Humans have been making new objects like tools for thousands of years using a variety of materials, including wood, stone, animal pelts, fabric, metals and, in the last few decades, plastic. The ‘technology’ for making these things has always been similar; create a design on paper, decide which material works best and then cut, bend, chip, whittle, weld, heat, and shape that material into the thing you wanted to make or, in some cases, create a mold and pour your material in. Everything had to be made from scratch, by hand, especially if you were making your particular object at home.

That all changed in 1992 when an inventor from the United States names Charles (Chuck) Hull created the very first stereolithography machine or SLA 3D Printer. Mr. Hull’s device was the first of its kind to create or ‘print’ a real, physical thing from a digital file, in 1 step, instantly revolutionizing how humans could create practically anything.

3D Printers Take Products from Idea to Market Much Faster

It didn’t take long for news of this new technology to reach inventors, manufacturers and more, all of whom were beyond excited that there was finally a technology that would allow them to create prototypes in-house, so to speak, and thus test any new designs that they had without the usual, massive up-front costs for tooling. 3D printers also allowed for much faster prototype testing, so that they could bring a new product to market much faster.

This combination of faster design and the lower cost was not a fact lost on manufacturers, as it would allow them to take a new product from idea to actual, saleable product in a much shorter amount of time and with a lot less investment, increasing their profits substantially.

Where and How did 3D Printing Technology Begin

I mentioned that the world of 3D printers began with Chuck Hull’s creation of the first SLA 3D Printer in 1992, but the technology for the process actually began in Japan, where Dr. Hideo Kodama was researching materials that would react to light, today known as photopolymers.

Dr. Kodama created an acrylic-based resin that, when exposed to ultraviolet (UV) light, would turn from its liquid form into a solid, plastic-like material. He published his findings along with the idea for a rapid-prototyping (RP) machine that would use the photopolymer resin to ‘print’ in layers, slowly but precisely printing layer upon layer until a solid, 3D object was created.

Interestingly, Dr. Kodama, who besides being and doctor, inventor and scientist, was also a patent lawyer. Unfortunately, he also made a huge blunder when, in 1980, he failed to get a patent for his RP technology because he failed to file his patent correctly.

Not long afterward a French team of engineers took what he had done and tried to take it further but, due to a relative lack of interest in the tech at the time, they were forced to give up due to a lack of funding. From there, in 1986, the aforementioned Chuck Hull took over. He is the holder of the first SLA patent and, as mentioned, the father of the modern 3D printer.

3D Printers were Not Initially Made for Home Use

Today, as we know, 3D printing has gotten affordable enough that many craftspeople, inventors and tinkerers can afford to purchase their own 3D printer. However, in its infancy, 3D printing was first adopted by large manufacturers as it allowed them to take an idea to market much more quickly using 3D printed prototypes.

Back then, the cost was much too high for most home-based inventors, much the same as regular printers and then laser printers were too exorbitantly expensive when they were first brought to market. As with most new technology, however, over time the technology is improved and the cost drops, which is why today millions of people have laser printers in their homes and offices and, soon enough, will likely also have 3D printers as well. (In fact, almost 300,000 private citizens do have them already.)

What is the process that allows 3D Printing to Work?

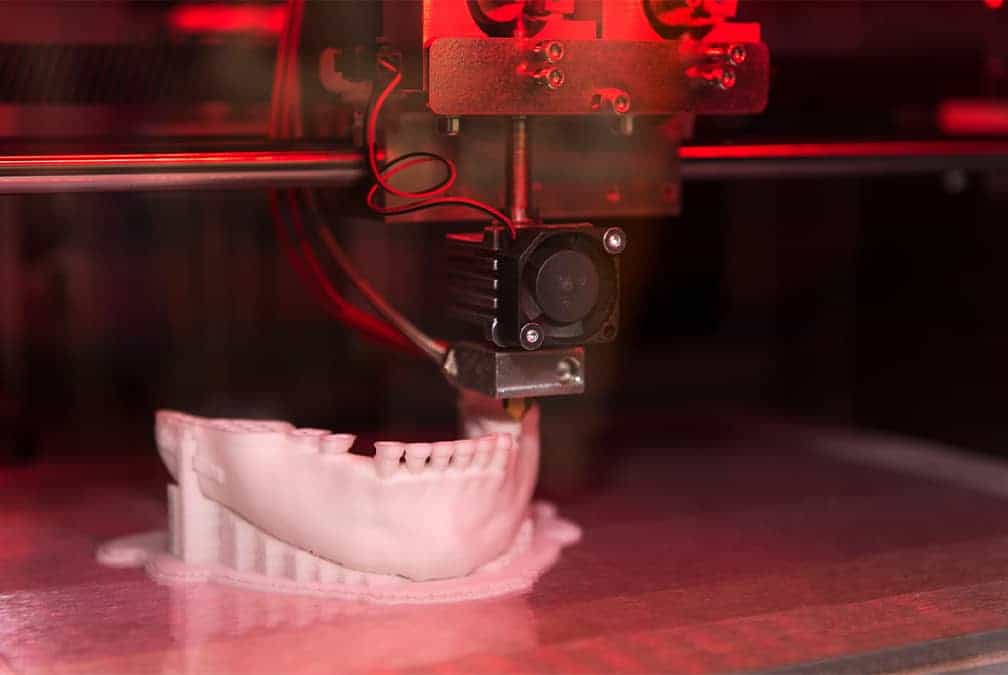

Like a laser printer for paper documents, a 3D printer follows a digital pattern from a computer, similar to a Word file, spreadsheet, photograph, etc. This digital pattern is what the 3D printer uses to print layer after layer of photopolymer resin (and, today, many other types of materials) one very specific slice at a time.

Called CAD (Computer Aided Design) files, these are in 3 dimensions on your computer and tell the printer what to add with every new layer, which gives us the origin of the term ‘additive manufacturing’, as layers are added onto each other to complete the printing task.

Speaking of materials, today there are the original photopolymers as well as thermoplastics, glass, paper, and wood (among others) all of which are extruded from the 3D printer onto a level base in the machine, building the printed object 1 layer at a time. The fact is, if you substitute ink for photopolymer, digital printing on paper and 3d printing are quite similar.

How Did 3D Printing Suddenly Become Affordable?

Actually, it didn’t happen ‘suddenly’, but did happen relatively quickly. As I mentioned, 3D printing actually started in the 1980s, so it’s been almost 4 decades. Plus, as with all technology, the cost to manufacture drops as the technology advances.

Back in the early 1990’s the cost to purchase a 3D printer was far out of reach of most hobbyists and home inventors. Today however a number of things have occurred that have made 3D printers affordable for home use, including improved accuracy, intuitive design that makes them almost as easy to use as a laser printer, and easier tools for creating 3D designs or models that the printer can read and use.

What Are the Different Types of 3D Printers?

In 1992 there were only photopolymers being used in 3D printing, and the only process was stereolithography (SLA). Today there are several new processes being used in 3D printing that go far beyond this.

- SLA – Stereolithography. The ‘grandparent’ of 3D printing, SLA uses UV light to create a 3D object with photopolymer resins.

- SLS – Selective Laser Sintering. This tech uses a powdered, plastic material as its base, which is then sintered or made solid by heating it with lasers.

- FDM – Fused Deposition Modeling. This process takes a thermoplastic filament (thread, string), heats it and extrudes it, in layers, to make the finished 3D product.

- DMLS – Direct Metal Laser Sintering. This process uses powdered metals to render a 3D object.

- EBM – Electronic Beam melting. Much like SLM, EBM instead uses a high-powered electron beam in place of a laser.

- LOM – Laminated Object Manufacturing. Using materials like paper, metal, and plastic, LOM is a rapid prototyping system that is catching on quickly.

- DLPO – Digital Light Processing. This process uses conventional light sources and micro-mirrors, allowing the resin to cool more quickly.

What Materials Can Be Used in 3D Printing?

While plastic is still the most widely used base for 3D printing, today there are many other materials being used to print a huge variety of products and tools. These include ‘super plastics’ which are being made from corn oil and soybean oil. Fantastically, at MIT 3 students actually created a working 3D printer for ice cream, and there have been 3D printing projects using human cells for medical purposes!

In the aviation industry, DMLS is growing fast, allowing them to streamline the manufacturing process and print ready-to-install parts using metals of different kinds. Graphene, from the precursor graphite, is a pure form of carbon that’s being tested as a 3D printing material as it has excellent conductive properties as well as being stronger and easier to insulate than many other materials.

For home use 3D printers, however, plastic photopolymer resins are the most typical and affordable, which is rather limiting in some ways but still gives the home hobbyist or inventor the ability to print a massive amount of different creations. Some manufacturers are already offering 3D printers that use metals but, until the economy of scale brings their costs down, they will be mostly out of affordable reach for home use.

What Can You Print with a 3D Printer?

The amount and type of products, tools and other objects that can be 3D printed are almost limitless. In fact, in the 3D printing world, it’s been said that “if you can draw it, you can print it”, which pretty much leaves the door wide open for almost anything.

Here’s a shortlist of some actual products that have been 3D printed.

- High Heel shoes

- Coffee Cup

- Kaleidoscopic Clock

- Tablet Stand

- Medical Models

- Children’s toys based on their drawings

- A Camera Lens

What Are the Major Advantages of 3D Printers for Home Use?

3D printing, as I discussed briefly already, has been a huge boon to many industries as it allows them to rapidly create new prototypes and tools with far less of an initial investment in time, manpower and funds. The same can be said, more or less, for home 3D printers.

Speed is a huge advantage because today a home hobbyist can take their idea, create a CAD design with easy-to-use software, up[load that design into the 3D printer and, within a few hours, have a useable prototype in their hands. The importance of this one factor is why 3D printing has become so insanely popular, as it transformed a process that use to take weeks, months and even years and reduced it down to hours. For example, creating an injection molding die can take up to 3 months, but can be done on a 3D printer in less than a day.

One Step Production is another advantage because it reduces the number of steps needed to take a product from an idea to a working prototype or actual, usable model. Let’s use a basic, steel door handle as an example. First, a CAD model is created. Next, the steel is clamped into place and the steel is cut and drilled using a custom jig. Then it’s welded, polished, sandblasted, primed, and painted and, 7 steps later, ready for sale and use.

Compare that to a 3D printer that can print the same door handle in 1 step. (It’s actually 2 if you consider creating the CAD design step #1). By reducing the process, a 3D printer greatly reduces the time, energy and cost to create something new.

Speaking of which, lowering the cost is a huge advantage to 3D printing. From the fact that a home 3D printer uses about the same amount of power as a laptop computer to the labor costs being almost completely removed, 3D printing significantly lowers the cost to make a product or tool.

Customization and design complexity are another 3D printing advantage, giving the home inventor the freedom to create practically anything, from complex designs to never-before-seen products. Being able to customize these products almost infinitely so that they fit the intended user perfectly is a huge plus as well.

Lastly, with the advent of new technologies and economies of scale, 3D printers have fallen dramatically in price. For example, in 2007 less than 100 3D printers under $5000.00 had been sold. In 2015, the latest year for which data was available, nearly 300,000 had been sold, and the price has lowered since then as well.

Conclusion

I hope you enjoyed this overview of 3D printers and now have a better understanding of how they work (similar to a laser printer), what materials can be used (many, but plastic photopolymer is most accessible), and what types of products can be created (almost limitless).

Today there are websites where you can create CADs and experiment with design, or use your own home software, and then print out those designs and have them in your hand in hours instead of weeks or months. As prices drop and new materials are created, the cost and creative abilities of 3D printers will continue to expand.

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.