I’ve been looking into getting a new bed for my 3d printer and was curious about whether a metal bed would work. I asked around and here’s what I found.

As a general rule, you can 3d print onto a metal bed. The main consideration is that the metal bed needs to be a sufficient thickness – over 3 mm and/or use a layer on top of the metal to limit the amount of heat. It’s best to use PEI or tape on top for thinner metal beds.

One of the most common and readily available metal beds is aluminium. In this article, I will explain how to use aluminium as a bed for your 3d printer, whether it works with all of the different filaments, as well as, how metal compares to glass.

Is a metal bed better than glass?

As a general rule, a metal bed and a glass bed work much the same. You can use either or, and the end print will have no significant difference. Some people prefer glass because it is extremely flat. But, glass is known to have issues with the print sticking to the bed.

This is easily solved by using a glue stick, hair spray, or a stick-on PEI layer such as BuildTak. With metal though, it still has the same issues and you also need to use a glue stick, or some hairspray so that the print sticks well and is easy to remove.

How do you print on an aluminium bed?

Let’s say you found an aluminium bed online, and are thinking about getting it. Is there anything extra you need to do with an aluminium bed?

Printing on an aluminium bed is exactly the same as printing on a glass bed. You must ensure that the 3d printer bed is quite thick, and ideally thicker than 3mm or use a protective layer on top such as PEI or tape. That will allow less heat transfer and stop the metal from warping.

A thin aluminium or metal bed will tend to warp and curl up or down at the edges. Overall, it can make the base of your print not perfectly flat. For that reason, it’s best to use an adhesive on top such as tape. It will absorb the heat and allow less of it to go into the metal.

Therefore, it won’t warp as easily. Because of these issues, I’m comfortable recommending glass over aluminium as there are additional drawbacks to aluminium that glass does not have.

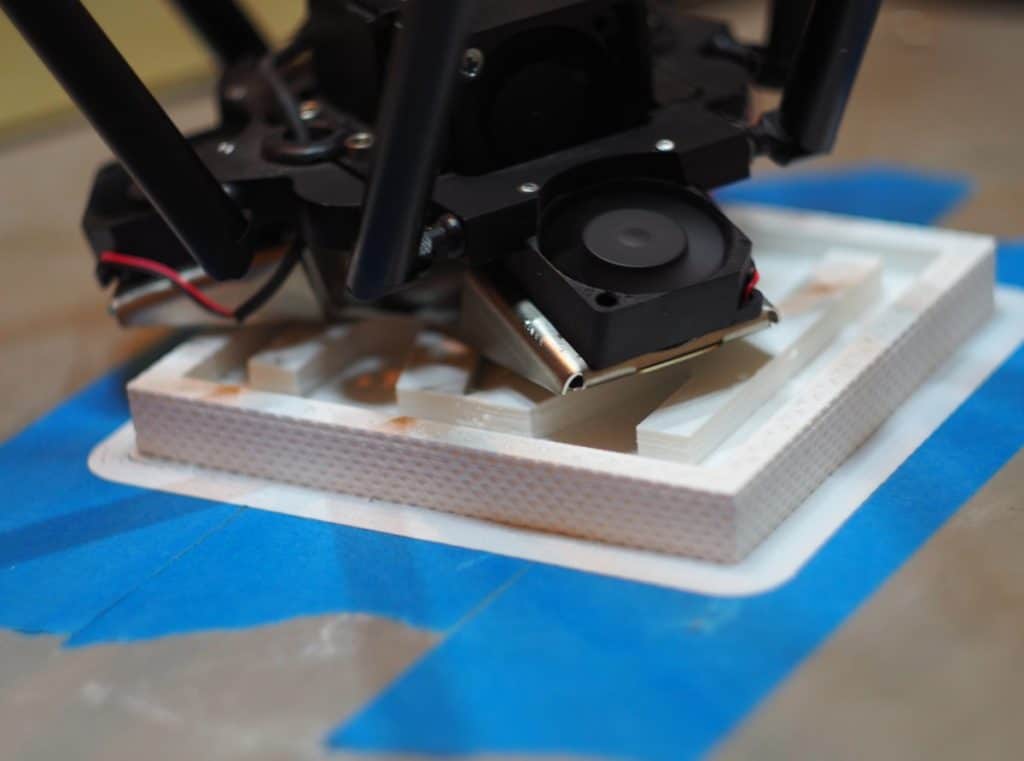

The bed that comes with most 3d printers has a top with a PEI coating. But, if you turn it over there can be an exposed piece of aluminium. And you can also print directly onto that. The trick is to make sure you apply 2 layers of glue on it using a glue stick.

It’s a good idea to go back and forward left to right. And then go over the top of it rubbing the glue the opposite way so that there are two coatings of glue.

Hairspray will also work great and you can use that instead of glue. Some people who have printed on aluminum have noticed that if you are printing in PLA then you can get away with not using glue or hairspray. But, you’ll definitely need some adhesive to print ABS.

Aluminium or glass?

So, should you use aluminium or glass, as a whole you can use either, and as long as the aluminium is thick enough you won’t notice a difference? In my opinion, though glass is slightly better because you don’t need to worry about it warping.

How do you print on metal surfaces?

So, it’s possible to 3d print onto metal. But, how do you do it?

3D printing onto metal is the same as printing on any other surface. It’s a good idea to have a glue stick of some hair spray handy as sometimes the filament will not stick to the metal plate. Similar to glass, if you apply a layer of glue or hair spray it will work perfectly.

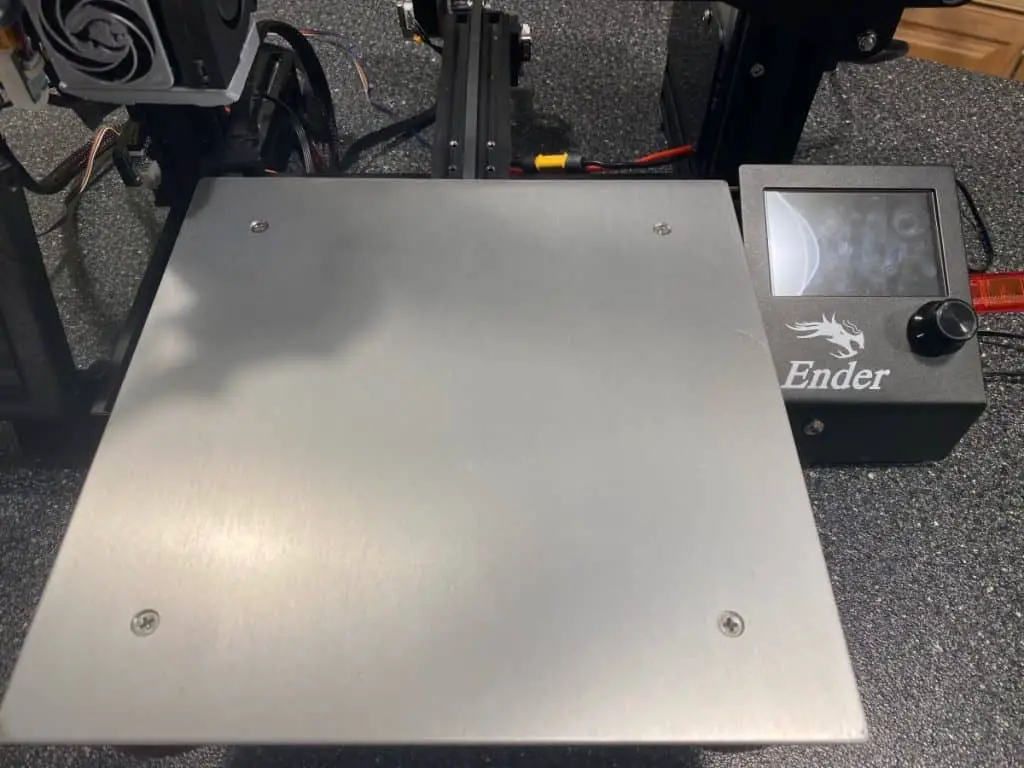

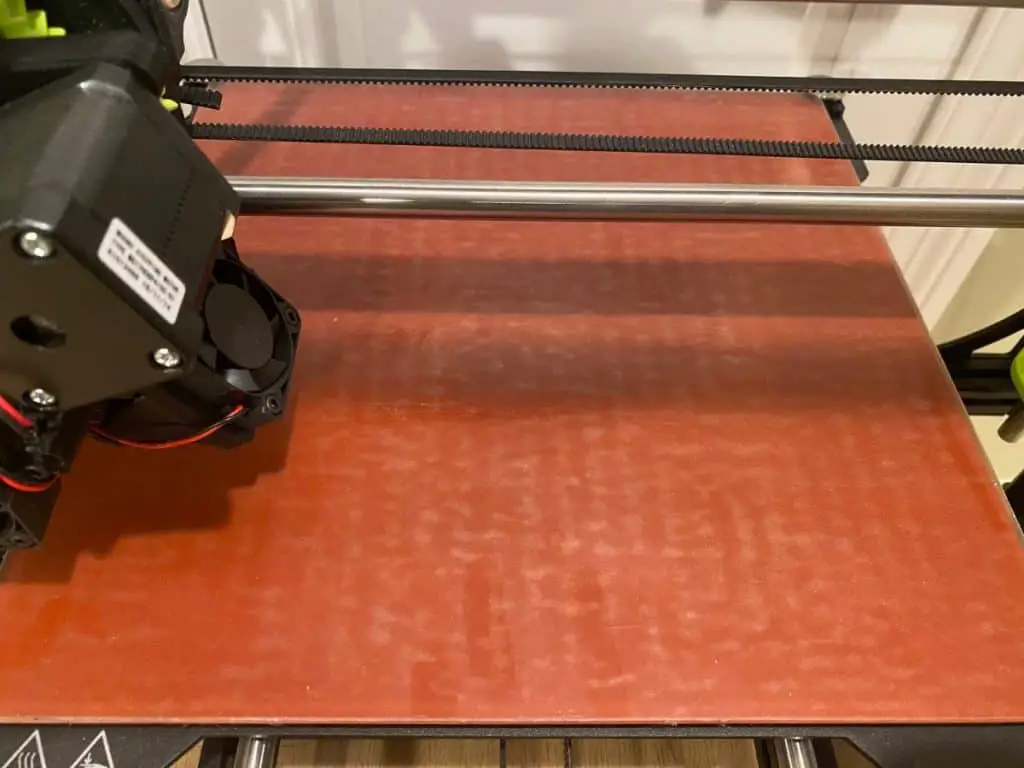

Certain 3d printers come standard with a PEI-covered aluminium plate. However, the metal is somewhat hidden because it’s on the underside of the plate, which has a layer of black PEI on top. Printing on a metal surface takes the exact same amount of time as printing on glass for example.

Does PLA stick to aluminium?

PLA is a very popular filament material and for good reason. It has a low melting point so it’s able to print in very fine detail. And it’s also fully biodegradable. But, will PLA stick to aluminium?

As a general rule, PLA will stick to aluminium. It’s also likely that you will not need to use an adhesive such as a glue stick or hair spray. However, other filaments such as ABS require an adhesive to stick to aluminium.

But, the material your build plate/bed is made out of is not always the only source of poor adhesion, and if you are having issues with your prints not sticking then it may be that your bed is slightly off alignment.

Can you 3D print directly on aluminium?

Certain surfaces like glass work better if you add an additional layer of PEI or Buildtak. However, is it necessary to add anything on top of aluminium or can you print on it directly?

As a whole, you can print directly on aluminium. But, it’s best to print a test layer to see if the print is sticking to the build plate. If not, then you should use 2 layers of glue stick or some hairspray. PLA will generally stick to aluminium without glue or hairspray.

The one issue with aluminium is that heat can warp it. Therefore, it’s best to only 3d print on an aluminium plate that is 3mm or thicker. And if you have the option a thicker plate is better. Because the thicker the aluminium the more heat it can absorb, and it will be less prone to bending.

Related Articles

- Best 3D Printer Build Plate

- How to Get Your Print to Stick to the Build Plate

- All About 3D Printer Plastic

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

- Cura Profiles

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.