Back in the ‘80s, history was made when Charles Hull created the process that opened the door for 3D printing technology and design. Creating 3D models with digital data made enormous leaps for manufacturers and creative minds. Today, we’ll dive into real-world problems that 3D printers help solve.

Here are the top 3 common problems that 3D printers solve:

- Finite resource material usage.

- Expensive, non-customizable assistive technology.

- Engineering problems in product manufacturing.

Let’s take a deeper look at these three problems that 3D printers have helped solve and how they continue to impact the modern world positively.

1. Finite Resource Material Usage

3D printing isn’t just an excellent way to make jewelry and trinkets; it can change the world.

Sustainability is an issue that has been invading production lines and manufacturing hubs for decades. As a result, the need to find solutions around sustainability and resource use is imperative– now more than ever.

Consumerism is rampant, inhaling finite resource material and exhaling waste and environmental decay.

According to statistics published by The United Nations, if the global population reaches 9.6 billion by 2050, it would take three planets’ worth of natural resources to sustain our current lifestyles.

There is still hope for our planet if people make massive changes in material usage and product development.

With consumerism at an all-time high, the need to explore other options for sustainable material usage is extreme. However, there are some 3D processes currently that are helping pave the way to sustainable manufacturing that are generally less wasteful than traditional manufacturing processes.

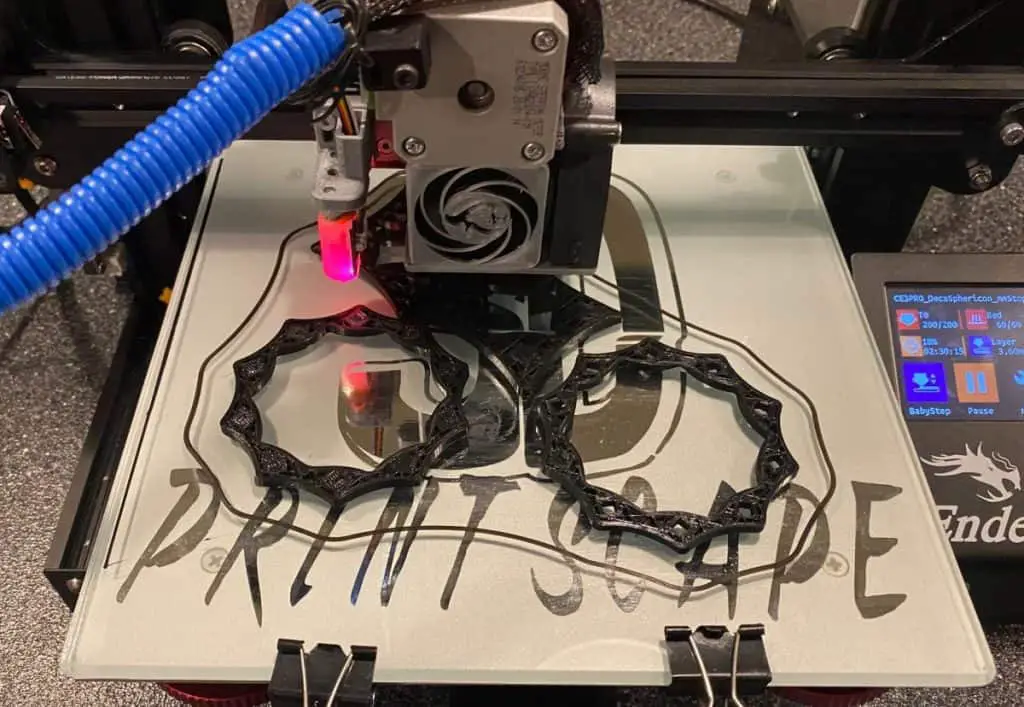

3D printing has come a long way since its original conception in 1984. Most recently, 3D printing has demonstrated the potential to streamline manufacturing, provide people with the means to make products at home, and cut down on the use of nonrenewable resources.

In 2019, 3D printers could print almost everything from houses to living tissue, according to this article from Makerbot.

Ideally, the world will continue to utilize and take advantage of advances in 3D printing technologies so that the manufacturing industry becomes sustainable.

One material that is overused in the manufacturing industry today is plastic. By 2050, there could be more plastic in the ocean than fish, according to this article from PrintLab.

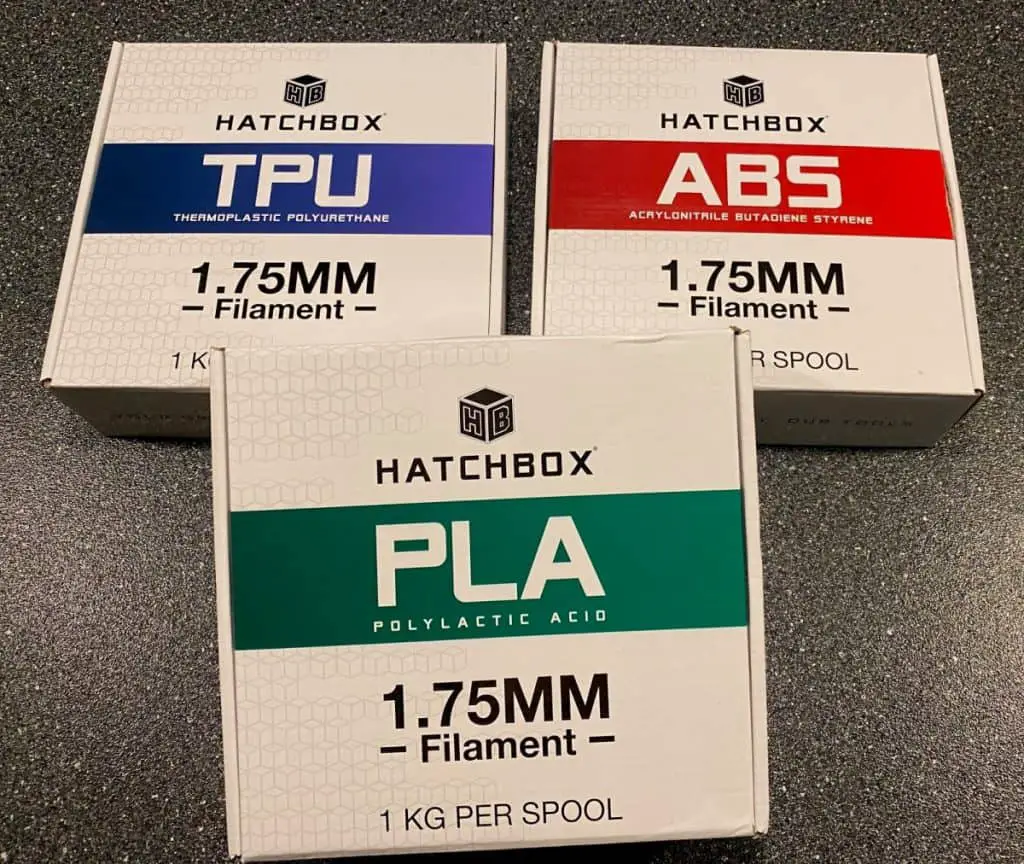

The good news is that 3D printing companies are exploring alternative materials that can be composted and reinvested into the Earth right from home. For example, PLA, one of the most popular 3D printing materials, is made using starches from plants such as potatoes or corn.

2. Expensive, Non-Customizable Assistive Technology

3D printing has significant potential in the modern world. Not only is it a source of sustainable manufacturing technology, but given proper creative license, it can change the way people live and function.

Assistive technology, also commonly known as adaptive aids, creates tools and devices for individuals living with a disability. Assistive technology aims to improve the day-to-day functionality and quality of life for individuals dealing with a disability.

Unfortunately, many mainstreams manufactured assistive technology products are costly, un-customizable, and often undesirable. This article published by the National Library of Medicine outlines a few issues with traditionally manufactured assistive technology.

While assistive technology can increase the quality of life for those living with a disability by improving chances for employment, independence, and overall life satisfaction, it is difficult for many who cannot afford these tools.

There is also a lack of centralized information and an evaluations system for these products. Often, third-party payers, like insurance companies, deny claims of their need so that they don’t have to pay for them for their patrons.

The good news is that 3D printing can help with potentially short and long-term solutions for people with disabilities.

Several annual national and international challenges encourage today’s scientifically inclined and creative youth. For example, many organizations encourage young school children to use 3D printing mechanisms to create assistive technology.

In yearly science fairs and Makeable 3D Printing Challenges, students are assigned to create a design that might improve the life of someone who has a specific disability. Then, they print a prototype and test it. Some of these models even make it to the manufacturing floor!

For instance, in 2021, a 10th-grade student at a rural school in Colorado created a voice-activated robotic device designed to assist physically challenged people with mealtimes using a 3D printer.

These designers often go a step further and make their designs open-source and shared on national platforms so that they can be downloaded, customized, and manufactured on a larger scale.

With the ability to directly print assistive technologies in your own home and share models in a split second, getting the support you need to live your best life has never been easier.

3. Engineering Problems in Product Manufacturing

Beyond creating sustainable pathways for the manufacturing industry, it has several other benefits for production companies. Quality manufacturing is time-consuming, costly, and sometimes risky.

Some current issues with traditional product manufacturing include:

- Extended production time

- Costly materials

- Risky mistake management

- High design complexities

3D printing, though, can help resolve all of these issues.

For example, quality manufacturing takes time, and traditional methods can take months before parts are ready to use. However, advances in 3D printing over the decades can cut down on the time it takes to make prototypes and designs for products.

According to this article from Forecast 3D, many manufacturers are reaping the benefits of nearly 70% reduced lead times on average with the expectation that the time will continue to decrease in the coming years.

Not only can manufacturers save time with 3D printing, but they can also save money. Using 3D printing, manufacturing industries can reduce labor costs and expensive finite materials.

Since most 3D printing processes are automated, manufacturers can significantly reduce labor costs, and as discussed previously, materials can also be cheaper.

Next, 3D printing solves issues with mistakes made in prototyping, which often cost a lot of time and money for traditional manufacturing techniques to correct.

With little or no molding and tool requirements necessary for 3D printing manufacturing, the risks associated with production are reduced or eliminated.

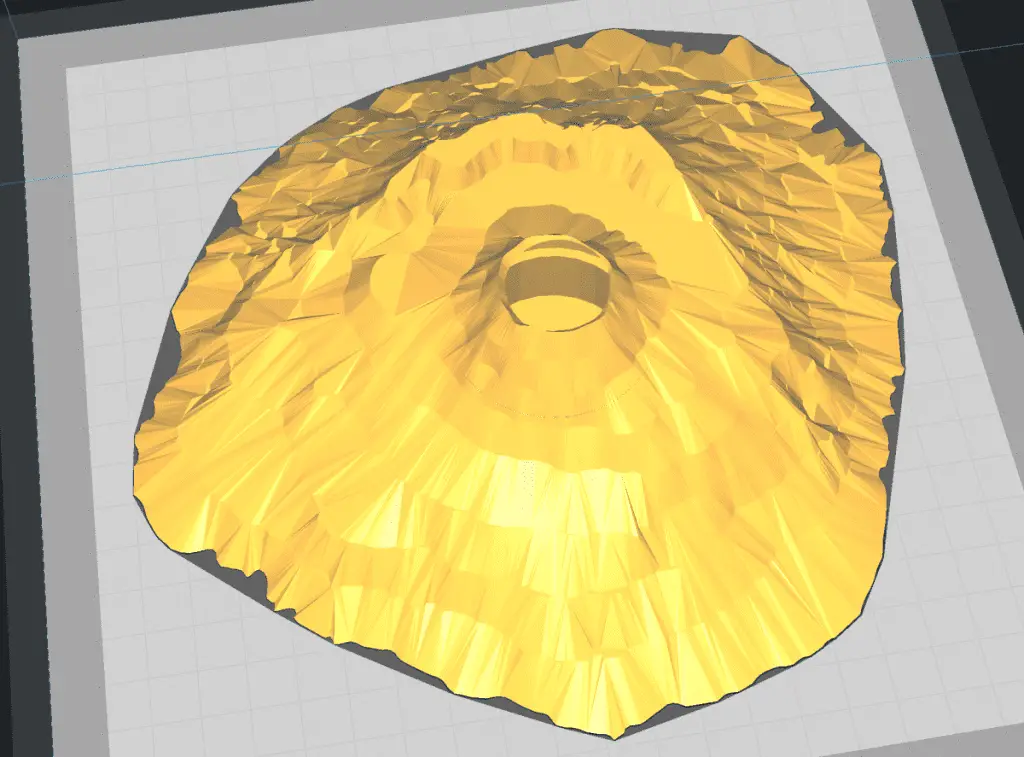

Finally, 3D printing offers significantly fewer restrictions on design than traditional manufacturing. That means that engineers have more freedom to create meaningful and valuable innovations.

By utilizing 3D printing, manufacturers will have more creative design licenses and reduce the lead time and costs associated with production.

Related Articles

- Most Popular 3D Printed Life Hacks

- 3D Printer Software – Detailed Overview!

- Can You Mix 3D Filament Colors?

- How to Print a File from Thingiverse (The Easy Way!)

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.