A 3D printer needs to be calibrated so that you don’t get failed prints, and you get the most perfect print you can. When you first got your 3D printer you will have calibrated it. But, how often should you need to calibrate your 3D printer?

You need to calibrate your 3D printer if you notice an issue with the first layer of a print, but generally not very often, no more than once every 2 to 3 months or more. But, you do need to adjust the extruder flow rate if you change filament brands, colors, or types.

Each filament has a unique temperature that your 3D printer should be set to and varies based on the brand, and color as they’re usually made from slightly different materials. A good rule of thumb when changing filament types is to do a very small test print and carefully observe it to see how well it’s printing.

Below, I will explain the times when you should calibrate your 3D printer in more detail so you have a really good idea about when you should calibrate your 3D printer.

How Often You Should Calibrate Your 3D Printer

The primary way to know is if the first layer you print has imperfections. This is also good because you can catch the calibration issue before using a lot of filament. The X, Y, and Z calibration for the nozzle are handled automatically when you begin each print. Therefore, you don’t need to check this. The main instances when you should check the calibration settings for your 3D printer are:

Here’s a helpful list of things that you should adjust/calibrate based on what you change when doing different prints:

| Thing you changed or issues you notices | What to calibrate |

|---|---|

| After changing the filament material | Speed, bridging settings |

| New brand of filament | Temperature, retraction, speed |

| New filament color | Temperature, speed |

| New spool of filament | Flow rate, temperature |

| First layer has imperfections | Speed, bridging, temp, retraction, flow rate, bed leveling |

| New extruder nozzle | Speed, temperature, retraction, bed leveling |

Generally, if you don’t change any of the settings when you change the filament type, brand, or color you will experience imperfections when you print. If it’s under-extruding when you change filament type it’s typically because the temperature is too low.

You should turn the temperature up a few degrees. If that hasn’t caused it to extrude as it should then turn up the extrusion multiplier by a few percentage points. It’s often necessary to change both the temperature and flow rate for a new type of filament before it will print without any imperfections.

New filament or extruder nozzle – most common times to calibrate

Extruder types are typically made of brass. Brass is quite a soft metal and as the filament moves through it, it will wear down the brass very slightly each time. Over the course of 3 months to a year the extruder will need to be replaced when you notice the print quality isn’t as good as when your nozzle was new.

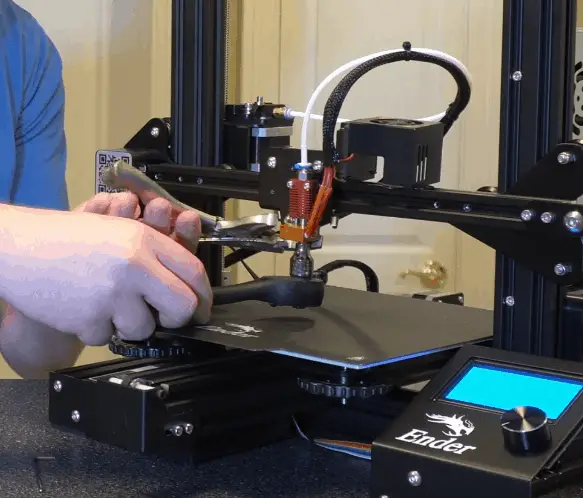

As you may know, replacing the extruder is a very sensitive operation, and you need to be sure not to damage any of the connected parts as you do it. A new nozzle will often have slightly different dimensions, or you might have replaced it with a nozzle that has a different diameter. This means you’ll need to do a small test print, prior to doing a print that you really care about.

Also, a roll of filament tends to last quite a while depending on the volume of 3D printing you’re doing. If you always use the same type of filament and have a few spools all of the same brand and type then you generally won’t need to calibrate your 3D printer.

But, it’s fairly common that you’ll experiment with different filament types and colors. So, changing the filament is one of the most common times when you’ll need to adjust some settings on your 3D printer, and calibrate it so that it’s printing as it should.

If the 3D printer is bumped

If you walk past your 3D printer and accidentally bump it with your hip, shoulder, or another part of your body. Or, you go to reach for something and accidentally give it a significant bump with your arm, you may need to calibrate your 3D printer.

This includes checking the bed leveling, and the tension on the belts. Whether you have caused an issue will be apparent when you do your next print. So, it’s always a good idea to do a small test layer, or small print if you significantly bumped your 3D printer or someone in your household. Also, pets such as cats might significantly move some of the parts as they are playing around your 3D printer.

How Often You Need To Level the 3D Print Bed

The 3D print bed should be perfectly level so that the filament does run in one direction causing a failed print. It’s fairly easy to level a 3D print bed, but how often do you need to do it?

A 3D print bed very rarely needs to be leveled, but you should check it once every 6 months. If you notice any imperfections in a test print or the first layer of a print you should check the print bed is level, and if you bump your 3D printer or move it, as this can affect how level the bed is.

I did an in-depth analysis of the question of when you should level your 3D print bed by collating the number of responses to this question. For example, how often people said that they level their print bed, and for what reasons. I summarized the results in a table and provided some additional info about it in this article about how often you need to level your 3D print bed.

When Should You Calibrate E Steps

The E steps value is typically set to 93.0 by default. The E steps value adjusts how much filament is extruded and can be adjusted in the settings on your 3D printer very easily. But, does it need to be changed often, and if so when should you do it?

Calibrate your E steps value when you notice any over or under extrusion. Otherwise, it should only need to be done once. Over extrusion produces extra blobs of filament that shouldn’t be there. Under extrusion is where there are gaps in the print layers.

I’ve made a really good video that shows everything you need to know about calibrating E steps, when it needs to be done, and exactly how to do it.

Related Articles

- 3D Printer Printing Too Thin – Let’s Fix It!

- 3D Printer Flow Rate Calibration – The Easy Way!

- Quick Guide to Change the Nozzle on a 3D Printer

- Five Reasons Your 3d Printer Stops Mid-Print

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.