In 3D printing, you can get 3D print files that other people have already created and print them on a 3D printer using Cura. Or, you can design your own 3D models. People that are new to 3D printing generally will learn how to design their own 3D print models, but today I will explain whether it’s possible to create a 3D print design using Cura.

It’s not possible to design or create 3D prints in Cura. Cura is a slicing software, its purpose is to prepare a 3D print model file into a format that a 3D printer can use. There are a range of software that are used to create 3D printed models such as TinkerCAD.

Cura is the most popular slicing software, and in general, a slicing software is always required to print using a 3D printer. However, to design the models and to make edits to existing models a different kind of program needs to be used.

Below, I will explain what programs can be used to create 3D print models that can be opened in Cura, and what exactly can be done to a 3D print file in Cura.

What Programs Can Be Used To Design 3D Prints

Since you can’t design 3D prints using Cura, it’s important to know how to design your own 3D prints from start to finish, as well as, how to edit existing print files. There are a range of programs that can be used to design 3D prints, these are what they are.

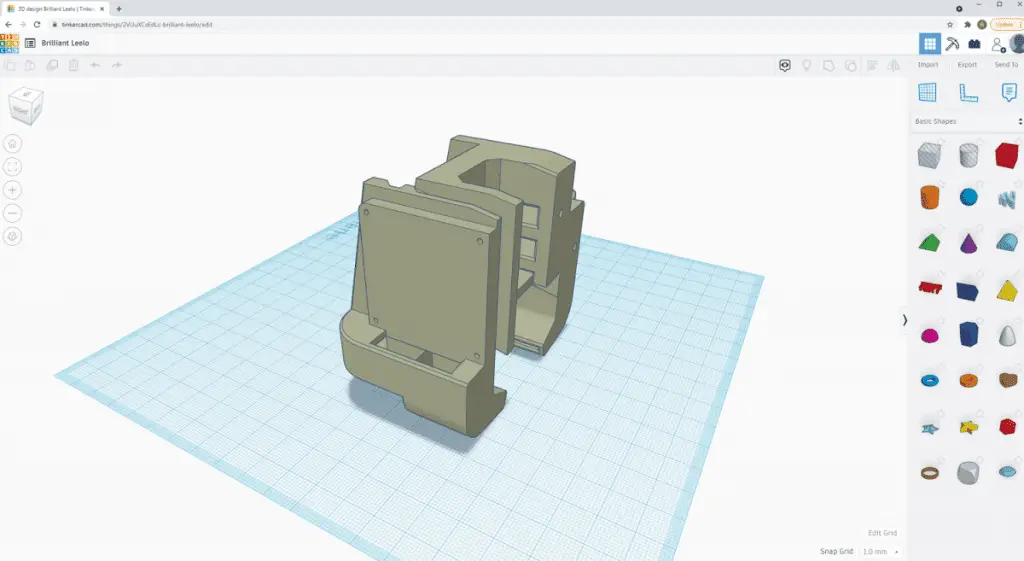

As a general rule, CAD programs can be used to design 3D print models. Examples, are TinkerCAD, AutoCAD, and Solidworks. CAD stands for computer-aided design. They have a user interface that has a 3D dimensional space where objects can be added and edited.

If you’ve ever used the photo editing software Photoshop you will be familiar with how CAD programs work. The main difference is that they work in 3 planes or 3 dimensions. They use the x, y, AND z coordinates. Regular photo editing and illustrating programs only work in 2 dimensions the x, and y plane.

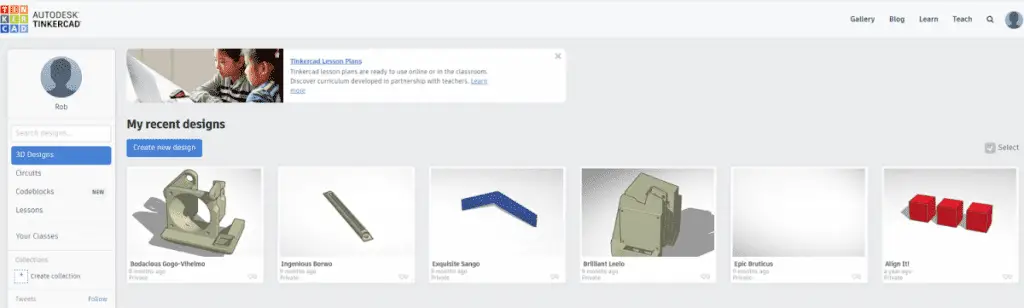

TinkerCAD is considered to be the easiest to learn on. It also has the added bonus of being completely free. It has a range of lessons that explain how designing 3D prints works, and how to do it.

Once you design an object in a CAD program, it’s then exported as a special format that can be interpreted by a 3D printer. There are only certain file types that can be read by a 3D printer.

Examples are:

- STL file (.stl)

- Compressed COLLADA Digital Asset Exchange (.zae)

- COLLADA Digital Asset Exchange (.dae)

- Open Compressed Triangle Mesh (.ctm)

When you use a CAD software to create a 3D model, it’s saved or exported to turn it into a file. Much like if you’re editing a Word document or Excel spreadsheet. Rather than a .doc, or .xls file it’s a .stl, or .dae, the exact file extension differs based on what program is used to create it.

This file is then opened in Cura. Cura will read all the information in the file. It will then turn it into a set of instructions that a 3D printer can understand and execute. Cura is known as a slicing software.

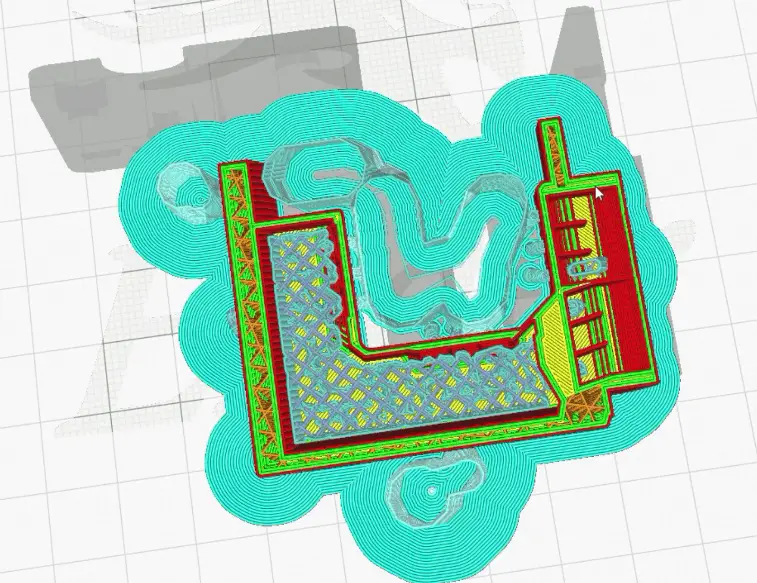

The term slicing refers to the fact that Cura will slice a whole model into individual layers. As you may know, a 3D printer prints one layer at a time. This is true whether a 3D printer is a resin 3D printer or a filament 3D printer. If you’re not yet aware these are the two main types of 3D printers. Resin creates 3D prints that are higher ‘resolution’.

Meaning they are clearer and have sharper detail. Resin and filament 3D printers themselves are the same price to buy. But, the operating costs such as the materials for a resin 3D printer are quite a bit more. I explained the reasons why in this article about why 3D printing with resin is so expensive.

Minor changes and edits that can be made with Cura

It’s possible to edit minor things in a model using Cura. However, you can not edit the overall design. According to the official Cura website, you can change how a model is filled. For example, whether it’s filled as a mesh with lots of open space or whether it fills in the model completely solid.

An example of how this would work for an individual model is shown in this article on the official Cura website.

How Do I Create a Cura File

Cura can open 3D print models, and then prepare them so that a 3D printer will print them. But, how exactly do you create a 3D model that can be opened in Cura?

As a general rule, you create it in a CAD software such as TinkerCAD. A computer-aided design (CAD) software allows you to create a 3D model, and then export that file as a type that Cura can open. Cura will then slice the file and you can then send it to your 3D printer to print it.

Cura works as the interface between the print file and the 3D printer. However, it can’t be used to create 3D models and it only processes existing 3D models. There are a range of CAD software that can be used to create 3D models. These software are very advanced and extremely high quality. The reason is these programs are also used a lot in other industries such as for designing building blueprints.

How Do You Make Cura Designs

3D print files/designs that people have created can be downloaded for free from websites like Thingiverse. There are also a few other good libraries of models. But, here’s how to design your own 3D print models to open in Cura.

Overall, these are made in computer-aided design (CAD) software such as TinkerCAD. TinkerCAD is completely free, is very high quality, and has free lessons showing how to use it. There are also paid professional CAD software such as AutoCAD, which are used in many industries.

These programs have a range of other inbuilt features. These are used to create machinery parts such as car engines. But, also in the building industry to turn an architect’s blueprint into a plan that a builder, plumber, and electrician can follow with extreme precision.

Related Articles

- Is Cura a CAD Software?

- Create a Temperature Tower Using Cura – The Easy Way

- Cura Profiles

- What OS Does Cura Run On?

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below. If you liked this article and want to read others click here.