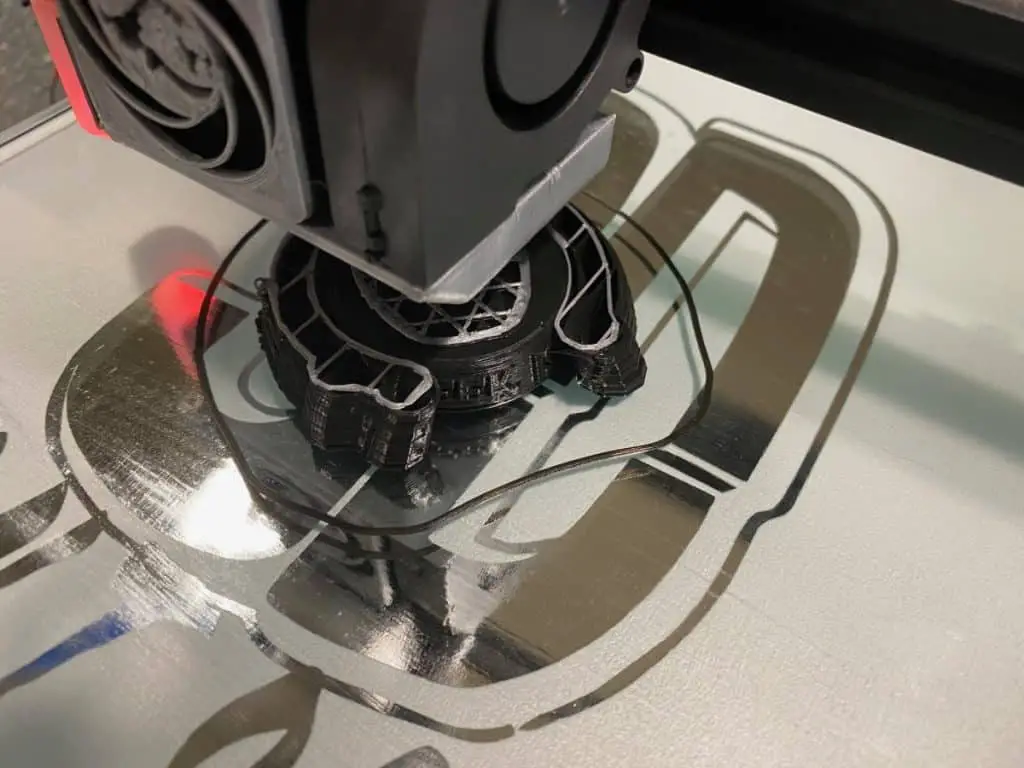

Essentially, a 3D printing skirt is a small circle of printed material that travels around the outer edges of the bed. It’s a loop that doesn’t connect to the primary object printed within the circle.

A skirt is printed before your primary print, making it a preliminary process that doesn’t adversely affect your 3D-printed project. Even if you don’t use a printing skirt, that’s perfectly fine.

Suppose you’re certain your 3D printing bed is even, your extruder filament material flows properly, and the filament layers adhere to their printed layers. Then you don’t need to print a skirt before printing your object.

That said, if you’re not confident about your bed level or filament flow and adhesion, you may be better off using a skirt. Notably, a 3D printing skirt isn’t the only type of pre-project printing process.

Rafts and brims are other 3D printing techniques often employed before a printer begins working on the primary object or project. That said, these foundational build plate adhesion techniques differ from a printing skirt in several ways.

A 3D Raft Is More Solid Than a Skirt

When considering the differences between a skirt and a raft (within the realm of 3D printing), it may be helpful to visualize an inflatable innertube and raft. The skirt is much like the innertube. It’s primarily circular, with ample space in the middle.

But a 3D printing raft is far more solid, much like an inflatable raft. Though it may not be very thick or substantial, any object printed upon it is firmly attached. In this way, a raft acts as a semi-permanent base for 3D-printed items.

A raft helps provide a slightly thicker foundation for items. Pre-printing a raft structure before printing an object can result in greater filament adhesion and improved item stability.

A Brim Is Slightly Thinner Than a Skirt

A 3D printing brim is similar to a skirt because it encircles your primary print. However, a brim attaches to the primary item, albeit via tenuous lines of filament that can be sheared away after the printing process ends and the printed object has cooled.

This printing technique gets its name from its physical similarity to a broad, circular hat brim. The primary purpose of a 3D printing brim is to add stability to a 3D-printed object.

Notably, a brim is often slightly thinner than a skirt. That’s because it’s designed to snap or peel away from the primary object with ease. This design feature contrasts with a raft, which utilizes a thicker platform that joins (potentially permanently) with 3D-printed objects.

Why Use a Skirt for 3D Printing?

Use a skirt 3D printing to ensure your printing bed is level, your filament is flowing from the extruder properly, and the filament material is adhering to itself in solid layers. However, a skirt won’t add stability to your printed object.

Again, as discussed earlier, you don’t need a skirt for 3D printing if you don’t have the concerns discussed above.

A Skirt Helps You Detect Bed Problems

The base upon which you build your 3D-printed objects is called the bed. And while many 3D printers feature secure beds with the printer’s legs or stand, these beds can become uneven when placed onto an uneven surface.

An uneven bed is a surefire way to end up with a warped or unstable object. However, detecting an uneven printing bed with the naked eye can be nearly impossible. But choosing to print a skirt before printing your primary item is a fantastic way to detect unevenness.

As a result, while a skirt is considered a minor waste of filament material, it can save you from wasting far more material. For this reason, producing a 3D printing skirt is often considered a valuable preliminary process, especially when working with larger or more intricate projects.

A 3D Printing Skirt Ensures Proper Material Adhesion

3D printers can utilize a variety of filament materials, but some of the most popular include:

- PLA

- ABS

- Nylon

- HDPE

These filament materials are often formed into long strands or coils that fit neatly into extruders. To create 3D-printed objects, ensure these materials are heated; this will form a thick liquid that slowly oozes from the extruder tip.

However, if a filament material hasn’t reached its optimal material, it might fail to stick to itself. When this happens, the layers comprising a printed object can’t adhere to one another, resulting in an unstable item that quickly crumbles.

Running a skirt around your printer bed can help you determine whether or not your filament is readily adhering. Consequently, a skirt is an excellent way to prime your extruder and material for further printing.

You Can Prime the Extruder and Filament Using a Skirt

If you fail to prime your filament extruder, you might struggle to get your filament material flowing. After all, the bulk of 3D printers heat filament materials to temperatures ranging between 350°F (176.67°C) and 1005°F (540.56°C).

It takes time for a printer (and its extruder) to reach proper temperatures. Additionally, filament from previous projects can accumulate and harden within the extruder tip.

As such, by starting your printing project without properly priming your tools and materials, you’re significantly affecting your filament flow, viscosity, and adhesion.

Printing a skirt around the perimeter of your bed is a fantastic way to check filament flow and consistency. You can also examine adhesion, ensuring that your primary project doesn’t suffer from separating layers.

Related Articles

- Cura Brim Build Plate Adhesion – Everything You Need to Know!

- Create a Temperature Tower Using Cura – The Easy Way

- Cura Profiles

- How to Print a File from Thingiverse (The Easy Way!)

- What Is 3D Printer Resolution?

- What Computer Do I Need for a 3D Printer?

Conclusion

A 3D printing skirt is a layer of 3D-printed material unattached to the primary 3D-printed object. The purpose of a skirt is to prime the extruder, ensure the printing material flows properly, and detect issues with the printing bed.

If you struggle to get your printing material to adhere to itself or settle evenly, you could benefit from printing a skirt before printing your primary item. But of course, those that aren’t dealing with such problems can opt to go without a 3D printing skirt.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.