Over-extrusion in 3D printing occurs when the printer deposits more material than is needed to create the desired object.

This can happen for a number of reasons, including high-temperature settings, extrusion multipliers, or malfunctioning extruders. In some cases, over-extrusion can be caused by a lack of sufficient cooling, which can cause the extruded material to expand and create excess material.

It’s also possible for over-extrusion to occur if the printer is not calibrated correctly, which causes the extruder to deposit too much material.

To prevent over-extrusion, it’s important to check and maintain your printer, and to ensure that the printer is properly calibrated and the settings are correct. I’ll share what I know about that, but first, let’s look at some common signs of over-extrusion.

Signs Of Over-Extrusion

There are a few signs that indicate that you are over-extruding when 3D printing. These signs include:

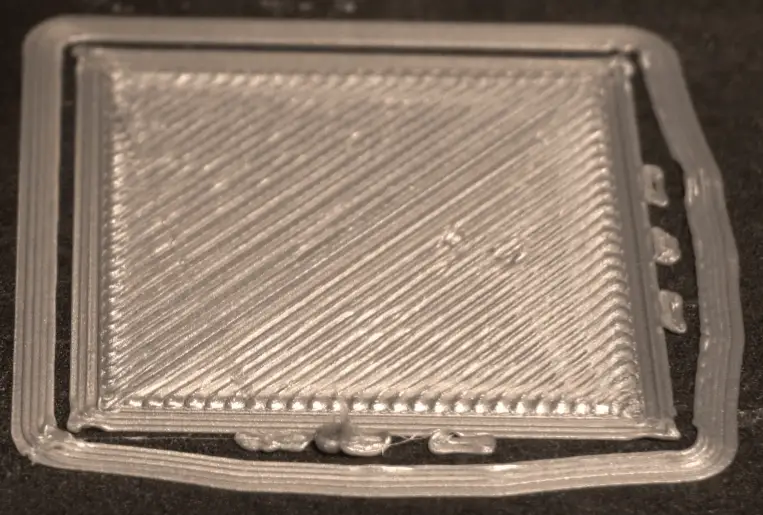

Over-extrusion can cause excess material to be deposited on the printed object, resulting in a thicker or wider object than intended. This excess material can also cause the object to have a rough or uneven surface, with visible layers or ridges.

It can cause the extruded material to string or ooze between the nozzle and the printed object, resulting in long strands of material or small droplets of material on the object. This can be especially noticeable when printing objects with sharp corners or fine details.

And it may cause the extruded material to build up in the nozzle, resulting in a blockage. This can cause the printer to stop extruding material altogether, or it can degrade the material quality with gaps or holes in the part.

Printing At A Temperature That’s Too High

Printing at a very high temperature can cause over-extrusion in a few different ways.

It can cause the extruded material to become more viscous, thin, and sticky. This causes the material to flow out of the nozzle too easily and results in more material being deposited than is needed.

Printing at a high temperature can cause the extruded material to expand as it cools and solidifies. This can cause excess material to be deposited, resulting in over-extrusion.

Finally, printing at a high temperature can also cause the extruded material to stick more strongly to the build platform and the previous layers of the object.

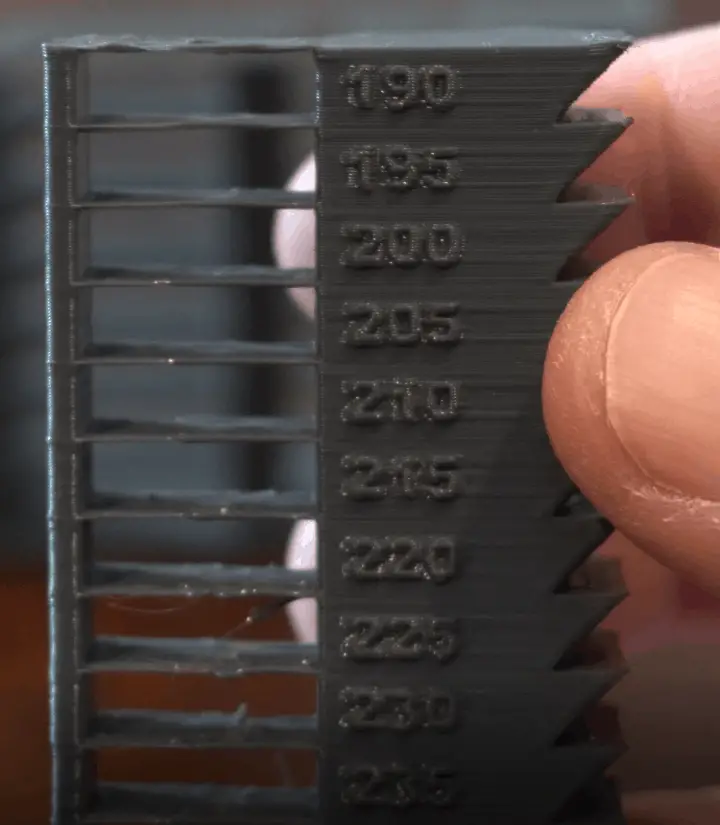

To avoid over-extrusion when printing at high temperatures, it’s important to adjust the printer’s temperature settings and monitor the printer closely during the printing process. In general, it’s a good idea to experiment with different temperatures to find the optimal setting for a given material and printer.

Insufficient Cooling

Insufficient cooling can cause over-extrusion in a few different ways.

When the extruded material is not properly cooled, it can remain soft and pliable for longer periods of time. This can cause the extruded material to sag or droop, resulting in excess material being deposited.

Insufficient cooling can cause the extruded material to stay fiery hot, which causes excess material to be deposited.

The hot end of a 3D printer heats and extrudes the filament. The materials and design of the hot end’s heating element can cause it to run at various temperatures. To reduce the risk of over-extrusion and improve print quality, you can upgrade to a hot end that runs cooler.

The extruder motor moves the filament through the hot end, so upgrading to a cooler extruder motor can help reduce the risk of over-extrusion and improve print quality.

Adjusting The Extrusion Multipliers To Prevent Over-Extrusion

In 3D printing, the extrusion multiplier is a setting that allows you to adjust the amount of filament that is extruded by the 3D printer. It is usually expressed as a percentage, with 100% being the default setting. Increasing the extrusion multiplier will cause the 3D printer to extrude more filament while decreasing it will cause the printer to extrude less.

You can fine-tune the amount of filament extruded using the extrusion multiplier setting, which can affect over-extrusion in 3D printing. If you set the extrusion multiplier too high, the 3D printer will extrude too much filament. However, if you set the extrusion multiplier too low, the printer will extrude too little filament, or “under-extrusion”.

To avoid over-extrusion, it is important to calibrate the 3D printer and experiment with different extrusion multiplier settings to find the optimal value for a given filament and print. This can help ensure that the 3D printer is extruding the correct amount of filament and producing consistent, high-quality prints.

Adjusting the extrusion multiplier in Cura

- Connect the Ender 3 to your computer using the USB cable.

- Open Cura and change to the “Custom” setting view.

- Right-click the “Configuration Settings Visibility”, Check off the “select all” and then close it again. This will give you the access you need.

- Scroll down to the “Extruder” section and locate the “Extrusion Multiplier” setting.

- Check the “Material” settings and adjust the “Flow” (Extrusion multiplier)

- Save the changes by clicking “OK” or “Apply”.

- Print a test piece using the adjusted extrusion multiplier and examine the results. If the test piece has too much or too little filament, adjust the extrusion multiplier again until the desired result is achieved.

Do Certain Filaments Cause Over-Extrusion?

Some 3D filaments are more prone to causing over-extrusion than others, and the risk of over-extrusion can also be influenced by factors such as the extrusion temperature and speed, and the settings of the 3D printer. Proper calibration and experimentation with different settings can help minimize the risk of over-extrusion.

Filaments that are more flexible or have a lower melting temperature, such as TPU (thermoplastic polyurethane) and PETG (glycol-modified PET), may be more prone to over-extrusion than more rigid filaments with a higher melting temperature, such as PLA (polylactic acid) or ABS (acrylonitrile butadiene styrene). This is because the lower melting temperature of these filaments can make them more prone to flow and cause excess material to be extruded.

Also, make sure that you have the right size filament selected in the menu of your printer. If the printer thinks you’re loading in a thinner filament than what you are, you’ll get over-extrusion.

Adjust The Rollers On The Gantry

Loosening the rollers on the gantry, which is the movable frame that holds the nozzle and moves it around the build plate, can sometimes help to eliminate over-extrusion by allowing the filament to feed more smoothly through the printer.

Here are some steps you can follow to loosen the rollers on your gantry:

- Switch the printer off and then unplug it from the outlet as well for safety.

- Check for the rollers on the underside of the gantry, near the front and back of the printer.

- Use a hex wrench to loosen the screws or bolts, but not so much that you remove the screws completely, just enough to allow the rollers to move more freely.

- Feel how the rollers move to see if they are loose enough. You should be able to easily move them with your fingers. If they are still too tight, loosen them a little more.

- Repeat the process on all of the rollers on the gantry.

Once you have loosened the rollers, test the printer by printing a calibration model. If the over-extrusion problem has been resolved, you can leave the rollers at their new position.

Related Articles

- 3D Printer Under-Extrusion – Common Causes and Fixes

- 3D Printer Printing Too Thin – Let’s Fix It!

- 3D Printer Flow Rate Calibration – The Easy Way!

- Quick Guide to Change the Nozzle on a 3D Printer

- Five Reasons Your 3d Printer Stops Mid-Print

- How to Print a File from Thingiverse (The Easy Way!)

Conclusion

So there are several causes of over-extrusion, with the main suspect being a high-printing temperature or incorrect extrusion multiplier settings. Less likely causes are insufficient cooling, tight rollers, and incorrect filaments being used.

It may also be settings within Cura related to the flow rate or filament size.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.