Most of us prefer a noise-free environment when working or relaxing at home. Now, if you’re a 3D printing hobbyist, you’re familiar with the whirring sound that 3D printers make. The magnitude of this noise may depend on the type of printer you’re using, but have you ever wondered why 3D printers are so loud?

3D printers make so much noise due to the vibrations produced by their moving components. 3D printer parts, including fans, stepper motors, and gears, are the major noise sources during 3D printing. Also, cheaper 3D printers tend to be louder than expensive ones.

In the rest of this article, I’ll discuss a few topics related to why 3D printers make noise. Read on to learn how loud 3D printers can get and how you can reduce the noise.

Why Are 3D Printers So Loud?

Most 3D printers are loud because some components produce sounds during the printing process. You’ll probably hear a whirring sound when your printer is working normally or when some parts are worn-out.

Let’s have a look at these sources of noise in 3D printers:

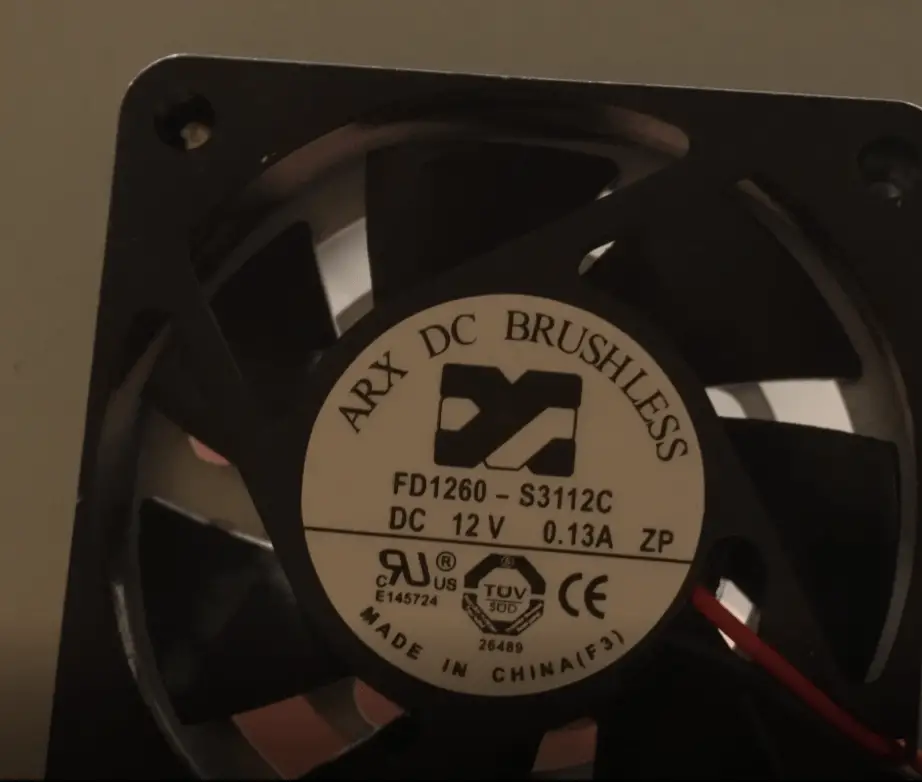

- Fans: They’re useful in cooling major 3D printer components, including extruders and hotends. Your printer may have two types of fans, the layer fan for cooling the deposited material and the hotend fan (cools the hotend). But fans are major noise contributors during 3D printing.

- Bearings: Bearings control motion during 3D printing by minimizing friction. They also produce some sounds as they work, which contributes to the overall noise of the 3D printer. However, some bearings make less noise than others.

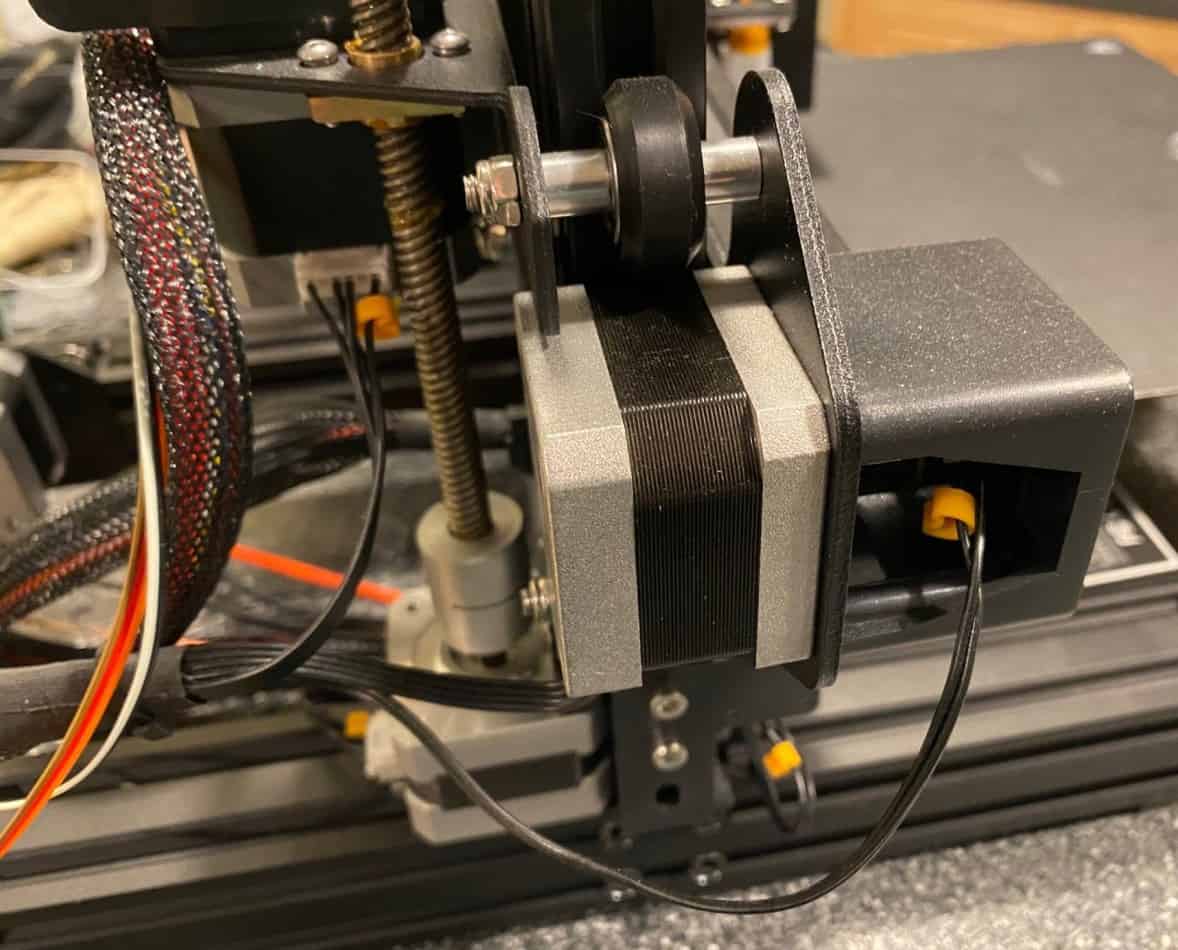

- Stepper motors: They’re vital components of a 3D printer as they move the print bed up and down. Moreover, they facilitate the completion of the printing process by carrying the build platform along the X, Y, and Z-axis. Stepper motors vibrate while working, which is one of the noise sources from 3D printers.

- Extruders: Extruderspush the melted materials and place them in an appropriate location to dry and produce the desired object. The extruder is usually quiet under normal circumstances. Sometimes, however, it may produce a clicking sound when it cannot push a filament toward the nozzle (filament grinding).

- The frame. Frames are aluminum or steel structures that hold a 3D printer’s components together. As the various 3D printer parts work (and move), they also cause vibrations on the frame. The frame may also vibrate if your printer is printing very fast.

Apart from moving components, your 3D printer could be making noise due to maintenance issues. For instance, if the gears, belts, and pulleys are defective, they’ll produce some sounds.

How Much Noise Do 3D Printers Make?

Most 3D printers produce a noise level of around 40 to 50 decibels, approximately the noise level of a normal conversation or background music. However, some printers are louder than this and can be a nuisance to noise-sensitive people.

Sometimes, 3D printers run for hours, depending on what you’re printing. Well, it’s more bearable when the machine is quiet, as too much noise may disturb you, your neighbors, or your family members. While most printers are normally quiet, others may make so much noise, indicating a defect somewhere.

A 3D printer that makes too much noise isn’t ideal, as it can “tell” people what it’s making. According to researchers from the University of California, you can reverse engineer the soundtracks of a 3D printer to reconstruct the original 3D model. This is possible because the sounds can tell the position and movement of the extruder, and you can utilize the information to recreate the print.

Factors That Affect the 3D Printer’s Noise Level

The noise level that your 3D printer produces may depend on the following factors:

Types of 3D Printer

We can categorize 3D printers into three groups depending on how quiet (or loud) they are when printing. So, printers in these categories have different features depicted in their work.

Here are the three printer categories and their properties:

- Open FDM Printers: They have no enclosures, and you can see the moving components when the printer is working. They make the most noise (around 60 decibels) compared to other 3D printer types.

- Enclosed FDM Printers: They have an acrylic hood that encloses the entire build area. These printers have minimal noise as the moving parts aren’t exposed to the environment. Hence, the noise level is about 54 decibels.

- Resin Printers. They have enclosures to protect the photocuring resin. They’re quieter than Open FDM printers but make more noise than other enclosed printers. Their noise level is 55decibles.

Quality of the Components

You can determine the quality of your 3D printer by how loud it is. Low-quality 3D printers have cheap mechanical components with looser tolerances or poorly put together parts. Hence, the different parts move more and produce more noise than high-quality components.

Maintenance Level

As mentioned earlier, your printer may produce some noise if some parts are worn out. For instance, bearings and gears may make sounds due to friction if not lubricated regularly. Hence, the level of maintenance may determine your printer’s working condition and the amount of noise it produces.

How Do I Reduce the Noise From My 3D Printer?

To reduce the noise from your 3D printer, you must first determine the noise source. Then, use an appropriate strategy to curb the noise. Hence, this may require you to install additional features or replace defective components.

Here are easy ways to reduce the noise from your 3D printer:

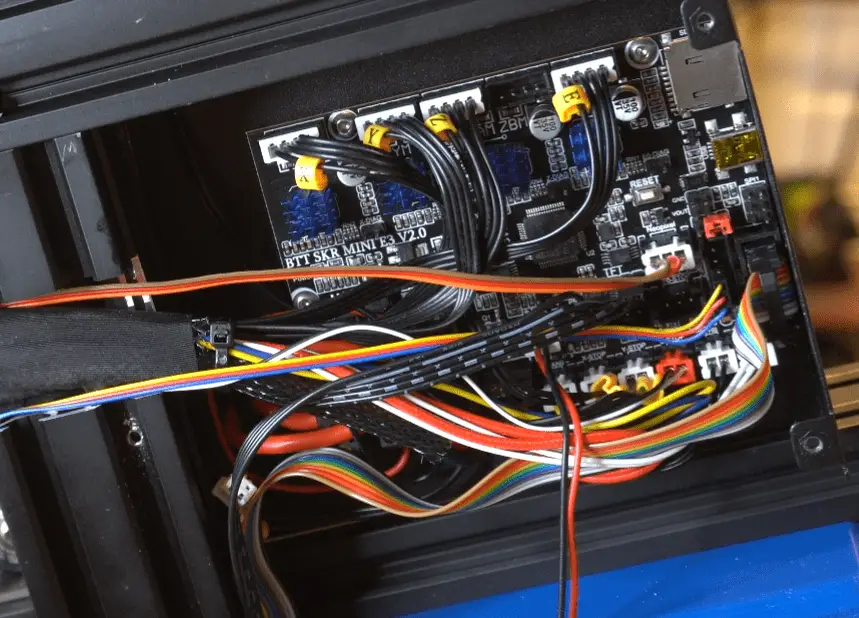

- Upgrade to a silent board. Upgrading to a silent board will make the biggest difference as far as noise goes. Silent boards like the SKR Mini e3 V2 make a huge difference because they use silent drivers for the stepper motors.

- Use dampers. These are rubberized mats that reduce vibrations produced by stepper motors.

- Tighten loose components. A printer’s fasteners, including bolts and screws, should be tight to minimize vibrations. You can either use hand tools to tighten them. Also, apply the Loctite Threadlocker (available on Amazon.com) to fasten their threads. It also protects the fasteners from rusting or corrosion.

- Use an enclosure. Like the dampers, an enclosure will reduce a printer’s noise through insulation. It also prevents print warping by reducing air currents entering the build platform.

- Decouple the printer. Ensure that your printer isn’t directly in contact with the table or another noise-producing material. So, you can place a mat, sponge, or foam under the printer to minimize vibrations.

- Reduce the fan’s noise. Install larger, high-quality fans that are quieter.

- Preventative maintenance. Keep your printer lubricated, and often wipe the parts to remove debris. Moreover, check your printer regularly to identify worn-out parts.

Related Articles

- 3D Printer Power Supply Silent Fan Upgrade – Install Guide!

- 3D Printer Enclosure – Do I Actually Need One?

- Ender 3 Fan Upgrade – My Choice and Install Guide

- How to Control 3D Printer Vibrations

Final Thoughts

3D printers have become a sensation worldwide due to their ability to turn ideas into reality. However, these printers may sometimes make a lot of noise due to moving components or defective ones. Therefore, regular maintenance and identifying the root noise will help reduce such noises.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.