3D printers are wonderous devices capable of endless printing possibilities. Using three axes – namely the X-, Y-, and Z-axis, your 3D printer is able to render various three-dimensional models. However, when one of these axes does not function properly, it can lead to subpar printing quality.

There are many possible reasons for a 3D printer’s Z-axis slipping during printing. This issue could be caused by eccentric nuts or coupler screws that are too loose and simply need to be tightened. The issue could also be caused by lead screw binding or wiring issues. Lubricating the printer may also solve the issue of a slipping Z-axis.

In this article, we’ll break down what you need to know about your 3D printer’s axes, particularly the Z-axis used for vertical motion. We’ll then break down the most common causes for a slipping Z-axis and what you can do to troubleshoot this issue.

A Guide to Your 3D Printer’s Axes

3D printers are remarkable devices that have made it possible to manufacture 3D objects across a wide variety of fields. From the uses of 3D printing in medicine to how it can be used in creating art, the various possibilities are still being discovered today.

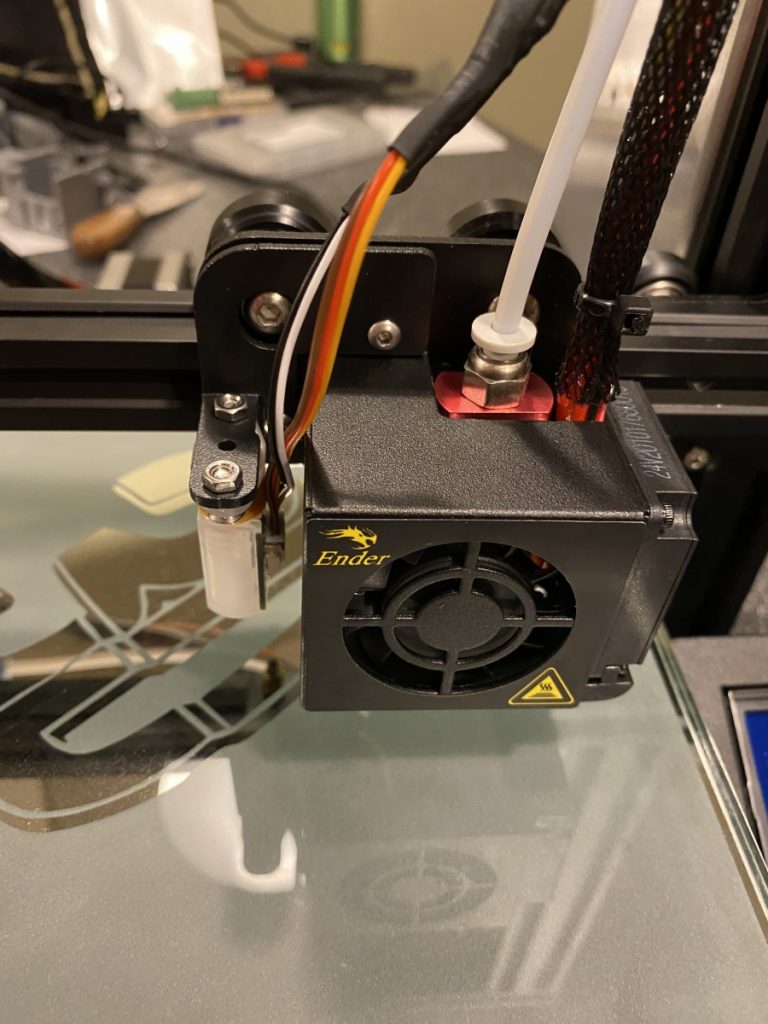

To function properly, a 3D printer utilizes three different axes, namely the X, Y, and Z axes. These three axes are crucial for your printer in creating three-dimensional objects. These axes are used by your printer to determine the position of the printer’s nozzle, which is used to render the 3D object.

The lateral movement of the printer’s nozzle is achieved using the X-axis and the Y-axis. The Z-axis, on the other hand, is responsible for vertical motion. Together, these three axes make it possible to render 3D models using a 3D printer.

The Z-axis, however, is especially important as it controls the upwards and downwards movement of your printer’s nozzle. This axis functions by utilizing a lead screw, which is a long screw that twists in order to render your chosen 3D model.

When one of these axes is not functioning properly, you’ll be able to notice it when examining your 3D printed object. This is particularly common with the vertical axis (or Z-axis), which we mentioned above. When this Z-axis slips during printing, it results in inferior 3D printing. This issue is also referred to as Z-wobble.

What is Z-Wobble in 3D Printing?

Many owners of 3D printers have experienced similar issues whereby their 3D printer’s Z-axis slips while rendering a model. This effectively ruins the model you are trying to print, not only wasting your time but precious printing materials.

Ultimately, Z-wobble refers to the incorrect movement of a 3D printer’s Z-axis while rendering a 3D model. In a final product, the evidence of this can be seen when the printed object’s layers are not perfectly aligned laterally (or sideways) due to an impairment of the Z-axis.

The function of the Z-axis is to control the up and down movement of the printer’s nozzle. This functionality is by a long twisting screw known as the lead screw. Z-wobble is most commonly caused by a lead screw that has bent. However, there are a few other reasons that could explain why your Z-axis is slipping during printing.

If you suspect your Z-axis is negatively affecting the quality of your printed models, it’s important to be able to troubleshoot your problem so that you can fix it and get back to printing. Keep reading as we outline the most common causes for a slipping Z-axis and how to fix it!

Reasons Your Z-Axis is Slipping (and What to Do)

These are the most common reasons your 3D printer’s vertical axis is slipping – and what you can do to fix the issue. Being aware of the causes will also help you to monitor these aspects and prevent any future 3D renders from being ruined by a slipping Z-axis.

#1 Your 3D Printer’s Eccentric Nuts are Loose

One of the most common causes for a 3D printer with a Z-axis that slips while rendering a model is a loose eccentric nut. Eccentric nuts are attached to both sides of your printer’s Z-axis, and these nuts are used for tension adjustment.

How to Fix It:

Luckily, the fix for this issue is quite simple. Using an adjustable wrench, you’ll be able to tighten the eccentric nuts. If this was the cause for your slipping vertical axis, tightening these nuts will solve your problem.

If you’ve never tightened your 3D printer’s eccentric nuts before, this video guides you through the process.

#2 Your Z-Coupler Screws are Loose

If your 3D printer’s Z-Coupler’s screws are not sufficiently tightened, this could be the reason your printer’s Z-axis is slipping while you’re busy printing. Your printer’s Z-coupler has two screws that would have been tightened when your printer was assembled. Over time, however, these screws can become loose and cause your Z-axis to slip.

How to Fix It:

If loose Z-axis coupler screws are to blame for your 3D printing troubles, this issue can be fixed by simply ensuring that the screws are adequately tightened. Make sure to tighten the screws found on both sides of your Z-axis coupler.

#3 Your Lead Screw is Binding

When your 3D printer’s lead screw nut is too tight, it can result in your 3D printer having more restricted movements while rendering your given model. When your lead screw is not properly installed, or the nuts are too tight, it can lead to binding issues. This, in turn, will lead to incongruous 3D printing of models.

How to Fix It:

To prevent errors caused by overly tight lead screw nuts, which result in the restricted movement of your Z-axis, the lead screw nuts may need to be slightly loosened. When these nuts are too tight, they can result in the binding of your lead screw as the motor has been turned closer to the printer’s vertical frame.

If you suspect binding has affected your printer’s lead screw, this video will provide more information on how to prevent this issue from happening in the future.

#4 Your Z-Axis is Not Lubricated

Sometimes it’s not a nut that’s too tight or a screw that’s too loose; sometimes it’s just about the proper lubrication for your printer’s Z-axis! If you’ve checked the other common causes of a slipping Z-axis and haven’t found the cause of your slipping Z-axis, it could be down to poor lubrication.

How to Fix It:

Luckily, this fix is a simple one! By using an appropriate lubricant spray, you can ensure that your 3D printer is appropriately lubricated.

If you’re not quite sure how to safely lubricate your 3D printer, this YouTube video will show you exactly how to do it!

#5 Faulty Wiring is to Blame

If you’ve exhausted your options and haven’t found the cause for your slipping Z-axis on your 3D printer, it could be caused by faulty wiring. While this is not the most common error, it has been known to happen!

How to Fix It:

If your 3D printer is still under warranty, you may be able to get the manufacturer to take a look at your 3D printer to find and fix the cause of your slipping Z-axis. Alternatively, you can always have a qualified technician take a look at your printer to determine the root of your problems and find a solution that works for you!

Related Articles

- What Is the Lifespan of a 3D Printer?

- Can You 3D Print on a Metal Bed?

- Best 3D Printer Build Plate

- How to Get Your Print to Stick to the Build Plate

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

- Cura Profiles

Conclusion

In this article, we looked at the different factors that could be causing your 3D printer’s Z-axis to slip while rendering your 3D model. By using our list of causes, you’ll be able to troubleshoot your slipping Z-axis and get back to your printing in no time!

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.